Академический Документы

Профессиональный Документы

Культура Документы

What Is An Example of An Inspection Checklist For A Manufacturing Facility

Загружено:

aKureishiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

What Is An Example of An Inspection Checklist For A Manufacturing Facility

Загружено:

aKureishiАвторское право:

Доступные форматы

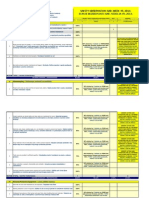

What is an example of an inspection checklist for a

manufacturing facility?

The examples outlined below do not list all the possible items for manufacturing facilities. The

best checklist for your workplace is one that has been developed for your specific needs.

Whatever the format of the checklist, provide space for the inspectors' signatures and the date.

Inspectors: Date:

(O)Satisfactory

(X) Requires Action

Location Condition Comments

Training

Is training provided for each person newly assigned to a

job?

Does initial training include a thorough review of hazards

and accidents associated with the job?

Is adequate instruction in the use of personal protective

equipment provided?

Is training for the use of emergency equipment provided?

Are workers knowledgeable in the "Right to Refuse"

procedures?

Environment

Are resources available to deal with very hot or very cold

conditions (drinking water, lined gloves, insulated boots)?

Is the rain/cold weather gear that is provided comfortable,

and light enough so as not to constitute a hazard?

Are work surfaces and grip surfaces safe when wet?

Do workers know the symptoms of heat cramps/heatstroke,

or frost bite/hypothermia?

Work Process

Are repetitive motion tasks properly paced and kept to a

minimum?

Are the material safety data sheets placed in locations

accessible to all employees?

Are hazards signalled by signs and tags?

Have all trucks, forklifts and other equipment been

inspected and maintained?

Are lockout or tagout procedures in place and followed?

Is ventilation equipment working effectively?

Is the fume and dust collection hood working effectively?

Are the safety showers and eye wash stations in the proper

locations and in good working condition?

Fire Emergency Procedures

Is there a clear fire response plan posted for each work

area?

Do all workers know the plan?

Are drills held regularly?

Are fire extinguishers chosen for the type of fire most

likely in that area?

Are there enough extinguishers present to do the job?

Are extinguisher locations conspicuously marked?

Are extinguishers properly mounted and easily accessible?

Are all extinguishers fully charged and operable?

Are special purpose extinguishers clearly marked?

Means of Exit

Are there enough exits to allow prompt escape?

Do employees have easy access to exits?

Are exits unlocked to allow egress?

Are exits clearly marked?

Are exits and exit routes equipped with emergency

lighting?

Warehouse and Shipping

Are dock platforms, bumpers, stairs and steps in good

condition?

Are light fixtures in good condition?

Are all work areas clean and free of debris?

Are stored materials properly stacked and spaced?

Are tools kept in their proper place?

Are there metal containers for oily rags and for rubbish?

Are floors free of oil spillage or leakage?

Is absorbent available for immediate clean-up of spills and

leaks?

Are all flammable and combustible products stored

appropriately? For example: Are Class I (one) flammable

products (as per NFPA or your local fire code) stored in

Class I approved buildings or outside the warehouse?

Loading/Unloading Racks

Are steps, railings and retractable ramps on raised

platforms in good repair?

Is piping and in-line equipment in good condition and free

of leaks?

Are loading arms operating satisfactorily?

Do submerged filling two-stage valves operate properly?

Are bonding and grounding cables free of breaks or

damage?

Are connections tight and sound?

Is the general condition of wiring and junction boxes, etc.

in good condition (visual inspection)?

Lighting

Is the level of light adequate for safe and comfortable

performance of work?

Does lighting produce glare on work surfaces, monitors,

screens and keyboards?

Is emergency lighting adequate and regularly tested?

Machine Guards

Are all dangerous machine parts adequately guarded?

Do machine guards meet standards?

Are lockout procedures followed when performing

maintenance with guards removed?

Electrical

Is the Canadian Electrical Code adhered to in operation,

use, repair and maintenance?

Are all machines properly grounded?

Are portable hand tools grounded or double insulated?

Are junction boxes closed?

Are extension cords out of the aisles where they can be

abused by heavy traffic?

Is permanent wiring used instead of extension cords?

Tools and Machinery

Are manufacturers' manuals kept for all tools and

machinery?

Do power tools conform to standards?

Are tools properly designed for use by employees?

Are defective tools tagged and removed from service as

part of a regular maintenance program?

Are tools and machinery used so as to avoid electrical

hazards?

Is proper training given in the safe use of tools and

machinery?

