Академический Документы

Профессиональный Документы

Культура Документы

222853

Загружено:

AshutoshОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

222853

Загружено:

AshutoshАвторское право:

Доступные форматы

Indian Institute of Manaeement Luckno% , 2013-14P,,,

MID-TERM EXAMINATION

SUPPLY CHAIN MANAGEMENT

PGP-I Term III SECTION: C and D

Time: 1'./2 Hours Marks: 60

Instructions:

1.Closed book, closed notes exam. Required Statistical Table is provided at the end of this question paper.

2.Answers to different questions must start on a new page .

3.Please read the questions carefully . before assuming anything. Do not assume unnecessarily. State clearly all

the assumptions if you are using any.

4.Numbers on the extreme right hand side indicate marks for that question and!or its part.

1 1151

a.The annual demand for a product is 15,600 units. The weekly demand is 300 units with a OS

standard deviation of 90 units. The cost to place an order is 531_20, and the time from

ordering to receipt is four weeks. The annual inventory carrying cost is $0.10 per unit Find the

reorder point necessary to provide a 98 percent service probability.

Suppose the production manager is asked to reduce the safety stock of this item by 50

percent. If she does so, what will the new service probability be?

b.Mr. TVS Susuki needs a specialized throttle valve that has been offered b a vendor that too 10

with some quantity discounts if he will purchase more than his present order quantities. The

new volumes and prices are:

Range of Order Quantities 1 399 400 699 700+

Acquisition Cost per Valve (5) 2.20 2.00 1.80

Mr. Susuki asks you to investigate the new prices under two sets of assumptions:

1) Orders are received all at once, and 2) deliveries are gradual.

You have developed these estimates: Annual Demand = 10,000, Carrying cost per valve/per

year = 20% of valve cost, and ordering cost = $5.50 per order. Production rate is 120 valve

per day and consumption would be 40 valve per day.

Work out your recommendations to Mr. Susuki considering both the assumptions.

2. Products are shipped from a company's factory warehouse to two regional w arehouses, the 1151

forecasted demands for these warehouses A and B for the next five eeks are (130, 190, 280,

150, 310) and (2 10, 140. 180, 150, 140) respectively. Scheduled Receipts in Week 1 for the

warehouses A and B are 250 and 150 respectively. Also we know that the previous week's

ending inventories are 230 for warehouse A and 180 for warehouse B. Lead time for shipping

products from the warehouse at the factory to warehouse A is 2 weeks, the standard shipping

quantity is 250 units, and the safety stock at A is 150 units. Lead time for shipping products

from the Warehouse at the factory to warehouse B is 1 week, the standard shipping quantity is

150 units, and the safety stock for warehouse B is 80 units. Lead time for final assembly of

products and moving them into the warehouse at the factory is 1 week, the standard production

lot size is 500 units, and the safety stock is 150 units. The warehouse at the factory has an

ending inventory of 100 in the previous week, and a scheduled receipt in Week 1 of 500.

a.Complete the DRP records for both the warehouses A, B and the warehouse at the factory. 12

b.In what way can you relate this with the factory MRP? 03

Вам также может понравиться

- ReadmeДокумент21 страницаReadmeAshutoshОценок пока нет

- Special Recruitment Drive (SRD) To Fill Up Backlog Vacancies of SCSTOBC (NCL) PWD and Current Year VacanciesДокумент2 страницыSpecial Recruitment Drive (SRD) To Fill Up Backlog Vacancies of SCSTOBC (NCL) PWD and Current Year VacanciesAshutoshОценок пока нет

- Chapter12retailformats 160130042258Документ46 страницChapter12retailformats 160130042258AshutoshОценок пока нет

- Bharat Petroleum Corporation LimitedДокумент10 страницBharat Petroleum Corporation LimitedAshutoshОценок пока нет

- 1453975109ch 4 Bond ValuationДокумент50 страниц1453975109ch 4 Bond ValuationAshutoshОценок пока нет

- Bidding History: Relax! Bidding Has Ended!Документ1 страницаBidding History: Relax! Bidding Has Ended!AshutoshОценок пока нет

