Академический Документы

Профессиональный Документы

Культура Документы

Modeling and Simulation of A Gas Turbine Engine For Power Generation

Загружено:

عبد الرحمن ابو علىОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Modeling and Simulation of A Gas Turbine Engine For Power Generation

Загружено:

عبد الرحمن ابو علىАвторское право:

Доступные форматы

Modeling and Simulation of a Gas

Turbine Engine for Power

Generation

The gas turbine engine is a complex assembly of a variety of components that are

designed on the basis of aerothermodynamic laws. The design and operation theories of

these individual components are complicated. The complexity of aerothermodynamic

analysis makes it impossible to mathematically solve the optimization equations involved

in various gas turbine cycles. When gas turbine engines were designed during the last

century, the need to evaluate the engines performance at both design point and off design

conditions became apparent. Manufacturers and designers of gas turbine engines became

aware that some tools were needed to predict the performance of gas turbine engines

Qusai Z. Al-Hamdan especially at off design conditions where its performance was significantly affected by the

Air Force Engineering Branch, load and the operating conditions. Also it was expected that these tools would help in

Royal Jordanian Air Force, predicting the performance of individual components, such as compressors, turbines,

Amman, Jordan combustion chambers, etc. At the early stage of gas turbine developments, experimental

e-mail: qusai@go.com.jo tests of prototypes of either the whole engine or its main components were the only

method available to determine the performance of either the engine or of the components.

Munzer S. Y. Ebaid However, this procedure was not only costly, but also time consuming. Therefore, math-

Head of Scientific Research Department, ematical modelling using computational techniques were considered to be the most eco-

King Abdullah II Design and Development Bureau nomical solution. The first part of this paper presents a discussion about the gas turbine

(KADDB), modeling approach. The second part includes the gas turbine component matching be-

Amman, Jordan tween the compressor and the turbine which can be met by superimposing the turbine

performance characteristics on the compressor performance characteristics with suitable

transformation of the coordinates. The last part includes the gas turbine computer simu-

lation program and its philosophy. The computer program presented in the current work

basically satisfies the matching conditions analytically between the various gas turbine

components to produce the equilibrium running line. The computer program used to

determine the following: the operating range (envelope) and running line of the matched

components, the proximity of the operating points to the compressor surge line, and the

proximity of the operating points at the allowable maximum turbine inlet temperature.

Most importantly, it can be concluded from the output whether the gas turbine engine is

operating in a region of adequate compressor and turbine efficiency. Matching technique

proposed in the current work used to develop a computer simulation program, which can

be served as a valuable tool for investigating the performance of the gas turbine at

off-design conditions. Also, this investigation can help in designing an efficient control

system for the gas turbine engine of a particular application including being a part of

power generation plant. DOI: 10.1115/1.2061287

1 Modeling of Gas Turbine Components mathematical model for each component was created using physi-

cal laws or emphrical data when available. The thermodynamic

Aero-derivative and industrial gas turbine engines are used for

properties of combustion gases and air at various stages through-

a variety of applications, such as electrical power generation, driv- out the gas turbine are calculated by considering variation of tem-

ing pumps, compressors on gas and liquid fuels, etc. The engine perature or instead universal gas constant R can be used since

configuration may vary to suit the application. The common con-

R is temperature independent.

figurations are a single-, twin-, or triple-spool construction or a

Tables containing the values of the specific heats against tem-

single-stage or multistage construction. In this study only the gas

perature variation have been published in many references, such

turbines used for electrical power generation are considered. as Chappel and Cockshutt 1. In the present work, to compute the

A gas turbine engine essentially consists of the following com- values of specific heats at constant pressure and various tempera-

ponent parts: i intake, ii compressors, iii combustion cham- tures for air and combustion gases, data from the tables were fitted

bers, iv turbines, and v engine auxiliaries, such as fuel with polynomial curves to obtain Eqs. 15. These equations

pump, lubrication pump, electrical power supply, starting gear, provide details of the polynomials. Here, Ta and Tg refer to the

and control system. A block diagram of the gas turbine engine average temperatures during the compression and expansion pro-

showing these components is given in Fig. 1. cesses in the compressor and turbine, respectively.

Overall performance of the complete gas turbine engine is For air at the low-temperature range of 200 800 K,

mainly determind by the main components i, ii, iii, and iv. The

CPa = 1.0189 103 0.13784Ta + 1.9843 104T2a + 4.2399

Contributed by the Gas Turbines Electric Power of the International Gas Turbine

Institute of ASME for publication in the JOURNAL OF ENGINEERING FOR GAS TURBINES 107T3a 3.7632 1010T4a 1

AND POWER. Manuscript received February 22, 2004; final manuscript received April

27, 2005. Review conducted by S. van der Linden. For air at the high-temperature range of 800 2200 K,

302 / Vol. 128, APRIL 2006 Copyright 2006 by ASME Transactions of the ASME

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/ on 05/11/2013 Terms of Use: http://asme.org/terms

Table 1 Dimensionless compressor parameters

Fig. 1 Schematic diagram of simple gas turbine engine

CPa = 7.9865 102 + 0.5339Ta 2.2882 104T2a + 3.7421

108T3a 2

For specific heats of products of combustion,

C Pg = CPa + f/1 + fBT 3

where BT at the low-temperature range of 200 800 K, termined easily.