Confined Spaces

Are the confined space procedures and training available

and followed by all involved?

Are entry and exit procedures adequate?

Are emergency and rescue procedures in place (e.g. trained

safety watchers)?

Housekeeping

Is the work area clean and orderly?

Are floors free from protruding nails, splinters, holes and

loose boards?

Are aisles and passageways kept clear of obstructions?

Are permanent aisles and passageways clearly marked?

Are covers or guardrails in place around open pits, tanks

and ditches?

Floor and Wall Openings

Are ladder-ways and door openings guarded by a railing?

Do temporary floor openings have standard railings or

someone constantly on guard?

Stairs, Ladders and Platforms

Are stairs and handrails in good condition?

Are ladders free of defects?

Are ladders set up properly before use?

Are the elevated platforms properly secured and do they

have handrails?

Elevating Devices

Are elevating devices used only within capacity?

Are capacities posted on equipment?

Are they regularly inspected, tested and maintained?

Are controls of the "dead man" type?

Are operators trained?

Sound Level/Noise

Are regular noise surveys conducted?

Is hearing protection available and used properly?

Temporary Work Structures

Are temporary work structures used only when it is not

reasonably practicable to use permanent ones?

Are excavations properly shored, free of large objects

(rocks, etc.) at the edges?

Employee Facilities

Are facilities kept clean and sanitary?

Are facilities in good repair?

Are cafeteria facilities provided away from toxic

chemicals?

Are hand washing facilities available?

Medical and First Aid

Do all employees know how to get first aid assistance when

needed?

Do the first-aiders know when and to which hospital or

clinic an injured person should be taken?

Are there employees trained as first-aid practitioners on

each shift worked?

Are first-aid kits provided as per jurisdictions first-aid

regulations?

Are first-aid supplies replenished as they are used?

Personal Protective Equipment (PPE)

Is required equipment provided, maintained and used?

Does equipment meet requirements?

Is it reliable?

Is personal protection utilized only when it is not

reasonably practicable to eliminate or control the hazardous

substance or process?

Are the areas requiring PPE usage properly identified by

warning signs?

Materials Handling and Storage

Is there safe clearance for all equipment through aisles and

doors?

Is stored material stable and secure?

Are storage areas free from tipping hazards?

Are only trained operators allowed to operate forklifts?

Is charging of electric batteries performed only in

designated areas?

Are dock boards (bridge plates) used when loading or

unloading from dock to truck or dock to rail car?

Are necessary warning devices and signs in use for railway

sidings?

Are specifications posted for maximum loads which are

approved for shelving, floors and roofs?

Are racks and platforms loaded only within the limits of

their capacity?

Are chain hoists, ropes and slings adequate for the loads

and marked accordingly?

Are slings inspected daily before use?

Are all new, repaired, or reconditioned alloy steel chain

slings proof-tested before use?

Are pallets and skids the correct type and inspected?

Do personnel use proper lifting techniques?

Is the size and condition of containers hazardous to

workers?

Are elevators, hoists, conveyors, balers, etc., properly used

with appropriate signals and directional warning signs?

Вам также может понравиться

- Warehouse Audit ChecklistДокумент2 страницыWarehouse Audit ChecklistNada GHAZOUANI100% (1)

- Safety Audit ChecklistДокумент5 страницSafety Audit ChecklistAbhishekОценок пока нет

- General Workplace Inspection ChecklistДокумент4 страницыGeneral Workplace Inspection ChecklistEagle1968Оценок пока нет

- Lab Audit FormДокумент6 страницLab Audit Formmahesh90600Оценок пока нет

- Hazards ChecklistДокумент7 страницHazards ChecklistRemeras TartagalОценок пока нет

- Contractor Camp Inspection Check List Rev 9-12 16.00hrДокумент6 страницContractor Camp Inspection Check List Rev 9-12 16.00hranshseОценок пока нет

- Manufacturing Plant Audit ChecklistДокумент6 страницManufacturing Plant Audit ChecklistAnurag SrivastavaОценок пока нет

- Random Safety Audit Checklist & Score CardДокумент6 страницRandom Safety Audit Checklist & Score Cardpatilrvaibhav123Оценок пока нет

- New Equipment Inspection ChecklistДокумент6 страницNew Equipment Inspection ChecklistNate100% (2)

- Tool Box TalkДокумент2 страницыTool Box TalkAnonymous X3PnFL6100% (1)

- Safety Audit ChecklistДокумент20 страницSafety Audit ChecklistDeep Narayan Jaiswal0% (1)

- Safety Inspection ChecklistДокумент5 страницSafety Inspection ChecklistAnuj Kjoy67% (3)