- The Commercial Banking Industry: Money and Capital MarketsДокумент29 страницThe Commercial Banking Industry: Money and Capital MarketsAshutoshОценок пока нет

- Ninewestcaseanalysis 110606170817 Phpapp01Документ7 страницNinewestcaseanalysis 110606170817 Phpapp01AshutoshОценок пока нет

- Nineweststoregroup5 140107015711 Phpapp02Документ14 страницNineweststoregroup5 140107015711 Phpapp02AshutoshОценок пока нет

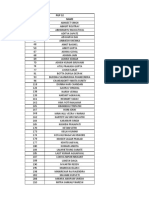

- PGP 32 and 33 student detailsДокумент5 страницPGP 32 and 33 student detailsAshutoshОценок пока нет

- New Text DocumentДокумент1 страницаNew Text DocumentAshutoshОценок пока нет

- 2014 JR MetaAnalysis ArticleДокумент22 страницы2014 JR MetaAnalysis ArticleVikasОценок пока нет

- Infosys Annual Report 2016-17plДокумент1 страницаInfosys Annual Report 2016-17plAshutoshОценок пока нет

- CH 07Документ26 страницCH 07AshutoshОценок пока нет

- 21 Managing Digital Communications Online Social Media and Mobile PPT 2016 11-26-13!04!47Документ23 страницы21 Managing Digital Communications Online Social Media and Mobile PPT 2016 11-26-13!04!47Ashutosh100% (1)

- 21 Managing Digital Communications Online Social Media and Mobile PPT 2016 11 26 13 04 47 PDFДокумент23 страницы21 Managing Digital Communications Online Social Media and Mobile PPT 2016 11 26 13 04 47 PDFAshutoshОценок пока нет

- Transport ScheduleДокумент1 страницаTransport ScheduleAshutoshОценок пока нет

- Internal Analysis: Resources, Capabilities, and Activities: Mcgraw-Hill/IrwinДокумент46 страницInternal Analysis: Resources, Capabilities, and Activities: Mcgraw-Hill/IrwinAshutoshОценок пока нет

- PGP 32 and 33 student detailsДокумент5 страницPGP 32 and 33 student detailsAshutoshОценок пока нет

- Kotler Mm13e Media 14Документ33 страницыKotler Mm13e Media 14AshutoshОценок пока нет

- SampleДокумент23 страницыSampleHean Lee KangОценок пока нет

- Chap 010Документ19 страницChap 010AshutoshОценок пока нет

- 2014 JR MetaAnalysis ArticleДокумент22 страницы2014 JR MetaAnalysis ArticleVikasОценок пока нет

- Bidding History: Relax! Bidding Has Ended!Документ1 страницаBidding History: Relax! Bidding Has Ended!AshutoshОценок пока нет

- Group 7 PricingДокумент3 страницыGroup 7 PricingAshim Sarkar100% (1)

- RegressionДокумент6 страницRegressionAshutoshОценок пока нет

- New Text DocumentДокумент1 страницаNew Text DocumentAshutoshОценок пока нет

- Abm13040 Gaurav Master CV Submission 1 FinalДокумент10 страницAbm13040 Gaurav Master CV Submission 1 FinalAshutoshОценок пока нет

- Strategy & Sustainable Opportunities: Midhurst With The 5 Town Network & ChichesterДокумент70 страницStrategy & Sustainable Opportunities: Midhurst With The 5 Town Network & ChichesterAshutoshОценок пока нет

- Catchment Analysis of Big BazaarДокумент15 страницCatchment Analysis of Big Bazaarshobhit_patel19Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Application BALCANДокумент2 страницыApplication BALCANIlie SarbuОценок пока нет

- Drop Ship Across OUДокумент46 страницDrop Ship Across OUzeeshan78Оценок пока нет

- English For Port ManagementДокумент5 страницEnglish For Port ManagementElisa Bandeira0% (2)

- Shipping KPI Quick Sheet, Version 2.5: Health and Safety PerformanceДокумент2 страницыShipping KPI Quick Sheet, Version 2.5: Health and Safety Performanceshivarachappa100% (1)

