Академический Документы

Профессиональный Документы

Культура Документы

LH7Series Hdraulic Cylinder

Загружено:

parthibanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

LH7Series Hdraulic Cylinder

Загружено:

parthibanАвторское право:

Доступные форматы

2.

110/1

Vol 12-07

HYDRAULIC CYLINDERS - LH7 Series

v Rated pressure 50 kg/cm 2, Peak pressure 70 Kg/cm 2.

v Cylinder bore diameter upto 350mm.

v Standard temperature range : -20 C to 90 .C

o

(special seals for higher temperatures upto 180 C optional) INDEX

SPECIFICATION OF MATERIALS

END COVERS : Precision machined steel

CYLINDER :Cold drawn seamless

BARREL steel, honed and

polished internally to a ES PS

maximum surface BORE PR RT OL PL TL PP TR NP EP TC

(Sq) (BSP)

roughness of Ra=0.4

microns. 25 12 40 M10X1.25 1/4" 115 8 15 62 M6x1 8 12 28

PISTON : Steel, single piece, 40 16 54 M12X1.25 3/8" 131 8 20 75 M8x1.25 10 14 40

precisely machined for

50 20 68 M14X1.5 3/8" 135 10 25 75 M8x1.25 10 14 50

perfect alignment.

63 25 76 M20X1.5 3/8" 152 10 30 83 M10x1.5 12.5 17 60

PISTON :Teflon composite for 80 28 94 M22X1.5 1/2" 171 12 30 99 M12x1.75 15 18 73

BEARING maximum rigidity

100 36 112 M27X2 1/2" 198 16 45 113 M12x1.75 15 20 89

125 45 148 M36X2 1/2" 208 18 45 122 M16x2 18 21 113

PISTON ROD : Medium carbon steel,

ground,hard-chrome 160 56 184 M42X2 3/4" 251 20 50 140 M16x2 18 26 138

plated and polished to a

maximum roughness of

Ra=0.4 microns.

PISTON ROD : Phosphor-bronze or PISTON AREA, ACTION FORCE, VELOCITIES AND FLOWS

BEARING teflon composite for

maximum rigidity Action Force in kgf Piston velocities Requisite flow

Piston area

Cylinder Rod dia at pressure= in m/s in ltr/min for

Cm2

Dia mm mm At flow=1 ltr/min Velocity=0.1m/s

30kg/cm 2 50kg/cm 2

SEALING : Wide range of + - + - + - + - + -

SYSTEM International std

sealing systems to suit 25 12 4.9 3.6 147 108 245 180 0.034 0.0460 2.94 2.16

various applications &

temperatures. 40 16 12.6 10.5 378 315 630 525 0.0132 0.015 7.56 6.30

MOUNTINGS : Accurately machined 50 20 19.6 16.8 588 504 980 840 0.0085 0.0099 11.76 10.08

steel suitable for heavy 63 25 31.2 26.3 936 789 1560 1315 0.0053 0.0063 18.72 15.78

duty application.

80 28 50.3 44.1 1509 1323 2515 2205 0.0033 0.0038 30.18 26.46

TIE RODS : Cold drawn steel

100 36 78.5 68.4 2355 2052 3925 3420 0.0021 0.0024 47.10 41.04

125 45 122.7 106.8 3681 3204 6135 5340 0.0013 0.0016 73.62 64.08

160 56 201.1 175.5 6033 5265 10055 8775 0.00082 0.00095 120.66 105.30

PRECISION ENGINEERING ACCESSORIES

B-109, 2nd Cross, KSSIDC Indl., Estate,

1st Stage, Peenya, BANGALORE - 560 058

Subject to change without notice

Ph: 080-28394210,28394134 Fax : 28392542

e-mail: info@preacindia.com

website: www.preacindia.com .......Cont d

2.110/2Vol 12-07

STANDARD MOUNTINGS and

Ordering Details for LH7 Series INDEX

BORE

25 40 50 63 80 100 125 160

DIA

FL 65 78 100 108 134 154 200 236

CC 52 66 84 92 114 134 174 210

BB 28 42 52 58 72 90 118 156

MH 6.6 6.6 9 9 11 11 14 14

FT 8 10 10 16 16 20 20 25

SP 4 4 4 4 4 4 4 4

SD 27 44 44 62 62 88 88 100

FP 12 12 14 14 16 20 22 24

RP 131 149 155 178 199 234 246 296

CB 12 20 20 20 32 32 32 40

TT 8 12 12 12 16 16 16 20

ED 10 12 12 12 20 20 20 25

CE 18 20 20 20 32 32 32 40

EP 141 159 165 182 215 246 258 311

LC 65 90 98 100 118 128 135 168

LL 70 98 112 120 146 168 228 264

FC 58 78 92 100 122 144 192 228

LI 8 22 22 22 32 32 40 40

LE 8 10 10 10 12 12 18 18

LT 8 12 12 12 20 20 25 28

LF 20 30 36 40 50 60 76 95

FH 7 11 11 11 14 14 22 22

LP 50 39 37 52 53 74 73 85

WT 25 32 38 38 50 50 50 58

TD 80 104 118 130 150 170 208 278

ST 48 58 76 84 100 125 162 208

DL 20 25 25 25 25 25 25 35

TP To Be Specified By Customer

MOUNTINGS OTHER THAN OUR STANDARD CAN ALSO BE OFFERED

ORDERING DETAILS

Example: - LH7-100/500-FF-36-CB- (X)-FC/***

Piston rod Accessories & Sealing

Series Bore Sizes Stroke M ountings Cushioning

Sizes Special Features System Code

LH7 f 25-350m m To be FF- Front Flange f 12-140m m CB-Cushioned PRE- Rod Eye

Rated (12 Std sizes) specified RF-Rear flange (12 Std sizes) at both Ends PRF- Rod Fork FC/***

