Академический Документы

Профессиональный Документы

Культура Документы

Outokumpu Stainless Steel Wall Chart PDF

Загружено:

cnaren67Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Outokumpu Stainless Steel Wall Chart PDF

Загружено:

cnaren67Авторское право:

Доступные форматы

Outokumpu

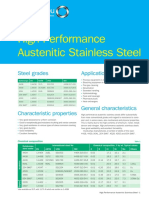

Stainless Steel Grades

Steel designation Typical chemical composition. % by wt. Steel designation Typical chemical composition. % by wt.

Outokumpu EN ASTM UNS ISO C N Cr Ni Mo Others Products Outokumpu EN ASTM UNS ISO C N Cr Ni Mo Others Products

4600 1.4600 - - - 0.02 11.2 0.85 Ti HS LDX 2101 1.4162 - S32101 4162-321-01-E 0.03 0.22 21.5 1.5 0.3 5Mn Cu PHCBRSTD

4512 1.4512 409 - - 0.02 11.5 0.2 Ti HCS 23042 1.4362 - S32304 4362-323-04-I 0.02 0.1 23 4.8 0.3 Cu PHCBRSTD

Duplex

4003 1.4003 - S40977 4003-410-77-I 0.02 11.5 0.5 PHCS LDX 2404 1.46621 - S82441 - 0.02 0.27 24 3.6 1.6 3Mn Cu PHCBRST

4000 1.4000 410S S41008 4000-410-08-I 0.03 12.5 PHCS 2205 1.4462 - S322054 4462-318-03-I 0.02 0.17 22 5.7 3.1 PHCBRSTD

4589 1.4589 - S42035 - 0.045 14 1.65 0.25 Ti HCS 4501 1.4501 - S32760 4501-327-60-I 0.02 0.27 25.4 6.9 3.8 W Cu PBRST

Wet corrosion and general service

4016 1.4016 430 S43000 4016-430-00-I 0.05 16.2 HCBRS 2507 1.4410 - S32750 4410-327-50-E 0.02 0.27 25 7 4 PHCBRST

Ferritic

4511 1.4511 - - 4511-430-71-I 0.02 16.2 Nb HCS 4310 1.4310 301 S30100 4310-301-00-I 0.1 17 7 HCBRS

4520 1.4520 - - 4520-430-70-I 0.02 16.2 Ti HCS 4618 1.4618 - - 4618-201-76-E 0.06 16.6 4.6 1.7Cu 7.9Mn HCS

4510 1.4510 439 S43035 4510-430-35-I 0.02 17 Ti HCS 4318 1.4318 301LN S30153 4318-301-53-I 0.02 0.14 17.7 6.5 HC S

4509 1.4509 - S43940 4509-439-40-X 0.02 18 Ti Nb HCS 4376 1.4376 - - - 0.035 0.2 17.5 4 6.8Mn HCS

4607 1.46071 - - - 0.02 19 Ti Nb HCS 4372 1.4372 201 S20100 4372-201-00-I 0.05 0.2 17 4 7Mn HCS

4113 1.4113 434 S43400 4113-434-00-I 0.045 16.5 1 HCS 4301 1.4301 304 S30400 4301-304-00-I 0.04 18.1 8.1 PHCBRST

Wet corrosion and general service

4513 1.4513 - S43600 4513-436-00-J 0.02 17 1 Ti HCS 4307 1.4307 304L S30403 4307-304-03-I 0.02 18.1 8.1 PHCBRST

4521 1.4521 444 S44400 4521-444-00-I 0.02 18 2 Ti Nb PHCS 4311 1.4311 304LN S30453 4311-304-53-I 0.02 0.14 18.5 9.2 PHCRS

