Академический Документы

Профессиональный Документы

Культура Документы

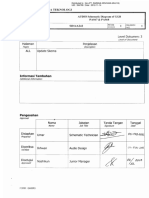

WM 008801

Загружено:

Ramón RocaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

WM 008801

Загружено:

Ramón RocaАвторское право:

Доступные форматы

TIG - Direct-Current Welding with High-Frequency Pulses, an Interesting

Process Variant

D. Dzelnitzki, Muendersbach

Welding current I [A]

1 Introduction

Tungsten-inert-gas welding (TIG) is one of the most

important joining technologies in welding-related fabri-

cation. High-quality weld joints without spattering and

IP

slags qualify this welding technology for the major part

Im

of metals. As the filler-metal supply is separated from

IG

the arc, the molten pool can be controlled in the best tG tP

way possible - an advantage which ensures the quality Time t [s]

of the execution of the weld but entails a relatively low

1 pulse cycle = 1/f

deposition rate and welding speed. If the welding

speed is increased, the arc looses some of its stability IG = basic current f = pulse frequency

and the penetration decreases. Above a critical value, Im = medium amperage tG = basic time

depending on the welding parameters selected, no IP = pulse current tP = pulse time

continuous weld can be achieved any more [1]. tP x 100%

On the basis of these experiences, several TIG pulse duty ratio T =

(tG+tP)

torches are combined (multi-cathode torch), or TIG

Fig. 1. TIG - Pulsed-arc welding, terms

dual-flow torches as well as plasma torches are used

in order to increase the welding speed in automatic A pulse frequency of 0.5 - 6 Hz should be selected,

fabrication processes. The high requirements in torch because higher values practically do not result in a

construction and torch operation turn out to be a dis- temperature difference between pulse and basic level

advantage in this respect. and thus produce a temperature course similar to non-

With laser welding devices, a considerable increase in pulsed TIG welding. In this respect, 40 - 60 % is con-

the welding speed can be achieved. However, the high sidered to be a sensible pulse duty ratio [2].

costs and the extremely low efficiency often hinder the Under these circumstances, we have to face the

employment of these devices. question: What is the use of TIG direct-current welding

TIG direct-current welding with high-frequency pulses with high-frequency pulses?

also leads to a considerable increase in the welding The arc provides the answer. By heterodyning with a

speed. In ranges of material thicknesses up to about 2 frequency of a few Hertz to 35 kHz, its shape can be

mm, this welding method thus represents an interest- influenced. The arc column is contracted and as-

ing low-cost alternative to multi-cathode and laser sumes a cylindrical shape [3]. In consequence, the arc

welding. pressure rises, fig. 2.

2 Characteristics of high-frequency TIG pulsed-

arc welding

2.1 Process principle

TIG welding with pulsating current has been known for

many years. It is mostly used for fully-mechanised and

automatic welding processes. The welding current

Arc pressure TN

weaves periodically between a high (pulse current Ip)

and a low (basic current IG) value. In the basic-current

phase, the low temperature causes a decrease in the

volume of the molten pool. Thus, the heat input is

reduced and optimum control of the molten bath is

ensured. Of course, the pulse parameters (pulse cur-

rent Ip , basic current IG, pulse frequency f and the

pulse duty ratio T), fig. 1, must be adjusted precisely to Pulse frequency f

the respective application in order to guarantee the

desired difference of the temperature between high- Fig. 2. Arc pressure as a function of the pulse frequency [3],

tungsten electrode: 2,4 mm, 2% thoriated, sharpening

current and low-current phase. According to [2], the

angle of the electrode: 60,

ratio between pulse and basic current (Ip /IG ) should medium amperage: 50 A, current amplitude: 150 A,

be 1.25 - 4. basic current: 5 A, arc length: 2 mm

2000 EWM HIGHTEC WELDING GmbH 1/4 WM008801.DOC; 08.00

penetration TN Arc length lLB

10 kHz

0 Hz

Pulse current IP

Fig. 3. Change of the penetration in TIG welding with pulse

heterodyning of the welding current [3]

1 TN = f (IP), 2 TN = f (LB) 10 kHz, 3 PN = f (LB) 0 Hz Fig. 4b. Arc formation of non-pulsed TIG- welding [4],

IS = 292 A, vS = 2,0 m/min,

While, up to a frequency of about 5 kHz, this effect is shielding gas: 95% Ar + 5% H2

very strong, further frequency increases do only cause

minimal arc-pressure increases. Besides the pulse 2.2 Power sources and equipment

frequency, a growing pulse-current amplitude addi-

tionally reinforces the arc pressure on the molten bath For welding applications, two types of power sources

at the same effective value of the welding current [3]. are available, which are designed for a maximum

This way, both welding parameters, pulse frequency welding current of 500 A and 1000 A respectively,

and pulse-current amplitude, make the arc column fig. 5.

extremely stiff. This stiffness permits to increase the

welding speed. Even at high speeds a continuous

seam with good penetration is formed, fig. 3.

