Академический Документы

Профессиональный Документы

Культура Документы

26.value Stream Mapping (VSM)

Загружено:

eddiekuangОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

26.value Stream Mapping (VSM)

Загружено:

eddiekuangАвторское право:

Доступные форматы

CQE Training & Consultancy (0187064-K)

Registered Office : No. 46, Lorong Bintang, Taman Tasik Permai, 34000 Taiping, Perak. Malaysia.

Operating Office : No. 85A (1st. Floor), Jalan Barrack, 34000 Taiping, Perak. Malaysia.

T : +605-805 2722 / +605-808 8028 F : +605-805 2721 M : +6012-505 2720 / +6012-550 2721

E : cqetrg@streamyx.com or cqetraining@gmail.com W : http://www.cqetraining.com B : http://cqeblog.blogspot.com

VALUE STREAM MAPPING (VSM)

(PUBLIC / IN-HOUSE TRAINING PROGRAMME)

SBL

Introduction Scheme

Lean thinking has become a widely adopted improvement approach that can greatly simplify processes and

improve performance. At the heart of Lean thinking is the focus on creating value for the customer and

eliminating waste. The stream of activity within an organisation that creates customer value is called the value

stream. Value Stream Mapping is the tool used to understand, analyse and improve a value stream. The focus

of this 2-day Value Stream Mapping training course is to provide delegates with the practical skills to use

value stream mapping in a service or manufacturing organisation.

Value Stream Mapping (VSM) enables a company to identify and eliminate waste, thereby streamlining work

processes, cutting lead times, reducing costs and increasing quality. Through Value Stream Mapping, a team

of employees can map the current state from customer back to raw material including all steps, both value-

added and non-value-added, and develop a future state vision to act as a blueprint for lean activities. The

future state often represents a significant change compared to the way the company currently operates. The

value stream mapping team will develop an implementation strategy to make the future state a reality.

Also available as

Learning Outcomes/Objectives in-house programme

This course is specifically developed to provide participants in the manufacturing and servicing industry the

uses a blend of theory and practical exercises. During the Value Stream Mapping course delegates will

develop an understanding of:-

Customer value and the key elements and methods of Value Stream Mapping

View all products from a system perspective

See the flow of your value stream and wastes in the flow

How to define and analyse the current state value stream map - material and information flows

The three stages to develop an ideal future state map

Draw a blueprint for lean transformation the future state map

Prioritise activities needed to achieve the future state

How to derive a Kaizen improvement plan

Prepared by : Mr . Eddie Kuang Copyright 2001-2013. All Rights Reserved -1-

CQE Training & Consultancy (0187064-K)

Registered Office : No. 46, Lorong Bintang, Taman Tasik Permai, 34000 Taiping, Perak. Malaysia.

Operating Office : No. 85A (1st. Floor), Jalan Barrack, 34000 Taiping, Perak. Malaysia.

T : +605-805 2722 / +605-808 8028 F : +605-805 2721 M : +6012-505 2720 / +6012-550 2721

E : cqetrg@streamyx.com or cqetraining@gmail.com W : http://www.cqetraining.com B : http://cqeblog.blogspot.com

Program Contents

Introduction to Value Stream Mapping (VSM)

Understanding Customer Value

Characteristics, Benefits and Importance of Value Stream Mapping

o Value add, value enabling and non-value adding activities

Elements of Value Stream Mapping

Current State Map: Step-By-Step Guide

Establish Takt Time

Compile Present State Map

Future State Map: Step-By-Step Guide

Compile Future State Map

Common Symbols Used

Limitations of Value Stream Mapping

Supporting Tools and Techniques

Who should attend

Managers, Engineers, Executives, Supervisors, Quality Practitioners and any member of an organisation who

is from Process, Research and Development, Quality and Production will find this course relevant and

beneficial to their job function related to Lean Manufacturing, Operation, Administration and Servicing.