4006 1.4006 410 S41000 4006-410-00-I 0.12 12 PHCBRS 4541 1.4541 321 S32100 4541-321-00-I 0.04 17.3 9.1 Ti PHCBRST

4550 1.4550 347 S34700 4550-347-00-I 0.05 17.5 9.5 Nb PHCBRST

precipitation hardening

4005 1.4005 416 S41600 4005-416-00-I 0.1 13 S BRS

4021 1.4021 420 S42000 4021-420-00-I 0.2 13 PHCBRS 4305 1.4305 303 S30300 4305-303-00-I 0.05 17.3 8.2 S PBRS

Martensitic and

4031 1.4031 420 S42000 4031-420-00-I 0.38 13.5 HCS 4303 1.4303 305 S30500 4303-305-00-I 0.04 17.7 12.5 HCRS

4034 1.4034 420 S42000 4034-420-00-I 0.45 13.7 HCS 4306 1.4306 304L S30403 4306-304-03-I 0.02 18.2 10.1 PHCBRST

4028 1.4028 420 S42000 4028-420-00-I 0.3 12.5 HCBS 4567 1.4567 - S30430 4567-304-30-I 0.01 17.7 9.7 3.0Cu BRS

4313 1.4313 434 S41500 4313-415-00-I 0.03 12.5 4.1 0.6 PS 4640 1.4640 - - - 0.06 18 6.5 1.7Cu 1.8Mn HCS

4401 1.4401 316 S31600 4401-316-00-I 0.04 17.2 10.1 2.1 PHCBRST

Austenitic

4542 1.4542 630 S174003 - 0.02 15.5 4.8 3.4Cu Nb BRS

4116 1.4116 - - 4116-420-77-E 0.5 14.4 0.55 V HCS 4404 1.4404 316L S31603 4404-316-03-I 0.02 17.2 10.1 2.1 PHCBRST

4110 1.4110 - - 4110-420-69-E 0.5 14.8 0.63 HCS 4427 1.44271 - - - 0.05 16.9 10.7 2.5 S P

4568 1.4568 631 S17700 - 0.08 17 7 1.0Al RS 4436 1.4436 316 S31600 4436-316-00-I 0.04 16.9 10.7 2.6 PHCBRST

4122 1.4122 - - 4122-434-09-I 0.41 16.1 1 HCS 4432 1.4432 316L S31603 4432-316-03-I 0.02 16.9 10.7 2.6 PHCBRST

4574 1.4574 - - - 0.08 14.5 7.5 2.2 1.1Al CS 4406 1.4406 316LN S31653 4406-316-53-I 0.02 0.14 17.2 10.3 2.1 PHCRST

4713 1.4713 - - - 0.06 6.5 0.8Si 0.8Al PHCS 4441 1.4441 - - - 0.02 17.6 14.5 2.8 HCS

4724 1.4724 - - 4724-405-77-I 0.07 12.5 1.0Si 0.9Al PHCS 4429 1.4429 - S31653 4429-316-53-I 0.02 0.14 17.3 12.5 2.6 PRS

Ferritic

Heat and creep

4736 1.4736 - - - 0.02 17.5 1.8Al Ti HCS 4571 1.4571 316Ti S32100 4571-316-35-I 0.04 16.8 10.9 2.1 Ti PHCBRST

4742 1.4742 - - 4742-430-77-I 0.07 17.5 1.0Si 1.0Al PHCS 4435 1.4435 316L - 4435-316-91-I 0.02 17.3 12.6 2.6 PHCBRST

4762 1.4762 - - 4762-445-72-I 0.08 23.5 1.0Si 1.5Al PHCS 3952 1.39521 - - - 0.02 0.18 16.9 13.2 2.7 P

4438 1.4438 317L6 S31703 4438-317-03-I 0.02 18.2 13.7 3.1 PCBRST

4948 1.4948 304H S30409 4048-304-09-I 0.05 18.1 8.3 PHCBRST 4439 1.4439 317LMN5 S31726 4439-317-26-E 0.02 0.14 17.3 13.7 4.1 PHCST

4878 1.4878 321H - - 0.05 17.3 9.1 Ti PHCBRST 725LN 1.4466 - S31050 4466-310-50-E 0.01 0.12 25 22.3 2.1 P

Austenitic

153 MA 1.4818 - S30415 4818-304-15-E 0.05 0.15 18.5 9.5 1.3Si Ce PCRST 3964 1.39641 - - - 0.02 0.27 20.5 15.4 3.2 4.3Mn Nb P

4833 1.4833 309S S30908 4833-309-08-I 0.06 22.3 12.6 PHCBRST 904L 1.4539 904L N08904 4539-089-04-I 0.01 20 25 4.3 1.5Cu PHCBRST