The figures 4a and 4b offer a comparison between the

arc formation of non-pulsed TIG welding and high-

frequency pulsed welding. With non-pulsed TIG weld-

ing, the arc silhouette shows deformations in the op-

posite welding direction, fig. 4b. The 6 kHz-pulsed arc

has a symmetric and more contracted shape, fig. 4a

[4]. In consequence, the arc is more stable.

Fig. 5. High-frequency- TIG- pulsed-welding power source

inverter

TIG 1000 DC

Fig. 4a. Arc formation of high-frequency TIG- pulsed-arc

welding [4],

f = 6 kHz, IP =375 A, Im = 292 A, vS = 2,0 m/min

They have an inverter power module, which is char-

shielding gas: 95% Ar + 5% H2 acterised by high efficiency and insensitivity towards

mains-voltage fluctuations. The pulse parameters are

set via a remote control, fig. 6. It enables the system

to pulse the welding current up to 8 kHz.

2000 EWM HIGHTEC WELDING GmbH 2/4 WM008801.DOC; 08.00

Fig. 7a. Weld formation of high-frequency TIG pulsed-arc welding

of an I-seam [4],

parent metal: 1.4301, t = 2 mm, f = 6 kHz,

Fig. 6. Remote control for high-frequency TIG pulsed welding, IP = 375 A, Im = 292 A, vS = 2,4 m/min, shielding gas:

operating elements 95%Ar + 5%H2, no filler metal

A power source only meets the requirements for opti-

mal current shapes (high, rectangular current pulses),

if it has very good dynamic features. However, this

makes anti-noise measures necessary in order to face

the noise pollution.

Special attention must be paid to the torch. The elec-

trode tip should display low surface roughness to

achieve long life at high current load. Equipping the

water-cooled torch with a gas lense is advisable.

3 Practical experiences and prospects

Areas of application of high-frequency TIG pulsed-arc

welding are continuously-fabricating welding automa-

tions of half-finished products such as tubes, foils and

strips, as well as the fabrication of parts, waste-gas

tubes, bellows or shapes, for instance.

Weldable metals are e.g. low- and high-alloy steels, Fig. 7b. Weld formation of non-pulsed TIG welding of an

nickel-based alloys, copper and titanium alloys and I-seam [4],

parent metal: 1.4301, t = 2 mm,

aluminium-based alloys These different materials re-

IS = 292 A, vS = 1,6 m/min,

quire a careful selection of the shielding gas, since the shielding gas: 95%Ar + 5%H2, no filler metal

thermal flux of the arc is determined by the type and

the composition of the shielding gas [3]. What makes the difference between both methods is

Apart from argon/hydrogen mixtures (95% Ar / 5% H2), the achieved welding speed. The pulse heterodyning

argon/helium mixtures (50% Ar / 50% He) have turned resulted in a 50% increase under identical circum-

out to be suitable. stances. In spite of an identical medium amperage of

Welding experiments have been carried out mainly 292 A, the welding speed during non-pulsed operation

with butt welds, fig. 7a and 7b [4]. The material thick- had to be reduced from 2.4 m/min to 1.6 m/min in

ness was 2 mm. There, considerable differences con- order to achieve complete fusion.

cerning the weld formation could be observed. While a Another high-frequency TIG pulsed-arc welding cycle

concentrated penetration was formed with 6kHz- at a tube of the same material thickness even brought

pulsed arc welding, fig. 7a, the typical TIG penetration about a welding speed of 2.7 m/min,fig. 8.

shape developed in the macrosection, fig. 7b, of non-

pulsed welding.

2000 EWM HIGHTEC WELDING GmbH 3/4 WM008801.DOC; 08.00

Bibliography:

[1] Cui, H. u.a.:

Laserinduziertes Fokussieren des WIG- Lichtbo-

gens.

DVS- Berichte, Band 146, S. 139-143

(Cui, H. and others: Laser-induced focussing of the

TIG arc. DVS reports, volume 146, pp. 139-143)

[2] Killing, U.:

Geeignete Parameter fr das WIG- Impulslichtbo-

genschweien.

Jahrbuch Schweitechnik `94,

Fig. 8. Weld formation of high-frequency pulsed-arc welding

Deutscher Verlag fr Schweitechnik

at a tube; DVS- Verlag GmbH,

parent metal: 1.4301, t = 2 mm, vS = 2,7 m/min, Dsseldorf, 1993, S. 108 - 114

shielding gas: 95% Ar + 5% H2, no filler metal (Killing, U.: Suitable parameters for TIG pulsed-arc

welding. `94 Yearbook of welding technology,

A prerequisite to turn such a technology successfully German

into practice is the integration of power-source tech- publishing house for welding technology

nology, on the one hand, and process technology, on DVS GmbH, Dsseldorf, 1993, pp. 108-114)

the other hand.