The final stagnation temperature in the compression process To2

BT = 3.59494 102 + 4.5164Tg + 2.8116 103T2g 2.1709 can be calculated from the following equation:

105T3g + 2.8689 108T4g

and BT at high-temperature range of 800 2200 K,

1.2263 1011T5g 4

To2 = To1 +

To1

c

Po2

Po1

a1/a

1 9

BT = 1.0888 103 0.1416Tg + 1.916 103T2g 1.2401 In order to solve Eqs. 69 the needed input data can be ob-

tained from the compressor performance map. This may require

106T3g + 3.0669 1010T4g 2.6117 1014T5g 5 interpolation and will be dealt with in the section dealing with

computer simulation.

1.1 Compressor Modeling and Analysis. The performance

of a compressor is fully described by a number of dimensionless 1.2 Combustion Chamber Modeling and Analysis. The

parameters. The dimensionless parameters would be the same for combustion chamber performance is normally given in terms of

every system of units. The dimensionless parameters are shown in combustion efficiency cc and the factor for the loss of stagnation

Table 1. pressure cc. Using these parameters the fuel/air ratio F and the

Compressor performance, sometimes called compressor map, is stagnation pressure at the exit of the combustion chamber Po3 can

usually represented by overall performance characteristics as be determined from Eq. 10 and 11. However, there are many

shown in Fig. 2. These maps are in general, obtained experimen- good programs that provide a more accurate determination of F,

tally but sometimes they can be predicted with reasonable accu- such as the NASA chemical equilibrium program of Gordon and

racy using geometric properties of the components, i.e., intake, McBride 5.

impeller, diffuser, and casing 24. 1

Mathematically, the compressor performance is described using F= 10

the dimensionless parameters as given below ccLCV

1

C PgTo3 To2

c

=

1 1

d22 Po1 2 c

d 2N

CPaTo1

1

aCPaTo1

m

d22 Po1

Po2

Po1

a1/a

1

c

N m

= f c, ,

a Po2

Po1

, 7

Equation 6 is in complete dimensionless form, and Eq. 7 is the

general form.

The compression power Wc is given by

Wc = d22 Po1CPaTo1

aCPaTo1 1

m

d22 Po1 c

Po2

Po1

a1/a

1 8

Using the compressor characteristics, if any two dimensionless

parameters are known then the rest of the parameters can be de- Fig. 2 General compressor characteristics map

Journal of Engineering for Gas Turbines and Power APRIL 2006, Vol. 128 / 303

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/ on 05/11/2013 Terms of Use: http://asme.org/terms

Table 2 Dimensionless turbine parameters t

d22 Po3

=

1

2

t

d 2N

C PgTo3

1

gC PgTo3

m

d22 Po3

1

Po4

Po3

g1/g

12

t

N m

= f t, ,

g Po3

, Po4 13

Equation 12 is in complete dimensionless form, and Eq. 13 is

the general form.

The expansion power Wt and the final stagnation temperature

To4 in the expansion process are calculated using Eqs. 14 and

15, respectively.

Wt = d22 Po3C PgTo3

gC PgTo3

m

d22 Po3

P

t 1 o4

Po3

g1/g

14

To4 = To3 To3t 1

Po4

Po3

g1/g

15

2 Component Matching

Considering a simple gas turbine used for electrical power gen-

eration application schematically shown in Fig. 1. The perfor-

mance of the compressor and the turbine are known by their char-

acteristics maps as shown in Figs. 2 and 3. In this gas turbine

engine, the components matching should meet the following con-

Po3 = 1 ccPo2 11 ditions:

1.3 Turbine Modeling and Analysis. The performance char- i. The compressor shaft speed equals the turbine shaft speed,

acteristics of a turbine, such as those of a compressor, are fully Nc = Nt = N

described by a number of dimensionless parameters. These param-

eters and their corresponding meanings are tabulated in Table 2 ii. The gas mass flow through turbine is of the sum the air

611. mass flow through compressor and the fuel mass flow,

The turbine performance is represented by overall performance g=m

m a+m

f

characteristics, also known as turbine map as shown in Fig. 3.