4828 1.4828 - - 4828-305-09-I 0.04 20 12 2.0Si PHCBS 254 SMO 1.4547 - S31254 4547-312-54-I 0.01 0.2 20 18 6.1 Cu PHCBRST

253 MA 1.4835 - S30815 4835-308-15-U 0.09 0.17 21 11 1.6Si Ce PHCBRST 4529 1.4529 - N08926/N08367 4529-089-26-I 0.01 0.2 20.5 24.8 6.5 Cu PCT

4845 1.4845 310S S31008 4845-310-08-E 0.05 25 20 PHCBRST 4565 1.4565 - S34565 4565-345-65-I 0.02 0.45 24 17 4.5 5.5Mn PHCST

4841 1.4841 314 S31400 4841-314-00-E 0.07 24.5 19.5 2.0Si PHCBRS 654 SMO 1.4652 - S32654 4652-326-54-I 0.01 0.5 24 22 7.3 3.5Mn Cu PCST

1

designation according to Stahl Eisen Liste (Register of European Steels). 2

also available as EDX 2304 with enhanced properties. 3 also available as S15500. 4 also available as S31803. 5 317LMN not available in all product forms. 6 also available as 317L with 11.7% Ni which is not consistent with 1.4438

1000EN-GB:8 Centrumtryck AB. Avesta. Sweden. May 2013

EN Material Standards EN Product Conditions Outokumpu Products Outokumpu Special Steel Conditions

EN 10088-1 Stainless steel grades general, EN 10302 Creep resisting steels and 1D Hot rolled, heat treated, pickled 2F Cold rolled, heat treated, pickled, skin P Hot rolled plate Quarto LIC for improved steel cleanness

not for ordering Ni/Co alloys 1E Hot rolled, heat treated, mechanically passed on roughened rolls H Hot rolled coil and sheet PRODEC for improved machinability

EN 10088-2 Stainless steel flat products for EN 10028-7 Stainless flat products for descaled 2R Cold rolled, bright annealed C Cold rolled coil and sheet HyTens for improved mechanical properties

general purposes pressure purposes 1G Hot rolled, ground 2G Ground B Bar CCS for improved mechanical properties

EN 10088-3 Stainless steel long products for EN 10272 Stainless rolled bar for pressure 1Q Hot rolled, quenched and tempered, pickled 2J Brushed or dull polished R Rod coil VKS for improved thickness tolerances

general purposes purposes 2H Work hardened 2K Satin polished S Semifinished (bloom, billet, ingot, slab) RAP2E for improved thickness tolerances

EN 10088-4 Stainless steel flat products, EN 10263-5 Stainless rod, bar and wire for cold 2E Cold rolled, heat treated, mech. desc, pickled 2M Patterned T Pipe and improved surface finish

technical delivery conditions, heading and cold extrusion 2D Cold rolled, heat treated, pickled 2W Profile rolled D DUPROFTM, profiles in high strength

steels for construction EN 10151 Stainless Steel Strip for Springs 2B Cold rolled, heat treated, pickled, skin passed 2L Coloured stainless steel

EN 10088-5 Stainless steel long products, 2BB* Cold rolled, heat treated, bright pickled, skin 2S Coated Multicertification is made on request to EN/ASTM/

technical delivery conditions, passed ASME as well as to superseded national standards

steels for construction

EN 10095 Heat resisting steels and Ni alloys * Outokumpu designation. The 2BB product confirms with standard surface finish 2B

LDX 2101, EDX 2304, LDX 2404, 254 SMO, 654 SMO, 153 MA and 253 MA are trademarks owned by Outokumpu Outokumpu sells in accordance with national and international standards required by customers and these are met in full

Вам также может понравиться

- Materials Data for Cyclic Loading: Low-Alloy SteelsОт EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsРейтинг: 5 из 5 звезд5/5 (2)

- Steel Grades 2 PDFДокумент2 страницыSteel Grades 2 PDFcanakyuz0% (1)

- Outokumpu Product Range WallchartДокумент4 страницыOutokumpu Product Range WallchartKevin YewОценок пока нет

- High Performance Austenitic Stainless SteelДокумент12 страницHigh Performance Austenitic Stainless SteelNitin VermaОценок пока нет

