Академический Документы

Профессиональный Документы

Культура Документы

Curtain Wall

Загружено:

jitenderaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Curtain Wall

Загружено:

jitenderaАвторское право:

Доступные форматы

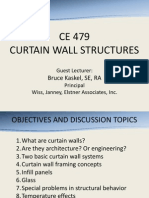

CURTAIN WALL

A curtain wall system is an outer covering of a building in which the outer walls are non-structural, but merely keep

the weather out and the occupants in. As the curtain wall is non-structural it can be made of a lightweight material

reducing construction costs. When glass is used as the curtain wall, a great advantage is that natural light can

penetrate deeper within the building. The curtain wall faade does not carry any dead load weight from the building

other than its own dead load weight. The wall transfers horizontal wind loads that are incident upon it to the main

building structure through connections at floors or columns of the building. A curtain wall is designed to resist air and

water infiltration, sway induced by wind and seismic forces acting on the building, and its own dead load weight

forces.

Curtain Wall Systems are typically designed with extruded aluminum members, although the first curtain walls were

made of steel. The aluminium frame is typically infilled with glass, which provides an architecturally pleasing building,

as well as benefits such as daylighting. However, parameters related to solar gain control such as thermal

comfort and visual comfort are more difficult to control when using highly-glazed curtain walls. Other common infills

include: stone veneer, metal panels, louvres, and operable windows or vents.

Curtain walls differ from store-front systems in that they are designed to span multiple floors, and take into

consideration design requirements such as: thermal expansion and contraction; building sway and movement; water

diversion; and thermal efficiency for cost-effective heating, cooling, and lighting in the building.

Stick systems[edit source | editbeta]

The vast majority of curtain walls are installed long pieces (referred to as sticks) between floors vertically and

between vertical members horizontally. Framing members may be fabricated in a shop, but all installation

and glazing is typically performed at the jobsite.

Unitized systems[edit source | editbeta]

Unitized curtain walls entail factory fabrication and assembly of panels and may include factory glazing. These

completed units are hung on the building structure to form the building enclosure. Unitized curtain wall has the

advantages of: speed; lower field installation costs; and quality control within an interior climate controlled

environment. The economic benefits are typically realized on large projects or in areas of high field labor rates.

Rainscreen principle[edit source | editbeta]

A common feature in curtain wall technology, the rainscreen principle theorizes that equilibrium of air pressure

between the outside and inside of the "rainscreen" prevents water penetration into the building itself. For example the

glass is captured between an inner and an outer gasket in a space called the glazing rebate. The glazing rebate is

ventilated to the exterior so that the pressure on the inner and outer sides of the exterior gasket is the same. When

the pressure is equal across this gasket water cannot be drawn through joints or defects in the gasket.

Infills

Infill refers to the large panels that are inserted into the curtain wall between mullions. Infills are typically glass but

may be made up of nearly any exterior building element.

Regardless of the material, infills are typically referred to as glazing, and the installer of the infill is referred to as

a glazier. More commonly this trade is now known as Fenestration.

Glass[edit source | editbeta]

By far the most common glazing type, glass can be of an almost infinite combination of color, thickness, and opacity.

For commercial construction, the two most common thicknesses are 1/4 inch (6 mm) monolithic and 1 inch

(25 mm) insulating glass. Presently, 1/4 inch glass is typically used only inspandrel areas, while insulating glass is

used for the rest of the building (sometimes spandrel glass is specified as insulating glass as well). The 1 inch

insulation glass is typically made up of two 1/4-inch lites of glass with a 1/2 inch (12 mm) airspace. The air inside is

usually atmospheric air, but someinert gases, such as argon or krypton may be used to offer better thermal

transmittance values. In residential construction, thicknesses commonly used are 1/8 inch (3 mm) monolithic and

5/8 inch (16 mm) insulating glass. Larger thicknesses are typically employed for buildings or areas with higher

thermal, relative humidity, or sound transmission requirements, such as laboratory areas or recording studios.