The increase of the penetration at the same welding [3] Schellhase, M.:

speed or a higher welding speed at a given throat Der Schweilichtbogen - ein technologisches

opens up areas of application to TIG direct-current Werkzeug.

welding with high-frequency pulses that have been Fachbuchreihe Schweitechnik, Band 84,

restricted to multi-cathode or laser systems so far. The Deutscher Verlag fr Schweitechnik (DVS)

big advantages of this welding process are, above all, GmbH,

its considerably lower costs and the energy savings Dsseldorf, 1985, S.86, 97-99

compared with the previously mentioned systems. . (Schnellhase, M.: The welding arc - a technological

tool. Welding technology book series, volume 84,

DVS GmbH,

Dsseldorf, 1985, pp. 86, 97-99)

[4] Mller, S.:

Untersuchungen zum Hochfrequenz-WIG- Impul-

slichtbogenschweien.

Bericht der Schweitechnischen Lehr- und Ver-

suchsanstalt Fellbach (1997).

(Mller, S.: Examinations into high-frequency TIG

pulsed-arc welding. Report of the Schweitechnis-

che Lehr- und Versuchsanstalt Fellbach, 1997)

2000 EWM HIGHTEC WELDING GmbH 4/4 WM008801.DOC; 08.00

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- SDM, Vol 2 Building Design Examples (LIght Frame, Masonry and Tilt Up)Документ334 страницыSDM, Vol 2 Building Design Examples (LIght Frame, Masonry and Tilt Up)dannychacon27100% (2)

- AISIS400 15 (1stprinting)Документ169 страницAISIS400 15 (1stprinting)Roberto Pérez LeónОценок пока нет

- Astm A 653 Redline PDFДокумент15 страницAstm A 653 Redline PDFNestor GalianoОценок пока нет

- C1513 PDFДокумент4 страницыC1513 PDFByron Paiz AragonОценок пока нет

- CSSBI Tablas de Carga Perfiles PDFДокумент60 страницCSSBI Tablas de Carga Perfiles PDFRamón RocaОценок пока нет

- S213-07-S1-09 Standard and Commentary (Reaffirmed 2012) - eДокумент72 страницыS213-07-S1-09 Standard and Commentary (Reaffirmed 2012) - eEdison Becerra100% (1)

- 6 CatДокумент11 страниц6 CatEduard Yesid Chacon LamusОценок пока нет

- CentSample PDFДокумент20 страницCentSample PDFRamón RocaОценок пока нет

- HandbookДокумент147 страницHandbookkt rajaОценок пока нет

- Kvidahl, Lee G. (Eds.) - Everyday Pocket Handbook For Gas Metal Arc Welding (GMAW) of Aluminum-American Welding Society (AWS) (1998) PDFДокумент30 страницKvidahl, Lee G. (Eds.) - Everyday Pocket Handbook For Gas Metal Arc Welding (GMAW) of Aluminum-American Welding Society (AWS) (1998) PDFiaguirre99Оценок пока нет

- Astm A588 PDFДокумент3 страницыAstm A588 PDFRamón Roca100% (2)

- The Everyday Pocket Handbook On Welded Joint DetailsДокумент30 страницThe Everyday Pocket Handbook On Welded Joint Detailsaqeel5Оценок пока нет

- AISI S210-07 (2012) Standard and Commentary - 2nd Printing - eДокумент28 страницAISI S210-07 (2012) Standard and Commentary - 2nd Printing - eEdison Becerra100% (1)

- AISI S230-07 (2012) Standard and Commentary - eДокумент372 страницыAISI S230-07 (2012) Standard and Commentary - eEdison BecerraОценок пока нет

- Plate and Box Girder DesignДокумент60 страницPlate and Box Girder DesignKrishna ChandranОценок пока нет

- AISI S230-07 (2012) Standard and Commentary - eДокумент372 страницыAISI S230-07 (2012) Standard and Commentary - eEdison BecerraОценок пока нет

- Brocas Dormer 2015 PDFДокумент564 страницыBrocas Dormer 2015 PDFDaniel DonosoОценок пока нет

- Astm c1513Документ4 страницыAstm c1513Ramón RocaОценок пока нет

- Fundamentals of Beam Bracing PDFДокумент16 страницFundamentals of Beam Bracing PDFGautham AllimuthuОценок пока нет

- Asme B18.6.4Документ50 страницAsme B18.6.4Ramón Roca70% (10)

- AISIS240 15 (1stprinting)Документ204 страницыAISIS240 15 (1stprinting)Roberto Pérez LeónОценок пока нет