- PR-Request FormДокумент2 страницыPR-Request FormVajid MadathilОценок пока нет

- Outokumpu - Wallchart Product RangesДокумент5 страницOutokumpu - Wallchart Product RangesXavierОценок пока нет

- FFFДокумент20 страницFFFAhmed AlsabaaОценок пока нет

- Outokumpu Steel Grades Properties Global StandardsДокумент20 страницOutokumpu Steel Grades Properties Global StandardsLance BlackstarОценок пока нет

- Atlas Steels Product Manual Section 9Документ12 страницAtlas Steels Product Manual Section 9Alexis A. Illarramendi G.Оценок пока нет

- Aço China - Cross Reference SteelДокумент12 страницAço China - Cross Reference SteelPaulo BaltorОценок пока нет

- PascaleSottoVangeli PDFДокумент18 страницPascaleSottoVangeli PDFAldo GiacheroОценок пока нет

- Grades: Grade EN / DIN Aisi/Astm Uns Ss Afnor OverigДокумент2 страницыGrades: Grade EN / DIN Aisi/Astm Uns Ss Afnor OverigIvan AlexievОценок пока нет

- Sss Sttttaaaaiiiinnnnlllleeeessssssss Sssstttteeeeeeeellllssss Typical Composition % Uns WNR Ss / C CR Ni Mo NB CuДокумент4 страницыSss Sttttaaaaiiiinnnnlllleeeessssssss Sssstttteeeeeeeellllssss Typical Composition % Uns WNR Ss / C CR Ni Mo NB CuAdriano Dorneles de OliveiraОценок пока нет

- SPECIFICATIONS OF PIPES & TUBESДокумент3 страницыSPECIFICATIONS OF PIPES & TUBESanescobar0001Оценок пока нет

- 4-Acetoxybutanoic Acid HNMRДокумент4 страницы4-Acetoxybutanoic Acid HNMRmlphoneuseОценок пока нет

- 5-MeO-DiPT HCL HNMRДокумент6 страниц5-MeO-DiPT HCL HNMRmlphoneuseОценок пока нет

- ISO 15510:2010 lists stainless steel grades with comparative designationsДокумент3 страницыISO 15510:2010 lists stainless steel grades with comparative designationstugulea72 GabiОценок пока нет

- PH Type Stepping Motors: - $I Ec-If C .TionsДокумент1 страницаPH Type Stepping Motors: - $I Ec-If C .TionsBrian ThompsonОценок пока нет

- Ferritic and martensitic stainless steel cross reference listДокумент1 страницаFerritic and martensitic stainless steel cross reference listPlant Head PrasadОценок пока нет

- Article - Stainless Steel Fasteners and Their Chemical CompositionДокумент3 страницыArticle - Stainless Steel Fasteners and Their Chemical Compositiongaju_scribdОценок пока нет

- Key Pump MaterialsДокумент1 страницаKey Pump MaterialsMajid TorabiОценок пока нет

- Stainless Steel Grade Composition ChartДокумент6 страницStainless Steel Grade Composition Charteusufiqbal100% (1)

- Stainless Steel Bar Types and Chemical CompositionsДокумент1 страницаStainless Steel Bar Types and Chemical CompositionsNikola KrajcevskiОценок пока нет

- KNOWLEDGE FOR A BRIGHTER FUTURE: GUIDE TO NICKEL ALLOYS IN SULPHURIC ACIDДокумент12 страницKNOWLEDGE FOR A BRIGHTER FUTURE: GUIDE TO NICKEL ALLOYS IN SULPHURIC ACIDjoseocsilvaОценок пока нет

- Bill of Material for Product ID 7148Документ1 страницаBill of Material for Product ID 7148Tridi PrintingОценок пока нет

- Chemical Composition of Stainless Steel (P-2)Документ1 страницаChemical Composition of Stainless Steel (P-2)candraОценок пока нет

- Standard steel and alloy types and their designationsДокумент1 страницаStandard steel and alloy types and their designationsmpptanksОценок пока нет

- PRN 059172 Rev 03.a Etest Selection Guide Final Art PDFДокумент2 страницыPRN 059172 Rev 03.a Etest Selection Guide Final Art PDFFatima VessaliusОценок пока нет