Glass may be used which is transparent, translucent, or opaque, or in varying degrees thereof. Transparent glass

usually refers to vision glass in a curtain wall. Spandrel or vision glass may also contain translucent glass, which

could be for security or aesthetic purposes. Opaque glass is used in areas to hide a column or spandrel beam or

shear wall behind the curtain wall. Another method of hiding spandrel areas is through shadow boxconstruction

(providing a dark enclosed space behind the transparent or translucent glass). Shadow box construction creates a

perception of depth behind the glass that is sometimes desired.

Fabric veneer[edit source | editbeta]

Fabric is another type of material which is common for curtain walls. Fabric is often much less expensive and serves

as a less permanent solution. Unlike glass or stone, fabric is much faster to install, less expensive, and often much

easier to modify after it is installed.

Stone veneer[edit source | editbeta]

Thin blocks (3 to 4 inches (75100 mm)) of stone can be inset within a curtain wall system to provide architectural

flavor. The type of stone used is limited only by the strength of the stone and the ability to manufacture it in the proper

shape and size. Common stone types used are: Arriscraft(calcium silicate);granite; marble; travertine; and limestone.

To reduce weight and improve strength, the natural stone may be attached to an aluminum honeycomb backing as

with the StonePly system.

Panels[edit source | editbeta]

Metal panels can take various forms including aluminum plate; thin composite panels consisting of two thin aluminum

sheets sandwiching a thin plastic interlayer; copper wall cladding, and panels consisting of metal sheets bonded to

rigid insulation, with or without an inner metal sheet to create a sandwich panel. Other opaque panel materials

include fiber-reinforced plastic (FRP), stainless steel, and terracotta. Terracotta curtain wall panels were first used in

Europe, but only a few manufacturers produce high quality modern terracotta curtain wall panels.

Louvers[edit source | editbeta]

A louver is provided in an area where mechanical equipment located inside the building requires ventilation or fresh

air to operate. They can also serve as a means of allowing outside air to filter into the building to take advantage of

favorable climatic conditions and minimize the usage of energy-consuming HVAC systems. Curtain wall systems can

be adapted to accept most types of louver systems to maintain the same architectural sightlines and style while

providing the necessary functionality.

Windows and vents[edit source | editbeta]

Most curtain wall glazing is fixed, meaning there is no access to the exterior of the building except through doors.

However, windows or vents can be glazed into the curtain wall system as well, to provide required ventilation or

operable windows. Nearly any window type can be made to fit into a curtain wall system.

Вам также может понравиться

- Astm E331-00Документ4 страницыAstm E331-00ELENA NAVASОценок пока нет

- Facades and InterfacesДокумент43 страницыFacades and Interfacesissamoune100% (2)

- Structural Silicone Glazing Manual: Tremco Sealant SolutionsДокумент0 страницStructural Silicone Glazing Manual: Tremco Sealant SolutionsPrantik Adhar SamantaОценок пока нет

- Paint DefectДокумент2 страницыPaint Defectanurag_4013100% (4)

- Installation Manual Curtain WallДокумент8 страницInstallation Manual Curtain WallPrantik Adhar Samanta0% (1)

- Concrete Mix Design DOE PDFДокумент15 страницConcrete Mix Design DOE PDFkarthiksamp100% (2)

- European - British Standards and Codes of PracticeДокумент6 страницEuropean - British Standards and Codes of PracticetanminweeОценок пока нет

- English IndianДокумент27 страницEnglish IndianjitenderaОценок пока нет

- Curtain Wall Manual - Section 8 InstallationДокумент32 страницыCurtain Wall Manual - Section 8 InstallationphilipОценок пока нет

- 1e5 Glass Structures l5 Me Glued ConnectionДокумент60 страниц1e5 Glass Structures l5 Me Glued ConnectionPaulОценок пока нет