This map is in general obtained experimentally but it can also be iii. Assuming that the pressure loss in the combustion cham-

predicted with reasonable accuracy by using geometric properties ber is a constant small percentage cc of the combustion

and on the basis of previous experience 24. chamber inlet pressure,

In the current work, turbine cooling has not been accounted for Po3 = 1 ccPo2

and will be taken into consideration in future work. Using the

turbine characteristics, if any two dimensionless parameters are iv. Assuming that the pressure loss in the compressor Inlet is

known then the rest of the parameters can be determined easily. a constant small percentage c of the atmospheric pres-

Mathematically, the turbine performance is described using the sure.

dimensionless parameters as follows:

Po4 = 1 cPo2 Po1

v. Power flows, also, in balance.

It should be noted that the second condition is subject to modi-

fication in that it is common practice to bleed air from the com-

pressor at various stations to provide cooling air for bearings and

turbine blade cooling. Quiet often it is sufficiently accurate to

assume that the bleed air equals the fuel flow, and therefore, the

mass flow is the same throughout the compressor and the turbine,

i.e., m a=m

g=m .

The steady-state or equilibrium operation of this gas turbine

engine can be achieved by the matching of its compressor and

turbine. Matching the compressor and the turbine can be done by

superimposing the turbine performance map on the compressor

map while meeting the components matching conditions. This

matching procedure is schematically shown in Fig. 1.

Superimposing the turbine performance map on the compressor

map can be achieved by applying Refs. 24 or by applying the

new approach of making both maps axes the abscissa and the

ordinate being identical. The main difficulty here is that of tem-

peratures: To1 for the compressor and To3 for the turbine. The

problem was solved by introducing a new dimensionless matching

Fig. 3 Turbine Characteristics Map parameter m N / d2c Po1 as presented in Sec. 2.1.

304 / Vol. 128, APRIL 2006 Transactions of the ASME

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/ on 05/11/2013 Terms of Use: http://asme.org/terms

2.1 The Compressor. The abscissa of the compressor char-

acteristics, i.e., the mass flow parameter is, m aCpaTo1 / d22c Po1.

The matching parameter m N / d2c Po1 was obtained by multiply-

ing the mass flow parameter with the dimensionless speed param-

eter d2cN / CpaTo1 as follows:

aCpaTo1

m

d22c Po1

d2cN

CpaTo1

=

mN

d2c Po1

16

Fig. 5 a Centrifugal pump in fluid-flow diagram, and b Pos-

sible information-flow blocks representing pump

The ordinate, i.e., the pressure ratio parameter Po2 / Po1, remains

unchanged. Once these transformations had been made, the com-

pressor characteristics map was plotted again where Po2 / Po1 as

This study concentrates on the second purpose. The perfor-

the ordinate and m N / d2c Po1 as the abscissa.

mance of the gas turbine plant at off-design conditions would

2.2 The Turbine. The abscissa of the turbine characteristics, always be of interest where the gas turbine simulation program for

i.e., the mass flow parameter is m gC pgTo3 / d22 Po3. The matching this purpose. This simulation may pin-point the cause of operating

parameter m gN / d2c Po4 was obtained by multiplying this param- problems or shows how the effectiveness of the gas turbine plant

eter with the dimensionless speed parameter, turbine pressure ra- may be improved.

tio, and the ratio of the turbine rotor diameter to compressor im- Essentially, transient operation of a gas turbine plant is more

peller diameter as follows: difficult than the steady-state operation of a gas turbine plant. That

field of study was considered to be outside the scope of present

gC pgTo3

m d2tN Po3 d2t gN

m paper.

2 =

d2t Po3 C pgTo3 Po4 d2c d2c Po4 3.1 Information-Flow Diagrams. For system simulation,

17 fluid-flow and energy-flow diagrams are standard engineering

tools. An equally useful tool is the information-flow diagram, for

To satisfy the compressor-turbine matching conditions specified example, a block diagram of a control system is an information-

g=m

previously, i.e., m and Po4 Po1. Then the matching pa-

a=m flow diagram wherein a block signifies that an output can be cal-

rameter of the turbine is equal to the matching parameter of the culated when the input is known. A centrifugal pump might ap-

compressor, i.e., pear in a fluid-flow diagram, such as shown in Fig. 5a, while in

the information-flow diagram the blocks shown in Fig. 5b. These

gN

m aN

m

= figures represent functions or expressions that permit calculation

d2c Po4 d2c Po1 of the outlet pressure for one block and the flow rate for the other.

For the turbine pressure ratio parameter, the ordinate axis of the A block, as in Fig. 5b, is called a transition function and may be

turbine characteristics map P03 / P04 for matching is developed an equation or may be tabular data to which interpolation would

into be applicable.

Figure 5 shows only one component. To illustrate how these

Po3 1 Po4 Po2 individual blocks can build the information-flow diagram for a gas

= 13 turbine plant, consider the simple gas turbine cycle in Fig. 1

Po4 1 cc Po1 Po1

shown earlier. The components in this cycle are the compressor,

Note that Po3 = 1 ccPo2 and Po4 Po1. the combustion chamber and the turbine.