- Stainless Steel International StandardsДокумент3 страницыStainless Steel International StandardsAmir MusaibОценок пока нет

- 202404-ASE Official Alloy ExtraДокумент1 страница202404-ASE Official Alloy Extrathegeneral2040Оценок пока нет

- Pupuk 7 RacikanДокумент10 страницPupuk 7 RacikanDimar KahuripanОценок пока нет

- Equivalent SpecificationsДокумент3 страницыEquivalent SpecificationsYudha Andrie Sasi ZenОценок пока нет

- Article - Calculation of Pitting Resistance Equivalent Numbers (PREN)Документ3 страницыArticle - Calculation of Pitting Resistance Equivalent Numbers (PREN)eugenio.gutenbertОценок пока нет

- S500MCДокумент2 страницыS500MCPankaj GuptaОценок пока нет

- Electrical data and motor specificationsДокумент2 страницыElectrical data and motor specificationsMea AurelieОценок пока нет

- Bab IiДокумент8 страницBab Iibeni firiyaОценок пока нет

- TNMG 160404 NN LT 10 108Документ1 страницаTNMG 160404 NN LT 10 108fabioОценок пока нет

- Stainless Steel Billets: Iron and Steel Co. LTDДокумент2 страницыStainless Steel Billets: Iron and Steel Co. LTDOrivaldo a. penaОценок пока нет

- Spectrocheck SpectrometerДокумент5 страницSpectrocheck SpectrometerChandra SekarОценок пока нет

- Welding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsДокумент1 страницаWelding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsLLОценок пока нет

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Документ3 страницыProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'bagusrindi2801Оценок пока нет

- Stainless Steel Data PDFДокумент4 страницыStainless Steel Data PDFRobert SumińskiОценок пока нет

- AA500 Series Detection Limits Analytical Instruments ScienceДокумент1 страницаAA500 Series Detection Limits Analytical Instruments ScienceAlexanderОценок пока нет

- 1N1742AДокумент4 страницы1N1742AM'handAyoubiОценок пока нет

- 3.1 MTC SampleДокумент2 страницы3.1 MTC SamplerendymulyadiОценок пока нет

- ASM Handbook, Vol 01 - Properties and Selection - Irons, Steels, and High Performance Alloys PDFДокумент2 страницыASM Handbook, Vol 01 - Properties and Selection - Irons, Steels, and High Performance Alloys PDFCésar Santana50% (4)

- Catalog Sicam 1 (Tevi)Документ32 страницыCatalog Sicam 1 (Tevi)orgas andreiОценок пока нет

- International Starch Institute: Wrought Stainless SteelsДокумент14 страницInternational Starch Institute: Wrought Stainless SteelsSilmina AdzhaniОценок пока нет

- 10C0003X0 Anixter Wire&Cable Catalog 2010 Sec08 Control Cable EN USДокумент50 страниц10C0003X0 Anixter Wire&Cable Catalog 2010 Sec08 Control Cable EN USFranciscoCantilloОценок пока нет

- CorrespondanceДокумент1 страницаCorrespondanceAyoub BOUFTINIОценок пока нет

- Annex A: (Normative)Документ6 страницAnnex A: (Normative)calvente27Оценок пока нет

- Stainless Steel Grades DatasheetsДокумент7 страницStainless Steel Grades DatasheetsYeda ZОценок пока нет

- Reference Assortment Kits for Non-Destructive Metal TestingДокумент1 страницаReference Assortment Kits for Non-Destructive Metal TestingAntonioCarlosSilvaОценок пока нет

- A 489 - 00 - Qtq4os1sruqДокумент6 страницA 489 - 00 - Qtq4os1sruqAnderson VelandiaОценок пока нет

- Ferritic and Martensitic Casting MaterialsДокумент2 страницыFerritic and Martensitic Casting MaterialsviyfОценок пока нет

- Ferritic and Martensitic Casting Materials SpecificationsДокумент2 страницыFerritic and Martensitic Casting Materials SpecificationsSinan YıldızОценок пока нет

- Balanta 31.12.2018 Pregatita Pentru ImportДокумент8 страницBalanta 31.12.2018 Pregatita Pentru Importaudit neroОценок пока нет