- StorefrontДокумент5 страницStorefrontMary Mae JeremiasОценок пока нет

- Brochure A - Kibo Bulletproof ProductsДокумент9 страницBrochure A - Kibo Bulletproof ProductsGeorgios XydeasОценок пока нет

- Kalzip StructuralДокумент44 страницыKalzip StructuralZoranОценок пока нет

- Design Components For Structural GlazingДокумент8 страницDesign Components For Structural GlazingnonspodОценок пока нет

- TREMCO Structural Silicone Glazing ManualДокумент44 страницыTREMCO Structural Silicone Glazing ManualLuiz CarlosОценок пока нет

- Aama 204-98Документ7 страницAama 204-98DavidОценок пока нет

- Condensation On GlassДокумент3 страницыCondensation On GlassMancasi RazvanОценок пока нет

- 04 4012 00 PDFДокумент38 страниц04 4012 00 PDFrmdarisaОценок пока нет

- Dow Corning Technical ManualДокумент88 страницDow Corning Technical ManualJerry100% (1)

- 1 ChrisBridgesRetainingwallsandSoilNailing PDFДокумент70 страниц1 ChrisBridgesRetainingwallsandSoilNailing PDFRivaiОценок пока нет

- Gate 2004Документ8 страницGate 2004Shailendra Mishra100% (1)

- Product - Library-Axilume Balustrade Technical ManualДокумент60 страницProduct - Library-Axilume Balustrade Technical ManualHSP19fОценок пока нет

- Curtain Wall Full TestingДокумент9 страницCurtain Wall Full TestingEdward CОценок пока нет

- CWDC 1 08 GasketsДокумент59 страницCWDC 1 08 GasketsJoni StulicОценок пока нет

- Point-Fixed Glass Wall Fitting Typical Product Catalog160PДокумент155 страницPoint-Fixed Glass Wall Fitting Typical Product Catalog160PNajib Kiwan100% (1)

- Wall and Skylight ConstructionДокумент33 страницыWall and Skylight Constructioncristian santillanОценок пока нет

- Structural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Документ38 страницStructural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Mohammad Yunus Salehi67% (3)

- Facade-Alumimum & Glazing Works Scope-Technical SpecificationsДокумент5 страницFacade-Alumimum & Glazing Works Scope-Technical SpecificationsHasnain SafdarОценок пока нет

- Curtain Wall NoAnswersДокумент20 страницCurtain Wall NoAnswersLuiz CarlosОценок пока нет

- A1-10 Curtain WallsДокумент58 страницA1-10 Curtain WallsZYWОценок пока нет

- Silicone Structural Glazing Manual - Dow CorningДокумент52 страницыSilicone Structural Glazing Manual - Dow Corningnithya174100% (2)

- UK-Kalzip-Systems Products and ApplicationsДокумент72 страницыUK-Kalzip-Systems Products and ApplicationsaddindxОценок пока нет

- SSGPGДокумент56 страницSSGPGtroyel99Оценок пока нет

- A1-10 Curtain WallsДокумент62 страницыA1-10 Curtain WallsJacky TiongОценок пока нет

- Introduction To Glass Curtain Wall SystemsДокумент7 страницIntroduction To Glass Curtain Wall SystemsguillermoОценок пока нет

- Rev EN 13830 41 e STF PDFДокумент81 страницаRev EN 13830 41 e STF PDFmuhammed_bulanОценок пока нет

- Curtain Wall Types: Technical Note No. 14Документ1 страницаCurtain Wall Types: Technical Note No. 14Eslam YahiaОценок пока нет

- CHEM181.Experiment 8 DetermiantionofDissolvedOxygenДокумент5 страницCHEM181.Experiment 8 DetermiantionofDissolvedOxygenDenampo Ivan MikhaelОценок пока нет

- Façade System: 18AR35 Atif MominДокумент11 страницFaçade System: 18AR35 Atif MominAtif MominОценок пока нет

- Fire-Rated Glass Document38Документ5 страницFire-Rated Glass Document38jefftemple0% (1)