Once these transformations had been made, the turbine charac- The information-flow diagram is arranged in Fig. 6 in a manner

teristics map was plotted again in terms of these new parameters that might be used if the net power output Wnet was to be calcu-

using Eqs. 17 and 18. lated for the system with a given rate of fuel mass flow rate, i.e.,

heat input at the combustion chamber. Further input information

includes the ambient conditions To1, Po1 and rotational speed N.

3 Gas Turbine Computer Simulation The compressor block diagram signifies that when the rota-

tional speed Nc, inlet pressure Po1, inlet temperature To1, and air-

A computer program for simulating a gas turbine engine would flow rate m a are specified, the outlet pressure Po2 and the com-

basically satisfy matching conditions analytically between the pressor efficiency c can be determined from the compressor

various components to produce the equilibrium running line. Rep- characteristics map as shown previously in Fig. 2 furthermore,

resenting this line either in the form of lookup tables or an equa- power Wc required by the compressor and outlet temperature To2

tion is known as modeling and solving that equation with the help can be calculated from Eqs. 8 and 9, respectively.

of a computer is computer simulation such that all energy and The combustion chamber block diagram signifies that when the

mass balances, all equations of state of working substances, and fuel flow rate m f , inlet temperature To2, and inlet pressure Po2 are

the performance characteristics of all components are satisfied. specified, the outlet pressure Po3 and the outlet temperature To3

Testing of the gas turbine engine is expensive and time consum- can be calculated from Eqs. 10 and 11, respectively.

ing. Therefore, simulation can be an economic and fast tool for The turbine block diagram signifies that when the rotational

predicting its performance. The simulation of the gas turbine en- speed Nt, inlet pressure Po3, inlet temperature To3, and gas flow

gine can be one of the following:

rate m g are specified, the outlet pressure Po4 and the turbine effi-

1. simulation at the design stage where no real gas turbine ciency t can be determined from the turbine characteristics map

engine to meet the design specifications yet exists as shown previously in Fig. 3. Furthermore, power Wt delivered

2. simulation at the application stage where engine is already by the turbine and outlet temperature To4 can be calculated from

constructed Eqs. 14 and 15, respectively.

3. simulation at the application stage where the generation of Sometimes the arrangement of the system permits a direct nu-

design data for additional or auxiliary equipment, such as merical calculation for the first component of the system using

Lube oil requirements, blow off valve requirements, and input information. The output information for this first component

limitations for transformers, etc., are needed is all that is needed to calculate the output information of the next

4. simulation for performance extrapolation of existing plant to component and so on to the final component of the system whose

meet higher output requirements output is the output information of the system. Such a system

Journal of Engineering for Gas Turbines and Power APRIL 2006, Vol. 128 / 305

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/ on 05/11/2013 Terms of Use: http://asme.org/terms

Fig. 7 Problems with reading compressor maps

to determine the values of the performance parameters for

any selected point on the performance map

iii. using a neural network technique to teach the computer

the pattern of the compressor characteristics then comput-

ing the performance parameters for any selected point on

the performance map

In the present work, the second option was chosen as it pro-

duced a more reliable estimate of the parameters at any point on

the component characteristics map.

3.2 Representation of Compressor and Turbine Maps in

the Computer Program. The compressor or turbine characteris-

tics in the standard format as shown in Figs. 2 and 3 cannot be

Fig. 6 Information flow diagram of a simple gas turbine engine used directly in the computer program; they require some process-

ing to convert the maps into a good numerical representation.

There are many problems and difficulties associated with the nu-

merical representation process.

simulation consists of sequential calculations.

Before starting the design of the computer program for simula- 3.3 Representation of Compressor Maps in the Computer

tion purposes, it was necessary to identify its main features. Those Program. It is not possible to read the compressor map param-

features are summarized as follows: eters with given speed NDim and pressure ratio Po2 / Po1, as there

might be two values for the mass flow parameter m Dim at given

i. The computer simulation should allow the user to simulate

pressure ratio see point A in Fig. 7.

components individually or as a complete plant.

ii. The simulation program should be modeled for the linking It is also not possible to determine the efficiency c from the

with another program to finally simulate the CPP plant. compressor map with given speed NDim and mass flow parameter

The outputs of this computer program should contain the m Dim, because at some parts of the compressor map the speed

needed parameters to start simulating the steam power lines can be vertical. Hence, there might be two values for the

plant. pressure ratio Po2 / Po1 at a single value of mass flow parameter

iii. The simulation program should be modular so that various m Dim see point B in Fig. 7.

modules may be assembled to represent different gas tur- Introducing a new coordinates, here called the BETA 4

bine plant configurations. lines, was the solution for this problem. This allowed an indepen-

iv. The simulation program should be user friendly and writ- dent map reading using the shape of the parameter lines with the

ten in such manner that data can be transferred from one line and speed parameter NDim.

