Академический Документы

Профессиональный Документы

Культура Документы

Cold Bending Fdat

Загружено:

Anonymous AdofXEYAgEАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cold Bending Fdat

Загружено:

Anonymous AdofXEYAgEАвторское право:

Доступные форматы

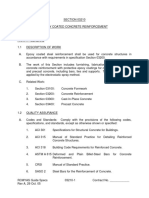

Wall Calculate

Dia, dia D, Radius Cold Bend Tangent thinning = d Maximum angle per

Size, Nom, Design pr SMYS, n= (R-

Sl No. Name of Pipeline System Actual D, (mm) thk, (mm) Material Multiplier Radius, length, 50/(n+1) maximum 1m of curved pipe

(inch) DP, (psig) (psi) (D/2))/D

(inch) (Note-3) (Note-5) (mm) (mm) (%) (Note- angle (deg) (Note-2)

4) from

(a) (b) (c) (d) (e) (f) (g) (h) (i) (j) (k) (l) (m) (n) (o) (r) (s)

1 18in Multiphase Liquid 18 18 457 26,97 3500 CS 65300 40 18288,00 1500,00 39,50 1,23 28,20 3,13

2 8in Gas Lift Gas 8 8,625 219,1 14,27 3500 CS 65300 40 8763,00 1500,00 39,50 1,23 58,85 6,54

3 6in Gas Injection Gas 6 6,625 168,3 18,26 6500 CS 65300 40 6731,00 1500,00 39,50 1,23 76,61 8,51

The calculated maximum angle is the angle that can be made from 12m of pipe (minus 2 times the minimum tangent length at each end of the bend). Without exceeding these limits,

Note-1

construction may use multiple smaller angle bends to form bigger angles.

The table also lists the angle per metre length of the pipe for the bend section (other than for the tangent length). Hence to calculate the angle for any given length,

Note-2

multiply the angle per metre with the length of the bend section. This does not consider any limitation on the cold bending machine.

Note-3 D is taken as the actual outside diameter.

Note-4 Wall thinning (%) is calculated as per PD 8010 part-1.

Note-5 The minimum permitted cold bend radius is 40D.

Note-6 Ovalisation due to cold bending shall not exceed 2.5% of nominal diameter.

Вам также может понравиться

- 6.4L - Power Stroke EngineДокумент16 страниц6.4L - Power Stroke EngineRuben Michel100% (2)

- As 4587-1999 Water Mist Fire Protection Systems - System Design Installation and CommissioningДокумент10 страницAs 4587-1999 Water Mist Fire Protection Systems - System Design Installation and CommissioningSAI Global - APAC100% (1)

- Romeo and Juliet RubricДокумент2 страницыRomeo and Juliet Rubricapi-237888592Оценок пока нет

- Technical, Operational, Practical, and Safety Considerations of Hydrostatic Pressure Testing Existing PipelinesДокумент63 страницыTechnical, Operational, Practical, and Safety Considerations of Hydrostatic Pressure Testing Existing PipelinesPasquale CutriОценок пока нет

- 1 - PL - FEED Lvl2Документ89 страниц1 - PL - FEED Lvl2Gladys WilliamОценок пока нет

- Engineering Deliverables List - 10 Sept 2020Документ190 страницEngineering Deliverables List - 10 Sept 2020bagus handoko100% (1)

- API 5L-2007 Specification For Line PipeДокумент153 страницыAPI 5L-2007 Specification For Line Pipetom787485100% (1)

- BGEP-JPKE-P133-PAXX-PL-08-142-0015-D (1) March 11Документ48 страницBGEP-JPKE-P133-PAXX-PL-08-142-0015-D (1) March 11Gururaj P KundapurОценок пока нет

- ASME B16.49 Factory Made Wrought Steel Butt Welding Induction Bends For Transportation and Distribution Systems PDFДокумент19 страницASME B16.49 Factory Made Wrought Steel Butt Welding Induction Bends For Transportation and Distribution Systems PDFMuhammadОценок пока нет

