Академический Документы

Профессиональный Документы

Культура Документы

Watt e Meter

Загружено:

harimadhavareddy0 оценок0% нашли этот документ полезным (0 голосов)

8 просмотров3 страницыnothing

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документnothing

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

8 просмотров3 страницыWatt e Meter

Загружено:

harimadhavareddynothing

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

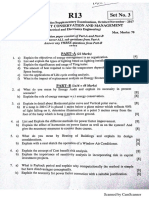

13.

1 Induction Type Wattmeter

These types of watt-meters operate on the same working principle on which the

induction type ammeter and voltmeter operates. These instruments can only be

used on ac supply while dynamo-meter type watt meters can be used on either ac

or dc supply system. Induction type watt-meters are useful only when the supply

and frequency remains constant. Since both the coils i.e. current coil and pressure

coils are necessary in such instrument, it is not essential to use shaded pole

principle. Because for producing a deflecting torque, two fluxes are essential with

suitable phase angle and it would be available from these two coils.

13.1.1 Construction

A watt-meter has two laminated electromagnet, one of which is excited by load

current or definite fraction of it, and is connected in series with the circuit, known

as series magnet and the other is excited by the current proportional to the applied

voltage or fraction of it and is always connected across the supply, known as shunt

magnet. An aluminum disc is so mounted so that it cuts the fluxes produced by

both the magnets. As a result of which, two e.m.fs are produced which induces

two eddy currents in the disc. C - Magnet is used to provide necessary damping

torque to the pointer, to damp out the oscillations. Deflecting torque is produced

due to interaction of these eddy currents and the inducing flux. Copper shading

bands are provided either on central limb or on the outer limb of the shunt magnet,

and can be so adjusted as to make the resultant flux in the shunt magnet lag behind

the applied voltage by 90. Both the watt-meters are provided with spiral springs

A and B, for producing controlling torque to counter balance the deflecting torque.

In Fig. 13.2 the spiral spring and damping magnet is omitted for simplicity. The

scale of such type instruments is quite uniform and extends over an angle of

300. Currents up to 100 A can be handled by these watt-meters directly where as

beyond this current transformers are used. Two types of induction type watt meters

are available. Line diagrams of both of the types are detailed in Fig. 13.1 and 13.2.

Fig. 13.1 Induction type wattmeter

In the form of the instrument shown in Fig. 13.1, two pressure coils are connected

in series in such a way that both of them send flux through the central limb. The

series magnet also carries two small current coils connected in series and wound so

that they magnetized their respective cores in the same direction. Correct phase

displacement between the fluxes produced by series and shunt magnet is obtained

by the adjustment of copper shading band on the central limb.

Fig. 13.2 Induction type wattmeter

In Fig. 13.2, there is only one pressure and one current coil. Two projecting poles

of shunt magnet are surrounded by a copper shading band whose position can be

adjusted for correcting the phase of the flux of this magnet with the applied

voltage. The pressure coil circuit of induction type instrument is made as inductive

as possible so that the flux of the shunt magnet may lag nearly by 90 behind the

applied voltage.

13.1.2 Advantages

The advantages of induction watt meters are the same as those of induction

ammeters long scale, freedom from effects of stray field, and have effective

damping torque.

13.1.3 Disadvantages

Following are the disadvantage of the induction type instruments:

a) Change in temperature causes variation in the resistance of the moving

element, affects the eddy currents therein, and so the operating torque. The

error due to this is in part offset by a balancing effect due to change in

temperature of the windings.

b) Change in frequency from that of the calibration value causes variations in

both the reactance of the voltage coil circuit, which is highly inductive, and

also in the amount of compensation from the phase compensating circuit.

Within the limits of frequency variation met within practice on the mains, this

last error in not important.

Вам также может понравиться

- 2023-24 Bet 106 Unit-1 Question BankДокумент2 страницы2023-24 Bet 106 Unit-1 Question BankharimadhavareddyОценок пока нет

- Boiler Performance - DataДокумент2 страницыBoiler Performance - DataharimadhavareddyОценок пока нет

- 2023-24 Bet 106 Unit-1 Question BankДокумент2 страницы2023-24 Bet 106 Unit-1 Question BankharimadhavareddyОценок пока нет

- Civil Title PageДокумент2 страницыCivil Title PageharimadhavareddyОценок пока нет

- 2023 Bet 106 Unit-2 Question BankДокумент2 страницы2023 Bet 106 Unit-2 Question BankharimadhavareddyОценок пока нет

- 24 Bet 106 Unit-2 Question BankДокумент2 страницы24 Bet 106 Unit-2 Question BankharimadhavareddyОценок пока нет

- "Application of Biofuels in Automotives ": Visveswaraiah Technological University, BelgaumДокумент23 страницы"Application of Biofuels in Automotives ": Visveswaraiah Technological University, BelgaumharimadhavareddyОценок пока нет

- Universal College of Engineering & Technology Department of Electrical & Electronics EngineeringДокумент1 страницаUniversal College of Engineering & Technology Department of Electrical & Electronics EngineeringharimadhavareddyОценок пока нет

- Rtps Unit # 7 Boiler Water ChemistryДокумент16 страницRtps Unit # 7 Boiler Water ChemistryharimadhavareddyОценок пока нет

- Lesson 1 Lesson 2 Lesson 3: LightingДокумент11 страницLesson 1 Lesson 2 Lesson 3: LightingharimadhavareddyОценок пока нет

- New Doc 2017-11-13Документ6 страницNew Doc 2017-11-13harimadhavareddyОценок пока нет

- Cricket Score SheetДокумент2 страницыCricket Score SheetharimadhavareddyОценок пока нет