module to another easily and efficiently. The auxiliary coordinates lines can be selected arbitrarily

with only two conditions. First, there are no intersections between

To produce a running line, analytically, the computer simulation the lines within the range of interest, and second, the lines are

program will use the components mathematical models and the equally spaced. The lines will have any numbers of lines with

components characteristics. That running line will be essential to each line has a parameter number starting from 1. The lines can

compute the various gas turbine performance parameters. be a parabolic lines or straight lines straight lines are special

In order to use these maps in a computer program it was nec- parabolic lines.

essary to have them in a special form. This form can take one of Three-dimensional look-up tables Tables 35 were created to

the following shapes: represent the compressor characteristics. These tables represented

i. deriving an equation to describe the performance of the the mass flow parameter m Dim versus rotational speed parameter

component and solving this equation to calculate the per- NDim, the pressure ratio Po2 / Po1 versus rotational speed parameter

formance parameters for any selected point on the perfor- NDim and the compressor efficiency c versus rotational speed

mance map parameter NDim.

ii. storing the compressor characteristics in look-up tables If the values of any parameter with line parameter are speci-

and then using an interpolation or extrapolation technique fied, the program searches and picks the other two parameters

306 / Vol. 128, APRIL 2006 Transactions of the ASME

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/ on 05/11/2013 Terms of Use: http://asme.org/terms

Table 3 Mass flow parameter versus rotational speed Table 6 Pressure ratio versus mass flow parameter of the

parameter compressor surge line

maps into tabulated data. This can be seen clear in Fig. 3, where at

from these look-up tables. The other problem with the numerical the chocking condition and same speed parameter, more than one

representation of the compressor map is the surge line. One or pressure ratio results from the same dimensionless mass flow

both of the following can achieve the solution to this problem: parameter.

Three-dimensional look-up tables, as in the compressor case,

i. deriving an equation to describe surge line and solving this have been developed and used to represent the turbine character-

equation to check if the points are beyond the surge line istics. These tables have the same forms as those of the compres-

ii. storing the surge line in look-up table and then use an sor characteristics shown in Table 6. In these tables, linear inter-

interpolation or extrapolation technique to check if the polation technique was also used to compute the values lying at

points are beyond the surge line intermediate points.

Either one of the two solutions can be efficient. In this program 3.5 Computer Simulation Program. The computer simula-

the second method was used for maintaining the consistency of tion program uses the components models based on either math-

the whole program Table 6 shows the pressure ratio Po2 / Po1 ematical equations or performance characteristics to achieve

versus mass flow parameter m Dim of the surge line. matching between the various components in the gas turbine

plant. This matching produces the engine equilibrium running

A linear interpolation technique was used to estimate the pa- line. The equilibrium running line can be used to calculate the

rameters values lying at intermediate points. This method of in- different gas turbine performance parameters.

terpolation is followed in most books of numerical analysis. The principal advantages of gas turbine simulation program

would be as follows

3.4 Representation of Turbine Maps in the Computer

Program. As in the compressor case, the lines must be intro- 1. The computer simulation program can help in investigating

duced to the turbine maps to solve the problem of converting the the effects of the components performance characteristics on

the performance of the complete engine. This investigation

can be carried out at the design stage without bearing the

cost of manufacturing and testing an expensive prototype.

Table 4 Pressure ratio versus rotational speed parameter

2. The conceptual designs of the engine can be studied and the

choice of particular concept can be made to suit the specified

operational requirements.

3. The matching of the components can be explored for the

design, off-design, and transient conditions.

4. The simulation program can serve as a valuable tool for

investigating the performance of the gas turbine at off-

design conditions. This investigation can help in designing

an efficient control system for the gas turbine engine for a

particular application, such as being a part of the combined

power and power CPP plant.

The information flow diagram for the simple gas turbine cycle

shown in Fig. 6 was used to create a computer simulation pro-

Table 5 Compressor efficiency versus rotational speed gram. The flow chart for the program logic is shown in Fig. 8. The

parameter program is also suitable for dealing with the simulation of other

configurations. But for the sake of brevity the flow charts for each

configuration have been omitted.

4 Results and Discussion of Modeling, Matching, and

Simulation

The output of the new methodology presented in this work is

illustrated graphically in Figs. 9 and 10, which show complete

typical performance characteristics of a centrifugal compressor

and complete typical performance characteristics of a radial tur-

bine 3, respectively.

In order to match the turbine with the compressor, Figs. 9 and

10 have to be reproduced by introducing the matching parameter

Journal of Engineering for Gas Turbines and Power APRIL 2006, Vol. 128 / 307

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/ on 05/11/2013 Terms of Use: http://asme.org/terms

Fig. 10 Complete performance characteristics of a radial tur-

bine 3

Superimposing Fig. 11 on Fig. 12 produces the complete

matching characteristics of the gas turbine performance as de-

picted in Fig. 13. At any point within the matching range the

following parameters can be computed as given in Table 7.

