Академический Документы

Профессиональный Документы

Культура Документы

Calibrating particulate monitors for low emission concentrations

Загружено:

Tomy SetiyadiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Calibrating particulate monitors for low emission concentrations

Загружено:

Tomy SetiyadiАвторское право:

Доступные форматы

RM-QG6 Calibrating particulate-monitoring continuous emission

monitoring systems (CEMs), especially for low concentrations of particulate

matter

Quick guide RM-QG6 Issued September 2009 Review due by September 2010

Title (max 3 lines) * DRAFT TEMPLATE - DO NOT USE! *

1. Scope

This note describes the procedures for calibrating particulate monitors according to the

requirements of BS ISO 10155, and BS EN 14181 (as supplemented by BS EN 13284-2),

especially for low concentrations of particulate matter.

2. Practical Guidance

2.1 Background

ISO 10155 and BS EN 14181 (supplemented by BS EN 13284-2) specify that a test

laboratory shall calibrate continuous emission monitoring systems (CEMs) for particulate

matter (PM) using parallel measurements with a specified number of repetitions of a

standard reference method (SRM), as given in Table 1. These two standards are based

on the premise that CEMs have a linear response to increasing concentrations of uniform

particulate, when using reference materials or methods. In order to derive a reliable

calibration function, these standards require the following:

A good spread of data, or medium to high-level clusters (including some values at or

near zero for all cases) in situations where EN 14181 applies.

An acceptable level of accuracy and precision for the SRM or reference materials.

A regression line which passes through zero, or near to zero.

If the correlation co-efficient (R2) of the regression line for the CEM and SRM data is 0.9 or

more, then the calibration function will most likely be valid. However, there are two

common conditions where it is not possible to apply the above requirements:

Low-level clusters of data this is very common for emissions of PM, especially when

the industrial process is equipped with bag filters.

When the R2 value is under 0.9.

Whenever there are low-level clusters of data, the uncertainty of the SRM will be

proportionally greater with respect to the measured emissions. In such cases, there will be

a greater degree of relative scatter of data points, which is reflected by a low R2 value. In

such cases, the test laboratory cannot produce a reliable calibration function using SRM

data.

This Quick Guide provides guidance on calibrating PM CEMs where there is a spread of

data, medium to high-level clusters, or low-level clusters.

Doc No: RM-QG-6 Version: 1a Last printed: Page: 1 of 7

2.2 Cases where there is a spread of data

There is a spread of data when the measurements can range from zero up to the ELV,

and where the difference of the highest and lowest readings is more than 15% of the ELV.

In such cases, calibrate particulate monitors as follows:

Apply EN 14181 and EN 13284-2 for sites falling under the incineration and large-

combustion plant Directives.

Apply ISO 10155 for other types of installation

Ensure that there are values near or at zero.

Take the number of repetitions of the SRM, as specified in Table 1.

2.3 Cases where there is a medium to high-level cluster of data

There is a medium to high-level cluster of data when the measurements are above 30% of

the ELV, and when the difference of the highest and the lowest readings is not more than

15% of the ELV. In such cases, calibrate particulate monitors as follows:

Apply EN 14181 and EN 13284-2 for sites falling under the incineration and large-

combustion plant Directives.

Apply ISO 10155 for other types of installation, following the provisions in 2.9 of

this document.

Ensure that there are values near or at zero.

Take the number of repetitions of the SRM as specified in the standards in Table 1.

2.4 Cases where there are low-level clusters of particulate emissions

These are very common. If the emissions during a calibration exercise are low, i.e. less

than 30% of the daily average ELV, then it is likely that the R2 value will be below 0.9. The

R2 value is likely to fall when the cluster of emissions is closer to zero. In such cases, the

test laboratory should use surrogates to calibrate the CEM if this is practicable. Although

surrogates can be used to calibrate CEMs for gases if the SRM data is insufficient for

calibration, this may not be the case with particulate monitors. Therefore if the SRM data

is not sufficient enough to calibrate particulate monitoring CEMs and the surrogates are

not valid, then a different approach is needed (see section 2.7).

