Академический Документы

Профессиональный Документы

Культура Документы

Experimental Behavior of Composite Infilled Column by Using Silicafume & Metakaolin

Загружено:

IAEME PublicationОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Experimental Behavior of Composite Infilled Column by Using Silicafume & Metakaolin

Загружено:

IAEME PublicationАвторское право:

Доступные форматы

International Journal of Civil Engineering and Technology (IJCIET)

Volume 8, Issue 1, January 2017, pp. 203208, Article ID: IJCIET_08_01_021

Available online at http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=1

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

IAEME Publication

EXPERIMENTAL BEHAVIOR OF COMPOSITE

INFILLED COLUMN BY USING SILICAFUME &

METAKAOLIN

M. R. Ganesamoorthy

Research Scholar, St. Peters University, Chennai, India

Dr. S. Arivalagan

Professor, Dr. M.G.R Educational and Research Institute, Chennai, India

ABSTRACT

Type of column that incorporates two materials or elements of design in its structure is a

composite column. In engineering, a composite column may also be understood to mean a column

of concrete reinforced by a steel core. The latter type of composite column is often used in

construction due to its structural advantages, including corrosion protection and increased

strength. These structures are intended to be load-bearing and have many advantages over plain

steel or concrete .The steel backbone of a composite column lends increased strength and

resistance to buckling. Since steel is lighter than concrete but also stronger, the necessary support

structures are smaller and more lightweight than they would be if only concrete were being used.

These advantages make composite columns an efficient and economical solution for large-scale

construction projects. Use of Metakaolin and silica fume as partial replacement of cement in

concrete for strength and economy. The proper dispersion of cement, Metakaolin and Silicafume in

the concrete and composite column plays an important role in this study. The experimentation is

performed for different water cement ratio of 0.35 to 0.5% for in composite column of Square and

Circular Section. Then the specimens are to be tested on 7thday, 14thday, 28th day

Key words: Metakaolin, Silicafume, Steel-concrete, composite columns

Cite this Article: M.R. Ganesamoorthy and Dr. S. Arivalagan. Experimental Behavior of

Composite Infilled Column by using Silicafume & Metakaolin. International Journal of Civil

Engineering and Technology, 8(1), 2017, pp. 203208.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=1

1. INTRODUCTION

Steel-concrete composite columns were used over years for its advantages in fire protection. In recent

years it is widely employed in many structural applications including the supporting platforms of offshore

structures, bridges, columns in seismic zones and more as it combines the tensile and ductile properties of

steel with compressive strength of concrete. Its advantages include: Higher strength-to-weight ratio and

higher rigidity than conventional reinforced concrete column. Higher ductility and toughness for resisting

reversal load. Higher load carrying capacity due to the composite action between steel and concrete.

Saving in material and construction time. Steel tubes are also used as permanent formwork. In hollow steel

tubular sections which are predominantly used in high rise buildings, both inward and outward buckling is

http://www.iaeme.com/IJCIET/index.asp 203 editor@iaeme.com

M.R. Ganesamoorthy and Dr. S. Arivalagan

found. Whereas for the concrete-filled steel tube, only outward buckling is found in the tube, and the inner

concrete fails in a more ductile fashion. The interaction between the concrete and the steel section in the

composite enhances it to carry large axial load. The bending moments, tensile and shear forces are resisted

by the concrete which is reinforced by steel section. The concrete in a composite column reduces the

potential for buckling of the steel section in addition to resisting compressive loading. There is an increase

in the lateral expansion of the concrete infill until it reaches the lateral expansion of the steel, at a particular

strain. The micro-cracking in the concrete begins to take place whereas the structural steel expansion

remains the same at this stage. This acceleration in the concrete expansion results in an interactive contact

between the two materials. Hence, bond stresses are developed and the concrete will be subjected to tri-

axial stresses while the structural steel to biaxial stresses [3]. Based on the transfer of force between

concrete and steel the longitudinal stress in the confining tube varies. The strain level at which

confinement occurs is debated among researchers to range from 0.001 to 0.002. Some scientists such as