Methodology

The program would be conducted by using the following

materials / aids :-

Course Notes

OHP / LCD

Video Showing

Lecturettes

Prepared by : Mr . Eddie Kuang Copyright 2001-2013. All Rights Reserved -2-

CQE Training & Consultancy (0187064-K)

Registered Office : No. 46, Lorong Bintang, Taman Tasik Permai, 34000 Taiping, Perak. Malaysia.

Operating Office : No. 85A (1st. Floor), Jalan Barrack, 34000 Taiping, Perak. Malaysia.

T : +605-805 2722 / +605-808 8028 F : +605-805 2721 M : +6012-505 2720 / +6012-550 2721

E : cqetrg@streamyx.com or cqetraining@gmail.com W : http://www.cqetraining.com B : http://cqeblog.blogspot.com

Duration

2 days

Participants

Max ~25 pax

Prepared by : Mr . Eddie Kuang Copyright 2001-2013. All Rights Reserved -3-

Вам также может понравиться

- Lean Assessment2Документ18 страницLean Assessment2Yenaro CortesОценок пока нет

- Value Stream and Process Mapping - Rev 1Документ20 страницValue Stream and Process Mapping - Rev 1scowelОценок пока нет

- Date: # of Y's: 25 % 6-S ChecklistДокумент36 страницDate: # of Y's: 25 % 6-S Checklisthariharasubramaniananian.s s.Оценок пока нет

- Optimize lean thinking processes with value stream mappingДокумент23 страницыOptimize lean thinking processes with value stream mappingEko DiptyoadiОценок пока нет

- Rolled Throughput Yield (6 Sigma)Документ8 страницRolled Throughput Yield (6 Sigma)Laaiba IshaaqОценок пока нет

- 12 Success Factors PDF PDFДокумент3 страницы12 Success Factors PDF PDFMd. Injamamul HaqueОценок пока нет

- Industrial Solutions, Inc: Lean Assessment ScorecardДокумент5 страницIndustrial Solutions, Inc: Lean Assessment Scorecardrgrao85Оценок пока нет

- Exercises Value Stream MappingДокумент3 страницыExercises Value Stream MappingLize Nel100% (1)

- Lean in ServicesДокумент1 страницаLean in ServicesSandeep SinghОценок пока нет

- Rapid Plant Assessment Tables and ChartsДокумент14 страницRapid Plant Assessment Tables and ChartsjitendrasutarОценок пока нет

- Toyota Executive SummaryДокумент16 страницToyota Executive SummaryAmirahОценок пока нет

- Investigating The Effect of Value Stream Mapping On Procurement Effectiveness A Case StudyДокумент12 страницInvestigating The Effect of Value Stream Mapping On Procurement Effectiveness A Case StudyJorge Alejandro Patron ChicanaОценок пока нет

- 1-5 The 12 Step BTS Process & Road MapsДокумент30 страниц1-5 The 12 Step BTS Process & Road Mapsanjo0225Оценок пока нет

- Value Stream Mapping BasicsДокумент24 страницыValue Stream Mapping BasicsPedro PérezОценок пока нет

- Lean 6 Sigma MaturityДокумент15 страницLean 6 Sigma MaturityYap Yun FungОценок пока нет

- LEAN Continuous Improvement KaizenДокумент4 страницыLEAN Continuous Improvement KaizenHafis BonterОценок пока нет

- What Is QFD?: Dr. Yoji AkaoДокумент6 страницWhat Is QFD?: Dr. Yoji AkaoAОценок пока нет

- Lean Value Stream: Mapping & AnalysisДокумент34 страницыLean Value Stream: Mapping & AnalysisJose SantosОценок пока нет

- Improving Performance Through Business Process ManagementДокумент4 страницыImproving Performance Through Business Process ManagementArk Group0% (1)

- Server Backup Six Sigma Case StudyДокумент2 страницыServer Backup Six Sigma Case StudySteven BonacorsiОценок пока нет

- MODULE 4 Value Stream Mapping MIT PDFДокумент38 страницMODULE 4 Value Stream Mapping MIT PDFJosephОценок пока нет