2.5 Using surrogates

Surrogates typically have three roles when applied to particulate monitors:

Testing the response time.

Testing the linearity

Determining stability through zero and span tests.

There may be occasions when surrogates can be used to calibrate particulate monitors,

but such cases are rare.

Doc No: RM-QG-6 Version: 1 Last printed: Page: 2 of 7

2.6 Procedure for calibrating particulate CEMs when either SRM data or

surrogates are valid

If the R2 value of the regression line for the SRM and CEM data is more than 0.9, then

the test laboratory shall determine a calibration function and apply this to CEM.

If the R2 value is less than 0.9, then the test laboratory shall use surrogates to calibrate

the CEM if this is possible.

If the CEM is sufficiently precise and the test laboratory minimises the uncertainty of the

SRM as far as practicable, then the R2 value will be higher.

The test laboratory may find that it is not possible to determine a meaningful calibration

function; for example, when most or all of the reported PM values are at or near zero. If

so, then the test laboratory shall do the following instead of the variability test specified in

EN 14181:

Determine an average and standard deviation for the CEM data and SRM data.

Compare the averages of the CEM data and SRM by using the 95% confidence

interval specified in applicable Directives.

The results are acceptable if both averages lie within the 95% confidence interval.

If the applicable legislation does not specify a 95% confidence interval, then apply a

value of 30% of the daily-average or similar applicable average ELV.

2.7 Setting up CEMs if surrogates cannot be used to calibrate the CEM

There will be situations when calibration is impossible, due to:

Low clusters of emissions, meaning that the data does not meet the requirements of

BS EN 13284-2 or ISO 10155.

Surrogates may be useful for zero, span and linearity tests, but the resultant data

cannot be meaningfully related to concentrations of particulate.

In such cases, the particulate monitor cannot be used as a quantitative monitor for

particulate, but can serve as a qualitative indicator. Therefore if the emissions are

consistently low, we recommend that:

The SRM is used to verify that the emissions are low.

Surrogates are used to check the linearity, and zero and span settings of the monitor.

The monitor is set on its most sensitive range, in order to alert the operator that the

control devices for particulate may need attention if an increase in emissions is

observed.

2.8 Requirements of BS EN 14181

BS EN 14181 has two requirements which require the use of surrogates and related

procedures:

Linearity tests. The test laboratory can also use the results of this test as an alternative

means of calibration if there is insufficient SRM data.

Zero and span tests.

Doc No: RM-QG-6 Version: 1 Last printed: Page: 3 of 7

If the design of the CEM does not provide for conventional zero and span tests, then the

operator may use an alternative procedure that reflects the response of the CEM, if it were

measuring the target determinand.

If the design of the CEM does not provide for linearity and drift checks at all, once the

CEM is operating on an industrial process, then the operator will not be able comply with

BS EN 14181.

2.9 Applying ISO 10155 medium to high-level clusters

ISO 10155 describes a procedure for calibrating PM CEMs using repetitions of the SRM.

This standard is based on the premise that the emissions will vary, or can be varied. Then

the test laboratory repeats the SRM three times at three different concentrations, therefore

producing nine SRM measurements.

ISO 10155 therefore provides for cases where there is a spread of data, but not for

clusters. In order to determine calibration factors for PM CEMs at installations where the

emissions are not low (i.e. above 30% of the ELV), but occur as medium to high-level

clusters, use the following procedure.

Ensure that the CEMs read zero when the emissions are zero.

Take at least five SRM measurements when the process is operating normally.

Take an average of the SRM measurements and the CEM measurements, and

then use these averages to determine a calibration factor.

There is no need to perform the statistical tests specified in ISO 10155, as these tests

apply to cases where linear regression can be applied, i.e. when there is a spread of data.

2.10 Functional tests

All the applicable standards for PM CEMs include functional tests. These are mandatory

for installations which require operators to apply EN 14181 and EN 13284-2. We strongly

recommend that operators ensure that functional tests are performed on PM CEMs in

cases where ISO 10155 applies.