Knowles and Park concluded that concrete confinement happens suddenly at about (strain of 0.002) just as

the concrete starts dilation [4]. While other researchers as Tsuji, et al. and Zhang, et al. proposed a steady

increase in the concrete confinement starting right after the occurrence of micro-cracking in the concrete

(strain of 0.001), till full confinement is met at a strain around 0.001[5],[6].The circumferential stresses are

developed in the structural steel due to two factors: 1. Longitudinal stresses from loading. 2. Lateral

pressure from concrete dilation. Based on the steel utilized in the composite element, the steel could have

reached its capacity prior to their yield in this stage. The tube would not be able to sustain the normal yield

stress if tube yielding occurs before the biaxial state of stress leading in the transfer of load from tube to

concrete. Conversely, if the confining tube has not yet yielded, the extra axial capacity needed from the

steel tube before yielding will be reduced [7]. The concrete industry is constantly looking for

supplementary cementitious material with the objective of reducing the solid waste disposal problem.

Cement is partially replaced by silica Fume and Metakaolin with the replacement level of 50% is employed

in this experimental procedure.

2. TEST SPECIMENS AND MATERIAL PROPERTIES

Cross sections of both Square and circular specimens are mentioned in table1. The height of the specimens

were fixed as 500mm and 1000mm. Steel plates of 150mm x150mm and thickness of 3mm was welded at

top and at the bottom ends. A minimum 28-day curing time was applied to gain a standard concrete

compressive strength of the core concrete specimens after pouring of concrete into the steel tubes. The

amount of cement, silica fume, Metakaolin, water and aggregates used during the pour of concrete in the

steel tube for two different mixes are given in table 2. Compressive strength of conventional and MSC

concrete for the mentioned mix was obtained as 28.4 MPa and 31.3 MPa for M20 grade of concrete. For

M40 grade of concrete the compressive strength was given by 47.2MPa and 48.1MPa for conventional and

MSC concrete respectively. Modulus of elasticity and yield stress of steel chosen is 200000 MPa and

355MPa.

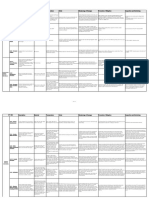

Table 1 Cross sectional properties of specimens

Label Breadth/Outer Thickness (Mm) Height (Mm)

Diameter (Mm)

CS1 114 2 1000

CS2 114 2 500

SS1 100 2 1000

SS2 100 2 500

http://www.iaeme.com/IJCIET/index.asp 204 editor@iaeme.com

Experimental Behavior of Composite Infilled Column by Using Silicafume & Metakaolin

Table 2 Material Quantities

Type Of Concrete Materials Quantity(Kg)

M20 Mix M40 Mix

Conventional Concrete Cement 13 15.13

Fine Aggregate 24.075 23.82

Coarse Aggregate 41.06 38.75

MSC Concrete Cement 6.495 7.6

Fine Aggregate 24.075 23.82

Coarse Aggregate 41.06 38.75

Silica Fume 3.2 3.8

Metakaolin 3.2 3.8

3. INSTRUMENTATION

Displacement gauges named Linear Variable Differential Transducer (LVDT) were used to measure

elongation and shortening along a working axis. A strain gauge was the unit deformation measurement

apparatus which worked the electrical output values of the elongation and shortening phenomena placed

along the longitudinal direction according to the electrical resistance. The measurement resistance of the

strain gauges had to be at 120+_0.5 range. Universal testing machines of capacity 300 tonnes and

100tonnes were used to give the required load to the specimen. In total two strain gauges were placed on

two sides of the specimens vertically and two displacement gauges were placed on the remaining two sides

as shown in Figure 1. One displacement gauge was placed at the top to measure the axial shortening.