- AISIS400 15 (1stprinting)Документ169 страницAISIS400 15 (1stprinting)Roberto Pérez LeónОценок пока нет

- Astm A 653 Redline PDFДокумент15 страницAstm A 653 Redline PDFNestor GalianoОценок пока нет

- Cssbi 57Документ69 страницCssbi 57jachoijachoiОценок пока нет

- AISI S210-07 (2012) Standard and Commentary - 2nd Printing - eДокумент28 страницAISI S210-07 (2012) Standard and Commentary - 2nd Printing - eEdison Becerra100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- David EsseiniДокумент10 страницDavid Esseiniশুভ MitraОценок пока нет

- Modernization of Relay ProtectionДокумент5 страницModernization of Relay Protectiontecnologia para el cambioОценок пока нет

- 975 Helukabel Cables-Wires 2012-2013Документ125 страниц975 Helukabel Cables-Wires 2012-2013AbdelRhman ElfkyОценок пока нет

- Data Pengamatan 1. Manual: Hubungan PSV Dengan F1 Hot Pump Setting: 50%Документ42 страницыData Pengamatan 1. Manual: Hubungan PSV Dengan F1 Hot Pump Setting: 50%Sri WahyuniОценок пока нет

- S ParametersДокумент4 страницыS Parametershub23Оценок пока нет

- Sepeaker Aktif POLYTRON PAS 67 - 68Документ3 страницыSepeaker Aktif POLYTRON PAS 67 - 68Waton Rinekso0% (1)

- Micom Alstom P642, P643, P645: Transformer Protection RelayДокумент790 страницMicom Alstom P642, P643, P645: Transformer Protection RelayEAST. KWAK100% (2)

- ABB VD4 Draw-Out MV Breaker TK 520 - EДокумент48 страницABB VD4 Draw-Out MV Breaker TK 520 - EM. ShaatОценок пока нет

- Batch Basics Three Levels Doing Batch System Structure Phase Logic Interface PricingДокумент21 страницаBatch Basics Three Levels Doing Batch System Structure Phase Logic Interface Pricingtricky777Оценок пока нет

- OrCAD Altium Migration Guide PDFДокумент8 страницOrCAD Altium Migration Guide PDFElafanОценок пока нет

- Interpretation of Mass Spectra-4EdДокумент329 страницInterpretation of Mass Spectra-4EdJF Echeverria100% (1)

- CONTACTORESДокумент10 страницCONTACTORESRaúl MendozaОценок пока нет

- ECE357 Course InformationДокумент7 страницECE357 Course InformationVictor HughesОценок пока нет

- Pnwman Feb12Документ194 страницыPnwman Feb12batrarobinОценок пока нет

- Chapter 11 AC ResonanceДокумент20 страницChapter 11 AC ResonanceErin LoveОценок пока нет

- ELEC2142 Week 1 Class NewadditionalДокумент48 страницELEC2142 Week 1 Class NewadditionalJoseph NguyenОценок пока нет

- Amted310010en WebДокумент120 страницAmted310010en WebMemo TipОценок пока нет

- Android Bluetooth Sample CodeДокумент5 страницAndroid Bluetooth Sample CodebhushanhuntОценок пока нет

- Automatic Control Systems - Electronics and Communication Engineering Questions and Answers - 1Документ9 страницAutomatic Control Systems - Electronics and Communication Engineering Questions and Answers - 1Rian RiveraОценок пока нет

- Köhler Illumination: PrinciplesДокумент3 страницыKöhler Illumination: PrinciplesGiovany Marín100% (1)

- Smart MaterialsДокумент1 страницаSmart MaterialsThejas GowdaОценок пока нет

- Graphene Transistors by Frank SchwierzДокумент10 страницGraphene Transistors by Frank SchwierzshreypathakОценок пока нет

- Homework3 Yasser El Mehdi DIBДокумент1 страницаHomework3 Yasser El Mehdi DIBYasser DibОценок пока нет

- Mastering Stm32 SampleДокумент119 страницMastering Stm32 SampleRached Mairchi100% (1)

- ChaptedOPANT dIFFUSION 7 Dopant Diffusion - IДокумент32 страницыChaptedOPANT dIFFUSION 7 Dopant Diffusion - IEbrahim NikОценок пока нет

- Modular Lead Exit - Info SheetДокумент2 страницыModular Lead Exit - Info SheetSunil GurubaxaniОценок пока нет

- LAN DesignДокумент6 страницLAN DesignLeanne RuthОценок пока нет

- Bl6 ManualДокумент175 страницBl6 ManualDelipsy HdzОценок пока нет

- Devices Connected To Your NetworkДокумент1 страницаDevices Connected To Your NetworkSuper WhippedОценок пока нет