- EF PTW Audit FormДокумент1 страницаEF PTW Audit FormdammyОценок пока нет

- FORMOPITO004.06 (OPITO Policy - Maintenance and Inspection)Документ27 страницFORMOPITO004.06 (OPITO Policy - Maintenance and Inspection)maja_todorovska_6Оценок пока нет

- IMS Audit - Version 1Документ11 страницIMS Audit - Version 1arobОценок пока нет

- Sol Ohsms Lac Student Course Notes 2020Документ74 страницыSol Ohsms Lac Student Course Notes 2020Sahara SneedanОценок пока нет

- ISO 45001 2018 On Site Supplier Audit Checklist SampleДокумент4 страницыISO 45001 2018 On Site Supplier Audit Checklist SampleAmr EssamОценок пока нет

- Hse Powerpoint - pptx1Документ161 страницаHse Powerpoint - pptx1Gbenga Mobolade100% (3)

- Contoh Workplace Inspection Procedure and Checklist PDF 1.1MBДокумент10 страницContoh Workplace Inspection Procedure and Checklist PDF 1.1MBmae_blurОценок пока нет

- General Chemical Safety Inspection ChecklistДокумент3 страницыGeneral Chemical Safety Inspection ChecklistRizwan Khan100% (2)

- Safety Inspection ChecklistДокумент2 страницыSafety Inspection ChecklisterinОценок пока нет

- Workplace-Safety - Inspection - ChecklistДокумент2 страницыWorkplace-Safety - Inspection - ChecklistNaba majead100% (2)

- Matrix ImsДокумент6 страницMatrix Imsmuhammad AndiОценок пока нет

- QMS Internal Audit Schedule Template ISO 45001Документ1 страницаQMS Internal Audit Schedule Template ISO 45001Gaurav DeshwalОценок пока нет

- Safety PORR SAR - Week 49-2013Документ11 страницSafety PORR SAR - Week 49-2013Darjan VeličkovОценок пока нет

- H S ChecklistДокумент17 страницH S ChecklistkhajaimadОценок пока нет

- IMS-QHSE ChecklistДокумент11 страницIMS-QHSE ChecklistDerrick AgabaОценок пока нет

- Health and Safety ProceduresДокумент10 страницHealth and Safety ProceduresSash1693100% (1)

- Internal Audit IMS ChecklistДокумент11 страницInternal Audit IMS ChecklistBobby Lawrence100% (2)

- Planned Safety InspectionДокумент104 страницыPlanned Safety InspectionKirstie Lou Sales100% (1)

- Storage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsДокумент1 страницаStorage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsArshad MahmoodОценок пока нет

- Forklift SafetyДокумент10 страницForklift SafetybanguliekОценок пока нет

- Gap-Analysis Checklist of ISO 45001-2018Документ7 страницGap-Analysis Checklist of ISO 45001-2018wf4sr4rОценок пока нет

- Behaviour Based Safety: Presented byДокумент14 страницBehaviour Based Safety: Presented bynasrul dracoОценок пока нет

- Training On ISO 14001, Clause No.: 6.1.2 Environmental Aspects (AI)Документ37 страницTraining On ISO 14001, Clause No.: 6.1.2 Environmental Aspects (AI)sankusi_rkflОценок пока нет

- ObjectivityДокумент7 страницObjectivityvaratharaj bОценок пока нет

- Workplace Inspection ChecklistДокумент64 страницыWorkplace Inspection ChecklistMHDОценок пока нет

- General Industry Safety ChecklistДокумент1 страницаGeneral Industry Safety Checklistjuaco_vm100% (1)

- EMS & OHSMS Internal Audit ChecklistДокумент44 страницыEMS & OHSMS Internal Audit ChecklistRaajha Munibathiran92% (13)

- Internal Audit Checklist 108Документ5 страницInternal Audit Checklist 108Harkesh BansalОценок пока нет

- Risk AssessmentДокумент3 страницыRisk AssessmentmiaicarbaОценок пока нет

- Workplace Safety and Health Framework Development and ImplementationДокумент3 страницыWorkplace Safety and Health Framework Development and ImplementationRias SahulОценок пока нет

- Mockdrill 161210094307Документ10 страницMockdrill 161210094307GobindaSahu100% (1)

- Fire Audit ChecklistДокумент4 страницыFire Audit ChecklistnifskolОценок пока нет

- Office Safety ChecklistДокумент3 страницыOffice Safety ChecklistJaijeev Pali100% (1)