Experiments were performed only under the effect of an axial compression load assumption. Possible

shear force and bending moment values caused by eccentric loading and deformation during the test

process were ignored. The top and bottom ends were assumed to be roller supports that permit only axial

force transition. This is achieved by placing steel balls at the top as well as bottom ends.

http://www.iaeme.com/IJCIET/index.asp 205 editor@iaeme.com

M.R. Ganesamoorthy and Dr. S. Arivalagan

3.1. Infilled Circular Section

Compressive strength of CC (N/mm2)

7 days 14 days 28 days

96 106 111

97 104 110

96 98 109

96 102.6 110

Compressive strength of MSC (N/mm2)

7 days 14 days 28 days

107.5 117 120

109 116 121

106 119 122

107.5 117.3 121

3.2. Infilled Square Section

Compressive strength of CC (N/mm2)

7 days 14 days 28 days

98 107 114

99 106 110

98 100 113

98.3 105 112

Compressive strength of MSC (N/mm2)

7 days 14 days 28 days

109 115 118

111 113 117

107 113 121

109 113.6 118.6

http://www.iaeme.com/IJCIET/index.asp 206 editor@iaeme.com

Experimental Behavior of Composite Infilled Column by Using Silicafume & Metakaolin

3.3. Deflection Curve for Normal Concrete at 28 Days

5

DEFLECTION

4

3

2

1

0

1 2 3 4

LOAD KN/M^2

Series2 Series4

3.4. Deflection Curve for Infilled Concrete at 28 Days

8

DFLECTION

7

6

5

4

3

2

1

0

1 2 3 4

LOAD KN/M^2

Series2 Series4

4. CONCLUSIONS

The following conclusions were made from the experiments performed:

Concrete filled steel tubes have 1.8times higher strength than hollow tubes.

The increase in compressive strength of infill increases the load carrying capacity by 10% for conventional

concrete infill and 20% form MSC concrete infill

MSC concrete infilled steel tubes have 6%-15% higher strength than conventional concrete filled steel tubes.

Circular sections have 10% higher load carrying capacity compared to square sections.

Load carrying capacities of specimens is observed to increase by 35%-40% with a decrease in the

height/thickness ratio.

REFERENCES

[1] McCormac, J. C. Structural steel design, 4th ed., m. j. horton, Ed., Pearson prentice hall, 2007.

[2] Furlong, R. W. "Strength of steel encased concrete beam-columns," American Society of Civil

Engineers, vol. 93, no.ST 5, pp. 113124,1967.

[3] Kuranovas, A., and Kvedaras, A. K., "Behavior of hollow-concrete steel tubular composite elements,"

Journal of Civil Engineering and Management , vol. II, no. 13,p p. 131141, 2007.

[4] Knowles, R. B. and Park, R., "Axial Load Design for Concrete Filled Steel Tubes," Journal of the

Structural Division, ASCE, vol. 96, no. 10,pp. 2125-2153, 1970.

http://www.iaeme.com/IJCIET/index.asp 207 editor@iaeme.com

M.R. Ganesamoorthy and Dr. S. Arivalagan

[5] Tsuji, B., Nakashima, M. and Morita, S., "Axial Compression Behavior of Concrete Filled Circular Steel

Tubes," in Third International Conference on Steel-Concrete Composite Structures, Fukuoka, Japan,

1991.

[6] Zhong, S. T., "The Concrete Filled Steel Tubular (CFST) Structures in China," in the Third International

Conference on Steel-Concrete Composite Structures, Fukuoka, Japan, 1991.

[7] Gourley, B. C., Tort, C., Denavit, M. D., Schiller, P. H. and Hajjar, J. F., "A synopsis of studies of the

monotonic and cyclic behavior of concrete filled steel tube beam-columns," Newmark Structural

Laboratory Report Series (ISSN 1940-9826), Urbana, Illinois, 2008.

[8] OShea M, BridgeR. Design of circular thin-walled concrete filled steel tubes. J StructEng ASCE2000;

126:1295303.

[9] FujimotoT, MukaiA, NishiyamaI, SakinoK. Behavior of eccentrically loaded concrete-filled steel

tubular columns. JStructEngASCE,130;2004;20312.