- Technical Data Sheet Product CatalogueДокумент16 страницTechnical Data Sheet Product CatalogueKamalОценок пока нет

- Mosfet de PotenciaДокумент7 страницMosfet de Potenciaalb_fedeОценок пока нет

- Casting AlloysДокумент2 страницыCasting Alloysgalvaosilva100% (1)

- Omega PID TunningДокумент4 страницыOmega PID TunningOwaisОценок пока нет

- Safety InstructionsДокумент6 страницSafety Instructionscnaren67Оценок пока нет

- Agitation Data Sheet: A. GeneralДокумент2 страницыAgitation Data Sheet: A. Generalcnaren67Оценок пока нет

- Performance of Packed Extraction TowerДокумент7 страницPerformance of Packed Extraction Towercnaren67Оценок пока нет

- Airtel international roaming value offer termsДокумент4 страницыAirtel international roaming value offer termscnaren67Оценок пока нет

- Evap StripДокумент2 страницыEvap Stripcnaren67Оценок пока нет

- Safety InstructionsДокумент6 страницSafety Instructionscnaren67Оценок пока нет

- Nitrite in Fish Ponds PDFДокумент4 страницыNitrite in Fish Ponds PDFcnaren67Оценок пока нет

- Petroleum Fraction at Ion OverviewДокумент35 страницPetroleum Fraction at Ion Overviewphobos2000Оценок пока нет

- New HAZOP MethodologyДокумент25 страницNew HAZOP Methodologycnaren67100% (1)

- Sieve Plate ColumnsДокумент6 страницSieve Plate Columnscnaren67Оценок пока нет

- Seri Fib ExtractionДокумент1 страницаSeri Fib Extractioncnaren67Оценок пока нет

- PVC Cables FinolexДокумент8 страницPVC Cables FinolexMaria DenetОценок пока нет

- Rototherm PDFДокумент2 страницыRototherm PDFcnaren67Оценок пока нет

- Hi SpeedДокумент2 страницыHi Speedcnaren67Оценок пока нет

- Chem Compat Chart - HaywardДокумент12 страницChem Compat Chart - HaywardpdlhОценок пока нет

- Project 2013 Quick ReferenceДокумент3 страницыProject 2013 Quick Referencecnaren67Оценок пока нет

- Design Manual Mist Eliminator - NewДокумент16 страницDesign Manual Mist Eliminator - Newashif100% (2)

- Chocolate Making Process PDFДокумент1 страницаChocolate Making Process PDFcnaren67Оценок пока нет

- Compatibility Chart For ChemicalsДокумент3 страницыCompatibility Chart For Chemicalscnaren67Оценок пока нет

- Aspen Plus TipsДокумент16 страницAspen Plus Tipscnaren67Оценок пока нет

- AMCA 205-10 (Rev - 2011) PDFДокумент17 страницAMCA 205-10 (Rev - 2011) PDFv2304451Оценок пока нет

- 5.7 Hazop V1.0Документ14 страниц5.7 Hazop V1.0Isabela AlvesОценок пока нет

- Tert-Butanol Dehydration To Isobutylene Via Reactive DistillationДокумент3 страницыTert-Butanol Dehydration To Isobutylene Via Reactive DistillationKah AikОценок пока нет

- AntisurgeДокумент6 страницAntisurgesch203Оценок пока нет

- Pub ColdlimesofteningДокумент8 страницPub Coldlimesofteningcnaren67Оценок пока нет

- Chlorine Scrubbing Technical Note: Process Design and Heat of ReactionДокумент3 страницыChlorine Scrubbing Technical Note: Process Design and Heat of Reactioncnaren67Оценок пока нет

- Omega PID TunningДокумент4 страницыOmega PID TunningOwaisОценок пока нет

- Common Mistakes in HazopsДокумент4 страницыCommon Mistakes in HazopsbrounietaОценок пока нет

- E Mat: Engineering MaterialsДокумент135 страницE Mat: Engineering MaterialsStevenson CacОценок пока нет

- Module 6 BmeДокумент293 страницыModule 6 BmeEshan ChowdhuryОценок пока нет

- Galvanize Galvanize Business Unit: Trust Us To GalvanizeДокумент6 страницGalvanize Galvanize Business Unit: Trust Us To GalvanizeAdet WildanОценок пока нет