- Safety Department Checklist FormatДокумент32 страницыSafety Department Checklist Formatrockyvinoo100% (18)

- EHS Audit ChecklistДокумент6 страницEHS Audit ChecklistVIJAY BHARATEОценок пока нет

- Planned Job ObservationДокумент52 страницыPlanned Job ObservationJohn Mark DulawanОценок пока нет

- Scaffolding Safety Checklist PDF enДокумент3 страницыScaffolding Safety Checklist PDF enarya100% (2)

- Warehouse Safety ChecklistДокумент2 страницыWarehouse Safety ChecklistOmkar BhavleОценок пока нет

- 3-HIRARC (Hazard Identification, Risk Assessment and Risk Control)Документ7 страниц3-HIRARC (Hazard Identification, Risk Assessment and Risk Control)A. RAHMAD BIN NGAH / UPM100% (1)

- 6S (5S+1) Audit Check Sheet AdaptiveBMSДокумент4 страницы6S (5S+1) Audit Check Sheet AdaptiveBMSAndrugrasu GrasuОценок пока нет

- Written Lockout/Tagout Program University of South Carolina (Enter Department Name Here)Документ13 страницWritten Lockout/Tagout Program University of South Carolina (Enter Department Name Here)SaidОценок пока нет

- Accident Witness Statement FormДокумент4 страницыAccident Witness Statement FormVictorОценок пока нет

- EMS AuditДокумент62 страницыEMS AuditMansoor AliОценок пока нет

- Inspection ChecklistsДокумент6 страницInspection Checklistsmegaspice0% (1)

- Inspection Checklists - Sample Checklist For Manufacturing Facilities - OSH AnswersДокумент6 страницInspection Checklists - Sample Checklist For Manufacturing Facilities - OSH Answersshahira100% (1)

- Inspectors: DateДокумент7 страницInspectors: DateMuruganОценок пока нет

- JAFZA Warehouse Inspection ChecklistsДокумент8 страницJAFZA Warehouse Inspection ChecklistsPerwez21100% (1)

- Laydown Yard ChecklistДокумент6 страницLaydown Yard Checklistjonathan cambaОценок пока нет

- Title SOP Incubator Operation QC 047 01Документ12 страницTitle SOP Incubator Operation QC 047 01aKureishiОценок пока нет

- SOP of Media PreparationДокумент8 страницSOP of Media PreparationaKureishiОценок пока нет

- Airborne Particulate Cleanliness ClassesДокумент4 страницыAirborne Particulate Cleanliness ClassesaKureishiОценок пока нет

- SOP of Destruction of Culture MediaДокумент6 страницSOP of Destruction of Culture MediaaKureishiОценок пока нет

- SOP of SamplingДокумент8 страницSOP of SamplingaKureishiОценок пока нет

- Endotoxin CalculationsДокумент5 страницEndotoxin Calculationsjaks2771% (7)

- SOP of Water TestingДокумент17 страницSOP of Water TestingaKureishi67% (6)

- Autoclaves - Generic Assessment - L Use of AutoclavesДокумент1 страницаAutoclaves - Generic Assessment - L Use of AutoclavesaKureishiОценок пока нет

- Plant Risk Assessment FormДокумент7 страницPlant Risk Assessment FormaKureishiОценок пока нет

- Services On DemandДокумент13 страницServices On DemandaKureishiОценок пока нет

- Appendix-I PQ #. 1 Sampling Point: SP001 (Feed Water Inlet) : G Io N CH Lo Rid e Ni Tra TeДокумент14 страницAppendix-I PQ #. 1 Sampling Point: SP001 (Feed Water Inlet) : G Io N CH Lo Rid e Ni Tra TeaKureishiОценок пока нет

- FP 201112123122121Документ10 страницFP 201112123122121aKureishiОценок пока нет

- Task Risk Analysis FormДокумент5 страницTask Risk Analysis FormaKureishiОценок пока нет

- Risk Management Laboratory Standard Operating ProceduresДокумент10 страницRisk Management Laboratory Standard Operating ProceduresaKureishiОценок пока нет

- General Risk Assessment FormДокумент5 страницGeneral Risk Assessment FormaKureishiОценок пока нет

- White Paper Tri 2008Документ3 страницыWhite Paper Tri 2008aKureishiОценок пока нет

- Bugs and Drugs: A Summary of Pharmaceutical MicrobiologyДокумент20 страницBugs and Drugs: A Summary of Pharmaceutical MicrobiologyaKureishiОценок пока нет

- WSF AQC Presentation Richard Glindon Klaus Herick Tcm18-219589Документ21 страницаWSF AQC Presentation Richard Glindon Klaus Herick Tcm18-219589aKureishiОценок пока нет