- Lean OfficeДокумент21 страницаLean OfficebradleyjtennantОценок пока нет

- Lean Daily ManagementДокумент29 страницLean Daily ManagementNatarajan R100% (1)

- An Evolutionary Model of Continuous Improvement Behaviour: John Bessant, Sarah Caffyn, Maeve GallagherДокумент11 страницAn Evolutionary Model of Continuous Improvement Behaviour: John Bessant, Sarah Caffyn, Maeve GallagherNathalia Cáceres100% (1)

- Project Report On Maynard Operation Sequence TechniqueДокумент9 страницProject Report On Maynard Operation Sequence TechniqueEditor IJTSRDОценок пока нет

- Lean Six Sigma Asq Road MapДокумент2 страницыLean Six Sigma Asq Road Maphj100% (4)

- Set-Up Observation Analysis Sheet: TotalsДокумент23 страницыSet-Up Observation Analysis Sheet: TotalsKhaled KassemОценок пока нет

- VSMДокумент13 страницVSMnavingaikwad100% (1)

- P-Dmaic Roadmap r2 From SSIДокумент1 страницаP-Dmaic Roadmap r2 From SSIShiva KumarОценок пока нет

- Project: Establishing A Value-Driven BPM-DisciplineДокумент20 страницProject: Establishing A Value-Driven BPM-DisciplineMuhammad NaveedОценок пока нет

- Committing To A Lean Six-Sigma Roadmap: Merwan Mehta, PHD, Asq-CssbbДокумент36 страницCommitting To A Lean Six-Sigma Roadmap: Merwan Mehta, PHD, Asq-CssbbCarlos Delgado NietoОценок пока нет

- SigmaFlow VSM Reference ManualДокумент236 страницSigmaFlow VSM Reference ManualluisОценок пока нет

- DMAIC TemplateДокумент39 страницDMAIC Templateunknown139Оценок пока нет

- 3a 2 Card Kanban System CalculationsДокумент2 страницы3a 2 Card Kanban System CalculationsJose OrtegaОценок пока нет

- Lean Self AssessmentДокумент1 страницаLean Self Assessmentmh70100% (1)

- Six Sigma Approach KeyДокумент7 страницSix Sigma Approach Keydalaalstreet09Оценок пока нет

- A New Method of Bottleneck Analysis For Manufacturing SystemsДокумент4 страницыA New Method of Bottleneck Analysis For Manufacturing SystemsrizalОценок пока нет

- 5s Step by Step GuideДокумент10 страниц5s Step by Step GuideKalkidan MekuriyaОценок пока нет

- Checklist Lean Lab MS-TSДокумент15 страницChecklist Lean Lab MS-TSHartiniОценок пока нет

- What Is Business Process MappingДокумент8 страницWhat Is Business Process Mappingsheebakbs5144Оценок пока нет

- Lean Metrics GuideДокумент14 страницLean Metrics GuidebradleyjtennantОценок пока нет

- Lean Six Sigma CrosswordДокумент1 страницаLean Six Sigma CrosswordexamplecgОценок пока нет

- Enterprise Dynamics TutorialДокумент66 страницEnterprise Dynamics TutorialBaracОценок пока нет

- Lean Office AssessmentДокумент10 страницLean Office Assessmentanthony2069100% (1)

- Lean Six Sigma PDFДокумент28 страницLean Six Sigma PDFMohammed Said MaamraОценок пока нет

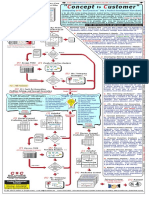

- " Oncept Ustomer": SolutionsДокумент1 страница" Oncept Ustomer": SolutionsJac DОценок пока нет

- Toyota Kata: Using Toyota's "Improvement and Coaching Katas" To Take Your Lab Team To A Higher Level of Problem-Solving and Performance ImprovementДокумент32 страницыToyota Kata: Using Toyota's "Improvement and Coaching Katas" To Take Your Lab Team To A Higher Level of Problem-Solving and Performance Improvementcheri kokОценок пока нет