- Curtain GlazingДокумент14 страницCurtain GlazingsuhailОценок пока нет

- Facade SelectionДокумент34 страницыFacade SelectionSarvesh TaleleОценок пока нет

- Curtain Wall (Revise1)Документ8 страницCurtain Wall (Revise1)Mohammad BurhanОценок пока нет

- 084413-Glazed Aluminum Curtain Walls (VersaWall SM 2500)Документ12 страниц084413-Glazed Aluminum Curtain Walls (VersaWall SM 2500)Md Jahangir AlamОценок пока нет

- Splicing of Mullion at Curtain WallДокумент14 страницSplicing of Mullion at Curtain WallKIARA ARGELОценок пока нет

- Semi Unitized SystemДокумент11 страницSemi Unitized SystemDEEKSHI MОценок пока нет

- Northclad AcmДокумент2 страницыNorthclad Acmresearcher911Оценок пока нет

- Designs CatalogДокумент77 страницDesigns CatalogGen MendozaОценок пока нет

- Heat Soak TestingДокумент9 страницHeat Soak Testinghisham1958Оценок пока нет

- H11 Roof and Wall Systems ............................................................................ 5Документ53 страницыH11 Roof and Wall Systems ............................................................................ 5Anonymous qabSVjzrAОценок пока нет

- Mistral Tower Value of System Design, Manufacturing and Installation in Cold Bent SSG UnitsДокумент18 страницMistral Tower Value of System Design, Manufacturing and Installation in Cold Bent SSG UnitsGino TironiОценок пока нет

- Kaskel 2012Документ37 страницKaskel 2012resurrection786Оценок пока нет

- Structural Glass ApplicationsДокумент61 страницаStructural Glass ApplicationsPaolo BartoliОценок пока нет

- Facade System Installation ManualДокумент30 страницFacade System Installation Manualdan calinescuОценок пока нет

- Cantilever Curtain WallДокумент18 страницCantilever Curtain WallkingdbmОценок пока нет

- Tn66-Tn67-Test-report To CWCT Tech Notes 66 67Документ13 страницTn66-Tn67-Test-report To CWCT Tech Notes 66 67GAPistОценок пока нет

- RODAN MANET LOOP Const PDFДокумент64 страницыRODAN MANET LOOP Const PDFpraveen0907Оценок пока нет

- Design of Concrete Masonry Walls For Blast Loading: TEK 14-21AДокумент9 страницDesign of Concrete Masonry Walls For Blast Loading: TEK 14-21Afoush bashaОценок пока нет

- Structural Assessment of Mashrabiya PerfДокумент9 страницStructural Assessment of Mashrabiya PerfSrikanth BhaskaraОценок пока нет

- 16 10 25 Epd 7 Reynaers Curtain Wall CW 50 r01Документ14 страниц16 10 25 Epd 7 Reynaers Curtain Wall CW 50 r01supadiОценок пока нет

- 17-10-23 Inhabit - Presentation Glass MakassarДокумент41 страница17-10-23 Inhabit - Presentation Glass MakassarBINAZIRОценок пока нет

- CVДокумент21 страницаCVAngelica chea NatividadОценок пока нет

- 13GR - 059 Bituthene HB Web PDFДокумент141 страница13GR - 059 Bituthene HB Web PDFWendel MeloОценок пока нет

- 0617-GGF Laminated Glass Leaflet WebДокумент3 страницы0617-GGF Laminated Glass Leaflet WebIbrahim SahinОценок пока нет

- Taj Mahal - Net SearchДокумент4 страницыTaj Mahal - Net SearchjitenderaОценок пока нет

- Ar - Alvar Aalto: Presented By-Priyanka Joon B.Arch. Sem - 4Документ17 страницAr - Alvar Aalto: Presented By-Priyanka Joon B.Arch. Sem - 4jitenderaОценок пока нет

- AttachmentДокумент10 страницAttachmentjitenderaОценок пока нет

- 25 - Renaissance and The Cult of PersonalityДокумент9 страниц25 - Renaissance and The Cult of PersonalityjitenderaОценок пока нет