- Bacterial en Do Toxins Test 1 Manual For PDFДокумент72 страницыBacterial en Do Toxins Test 1 Manual For PDFaKureishiОценок пока нет

- Fire Extinguisher Location and Placement: Fact SheetДокумент2 страницыFire Extinguisher Location and Placement: Fact SheetEli NaguitОценок пока нет

- QBDC - Season 5-RulebookДокумент50 страницQBDC - Season 5-RulebookHggvgОценок пока нет

- Actuation Data SheetДокумент7 страницActuation Data Sheetcomercial.jascorpsacОценок пока нет

- Dl311 Top Hammer Longhole Drill: Technical SpecificationДокумент4 страницыDl311 Top Hammer Longhole Drill: Technical SpecificationcblОценок пока нет

- Australian Standard: Gas Cylinders Part 1: General RequirementsДокумент9 страницAustralian Standard: Gas Cylinders Part 1: General Requirementscah_mbuhОценок пока нет

- Security Operations - Level 3Документ253 страницыSecurity Operations - Level 3एकेन्द्र केसीОценок пока нет

- SW Darth Vader Voice ChangerДокумент9 страницSW Darth Vader Voice ChangerjeanyoperОценок пока нет

- Ghs Safety Data Sheet: ParabondДокумент2 страницыGhs Safety Data Sheet: Parabondmanoj_sitecОценок пока нет

- DEE EHU 4-2-4 Risk RegisterДокумент36 страницDEE EHU 4-2-4 Risk RegisterJonasОценок пока нет

- Health-Safety-Coca ColaДокумент14 страницHealth-Safety-Coca ColaMet nicolaouОценок пока нет

- Marine Lite Catalogue - Part 1Документ20 страницMarine Lite Catalogue - Part 1mkccmОценок пока нет

- MSN 1737 (M) : Helicopter Emergency Landing AreasДокумент6 страницMSN 1737 (M) : Helicopter Emergency Landing AreasRamson RaymondОценок пока нет

- Fire StationДокумент67 страницFire StationRAGHVENDRA PRATAP SINGHОценок пока нет

- AS 2444-2001 ExtinguishersДокумент37 страницAS 2444-2001 ExtinguishersSaxon KimОценок пока нет

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company Sulfur, MoltenДокумент9 страницSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company Sulfur, MoltenGerome EugenioОценок пока нет

- (THE SAFETY) CatalogДокумент38 страниц(THE SAFETY) CataloggobilgobilОценок пока нет

- Construction Phase Site Fire Safety Plan TemplateДокумент0 страницConstruction Phase Site Fire Safety Plan TemplateBotenes Mallorca RhonОценок пока нет

- Hse Minimum Requirements For SubcontractorsДокумент4 страницыHse Minimum Requirements For SubcontractorsMy pouОценок пока нет

- NPF-FGCRT-060001Rev0 Fire Protection Design CriteriaДокумент20 страницNPF-FGCRT-060001Rev0 Fire Protection Design CriteriainnovativekarthiОценок пока нет

- Fire Extinguisher Register-FinalДокумент3 страницыFire Extinguisher Register-Finalpride mukwachariОценок пока нет

- International Fire Training Centre: Firefighter InitialДокумент5 страницInternational Fire Training Centre: Firefighter Initialmatthew02012010Оценок пока нет

- SmartLi 2.0 Quick GuideДокумент4 страницыSmartLi 2.0 Quick Guidesanizam79Оценок пока нет

- Fire Prevention ChecklistДокумент1 страницаFire Prevention ChecklistJosiahОценок пока нет

- Ear Drops Safety Data SheetДокумент5 страницEar Drops Safety Data SheetShehzadОценок пока нет

- ABS Fire Extinguisher CatalogueДокумент56 страницABS Fire Extinguisher CatalogueqwertyОценок пока нет

- Trolley Fire Extinguisher 45kg Co2 en MinДокумент1 страницаTrolley Fire Extinguisher 45kg Co2 en MinParvezОценок пока нет

- Alpolic FRДокумент48 страницAlpolic FRM. Murat ErginОценок пока нет

- Fire Extinguisher Placement and Design ProcedureДокумент16 страницFire Extinguisher Placement and Design ProcedureDIEGOZafОценок пока нет

- Safety QuestionsДокумент4 страницыSafety QuestionsHimanshu ShekharОценок пока нет

- Aramco PDFДокумент38 страницAramco PDFMuhammad Farooq Malik100% (1)