- Benchmarking & BPR for Optimal Business ProcessesДокумент34 страницыBenchmarking & BPR for Optimal Business Processesvkvivekvk1Оценок пока нет

- Kaizen ToolsДокумент11 страницKaizen Toolssinghpune19100% (1)

- Visual Factory (Actually Used in Factories)Документ19 страницVisual Factory (Actually Used in Factories)monu9999100% (2)

- ModelsGuidelines v5Документ37 страницModelsGuidelines v5Martin NolanОценок пока нет

- Lean 6-Sigma - Value Stream MappingДокумент8 страницLean 6-Sigma - Value Stream MappingAhmmad AwadОценок пока нет

- 04 The Six Sigma MethodologyДокумент53 страницы04 The Six Sigma Methodologychteo1976Оценок пока нет

- Lean Six Sigma Project CharterДокумент1 страницаLean Six Sigma Project CharterPedro KОценок пока нет

- V Buehler Lean Assessment TemplateДокумент23 страницыV Buehler Lean Assessment TemplateAntonio Fernández V.100% (1)

- Office (Eng)Документ31 страницаOffice (Eng)kingathur26681Оценок пока нет

- Lean Strategy by Shyam TalawadekarДокумент4 страницыLean Strategy by Shyam Talawadekartsid47Оценок пока нет

- Value Stream Mapping Software A Complete Guide - 2020 EditionОт EverandValue Stream Mapping Software A Complete Guide - 2020 EditionОценок пока нет

- Registration Form: SBL SchemeДокумент1 страницаRegistration Form: SBL SchemeeddiekuangОценок пока нет

- Aiag-Vda Fmea Handbook Training: (In-House / Public Training Programme)Документ3 страницыAiag-Vda Fmea Handbook Training: (In-House / Public Training Programme)eddiekuang100% (1)

- 58.EQA Act127 Introductiry Training PDFДокумент4 страницы58.EQA Act127 Introductiry Training PDFeddiekuangОценок пока нет

- Cost of Quality (Coq) : (Public / In-House Training Programme)Документ4 страницыCost of Quality (Coq) : (Public / In-House Training Programme)eddiekuangОценок пока нет

- Iso13485:2016 Medical Devices Qms Internal Audit TrainingДокумент4 страницыIso13485:2016 Medical Devices Qms Internal Audit TrainingeddiekuangОценок пока нет

- Lean Warehouse / Supply Chain Management (SCM) Training: (Public / In-House Training Programme)Документ4 страницыLean Warehouse / Supply Chain Management (SCM) Training: (Public / In-House Training Programme)eddiekuangОценок пока нет

- Cost of Quality (Coq) : (Public / In-House Training Programme)Документ4 страницыCost of Quality (Coq) : (Public / In-House Training Programme)eddiekuangОценок пока нет

- Lean Warehouse / Supply Chain Management (SCM) Training: (Public / In-House Training Programme)Документ4 страницыLean Warehouse / Supply Chain Management (SCM) Training: (Public / In-House Training Programme)eddiekuangОценок пока нет

- Integrated Environmental and OH&S Management Systems Introductory & Awareness TrainingДокумент4 страницыIntegrated Environmental and OH&S Management Systems Introductory & Awareness TrainingeddiekuangОценок пока нет

- Aiag-Vda Fmea Handbook Training: (In-House / Public Training Programme)Документ3 страницыAiag-Vda Fmea Handbook Training: (In-House / Public Training Programme)eddiekuang100% (1)

- 58.EQA Act127 Introductiry Training PDFДокумент4 страницы58.EQA Act127 Introductiry Training PDFeddiekuangОценок пока нет

- Integrated Environmental and OH&S Management Systems Introductory & Awareness TrainingДокумент4 страницыIntegrated Environmental and OH&S Management Systems Introductory & Awareness TrainingeddiekuangОценок пока нет

- Process Validation Training (PVT) : (Public / In-House Training Programme)Документ4 страницыProcess Validation Training (PVT) : (Public / In-House Training Programme)eddiekuangОценок пока нет