- New Doc 2017-11-13Документ2 страницыNew Doc 2017-11-13harimadhavareddyОценок пока нет

- R-13 Set-4Документ9 страницR-13 Set-4harimadhavareddyОценок пока нет

- Cricket Score SheetДокумент1 страницаCricket Score SheetharimadhavareddyОценок пока нет

- Lesson Plan Academic Year: 2018-19 2018/Univ/Eee/LpДокумент22 страницыLesson Plan Academic Year: 2018-19 2018/Univ/Eee/LpharimadhavareddyОценок пока нет

- Cricket Score SheetДокумент2 страницыCricket Score SheetharimadhavareddyОценок пока нет

- Lab External PlanДокумент1 страницаLab External PlanharimadhavareddyОценок пока нет

- WWW - Manaresults.Co - In: II B. Tech I Semester Regular Examinations, October/November - 2017 Network AnalysisДокумент11 страницWWW - Manaresults.Co - In: II B. Tech I Semester Regular Examinations, October/November - 2017 Network AnalysisharimadhavareddyОценок пока нет

- Electrical Engineering: "Manipulate The Power"Документ8 страницElectrical Engineering: "Manipulate The Power"harimadhavareddyОценок пока нет

- Lab Request FormatДокумент1 страницаLab Request FormatharimadhavareddyОценок пока нет

- Universal College EEE DEPARTMENTДокумент38 страницUniversal College EEE DEPARTMENTharimadhavareddyОценок пока нет

- Power Lab Catalouge ChennaiДокумент139 страницPower Lab Catalouge ChennaiharimadhavareddyОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- 5209 Aerospace T SealДокумент20 страниц5209 Aerospace T SealNicolasSuchОценок пока нет

- LG Rad 226B PDFДокумент65 страницLG Rad 226B PDFFrancisReis0% (1)

- Shell Spirax S6 Txme: Performance, Features & BenefitsДокумент2 страницыShell Spirax S6 Txme: Performance, Features & BenefitsAbdelhadi HoussinОценок пока нет

- Heydar Aliyev Cultural Centre: StructureДокумент3 страницыHeydar Aliyev Cultural Centre: Structurenusha rakheОценок пока нет

- Pic Attack1Документ13 страницPic Attack1celiaescaОценок пока нет

- Lesson 5 T-BeamsДокумент7 страницLesson 5 T-BeamsJoshua John JulioОценок пока нет

- Av36d303 SchematicДокумент30 страницAv36d303 SchematicLuis MorenoОценок пока нет

- DP Misc Wnt5 x86-32 ChangelogДокумент5 страницDP Misc Wnt5 x86-32 ChangelogBrandal KalocyОценок пока нет

- Physical and Mechanical Characterization of Fresh Bamboo For Infrastructure ProjectsДокумент10 страницPhysical and Mechanical Characterization of Fresh Bamboo For Infrastructure ProjectsLuanna Silva de Pires Campos AlvesОценок пока нет

- Remote Log-In, Electronic Mail and File Transfer: Solutions To Odd-Numbered Review Questions and ExercisesДокумент2 страницыRemote Log-In, Electronic Mail and File Transfer: Solutions To Odd-Numbered Review Questions and ExercisesAnurag UpadhyayОценок пока нет

- ASSAM - Uniform Zoning Regulation 2000Документ35 страницASSAM - Uniform Zoning Regulation 2000rajatesh1Оценок пока нет

- Size Matters: (Type The Document Subtitle)Документ16 страницSize Matters: (Type The Document Subtitle)SamarthGoelОценок пока нет

- ReactionsДокумент30 страницReactionskaloibestОценок пока нет

- 2014 03 Istanbul PDFДокумент3 страницы2014 03 Istanbul PDFFaraj DividОценок пока нет

- Calorific Value of Coal - A Useful DetailДокумент5 страницCalorific Value of Coal - A Useful Detailkaruna346Оценок пока нет

- Const Estimate Made EasyДокумент31 страницаConst Estimate Made EasyLorenzo SerranoОценок пока нет

- Nokia c7-00 Rm-675 Rm-691 Service Manual-12 v6Документ32 страницыNokia c7-00 Rm-675 Rm-691 Service Manual-12 v6sasquatch69Оценок пока нет

- Ibell RH26-26Документ18 страницIbell RH26-26SangaОценок пока нет

- Code Eac NaceДокумент2 страницыCode Eac NaceEvan BuwanaОценок пока нет

- Tutorial Sheet 7Документ2 страницыTutorial Sheet 7Muhammad NidzwanОценок пока нет

- WWW - Manaresults.Co - In: Set No. 1Документ4 страницыWWW - Manaresults.Co - In: Set No. 1Chanumolu DushyanthОценок пока нет

- SEMIKRON Product Catalogue 2014 2015Документ167 страницSEMIKRON Product Catalogue 2014 2015cesar oliveira0% (1)

- Fortranv 7Документ173 страницыFortranv 7mu4viewОценок пока нет

- Infinique Structured Cabling Installation ChecklistДокумент2 страницыInfinique Structured Cabling Installation Checklistroot75% (4)

- ASTM E1417 Penetrant Testing - 9 PDFДокумент11 страницASTM E1417 Penetrant Testing - 9 PDFbikaОценок пока нет

- SAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UKДокумент73 страницыSAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UKtracyhopyОценок пока нет

- Friction Loss Calculations of Irrigation Design A Foot Ball CourtДокумент13 страницFriction Loss Calculations of Irrigation Design A Foot Ball Courtmathewmanjooran100% (2)

- Blog #2Документ2 страницыBlog #2Anonymous uxozDvwYОценок пока нет