2.11 Regulation when particulate monitors cannot be calibrated

If a test report states that a particulate monitor cannot be calibrated due to very low

emissions, then the output of the CEM will be qualitative. Whilst it may be possible to

intuitively set the reading of the CEM to provide an output in mg.m-3, such readings will be

an approximation at best, with a strong likelihood of high levels of uncertainty. Unless it is

possible to produce higher, representative emissions from the process, such readings

should be disregarded for regulatory purposes when compared to an ELV, even if there is

an apparent breach of the ELV.

However, the output from the particulate monitor can demonstrate whether the process is

under control or not. Therefore such outputs should be regarded as an indicative trend,

which can then demonstrate if there is a significant change in the process resulting in an

increase in emissions that requires attention as soon as possible. Hence an operator must

have operational procedures in place to respond appropriately to such changes indicated

by the particulate monitors.

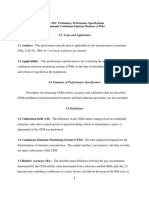

Figure 1 demonstrates how such a procedure could work, applying the following steps.

Doc No: RM-QG-6 Version: 1 Last printed: Page: 4 of 7

A set of three to five repetitions of a SRM must show that the emissions are

controlled and well below the ELV.

The SRMs also show that the CEM responds albeit with a high uncertainty to

low levels of particulate, and therefore provides an indication of low emissions, if not

accurate and precise measurements.

The operator notes the representative output that the CEM produces when the

emissions are low and well controlled. It is recommended that the output is in units

other than mg.m-3.

The operator plots the emissions on a chart, and includes upper and lower margins

of tolerance to allow for random, but acceptable variations in the outputs of the

CEM. These upper and low margins of allowable variations are agreed with the

Environment Agency.

If the output from the CEM changes and rises above the upper margin of error, then

the operator takes immediate action to investigate the causes of the change in the

output of the CEM, and then takes appropriate action to ensure that the readings

return to within the margins of tolerance as quickly as practicable.

When reporting emissions for annual emissions inventories, the operator may apply

two approaches:

Using an average based on the results of periodic monitoring, or:

Reporting a result which states that the emissions are not more than a result

based on the allowable uncertainty of the daily average ELV or similar medium-

term average ELV - expressed as a 95% confidence interval.

Figure 1 Using control charts for indicative monitoring.

100%

Agreed margins of

( e.g. 0 to 100%)

tolerance Abnormal operations

CEM readings

(Systematic variation)

Normal operations

(Random variations)

0%

2.12 Summary of procedures

Table 1 shows the conditions for CEMs providers and test laboratories to choose the most

applicable procedure.

Doc No: RM-QG-6 Version: 1 Last printed: Page: 5 of 7

3. Further Information

3.1 Quick Guides

RM-QG-01 Selecting continuous emission monitoring systems (CEMs)

RM-QG-03 Application of EN 14181

3.2 Technical Guidance Notes and MIDs

TGN M2 Monitoring of stack emissions to air

TGN M20 Quality assurance of continuous emissions monitoring systems

MID EN 13284-1

4. Feedback

Any comments or suggested improvements to this note should be e-mailed to Richard Gould at

richard.gould@environment-agency.gov.uk or internally to Gould, Rick.

Doc No: RM-QG-6 Version: 1 Last printed: Page: 6 of 7

Table 1 Procedures for calibrating particulate-monitoring CEMs

Process Spread of data (Spread > 15% of ELV) Medium to high-level cluster (Emissions Low-level cluster (Emissions not more than 30% of daily average

higher than 30% of daily average ELV) ELV; linear regression produces R2<0.9))

WID/LCPD Apply EN 14181 Apply EN 14181 Apply most of EN 14181

(QAL2)

Functional tests Functional tests Functional tests

Verify CEMs read zero at zero Verify CEMs read zero at zero Verify CEMs read zero at zero emissions

emissions emissions

5+ SRM repetitions over one

15+ SRM repetitions over 3+ days 15+ SRM repetitions over 3+ days

Perform variability test to determine acceptability

Calibration function plus statistical Calibration function plus statistical

Do not apply a calibration function from SRM data.

tests tests

Calibrate with surrogates if possible; if not, then set the

CEMs gain-factor to respond to process changes.