The turbine inlet temperature To3 lines of 650 and 1400 K were

computed and drawn in Fig. 13. It can be seen that the changes of

constant To3 lines at various pressure ratios are linear and showed

Fig. 8 Computer simulation flowchart

m N / d2c Po1. The transformation is shown in Figs. 11 and 12. For

the compressor it is worth noting that the constant speed lines

were shifted apart, nevertheless the trends stay the same. For the

turbine, the trend of the constant speed lines has changed. The

reason is because the turbine inlet temperature To3 is not constant

along any constant speed line while for the compressor case; the

compressor inlet temperature To1 is constant.

Fig. 11 Transformed performance characteristics of centrifu-

gal compressor

Fig. 9 Complete performance characteristics of a centrifugal Fig. 12 Transformed performance characteristics of radial

compressor 3 turbine

308 / Vol. 128, APRIL 2006 Transactions of the ASME

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/ on 05/11/2013 Terms of Use: http://asme.org/terms

Fig. 13 Complete matching characteristics of the gas turbine

performance

divergence at higher values of speed and pressure ratios. The area

between these two lines represents the accepted working range for

the gas turbine engine.

For a power generation driven by a gas turbine engine, let us

consider any running line, for example, a speed of 42,000 rpm.

For clearity, part of this running line enclosed by a rectangular Fig. 14 Matching characteristics at running line of 42,000 rpm

box in Fig. 13 was enlarged to produce Fig. 14. Based on the

graphical analysis, the above parameters can be calculated within

the specified working range. The output results are given in Tables a constant speed of 42,000 rpm. It can be noted that the variation

8 and 9. of torque and net power output is linear and increases at a constant

Using the results in Tables 8 and 9, the relationship between rate.

thermal efficiency and specific fuel consumption with the net

power output are drawn in Fig. 15. It shows that the maximum

thermal efficiency of 17.57% is attained, which corresponds to a 5 Closure

net power output of 228 kW and minimum specific fuel consump- Modeling, matching, and simulation of a gas turbine engine for

tion of 0.3327 kg/ kW. hr. power generation has been presented. A computer program for

Note that the low thermal efficiency is due to the fact that this simulating a gas turbine engine has been developed that can sat-

selected gas turbine engine has a pressure ratio r of 4 and tur- isfy the necessary matching conditions analytically and, thus,

bine inlet temperature To3 of 1000 K. achieve matching between the various components in order to

Figure 16 shows that the gas mass flow rate is decreasing with produce the equilibrium running line. Representing the data for

an increasing net power output. At the same time the gas exhaust this line either in the form of lookup tables or an equation is

temperature is increasing under the same condition. This can be known as modeling; solving that equation with the help of a com-

explained because the turbine is considered a constant volumetric puter is computer simulation. Thus, modeling and simulation to-

flow component. Increasing the turbine work output at constant gether satisfy all energy and mass balances, all equations of state

speed can be achieved by raising the turbine inlet temperature To3. of the working fluids, and the performance characteristics of all

In order to accommodate the same amount of volumetric mass components.

flow at this higher To3, the mass flow rate must decrease. Conse-

quently, the gas exhaust temperature increases.

Figure 17 shows the variation of temperatures To2, To3, and To4 Table 8 Calculated parameters within the specified working

with the net power output. It can be seen that the variation of To2 range of 42,000 rpm

is fairly small because To2 depends on the compressor pressure

ratio and within the working range of the constant speed of

42,000, the pressure ratio variation is small see Fig. 14.

Figure 18 shows the relationship between the turbine and com-

pressor torque with net power output of the gas turbine engine at

Table 7 Gas turbine parameters

Journal of Engineering for Gas Turbines and Power APRIL 2006, Vol. 128 / 309

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/ on 05/11/2013 Terms of Use: http://asme.org/terms

Table 9 Calculated parameters within the specified working

range of 42,000 rpm

Fig. 17 Variation of various temperatures at 42,000 rpm

The results of component matching, modeling, and simulation

are presented in this paper and lead to the following concluding

remarks: ii. Matching technique can be used to determine the follow-

i. Matching conditions between the compressor and the tur- ing:

bine may be met by superimposing the turbine perfor- the operating range envelope and running line of the

mance characteristics on the compressor performance matched components

characteristics with suitable transformation of the coordi- the proximity of the operating points to the compressor

nates. surge line

the maximum operating point at the maximum turbine

inlet temperature To3

most importantly, from the figures whether the gas tur-

bine engine is operating in a region of adequate compres-

sor and turbine efficiencies

iii. A computer program has been written for simulating a gas

turbine engine. This program basically satisfies the match-

ing conditions analytically between the various compo-

nents to produce the equilibrium running line. Hence, it

can serve as a very useful tool for simulating gas turbine

engines. The principal advantages of the gas turbine simu-

lation program are summarized as follows:

The computer simulation program can help in investigat-

ing the effects of the components performance charac-

teristics on the performance of the complete engine. This

investigation can be carried out at the design stage with-

Fig. 15 Variation of thermal efficiency and specific fuel con- out bearing the cost of manufacturing and testing an ex-

sumption at 42,000 rpm

pensive prototype.