- EcaДокумент6 страницEcajitenderaОценок пока нет

- Photoinduced Degradation of 2,4-Dichlorophenol in Water - Influence of Various Fe (III) CarboxylatesДокумент8 страницPhotoinduced Degradation of 2,4-Dichlorophenol in Water - Influence of Various Fe (III) CarboxylatesLilith angieОценок пока нет

- Assignment 1Документ32 страницыAssignment 1sharifah atiqahОценок пока нет

- Green DieselДокумент10 страницGreen DieselJimena HdzОценок пока нет

- High-Temperature Failure Analysis of 25Cr35NiNb TubeДокумент9 страницHigh-Temperature Failure Analysis of 25Cr35NiNb TubenikkiОценок пока нет

- Mason1954 Mason, W., & Wick, R. (1954) - Ferroelectrics and The Dielectric Amplifier. Proceedings of The IRE, 42 (11), 1606Документ15 страницMason1954 Mason, W., & Wick, R. (1954) - Ferroelectrics and The Dielectric Amplifier. Proceedings of The IRE, 42 (11), 1606Magdy Hussein Mourad MohammadОценок пока нет

- Chemrite PP FibreДокумент3 страницыChemrite PP FibreICPL-RWPОценок пока нет

- tnd14v 221kb00aaa0Документ56 страницtnd14v 221kb00aaa0jombo123Оценок пока нет

- Chemistry For Engineers: Assignment 1Документ4 страницыChemistry For Engineers: Assignment 1Thanh Tan PhamОценок пока нет

- Inorganic Chemistry Practice Booklet-1Документ65 страницInorganic Chemistry Practice Booklet-1godlanshul32Оценок пока нет

- LB Aw Arc SPT - enДокумент62 страницыLB Aw Arc SPT - enWaldir Donatti JuniorОценок пока нет

- 712-1010-001 - Avkcms - en 2205Документ6 страниц712-1010-001 - Avkcms - en 2205Vieru GabrielОценок пока нет

- Elevation 01 Elevation 04: C03 C01 C02 D01 D02 D03 D04 D05 D06 D07Документ1 страницаElevation 01 Elevation 04: C03 C01 C02 D01 D02 D03 D04 D05 D06 D07Abid AyubОценок пока нет

- Astm D4759Документ7 страницAstm D4759EfrilaОценок пока нет

- Phase Equilibrium Study in The CaOДокумент5 страницPhase Equilibrium Study in The CaOsattiricОценок пока нет

- Jacketed VesselsДокумент2 страницыJacketed VesselsImamRNОценок пока нет

- Power Facility Coatings Brochure BROPWДокумент5 страницPower Facility Coatings Brochure BROPWprakashОценок пока нет

- Pengaruh Lingkungan Minyak Mentah Terhadap Laju Korosi Pada Pipa Baja Karbon Dan Pipa GalvanisДокумент4 страницыPengaruh Lingkungan Minyak Mentah Terhadap Laju Korosi Pada Pipa Baja Karbon Dan Pipa GalvanisafifahОценок пока нет

- ChemДокумент2 страницыChemDBANJAN MAITYОценок пока нет

- F2 C6: Acids & AlkaliДокумент3 страницыF2 C6: Acids & AlkaliJas 408Оценок пока нет

- Effect of Pitting Corrosion On The Mechanical Properties of 316 Grade Stainless SteelДокумент6 страницEffect of Pitting Corrosion On The Mechanical Properties of 316 Grade Stainless SteelAnilОценок пока нет

- AbcdДокумент3 страницыAbcdNikesh ShahОценок пока нет

- 0002-SPC-HOBWT03-ME-8006 - C General Mechanical Specification Bryn Estyn Water Treatment PlantДокумент35 страниц0002-SPC-HOBWT03-ME-8006 - C General Mechanical Specification Bryn Estyn Water Treatment PlantzufriateguiОценок пока нет