- Process Validation Training (PVT) : (Public / In-House Training Programme)Документ4 страницыProcess Validation Training (PVT) : (Public / In-House Training Programme)eddiekuangОценок пока нет

- Geometric Dimensioning and Tolerancing (GD&T) : CQE Training & Consultancy PLTДокумент2 страницыGeometric Dimensioning and Tolerancing (GD&T) : CQE Training & Consultancy PLTeddiekuangОценок пока нет

- 35.process Validation TRGДокумент4 страницы35.process Validation TRGeddiekuangОценок пока нет

- Iso13485:2016 Medical Devices Qms Clause by Clause Deep Dive TrainingДокумент4 страницыIso13485:2016 Medical Devices Qms Clause by Clause Deep Dive TrainingeddiekuangОценок пока нет

- Productivity Improvement Techniques (Pit) Towards Maintaining CompetitivenessДокумент3 страницыProductivity Improvement Techniques (Pit) Towards Maintaining CompetitivenesseddiekuangОценок пока нет

- 16.MINITAB Software Application Training Couse Outline 2days - SPCДокумент4 страницы16.MINITAB Software Application Training Couse Outline 2days - SPCeddiekuangОценок пока нет

- 41.FMEA HIRARC CourseOutline 2daysДокумент4 страницы41.FMEA HIRARC CourseOutline 2dayseddiekuangОценок пока нет

- Cycle Time Management (CTM) : (Public / In-House Training Programme)Документ4 страницыCycle Time Management (CTM) : (Public / In-House Training Programme)eddiekuangОценок пока нет

- Mba Kaizen CourseoutlineДокумент5 страницMba Kaizen Courseoutlineeddiekuang100% (1)

- Poka-Yoke Mistake Proofing Manufacturing: (Public / In-House Training Programme)Документ3 страницыPoka-Yoke Mistake Proofing Manufacturing: (Public / In-House Training Programme)eddiekuangОценок пока нет

- 34.cycle Time Management CTMДокумент4 страницы34.cycle Time Management CTMeddiekuangОценок пока нет

- 48.CSR Training Based On EICCДокумент4 страницы48.CSR Training Based On EICCeddiekuangОценок пока нет

- 36.ISO DIS9001 2015 QMS Course OutlineДокумент4 страницы36.ISO DIS9001 2015 QMS Course OutlineeddiekuangОценок пока нет

- Industrial Problem N Appropriate MS TechniquesДокумент1 страницаIndustrial Problem N Appropriate MS TechniqueseddiekuangОценок пока нет

- Mba Kaizen CourseoutlineДокумент5 страницMba Kaizen Courseoutlineeddiekuang100% (1)

- 37.ISO14001 2015 EMS Course OutlineДокумент4 страницы37.ISO14001 2015 EMS Course OutlineeddiekuangОценок пока нет

- 40.effective Quality Environmental Safety MGMT Systems Internal Audit Course OutlineДокумент3 страницы40.effective Quality Environmental Safety MGMT Systems Internal Audit Course OutlineeddiekuangОценок пока нет

- Mental Status ExaminationДокумент4 страницыMental Status ExaminationZamranos67% (3)

- Broken Homes, Broken Hearts - Voices of Students From Broken FamiliesДокумент167 страницBroken Homes, Broken Hearts - Voices of Students From Broken FamiliesKyrelle Mae Lozada100% (1)

- NVH Active Sound Design - VI-gradeДокумент2 страницыNVH Active Sound Design - VI-gradeMithun RajuОценок пока нет

- 9-16-20 Assessments in Special Education Power PTДокумент32 страницы9-16-20 Assessments in Special Education Power PTHiba BarakatОценок пока нет

- AEF2 Files1-6 ProgTestBДокумент5 страницAEF2 Files1-6 ProgTestBMeryОценок пока нет

- Nursing Leadership Practice QuestionsДокумент15 страницNursing Leadership Practice QuestionsNneka Adaeze Anyanwu0% (2)