- Marine Outfall News LetterДокумент8 страницMarine Outfall News Lettermidhun1986Оценок пока нет

- Data Sheet - Pipeline Barred Tee: Category Sl. Attribute ValueДокумент2 страницыData Sheet - Pipeline Barred Tee: Category Sl. Attribute ValueYusri Fakhrizal100% (1)

- Determining Class LocationДокумент57 страницDetermining Class LocationJorgeSCZОценок пока нет

- SPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureДокумент1 страницаSPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureAris KancilОценок пока нет

- Pipelines InstallationДокумент24 страницыPipelines InstallationNoor Azreen100% (1)

- C5000 16 G28 B V04 B02 PDFДокумент321 страницаC5000 16 G28 B V04 B02 PDFAhmed OmarОценок пока нет

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОт EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОценок пока нет

- Marine Loading ArmДокумент2 страницыMarine Loading ArmAfolabi OlaniyiОценок пока нет

- Woc Hse Manual Standards: Woc LP EP DepartmentДокумент12 страницWoc Hse Manual Standards: Woc LP EP DepartmentAkram AlhaddadОценок пока нет

- SOFEC CALM BUOY FINAL 3page RedДокумент3 страницыSOFEC CALM BUOY FINAL 3page RedJ. Jorge TorresОценок пока нет

- Slide 1: Pipeline Ancillary EquipmentДокумент46 страницSlide 1: Pipeline Ancillary EquipmentadesloopОценок пока нет

- Tavistock PrimerДокумент13 страницTavistock PrimerSharon Schaff100% (1)

- Pipe Crossing Ref - 00Документ3 страницыPipe Crossing Ref - 00AndiОценок пока нет

- TGE Brochure 2010Документ12 страницTGE Brochure 2010ankeshkatochОценок пока нет

- T&A Flange Insulation Kits PDFДокумент4 страницыT&A Flange Insulation Kits PDFJuan CarlosОценок пока нет

- Jun 94Документ16 страницJun 94Ashok KumarОценок пока нет

- R435319004PB PDFДокумент9 страницR435319004PB PDFMuhammed SulfeekОценок пока нет

- CN Scrubber Dn3500 Rev04Документ58 страницCN Scrubber Dn3500 Rev04becemОценок пока нет

- TECHNICALVOLUMEIIAOFIIДокумент216 страницTECHNICALVOLUMEIIAOFIIRanjan KumarОценок пока нет

- Pipeline Pigs What Is A Pipeline Pig?Документ11 страницPipeline Pigs What Is A Pipeline Pig?Vicente GLОценок пока нет

- CFD Analysis of Sloshing Within TankДокумент6 страницCFD Analysis of Sloshing Within TankDipankar NathОценок пока нет

- Documents Accessories Cosasco Two Inch System PDFДокумент4 страницыDocuments Accessories Cosasco Two Inch System PDFAlex CarreraОценок пока нет

- Sep2017 - Zip - 24785717 - TD - MEC 23R8 01 51 D2 T02 SU 6501 Vol II of II PDFДокумент114 страницSep2017 - Zip - 24785717 - TD - MEC 23R8 01 51 D2 T02 SU 6501 Vol II of II PDFsuri345Оценок пока нет

- Anchor FlangeДокумент1 страницаAnchor FlangeHector MejiaОценок пока нет

- Equipment Delivery Erection Schedule-PCB Project 1Документ1 страницаEquipment Delivery Erection Schedule-PCB Project 1K.praveenОценок пока нет

- Egp ReportДокумент109 страницEgp ReportvyshnapramodОценок пока нет

- Lamination Recipe-700mmДокумент1 страницаLamination Recipe-700mmSai PrasathОценок пока нет

- E1 Technical Data Sheet - ShortДокумент2 страницыE1 Technical Data Sheet - ShortOmaiyio M. SaginiОценок пока нет

- SAES-L-470 PDF Download - Trenchless Pipelines Construction - PDFYARДокумент7 страницSAES-L-470 PDF Download - Trenchless Pipelines Construction - PDFYARZahidRafiqueОценок пока нет