Hydraulic in m m RC-Rear Clevis CR-Cushioned at FC- Seals: PTFE

Pressure of 50 RE-Rear eye Rear End SA- Single Acting

kg/cm 2 FL-Foot Lug CF-Cushioned at DE- Double Ended

IT-Interm ediate Front end (Etc)

Trunnion NC-Non-Cushioned

ET-Extended Tie Rod

NOTE:- The right of m odification for technical im provem ent is reserved. All dim ensions are in m m unless otherw ise specified.

PRECISION ENGINEERING ACCESSORIES

B-109, 2nd Cross, KSSIDC Indl., Estate,

1st Stage, Peenya, BANGALORE - 560 058

Subject to change without notice

Ph: 080-28394210,28394134 Fax : 28392542

e-mail: info@preacindia.com

website: www.preacindia.com

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Danh Sach Khach Hang VIP Diamond PlazaДокумент9 страницDanh Sach Khach Hang VIP Diamond PlazaHiệu chuẩn Hiệu chuẩnОценок пока нет

- Principles of SOAДокумент36 страницPrinciples of SOANgoc LeОценок пока нет

- Home Guaranty Corp. v. Manlapaz - PunzalanДокумент3 страницыHome Guaranty Corp. v. Manlapaz - PunzalanPrincess Aliyah Punzalan100% (1)

- Astm G184-06 PDFДокумент6 страницAstm G184-06 PDFparthibanОценок пока нет

- GSM Series AE07Документ12 страницGSM Series AE07parthibanОценок пока нет

- 1154 SeriesДокумент3 страницы1154 SeriesparthibanОценок пока нет

- Laboratory AssessmentДокумент15 страницLaboratory AssessmentparthibanОценок пока нет

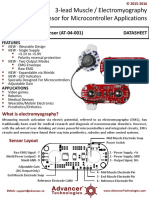

- At 04 001Документ8 страницAt 04 001parthibanОценок пока нет

- Curamik Design Rules DBC 20150901Документ8 страницCuramik Design Rules DBC 20150901Ale VuОценок пока нет

- EE1000 DC Networks Problem SetДокумент7 страницEE1000 DC Networks Problem SetAmit DipankarОценок пока нет

- Analisa RAB Dan INCOME Videotron TrenggalekДокумент2 страницыAnalisa RAB Dan INCOME Videotron TrenggalekMohammad Bagus SaputroОценок пока нет

- Bea Form 7 - Natg6 PMДокумент2 страницыBea Form 7 - Natg6 PMgoeb72100% (1)

- An Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)Документ18 страницAn Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)gurumurthy38Оценок пока нет

- The "Solid Mount": Installation InstructionsДокумент1 страницаThe "Solid Mount": Installation InstructionsCraig MathenyОценок пока нет

- Data Mining - Exercise 2Документ30 страницData Mining - Exercise 2Kiều Trần Nguyễn DiễmОценок пока нет

- Sworn Statement of Assets, Liabilities and Net WorthДокумент3 страницыSworn Statement of Assets, Liabilities and Net WorthShelby AntonioОценок пока нет

- PHP IntroductionДокумент113 страницPHP Introductionds0909@gmailОценок пока нет

- Review of Accounting Process 1Документ2 страницыReview of Accounting Process 1Stacy SmithОценок пока нет

- Practical GAD (1-32) Roll No.20IF227Документ97 страницPractical GAD (1-32) Roll No.20IF22720IF135 Anant PatilОценок пока нет

- Amel Forms & Logging SheetsДокумент4 страницыAmel Forms & Logging SheetsisaacОценок пока нет

- Health Informatics SДокумент4 страницыHealth Informatics SnourhanОценок пока нет

- PovidoneДокумент2 страницыPovidoneElizabeth WalshОценок пока нет

- Ssasaaaxaaa11111......... Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Документ167 страницSsasaaaxaaa11111......... Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Sunil Singh100% (1)

- Supreme Court of The United StatesДокумент296 страницSupreme Court of The United StatesABC News PoliticsОценок пока нет

- Admissibility of Whatsapp Messages in Court For Family MattersДокумент3 страницыAdmissibility of Whatsapp Messages in Court For Family Mattersnajihah adeliОценок пока нет

- Mounting BearingДокумент4 страницыMounting Bearingoka100% (1)

- Tracker Pro Otm600 1.5Документ19 страницTracker Pro Otm600 1.5Camilo Restrepo CroОценок пока нет

- August 2015Документ96 страницAugust 2015Cleaner MagazineОценок пока нет

- Reference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsДокумент43 страницыReference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsNisha JosephОценок пока нет

- HP Sustainability Impact Report 2018Документ147 страницHP Sustainability Impact Report 2018Rinaldo loboОценок пока нет

- TP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Документ12 страницTP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Felix ChewОценок пока нет

- Terms and Conditions 27 06 PDFДокумент4 страницыTerms and Conditions 27 06 PDFShreyash NaikwadiОценок пока нет

- Project Management: Chapter-2Документ26 страницProject Management: Chapter-2Juned BhavayaОценок пока нет

- RetrieveДокумент8 страницRetrieveSahian Montserrat Angeles HortaОценок пока нет