- Director of Purchasing or Purchasing Manager or Director of MateДокумент4 страницыDirector of Purchasing or Purchasing Manager or Director of Mateapi-77587911Оценок пока нет

- Business Form Report ChecklistДокумент2 страницыBusiness Form Report ChecklistcaplusincОценок пока нет

- Transfer and Business Taxation - MIDTERMДокумент14 страницTransfer and Business Taxation - MIDTERMYvette Pauline JovenОценок пока нет

- Order No.: Phone: Order Date: Fax: Ship Date: EmailДокумент4 страницыOrder No.: Phone: Order Date: Fax: Ship Date: EmailTamika_Samuel9341Оценок пока нет

- Materi10 Peta Keterkaitan Kegiatan Kantor Dan Fasilitas PabrikДокумент33 страницыMateri10 Peta Keterkaitan Kegiatan Kantor Dan Fasilitas PabrikIllyas JanuОценок пока нет

- Market Analysis of Iron OreДокумент46 страницMarket Analysis of Iron OrePranshuKashyap100% (1)

- Vas - IsfclДокумент2 страницыVas - IsfclPhú Nguyễn HoàngОценок пока нет

- Dole Philippines Inc. vs. Maritime CompanyДокумент4 страницыDole Philippines Inc. vs. Maritime CompanyKiko AguilarОценок пока нет

- CMRP Exam QuestionsДокумент18 страницCMRP Exam QuestionsExamsure944% (16)

- MCT0000230072Документ2 страницыMCT0000230072Anonymous 51rRHZeeYОценок пока нет

- Improving Railways' Market ShareДокумент20 страницImproving Railways' Market SharePrabubroto JaunandarОценок пока нет

- Procedure For Starting and Stopping of Sewage Treatment Plant On A ShipДокумент14 страницProcedure For Starting and Stopping of Sewage Treatment Plant On A ShipGabriel AzurenОценок пока нет

- Naval Blek enДокумент12 страницNaval Blek enGabriela DanaОценок пока нет

- Draft Clearance Process For Goods Entered Under PH Customs Bonded Warehousing (CBW) SystemДокумент12 страницDraft Clearance Process For Goods Entered Under PH Customs Bonded Warehousing (CBW) SystemPortCallsОценок пока нет

- CASES ON DISCHARGE OF CONTRACT THROUGH PERFORMANCE, AGREEMENT, BREACH, AND FRUSTRATIONДокумент5 страницCASES ON DISCHARGE OF CONTRACT THROUGH PERFORMANCE, AGREEMENT, BREACH, AND FRUSTRATIONVIVEKОценок пока нет

- ThermoweldДокумент276 страницThermoweldReginald D. De GuzmanОценок пока нет

- Goods Receipt Handling With Reference To Inbound DeliveryДокумент4 страницыGoods Receipt Handling With Reference To Inbound DeliveryBLОценок пока нет

- Garment Export ProcedureДокумент38 страницGarment Export ProcedureAkshath MavinkurveОценок пока нет

- Newsletter Alphaliner 2023-26Документ30 страницNewsletter Alphaliner 2023-26wee.kwanghui.ctmОценок пока нет

- Packing Declaration TemplateДокумент2 страницыPacking Declaration TemplateAndreasGozali100% (2)

- Export Finance PreshipmentДокумент11 страницExport Finance PreshipmentIftekhar Ahmed100% (1)

- 402kl ManualДокумент25 страниц402kl ManualerikaОценок пока нет

- Urban and Regional Transportation PlanningДокумент33 страницыUrban and Regional Transportation PlanningRomani Noel S. Chavez Jr.Оценок пока нет

- SAP TM Course Content.......Документ4 страницыSAP TM Course Content.......Prasad ChowdaryОценок пока нет

- Marina Memorandum Circular No. 106 (1995)Документ19 страницMarina Memorandum Circular No. 106 (1995)Alyssa Marie MartinezОценок пока нет

- Sales Reviewer MidtermДокумент24 страницыSales Reviewer Midtermlouis jansenОценок пока нет