[10] Kuranovas, A., and Kvedaras, A. K., "Behavior of hollow-concrete steel tubular composite elements,"

Journal of Civil Engineering and Management , vol. II, no. 13,p p. 131141,2007

[11] Dr. D. V. Prasada Rao and S. Venkata Maruthi. Effect of Nano - Silica on Concrete Containing

Metakaolin. International Journal of Civil Engineering and Technology(IJCIET), 7 (1), 2016, pp. 104-

112

[12] P. Uday Kumar and B. Sarath Chandra Kumar, Flexural Behaviour of Reinforced Geopolymer Concrete

Beams with GGBS and Metakaoline. International Journal of Civil Engineering and Technology

(IJCIET), 7(6), 2016, pp.260277.

http://www.iaeme.com/IJCIET/index.asp 208 editor@iaeme.com

Вам также может понравиться

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesДокумент10 страницImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurДокумент7 страницA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyДокумент14 страницModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Broad Unexposed Skills of Transgender EntrepreneursДокумент8 страницBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationОценок пока нет

- Voice Based Atm For Visually Impaired Using ArduinoДокумент7 страницVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiДокумент16 страницA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaДокумент9 страницA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsДокумент8 страницDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiДокумент16 страницInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationОценок пока нет

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesДокумент15 страницAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesДокумент18 страницRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentДокумент13 страницA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESДокумент9 страницEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDДокумент19 страницApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Various Fuzzy Numbers and Their Various Ranking ApproachesДокумент10 страницVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationОценок пока нет

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksДокумент10 страницA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsДокумент13 страницOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationОценок пока нет

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentДокумент8 страницKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationОценок пока нет

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceДокумент7 страницQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationОценок пока нет

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsДокумент13 страницAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationОценок пока нет

- A Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceДокумент5 страницA Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceIAEME PublicationОценок пока нет

- Sentiment Analysis Approach in Natural Language Processing For Data ExtractionДокумент6 страницSentiment Analysis Approach in Natural Language Processing For Data ExtractionIAEME PublicationОценок пока нет

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsДокумент13 страницPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationОценок пока нет

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelДокумент9 страницFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorДокумент7 страницModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationОценок пока нет

- Formulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationДокумент7 страницFormulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationIAEME PublicationОценок пока нет

- Ion Beams' Hydrodynamic Approach To The Generation of Surface PatternsДокумент10 страницIon Beams' Hydrodynamic Approach To The Generation of Surface PatternsIAEME PublicationОценок пока нет

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsДокумент9 страницAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationОценок пока нет

- A Review of Particle Swarm Optimization (Pso) AlgorithmДокумент26 страницA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Evaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesДокумент6 страницEvaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesIAEME PublicationОценок пока нет

- Experiment #1 / Unit 10 Solubility Curve of Potassium NitrateДокумент2 страницыExperiment #1 / Unit 10 Solubility Curve of Potassium Nitrateapi-368121935100% (1)

- SPE-10489-PA PVT y Scal PDFДокумент9 страницSPE-10489-PA PVT y Scal PDF'Andres TorregrosaОценок пока нет

- Iit Model Paper PDFДокумент14 страницIit Model Paper PDFstudysteps.in100% (2)

- Material Design and Characterization of High Performance Pervious ConcreteДокумент10 страницMaterial Design and Characterization of High Performance Pervious Concreteqwefqwefqwe fqwefqwОценок пока нет

- Physics Progect On Led As Light SensorДокумент10 страницPhysics Progect On Led As Light SensorShubham KumarОценок пока нет

- Inform Energy Sanicube InformationДокумент11 страницInform Energy Sanicube Informationh2odavidОценок пока нет

- Module - 1 Lecture Notes - 5: Remote Sensing: Introduction and Basic Concepts Spectral Reflectance CurvesДокумент13 страницModule - 1 Lecture Notes - 5: Remote Sensing: Introduction and Basic Concepts Spectral Reflectance CurvesYogesh SharmaОценок пока нет

- Comparative Investigation of Traditional and Modern Passive Design Strategies To Reduce The Energy Use in Residential Building of West-Maharashtra RegionДокумент17 страницComparative Investigation of Traditional and Modern Passive Design Strategies To Reduce The Energy Use in Residential Building of West-Maharashtra RegionAnonymous CwJeBCAXp100% (1)