- Double Block and Bleed With Ultra-Low Emission Options: Catalog 4190-FPДокумент17 страницDouble Block and Bleed With Ultra-Low Emission Options: Catalog 4190-FPAnandОценок пока нет

- IGEM - TD - 3 - Edition 5 - Introduction & ScopeДокумент16 страницIGEM - TD - 3 - Edition 5 - Introduction & ScopeMohamed alatrashОценок пока нет

- 6 Experience With New DNV Pipeline CodesДокумент33 страницы6 Experience With New DNV Pipeline CodesRakesh SundaramurthyОценок пока нет

- PPSC - Product Data Sheet 3lppДокумент1 страницаPPSC - Product Data Sheet 3lppjulianpirahОценок пока нет

- Hand Lever Cage ClampДокумент2 страницыHand Lever Cage ClampSMSUMINISTROS SRL.Оценок пока нет

- CVMCДокумент4 страницыCVMCAzhar HussainОценок пока нет

- Sa 672Документ7 страницSa 672lalitaliОценок пока нет

- FS 2004 A - Rev-7Документ78 страницFS 2004 A - Rev-7Maffone NumerounoОценок пока нет

- U BoltsДокумент14 страницU BoltsLuz DuarteОценок пока нет

- Cathodic Protection ProjectДокумент6 страницCathodic Protection Projectjamal AlawsuОценок пока нет

- Section 03210 Epoxy Coated Concrete ReinforcementДокумент7 страницSection 03210 Epoxy Coated Concrete ReinforcementgulzamanОценок пока нет

- 2632 PL DS 001 Line PipeДокумент3 страницы2632 PL DS 001 Line PipeAdvisОценок пока нет

- Technical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoДокумент27 страницTechnical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoIdung ChristopherОценок пока нет

- Ipc1998-2028 - Repairing Pipe Defects Without Operational Outages With PetrosleeveДокумент9 страницIpc1998-2028 - Repairing Pipe Defects Without Operational Outages With PetrosleeveDietmar WengerОценок пока нет

- Pigging TheoryДокумент10 страницPigging TheoryTarunОценок пока нет

- Hot Tapping Procedure Into Existing PLEMДокумент1 страницаHot Tapping Procedure Into Existing PLEMBalanОценок пока нет

- CV-Amit SinhaДокумент6 страницCV-Amit Sinharanjan sahooОценок пока нет

- Camisea Opt 2005 25-02-05Документ4 страницыCamisea Opt 2005 25-02-05davidmars100% (1)

- Wavistrong Product CatalogueДокумент114 страницWavistrong Product CatalogueBINODH DОценок пока нет

- 19 Common Seatwater Supply ProjectДокумент3 страницы19 Common Seatwater Supply ProjectJoseph NОценок пока нет

- 18 Inch 9 5 MM Combo (MFL+CLP+IMU) (Ver Data Sheet Pàg. 8) PDFДокумент19 страниц18 Inch 9 5 MM Combo (MFL+CLP+IMU) (Ver Data Sheet Pàg. 8) PDFOscar Miguel Fuquen SanabriaОценок пока нет

- Updated Boiler Punch List-Updated On 15.05.15Документ4 страницыUpdated Boiler Punch List-Updated On 15.05.15Manikandan elumalaiОценок пока нет

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988От EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockОценок пока нет

- Output Summary: SI UnitsДокумент14 страницOutput Summary: SI UnitsEduardoОценок пока нет

- Kurma Rao Saini - CVДокумент1 страницаKurma Rao Saini - CVAnonymous AdofXEYAgEОценок пока нет

- Kurma Rao Saini - Qualification Certificate044Документ10 страницKurma Rao Saini - Qualification Certificate044Anonymous AdofXEYAgEОценок пока нет

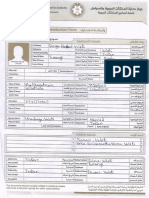

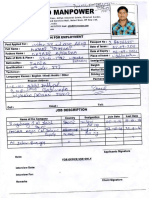

- Kurma Rao Saini - Introduction Form040Документ2 страницыKurma Rao Saini - Introduction Form040Anonymous AdofXEYAgEОценок пока нет