Fig. 16 Variation of exhaust flow and temperature at

42,000 rpm Fig. 18 Variation of torque values at 42,000 rpm

310 / Vol. 128, APRIL 2006 Transactions of the ASME

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/ on 05/11/2013 Terms of Use: http://asme.org/terms

The conceptual designs of the engine can be studied, and Subscripts

the choice of a particular concept can be made to suit the 1,2,3 state points in the cycles

specified operational requirements. gt gas turbine

The matching of the components can be explored for the s isentropic

design, off-design, and transient conditions. o stagnation

The simulation program can serve as a valuable tool for g gas

investigating the performance of the gas turbine at off- a air

design conditions. This investigation can help in design- c compressor

ing an efficient control system for the gas turbine engine t turbine

of a particular application, including being identical to cc combustion chamber

the combined power and power CPP plant.

Superscript

Acknowledgment Rate

The authors are especially thankful to Professor F.S Bhinder for

his guidance and valuable contribution. The authors would also References

like to thank the Royal Jordanian Air Force and King Abdullah II 1 Chappel, M. S., and Cockshutt, E. P., 1974, Gas Turbine Cycle Calculations:

Design & Development Bureau for their endless support and en- Thermodynamic Data Tables for Air and Combustion Products for Three Sys-

tems of Units, NRC No.14300, Ottawa.

couragement, and the University of Hertfordshire for its coopera- 2 Cohen, H., Rogers, G. F. C., and Saravanamuttoo, H. I. H., 1996, Gas Turbine

tion and help throughout this research program. Theory, 4th Edition, Longman, London.

3 Ainley, D. G., and Mathieson, G. C. R., 1957, A Method of Performance

Estimation for Axial-Flow Turbines, Aeronautical Research Council.

Nomenclature 4 Kurzke, J., 1996, How to Get Component Maps for Aircraft Gas Turbine

CP specific heat at constant pressure Performance Calculations, ASME paper 96-GT-164.

5 Gordon, S., and McBride, B., 1994, Computer Program for Calculation of

CV specific heat at constant volume Complex Chemical Equilibrium Compositions and Applications NASA Refer-

ratio of specific heats ence Publication 1311, Vols. I and II, Lewis Research Center, Cleveland, Ohio.

m mass flow rate 6 Walsh, P., and Fletcher, P., 1998, Gas Turbine Performance, 1st Edition,

Blackwell Science Ltd., London, pp. 175185, 200, 215.

w,W specific work output, work output 7 Bhinder, F. S., and Mango, O. I. K., 1995, A Parametric Study of the Com-

P pressure bined Power and Power CPP Plant for Generating Electricity, ASME Turbo

T temperature Cogeneration. Vienna.

r pressure ratio 8 Horlock, J. H., 1997, Aero-Engine Derivative Gas Turbines for Power Gen-

eration: Thermodynamic and Economic Perspectives, ASME J. Eng. Gas Tur-

efficiency bines Power, 1191, pp. 119123.

LCV lower calorific value 9 Horlock, J. H., 1995, Combined Power Plants: Past, Present and Future,

torque ASME J. Eng. Gas Turbines Power, 1174, pp. 608616.

F fuel-to-air ratio, function 10 Cerri, G., 1987, Parametric Analysis of Combined Gas-Steam Cycles,

ASME J. Eng. Gas Turbines Power, 1091, pp. 4655.

pressure loss in combustion chamber 11 Harman, R. T. C., 1981, Gas Turbine Engineering, First Edition, Macmillan

d diameter Press Ltd., London, UK.