WID/LCPD Apply EN 14181 Apply EN 14181 Apply most of EN 14181

(AST)

Functional tests Functional tests Functional tests

Verify CEMs read zero at zero Verify CEMs read zero at zero Verify CEMs read zero at zero emissions

emissions emissions

3 to 5+ SRM repetitions over one

5+ SRM repetitions over 1+ days 3 to 5+ SRM repetitions over 1+

Perform variability test to determine acceptability

days

Calibration function plus statistical

Do not apply a calibration function from SRM data.

tests Calibration function plus statistical

tests Calibrate with surrogates if possible; if not, then set the

CEMs gain-factor to respond to process changes.

Other Apply ISO 10155 Functional tests as specified in Functional tests as specified in ISO 10155

PPC/EPR ISO 10155

Functional tests Verify CEMs read zero at zero emissions

permits

Verify CEMs read zero at zero

Verify CEMs read zero at zero 3 SRM repetitions over 1 day

emissions

emissions

Calibrate with surrogates if possible; if not, then set the

5 SRM repetitions over 1 day

9+ SRM repetitions over 2+ days CEMs gain-factor to respond to process changes.

Average of SRM and CEM data to

Calibration function plus statistical

derive a calibration factor

tests

Doc No: RM-QG-6 Version: 1a Last printed: Page: 7 of 7

Вам также может понравиться

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisОт EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisРейтинг: 4 из 5 звезд4/5 (2)

- Two-Variable Regression Interval Estimation and Hypothesis TestingДокумент36 страницTwo-Variable Regression Interval Estimation and Hypothesis TestingOliver Tate-DuncanОценок пока нет

- Calibration of BalancesДокумент7 страницCalibration of BalancesebbasinghОценок пока нет

- BS 7882 - 2008 PaperДокумент25 страницBS 7882 - 2008 PaperMohamed Naser0% (1)

- Astm D1633-17 PDFДокумент4 страницыAstm D1633-17 PDFRaúl Meza100% (1)

- Matheson Gas Data Book 7th Edition PUBL 52Документ1 страницаMatheson Gas Data Book 7th Edition PUBL 52Tomy Setiyadi100% (3)

- Guidelines For Establishing Ethanol Plant Quality Assurance and Quality ControlДокумент25 страницGuidelines For Establishing Ethanol Plant Quality Assurance and Quality ControlKUKUОценок пока нет

- Lower (LEL) & Upper (UEL) Explosive Limits PDFДокумент1 страницаLower (LEL) & Upper (UEL) Explosive Limits PDFSale RadosavljevicОценок пока нет

- Practice Test 3 Bus2023 Spring09 SolutionsДокумент15 страницPractice Test 3 Bus2023 Spring09 SolutionsDorinel StreinuОценок пока нет

- Pub - Applied Ecology and Natural Resource Management PDFДокумент181 страницаPub - Applied Ecology and Natural Resource Management PDFYuli SariОценок пока нет

- EURAMET EA-10-04 U in Force MeasurementsДокумент16 страницEURAMET EA-10-04 U in Force MeasurementsdanicanaОценок пока нет

- Guide to Measuring Gas Quantity and QualityДокумент45 страницGuide to Measuring Gas Quantity and Qualityokey obi100% (2)

- Bird Surveys-Expedition Field Techniques.Документ144 страницыBird Surveys-Expedition Field Techniques.Marcelo Flores100% (1)

- Testing Synchrophasor DataДокумент8 страницTesting Synchrophasor DatamersiumОценок пока нет

- Changes To GMP Force Cleanroom Re-ClassificationsДокумент5 страницChanges To GMP Force Cleanroom Re-ClassificationsJose EvoraОценок пока нет