- Kurma Rao Saini - CVДокумент1 страницаKurma Rao Saini - CVAnonymous AdofXEYAgEОценок пока нет

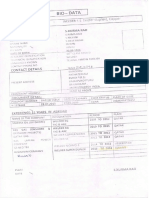

- JD FormДокумент1 страницаJD FormAnonymous AdofXEYAgEОценок пока нет

- Vantakula Rambabu-Experience CertificatesДокумент10 страницVantakula Rambabu-Experience CertificatesAnonymous AdofXEYAgEОценок пока нет

- JD FormДокумент1 страницаJD FormAnonymous AdofXEYAgEОценок пока нет

- Behra Dombo l9997839 CVДокумент28 страницBehra Dombo l9997839 CVAnonymous AdofXEYAgEОценок пока нет

- Pradhan Bhagirathi CVДокумент1 страницаPradhan Bhagirathi CVAnonymous AdofXEYAgEОценок пока нет

- Intro FormДокумент2 страницыIntro FormAnonymous AdofXEYAgEОценок пока нет

- Mohammad Mukhtar Ali-CvДокумент15 страницMohammad Mukhtar Ali-CvAnonymous AdofXEYAgEОценок пока нет

- JD FormДокумент1 страницаJD FormAnonymous AdofXEYAgEОценок пока нет

- Vantakula Rambabu-Resume PDFДокумент1 страницаVantakula Rambabu-Resume PDFAnonymous AdofXEYAgEОценок пока нет

- Pandi Devaraju Reddy p6303778 CVДокумент36 страницPandi Devaraju Reddy p6303778 CVAnonymous AdofXEYAgEОценок пока нет

- Receipt Report IE-2485530Документ1 страницаReceipt Report IE-2485530Anonymous AdofXEYAgEОценок пока нет

- Kommuji Eswar A Rao - Intro FormДокумент2 страницыKommuji Eswar A Rao - Intro FormAnonymous AdofXEYAgEОценок пока нет

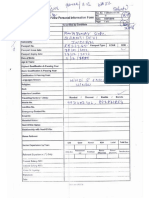

- 7.interview PersonalДокумент1 страница7.interview PersonalAnonymous AdofXEYAgEОценок пока нет

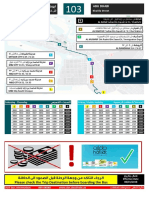

- Bus Service 103Документ2 страницыBus Service 103Anonymous AdofXEYAgEОценок пока нет

- Pyarechand Kumar - Qualification Certificate064Документ1 страницаPyarechand Kumar - Qualification Certificate064Anonymous AdofXEYAgEОценок пока нет

- 1144 TWI Diploma in Welding Engineering July 2012 PDFДокумент1 страница1144 TWI Diploma in Welding Engineering July 2012 PDFdaimaheshОценок пока нет

- Pradhan Bhagirathi - JD Manpower FormДокумент1 страницаPradhan Bhagirathi - JD Manpower FormAnonymous AdofXEYAgEОценок пока нет

- Rabindra Nayak - Qualification Certificate025Документ6 страницRabindra Nayak - Qualification Certificate025Anonymous AdofXEYAgEОценок пока нет

- Department of Clinical Biochemistry Liver Function TestДокумент1 страницаDepartment of Clinical Biochemistry Liver Function TestAnonymous AdofXEYAgEОценок пока нет

- Curriculum Vitae HariprasadДокумент2 страницыCurriculum Vitae HariprasadAnonymous AdofXEYAgEОценок пока нет

- String Weave and Heat InputДокумент4 страницыString Weave and Heat InputAnonymous AdofXEYAgEОценок пока нет

- Agent Application FormДокумент1 страницаAgent Application FormAnonymous AdofXEYAgEОценок пока нет

- Agent Application FormДокумент1 страницаAgent Application FormAnonymous AdofXEYAgEОценок пока нет