- DIN EN ISO 12944-4 071998-EnДокумент29 страницDIN EN ISO 12944-4 071998-EnChristopher MendozaОценок пока нет

- En 10210. S235JRH S275J0H S355J2HДокумент4 страницыEn 10210. S235JRH S275J0H S355J2HTARUNKUMARОценок пока нет

- Fit Up Welding Visual Inspection ReportДокумент2 страницыFit Up Welding Visual Inspection Reportmohd as shahiddin jafriОценок пока нет

- Boysen Paint CoverageДокумент2 страницыBoysen Paint CoverageAkoto At IkawyanОценок пока нет

- NAQPДокумент9 страницNAQProhitОценок пока нет

- Proposal Pekerjaan Painting PT Linde Indonesia - GresikДокумент16 страницProposal Pekerjaan Painting PT Linde Indonesia - GresikDicky ArdiansyahОценок пока нет

- Expanded MetalДокумент2 страницыExpanded Metalebastien2Оценок пока нет

- Lec 03 - Surface TreatmentДокумент26 страницLec 03 - Surface TreatmentchittineniОценок пока нет

- 3D Printing in Orthodontics: DR - Mohnish KumarДокумент20 страниц3D Printing in Orthodontics: DR - Mohnish Kumararpit maraikayarОценок пока нет

- Technical Data A-325 Heavy Hex Structural BoltsДокумент1 страницаTechnical Data A-325 Heavy Hex Structural BoltsZak OxmaniОценок пока нет

- Diecast Defects ManualДокумент57 страницDiecast Defects ManualPraveen CoolОценок пока нет

- Steelmaking Process OverviewДокумент19 страницSteelmaking Process OverviewYaSsin Saad100% (1)

- 3.3 Gear Materials and Heat Treatments TechnicalData KGSTOCKGEARSДокумент2 страницы3.3 Gear Materials and Heat Treatments TechnicalData KGSTOCKGEARSChin-Min YangОценок пока нет

- Welding Procedure SpecificationДокумент2 страницыWelding Procedure SpecificationWaranya Musika100% (1)

- 7.2. L NG QU T - ROVB2034 - dwg1-C-VB2034 - PRTДокумент1 страница7.2. L NG QU T - ROVB2034 - dwg1-C-VB2034 - PRTToàn NguyễnОценок пока нет

- NADCA standards, guidelines and checklists for die castingДокумент1 страницаNADCA standards, guidelines and checklists for die castingluisA1923Оценок пока нет

- 52812-FiatДокумент10 страниц52812-FiatAndres SuarezОценок пока нет

- 02 - Ch10 - Fundamentals of Metal CastingДокумент31 страница02 - Ch10 - Fundamentals of Metal CastingFaiq Sina Alfain100% (1)

- MIG Welding: A Seminar Report On byДокумент12 страницMIG Welding: A Seminar Report On bybmkaleОценок пока нет

- Jigs and Fixtures - Multiple Choice Questions (MCQ) and Answers 1-Jigs and Fixtures Are Used ForДокумент5 страницJigs and Fixtures - Multiple Choice Questions (MCQ) and Answers 1-Jigs and Fixtures Are Used ForRenuga Devi AОценок пока нет

- Hot Bar Polymer Welding1Документ2 страницыHot Bar Polymer Welding1Mugesh RanjanendranОценок пока нет

- Special steels A320 L7 - L7M American standards ASTMДокумент1 страницаSpecial steels A320 L7 - L7M American standards ASTMNarimane BentyОценок пока нет

- 1st QTR Review Sparrow ProgramДокумент28 страниц1st QTR Review Sparrow ProgramBernadette PeñaroyoОценок пока нет

- GMAW DefectsДокумент9 страницGMAW DefectsBASKARANОценок пока нет

- A182 PDFДокумент19 страницA182 PDFالGINIRAL FREE FIRE100% (2)

- Sandvik MTG FДокумент61 страницаSandvik MTG FOscar KellermanОценок пока нет

- Scuba Diving Mauritius RatesДокумент2 страницыScuba Diving Mauritius Ratesanwar.buchooОценок пока нет