- ACTG 381 Syllabus (Fall 2019) Elena Redko Portland State University Intermediate Financial Accounting and Reporting IДокумент11 страницACTG 381 Syllabus (Fall 2019) Elena Redko Portland State University Intermediate Financial Accounting and Reporting IHardly0% (1)

- Required Officer Like Qualities OLQs For Passing SSB InterviewsДокумент2 страницыRequired Officer Like Qualities OLQs For Passing SSB InterviewsSaahiel SharrmaОценок пока нет

- Science 10 - Q3 - W6 - D2Документ2 страницыScience 10 - Q3 - W6 - D2zenaida a academiaОценок пока нет

- 10 - PMDC Postgraduate Medical and Dental Education Standards and Regulation 2018Документ109 страниц10 - PMDC Postgraduate Medical and Dental Education Standards and Regulation 2018Shazin Javed0% (1)

- CRM Final Ppt-6Документ21 страницаCRM Final Ppt-6Niti Modi ShahОценок пока нет

- Assignment Number 1Документ5 страницAssignment Number 1Ren HarryОценок пока нет

- Introduction to Contract Management Framework WorkshopДокумент23 страницыIntroduction to Contract Management Framework WorkshopAdnan Ahmed100% (1)

- Finalcip 2Документ14 страницFinalcip 2Marilyn Claudine BambillaОценок пока нет

- Tutorials in Paediatric Differential Diagnosis 2ndДокумент2 страницыTutorials in Paediatric Differential Diagnosis 2ndYouzuf Iqbal100% (1)

- Primary Sources of Data and Secondary SoДокумент5 страницPrimary Sources of Data and Secondary Soashikur rahmanОценок пока нет

- RetinaFace: Single-stage Dense Face Localisation with Landmarks and Mesh DecodingДокумент19 страницRetinaFace: Single-stage Dense Face Localisation with Landmarks and Mesh DecodingKaran Singh RawatОценок пока нет

- Implementing Rules & Regulations of Republic Act No. 8972Документ15 страницImplementing Rules & Regulations of Republic Act No. 8972Katherine EvangelistaОценок пока нет

- Interpersonal Communication in Older Adulthood - Interdisciplinary Theory and Research 1994, SAGEДокумент281 страницаInterpersonal Communication in Older Adulthood - Interdisciplinary Theory and Research 1994, SAGERubén JacobОценок пока нет

- Sussessful Neurpsychological Rehabilitation in A Patient With Cerebellar Cognitive Affective SyndromeДокумент10 страницSussessful Neurpsychological Rehabilitation in A Patient With Cerebellar Cognitive Affective SyndromeCris RaОценок пока нет

- A51810195 Fahmitha Shawkath PДокумент1 страницаA51810195 Fahmitha Shawkath PsandeepОценок пока нет

- Sir Mokshagundam VisweswaraiahДокумент15 страницSir Mokshagundam VisweswaraiahVizag Roads100% (5)

- Case Study ProjectДокумент25 страницCase Study Projectapi-635543373Оценок пока нет

- Singing Game Music Lesson PlanДокумент5 страницSinging Game Music Lesson Planapi-491297297Оценок пока нет

- Psihologia Sociala ArticolДокумент71 страницаPsihologia Sociala ArticolLiana Maria DrileaОценок пока нет

- QB BCДокумент4 страницыQB BCMadhuri AggarwalОценок пока нет

- ANO HandbookДокумент113 страницANO HandbookPkrv Ver86% (7)

- Motivation LetterSocialДокумент2 страницыMotivation LetterSocialIrfan Rahadian SudiyanaОценок пока нет

- Melcs 4th Quarter TleДокумент1 страницаMelcs 4th Quarter TleJonRey GaricaОценок пока нет

- B SC Radiology Imaging Technology Upto 5th Sem Batch 2021Документ90 страницB SC Radiology Imaging Technology Upto 5th Sem Batch 2021radeem341Оценок пока нет