- Certification of AMS Acc. en 15267, Part 3 - Overview and First ExperienceДокумент11 страницCertification of AMS Acc. en 15267, Part 3 - Overview and First Experiencesalekojic5332Оценок пока нет

- Tabel Perkalian-PembagianДокумент2 страницыTabel Perkalian-PembagianJust Bajing92% (51)

- Fluid Condition HandbookLtd PDFДокумент44 страницыFluid Condition HandbookLtd PDFmauriciojj100% (2)

- MSL Technical Guide 25 Calibrating Balances: Ing and Calibration Laboratories by International AccrediДокумент7 страницMSL Technical Guide 25 Calibrating Balances: Ing and Calibration Laboratories by International AccrediPrabath De SilvaОценок пока нет

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsОт EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsОценок пока нет

- Principles of CalibrationДокумент10 страницPrinciples of CalibrationClark Joshua Fernandez100% (1)

- Understanding ISO 21501-4 Particle Counter CalibrationДокумент4 страницыUnderstanding ISO 21501-4 Particle Counter CalibrationPapaindoОценок пока нет

- BS Iec 60300-3-5-2001 - (2020-08-31 - 04-34-43 PM)Документ74 страницыBS Iec 60300-3-5-2001 - (2020-08-31 - 04-34-43 PM)daniela fabiola CisternasОценок пока нет

- Flare Gas Measurement Using Ultrasonic Transit-Time Flow MetersДокумент13 страницFlare Gas Measurement Using Ultrasonic Transit-Time Flow MetersAlvaro Andres Blanco Gomez100% (1)

- The Slovin FormulaДокумент3 страницыThe Slovin FormulaOdie Valdez80% (10)

- Thesis GuidelinesДокумент18 страницThesis GuidelinesAsad HamidОценок пока нет

- Total Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceДокумент5 страницTotal Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceJesus Gonzalez GracidaОценок пока нет

- Robustness of The QAL2 Calibration (EN14181) - Uncertainty On The Results Given by A Calibrated AMSДокумент9 страницRobustness of The QAL2 Calibration (EN14181) - Uncertainty On The Results Given by A Calibrated AMSmpicaОценок пока нет

- Robustness of QAL2 calibration for continuous emissions monitoringДокумент10 страницRobustness of QAL2 calibration for continuous emissions monitoringAnaibar TarikОценок пока нет

- Standard Deviation and Range Chart SOPДокумент5 страницStandard Deviation and Range Chart SOPJorge Luis Arevalo LopezОценок пока нет

- ISO6892Документ5 страницISO6892jeridОценок пока нет

- Calibrating Laboratory Balances ProcedureДокумент4 страницыCalibrating Laboratory Balances ProcedureDragan LazicОценок пока нет

- Residual Threshold PhilosophyДокумент9 страницResidual Threshold PhilosophyTim HoltanОценок пока нет

- Understanding ISO 6789 - Calibration Laboratories - BlogДокумент3 страницыUnderstanding ISO 6789 - Calibration Laboratories - BlogAntmavrОценок пока нет

- Sop17 15nov06Документ5 страницSop17 15nov06Ivancøvish Julian HuanccøОценок пока нет

- NIRS Quantitative Analysis GuideДокумент7 страницNIRS Quantitative Analysis GuideSherman HoОценок пока нет

- The Determination of Uncertainties in Charpy Impact TestingДокумент19 страницThe Determination of Uncertainties in Charpy Impact TestingAfriandiBayuОценок пока нет

- Astm D1945 14 2019Документ6 страницAstm D1945 14 2019Secretario SigmaОценок пока нет

- Tsb67 Data TestingДокумент21 страницаTsb67 Data TestingFrancisco M. RamosОценок пока нет

- CTM 034 PDFДокумент23 страницыCTM 034 PDFSantiago MontalvanОценок пока нет

- ANEMOMETER CALIBRATION PROCEDUREДокумент9 страницANEMOMETER CALIBRATION PROCEDUREbluesbankyОценок пока нет