Journal of Engineering for Gas Turbines and Power APRIL 2006, Vol. 128 / 311

Downloaded From: http://gasturbinespower.asmedigitalcollection.asme.org/ on 05/11/2013 Terms of Use: http://asme.org/terms

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Mechanical 5th Sem SyllabusДокумент21 страницаMechanical 5th Sem SyllabusVikram KumarОценок пока нет

- Valuation Primer for Compression Equipment ConferenceДокумент64 страницыValuation Primer for Compression Equipment ConferenceMayra Ayus VargasОценок пока нет

- Jet Engines: What Is A Jet Engine?Документ4 страницыJet Engines: What Is A Jet Engine?mrana_56100% (1)

- 6-Aircraft PropulsionДокумент32 страницы6-Aircraft PropulsionNeeraj K GahlotОценок пока нет

- Journal of Engineering For Gas Turbines and Power 2005.Vol.127.N2Документ226 страницJournal of Engineering For Gas Turbines and Power 2005.Vol.127.N2Ivan YurkoОценок пока нет

- Issue 67 FullДокумент108 страницIssue 67 FullMariano Salomon PaniaguaОценок пока нет

- Massachusetts Institute of Technology 2.006 Thermal-Fluids Engineering IIДокумент5 страницMassachusetts Institute of Technology 2.006 Thermal-Fluids Engineering IIMH MerhiОценок пока нет

- ATS 2010 GE MS6001B Sample Borescope Inspection ReportДокумент47 страницATS 2010 GE MS6001B Sample Borescope Inspection ReportThanapaet RittirutОценок пока нет

- Ger 3767c Single Shaft Combined Cycle Power Generation SystemДокумент22 страницыGer 3767c Single Shaft Combined Cycle Power Generation SystemSujeet Kumar100% (1)

- AC Eng CTRL & MNTRG - IntroДокумент2 страницыAC Eng CTRL & MNTRG - Intropotus09Оценок пока нет

- Experiment 1 - Orifice and Jet Flow MeterДокумент36 страницExperiment 1 - Orifice and Jet Flow MeterKim Lloyd A. BarrientosОценок пока нет

- CHAPTER 3 Turbine EnginesДокумент43 страницыCHAPTER 3 Turbine EnginesJP DavidОценок пока нет

- Plant Layout-CompressorsДокумент19 страницPlant Layout-Compressorshalder_kalyan9216Оценок пока нет

- Consensus On Operating Practices For Control of Water and Steam Chemistry in Combined Cycle and Cogeneration Power PlantsДокумент65 страницConsensus On Operating Practices For Control of Water and Steam Chemistry in Combined Cycle and Cogeneration Power Plantssha2sala100% (1)

- Cost Development Guidelines: PJM Manual 15Документ6 страницCost Development Guidelines: PJM Manual 15Mohamed Bin IerousОценок пока нет

- Low Load Operational Flexibility For Siemens G-Class Gas TurbinesДокумент17 страницLow Load Operational Flexibility For Siemens G-Class Gas TurbinesthryeeОценок пока нет

- THERMAL ENGINEERING QUESTION BANKДокумент12 страницTHERMAL ENGINEERING QUESTION BANKbharath devasothОценок пока нет

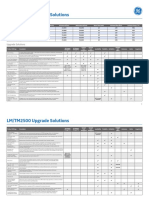

- LM TM2500 Upgrade Solutions PDFДокумент2 страницыLM TM2500 Upgrade Solutions PDFLibyanManОценок пока нет

- Power Plant Numerical ProblemsДокумент3 страницыPower Plant Numerical ProblemsRishav niroulaОценок пока нет

- Ge 6faДокумент1 страницаGe 6faAnish DonaldОценок пока нет

- The Case of Iran's Gas Turbine Industry PHD ThesisДокумент296 страницThe Case of Iran's Gas Turbine Industry PHD Thesismohmehr100% (1)

- (25452835 - Transactions On Aerospace Research) Infrared Signature Suppression Systems in Modern Military Helicopters PDFДокумент21 страница(25452835 - Transactions On Aerospace Research) Infrared Signature Suppression Systems in Modern Military Helicopters PDFBharat SatyakumarОценок пока нет

- 10.1115 - 93 GT 181Документ5 страниц10.1115 - 93 GT 181ali aОценок пока нет

- Aeroderivative Gas Turbine Analysis and TestДокумент4 страницыAeroderivative Gas Turbine Analysis and TestJorge Mario RodriguezОценок пока нет

- HiTEC-580 PDSДокумент2 страницыHiTEC-580 PDSmxk145Оценок пока нет

- Seminar Report On "Turbocharger and Performances of IC Engines" Submitted To TheДокумент24 страницыSeminar Report On "Turbocharger and Performances of IC Engines" Submitted To TheTejas UpadhyeОценок пока нет

- Combustor Tuning AbstractДокумент2 страницыCombustor Tuning AbstracthiemvaneziОценок пока нет

- (Catalog - Microturbine) ABB 22-30 M624Документ9 страниц(Catalog - Microturbine) ABB 22-30 M624ppourmoghaddamОценок пока нет

- GEK106881-MS6001 Starting System Detroit Diesel EngineДокумент8 страницGEK106881-MS6001 Starting System Detroit Diesel EnginekuldeepОценок пока нет

- ISO Parts - Bell Helicopter Catalog by NSN PDFДокумент33 страницыISO Parts - Bell Helicopter Catalog by NSN PDFEagle1968Оценок пока нет