- Transcript of Marks: Name: Date of BirthДокумент2 страницыTranscript of Marks: Name: Date of BirthAnonymous AdofXEYAgEОценок пока нет

- Transcript of Mark List: Harish RДокумент2 страницыTranscript of Mark List: Harish RAnonymous AdofXEYAgEОценок пока нет

- BPVC-IX-Interp Stnd-63 2015 Jan PDFДокумент6 страницBPVC-IX-Interp Stnd-63 2015 Jan PDFAnonymous AdofXEYAgEОценок пока нет

- Antennas and Wave Propagation - Nov - 2015Документ8 страницAntennas and Wave Propagation - Nov - 2015Jyothi SamanthulaОценок пока нет

- J.P. INSTRUMENTS EDM-730 ENGINE MONITORING SYSTEM - Aircraft Spruce (2017)Документ3 страницыJ.P. INSTRUMENTS EDM-730 ENGINE MONITORING SYSTEM - Aircraft Spruce (2017)ПетрОценок пока нет

- Balanced Cable Measurement Using The 4-Port ENAДокумент9 страницBalanced Cable Measurement Using The 4-Port ENAA. VillaОценок пока нет

- Manual Diagrama Detector de MetalesДокумент18 страницManual Diagrama Detector de MetalesEdmundo Cisneros0% (1)

- ch1 ProbsДокумент8 страницch1 ProbsEkrem GüldesteОценок пока нет

- 4 Chacon Et Al 2004Документ7 страниц4 Chacon Et Al 2004Luis Serrano CortezОценок пока нет

- Important Questions - BlockchainДокумент1 страницаImportant Questions - BlockchainHarsh Varshney100% (1)

- UntitledДокумент44 страницыUntitledFrancesco TauroОценок пока нет

- Microprocessor Lab ManualДокумент36 страницMicroprocessor Lab ManualsivagamasundhariОценок пока нет

- Journal Publishing ProcessДокумент1 страницаJournal Publishing Processmohamedr55104Оценок пока нет

- Ballsim DirectДокумент58 страницBallsim DirectDiego GaliciaОценок пока нет

- Product Management PRELIM EXAMДокумент24 страницыProduct Management PRELIM EXAMAlyssa marieОценок пока нет

- Ass AsДокумент2 страницыAss AsMukesh BishtОценок пока нет

- UT Dallas Syllabus For Math3303.501.10f Taught by Phillip Kisunzu (pxk091000)Документ7 страницUT Dallas Syllabus For Math3303.501.10f Taught by Phillip Kisunzu (pxk091000)UT Dallas Provost's Technology GroupОценок пока нет

- Aitkensmethod 170829115234Документ17 страницAitkensmethod 170829115234Yumi koshaОценок пока нет

- 1xEV RF Optimization Guidelines R24Документ83 страницы1xEV RF Optimization Guidelines R24lady_sОценок пока нет

- Elephant Catalog V13 PDFДокумент96 страницElephant Catalog V13 PDFsamuelОценок пока нет

- Ansoff's Matrix: Presented by:-P.Deepika Naidu Raj PatilДокумент17 страницAnsoff's Matrix: Presented by:-P.Deepika Naidu Raj PatilKritiYadavОценок пока нет

- Survey 2 Module 2Документ76 страницSurvey 2 Module 2veereshОценок пока нет

- SCCA2103 Leadership CommunicationДокумент6 страницSCCA2103 Leadership CommunicationsarahОценок пока нет

- Acceptance To An Offer Is What A Lighted Matchstick Is To A Train of GunpowderДокумент2 страницыAcceptance To An Offer Is What A Lighted Matchstick Is To A Train of GunpowderAnushka SharmaОценок пока нет

- ROV Inspection and Intervention VesselДокумент2 страницыROV Inspection and Intervention VesselAhmad Reza AtefОценок пока нет

- Staffing ProcessДокумент18 страницStaffing ProcessEbtesam EliasОценок пока нет

- GE 8 ETHICS Week2 9Документ54 страницыGE 8 ETHICS Week2 9Jay Ar OmbleroОценок пока нет