- A Guide For Choosing The Right Calibration For Torque TransducersДокумент6 страницA Guide For Choosing The Right Calibration For Torque Transducers320338Оценок пока нет

- EURAMET CG 18 02 Non Automatic Weighing InstrumentsДокумент83 страницыEURAMET CG 18 02 Non Automatic Weighing InstrumentsPurwanto NugrohoОценок пока нет

- Traceability and Uncertainty Analysis For A Calibration Process For Flowmeters, Using Coriolis Flowmeters As ReferenceДокумент11 страницTraceability and Uncertainty Analysis For A Calibration Process For Flowmeters, Using Coriolis Flowmeters As ReferenceTimo SmitsОценок пока нет

- GMP 11 Mar 2003 PDFДокумент6 страницGMP 11 Mar 2003 PDFFërnando Rodrîguëz HerreräОценок пока нет

- Ammonia CEMSДокумент18 страницAmmonia CEMSElizabeth Cares LiraОценок пока нет

- Knowledge: Coriolis Flowmeters in An LPG Custody Transfer ApplicationДокумент4 страницыKnowledge: Coriolis Flowmeters in An LPG Custody Transfer ApplicationSofiane MoussaouiОценок пока нет

- Control charts for mass calibrationДокумент11 страницControl charts for mass calibrationDonig FermanianОценок пока нет

- TG-119 IMRT Commissioning TestsДокумент15 страницTG-119 IMRT Commissioning TestsdumitracheОценок пока нет

- EG 15-14-1.2 Instrument Calibration: ScopeДокумент21 страницаEG 15-14-1.2 Instrument Calibration: ScopeaminОценок пока нет

- Calibration Method - Gas FlowДокумент9 страницCalibration Method - Gas FlowMazhar MahadzirОценок пока нет

- Duval 2005Документ7 страницDuval 2005Daniel LuchoОценок пока нет

- FWE200Документ12 страницFWE200Jorge Francisco Silva TapiaОценок пока нет

- DGA - DGA Gas-In-Oil Standards A Tool - M CyrДокумент14 страницDGA - DGA Gas-In-Oil Standards A Tool - M Cyrganeshrudra100% (1)

- Method Epa 7eДокумент36 страницMethod Epa 7eErick HidalgoОценок пока нет

- MID For 16911-1 Application To Manual Stack Emissions Monitoring V1 July 2014Документ11 страницMID For 16911-1 Application To Manual Stack Emissions Monitoring V1 July 2014lobopt77Оценок пока нет

- Some Fiber Optic Measurement ProceduresДокумент6 страницSome Fiber Optic Measurement ProceduresAmir SalahОценок пока нет

- 13 Determination of Solid Fatnjn Content in Edible Oils and FatsДокумент4 страницы13 Determination of Solid Fatnjn Content in Edible Oils and FatsCeyah NurrОценок пока нет

- EURAMET cg-18 v.02.1Документ84 страницыEURAMET cg-18 v.02.1Renato LameraОценок пока нет

- SOP10 - 20141022 - ReglasДокумент9 страницSOP10 - 20141022 - ReglasDiego LincangoОценок пока нет

- De-Embedding Using A VnaДокумент6 страницDe-Embedding Using A VnaA. VillaОценок пока нет

- Understanding ISO 21501-4 12-2010 DGДокумент4 страницыUnderstanding ISO 21501-4 12-2010 DGgirodadoОценок пока нет

- ChE170 Lecture 9 (Control Tuning) PDFДокумент27 страницChE170 Lecture 9 (Control Tuning) PDFRowieОценок пока нет

- Electronic Gas Measurement Auditing: Kenneth W. Blackburn Houston Flow Measurement, IncДокумент4 страницыElectronic Gas Measurement Auditing: Kenneth W. Blackburn Houston Flow Measurement, IncAneeshОценок пока нет

- Overcurrent Relay Advances for Modern Electricity NetworksОт EverandOvercurrent Relay Advances for Modern Electricity NetworksОценок пока нет

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceОт EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceОценок пока нет