- FaienceДокумент15 страницFaienceRenata TatomirОценок пока нет

- 2.Pv Semisolid FDAДокумент37 страниц2.Pv Semisolid FDARahayu Maulida RОценок пока нет

- Topic 6 - Concrete With Particular Properties PDFДокумент79 страницTopic 6 - Concrete With Particular Properties PDFWayne ChongОценок пока нет

- SugarcaneДокумент83 страницыSugarcaneabrahanОценок пока нет

- Standard SpecificationsДокумент5 страницStandard SpecificationsIan54321Оценок пока нет

- Ray OpticsДокумент52 страницыRay OpticsJack LupinoОценок пока нет

- Effects of Poultry Manure Supplemented by NPK 15-15-15 Fertilizer On Cucumber (Cucumis Sativus L.) Production in Port Harcourt (Nigeria)Документ7 страницEffects of Poultry Manure Supplemented by NPK 15-15-15 Fertilizer On Cucumber (Cucumis Sativus L.) Production in Port Harcourt (Nigeria)tino3528Оценок пока нет

- Tpl-Kipl Jvkarnalstp-20cdd003 Design Docoments Part 1 Client 28-11-18Документ1 057 страницTpl-Kipl Jvkarnalstp-20cdd003 Design Docoments Part 1 Client 28-11-18navneet3bawa100% (1)

- 571 SummaryДокумент3 страницы571 SummarySimbu Arasan100% (1)

- Bfs4063 & Bfs 40603 Concrete EngineeringДокумент4 страницыBfs4063 & Bfs 40603 Concrete EngineeringUtaya Kumar VeelmuruganОценок пока нет

- 5990 7413enДокумент20 страниц5990 7413enG_ASantosОценок пока нет

- Chemguard c333 Ar-Afff 3% MsdsДокумент7 страницChemguard c333 Ar-Afff 3% MsdsrendydunОценок пока нет

- NIA Graduate Program: Fall 2016: Full Course ListДокумент12 страницNIA Graduate Program: Fall 2016: Full Course ListMarsala NistoОценок пока нет

- CHAPTER 2design Against Static LoadДокумент33 страницыCHAPTER 2design Against Static LoadmanishtopsecretsОценок пока нет

- PROBLEM 17.129: SolutionДокумент14 страницPROBLEM 17.129: SolutiontaОценок пока нет

- A Review On Techniques To Enhance Electrochemical Remediation of Contaminated SoilsДокумент19 страницA Review On Techniques To Enhance Electrochemical Remediation of Contaminated SoilsAdelina96Оценок пока нет

- Analytical Concepts of Errors, Accuracy and Precision: Group: 2 Eman Fatima Fajar Eman Khadija LubainaДокумент12 страницAnalytical Concepts of Errors, Accuracy and Precision: Group: 2 Eman Fatima Fajar Eman Khadija LubainaAzhan HassanОценок пока нет

- Weo Water Treatment and ReuseДокумент4 страницыWeo Water Treatment and ReuseWendyОценок пока нет

- Spectrophotometric Determination of Nitrite and Nitrate Using Phosphomolybdenum Blue ComplexДокумент8 страницSpectrophotometric Determination of Nitrite and Nitrate Using Phosphomolybdenum Blue ComplexkhekhyОценок пока нет

- 9701 w05 QP 4Документ12 страниц9701 w05 QP 4Hubbak KhanОценок пока нет

- HPTLCДокумент46 страницHPTLCVedha K Chalam100% (1)

- Decarburization of SteelДокумент7 страницDecarburization of SteelSadeep MadhushanОценок пока нет

- Process Plant Equipment: Operation, Control, and ReliabilityОт EverandProcess Plant Equipment: Operation, Control, and ReliabilityРейтинг: 5 из 5 звезд5/5 (1)

- Laws of UX: Using Psychology to Design Better Products & ServicesОт EverandLaws of UX: Using Psychology to Design Better Products & ServicesРейтинг: 5 из 5 звезд5/5 (9)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОт EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОценок пока нет

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneОт EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneРейтинг: 4.5 из 5 звезд4.5/5 (5)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessОт EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessОценок пока нет