- Who Recommended Hand-Rub FormulationДокумент9 страницWho Recommended Hand-Rub FormulationSaeed Mohammed100% (2)

- XCF 170 Method 17 System Brochure 5.22.18 PDFДокумент3 страницыXCF 170 Method 17 System Brochure 5.22.18 PDFTomy SetiyadiОценок пока нет

- Mkji 1997Документ564 страницыMkji 1997Adib KurniawanОценок пока нет

- Jar Testing Apparatus SpecificationДокумент1 страницаJar Testing Apparatus SpecificationTomy SetiyadiОценок пока нет

- Brosur RegulerДокумент60 страницBrosur RegulerTomy SetiyadiОценок пока нет

- K3Документ10 страницK3Anonymous OEiGK0OZОценок пока нет

- CH 10Документ56 страницCH 10Rommel Yan100% (1)

- Sales Forecasting Best Practices and Their Impact On DRP and MRP Demand PlanningДокумент16 страницSales Forecasting Best Practices and Their Impact On DRP and MRP Demand Planninge2b teknologiesОценок пока нет

- Modeling MindsetsДокумент113 страницModeling MindsetsArchana ShОценок пока нет

- Determining Sample Size for Likert Scale SurveysДокумент6 страницDetermining Sample Size for Likert Scale Surveyscarrot123456Оценок пока нет

- Sta 2023Документ5 страницSta 2023Chrystelle CharlierОценок пока нет

- Module 4 Statistical Inference Estimation of Parameters Lesson 1 Estimation of Parameters Part 1.pДокумент5 страницModule 4 Statistical Inference Estimation of Parameters Lesson 1 Estimation of Parameters Part 1.pLee SuarezОценок пока нет

- ECSS-E-33-11A - Explosive Systems and DevicesДокумент64 страницыECSS-E-33-11A - Explosive Systems and DevicessebamonsuОценок пока нет

- PHStat2 Users GuideДокумент39 страницPHStat2 Users GuideAchal JainОценок пока нет

- Inferential Statistics: Estimation Hypothesis TestingДокумент59 страницInferential Statistics: Estimation Hypothesis TestingAgAОценок пока нет

- Mat 2377 Final Spring 2011Документ15 страницMat 2377 Final Spring 2011David LinОценок пока нет

- Introduction To Bayesian SEMДокумент127 страницIntroduction To Bayesian SEMmilicalazic123456789Оценок пока нет

- Fisher Information Notes: Confidence Intervals Using Maximum LikelihoodДокумент8 страницFisher Information Notes: Confidence Intervals Using Maximum LikelihoodPutri HamidahОценок пока нет

- Determining Pace Length LabДокумент1 страницаDetermining Pace Length Labvrb126Оценок пока нет

- ASHRAE Symposium AC-02-9-4 Cooling Tower Model-Hydeman PDFДокумент10 страницASHRAE Symposium AC-02-9-4 Cooling Tower Model-Hydeman PDFGonzalo RundОценок пока нет

- Chemical ComplianceДокумент27 страницChemical ComplianceWilson JustinoОценок пока нет

- Gravity Center and Hip AngleДокумент9 страницGravity Center and Hip AngleCristian BenalcázarОценок пока нет

- NR Reporting Summary FlatДокумент6 страницNR Reporting Summary FlatcretinusmaximusОценок пока нет

- L 32Документ7 страницL 32Gustavo Suarez CoronadoОценок пока нет

- Confident Reasoning On Raven'S Progressive Matrices Tests: Keith Mcgreggor and Ashok GoelДокумент7 страницConfident Reasoning On Raven'S Progressive Matrices Tests: Keith Mcgreggor and Ashok Goelabc123-1Оценок пока нет

- Impact of hostel satisfaction on student performanceДокумент9 страницImpact of hostel satisfaction on student performanceAzzyHazimah0% (1)

- Econ 140 Regression Analysis and Hypothesis TestingДокумент5 страницEcon 140 Regression Analysis and Hypothesis Testingchan chadoОценок пока нет