Академический Документы

Профессиональный Документы

Культура Документы

Concreting

Загружено:

Amalina YaniИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Concreting

Загружено:

Amalina YaniАвторское право:

Доступные форматы

Page:

METHOD STATEMENT FOR CONCRETING

1 of 11

Project: Rev: Date:

CADANGAN MENYAMBUNG SEMULA KERJA-KERJA PEMBANGUNAN RUMAH PENGINAPAN 00 23/02/2017

DBKL YANG MENGANDUNGI SEBUAH BANGUNAN 2 TINGKAT BLOK PENTADBIRAN,

SEBUAH BANGUNAN 3 TINGKAT, BLOK RUMAH PENGINAPAN DAN SEBUAH KOLAM

RENANG KANAK-KANAK DI ATAS LOT 1018, MUKIM SI RUSA DAERAH PORT DICKSON,

NEGERI SEMBILAN DARUL KHUSUS

1. GENERAL

This document covers the procedure to estabilish a method statement for all concreting

activities.

2. PURPOSE

The purpose of this document is to follow proper methodology and to construct the

concrete structure (i.e. ground floor column right up to roof beam inclusive of R.C

Staircase) according to the construction drawing.

3. SCOPE

The scope of the work method statement is to outline the procedure and work sequence for

all concreting activities and documentation procedures. This Works Method details the

followings:

Manpower & Equipment used.

Methodology.

Safety & Environmental Programme

QA/QC Programme

MEGA BINA SDN. BHD. MS/PD/DBKL#2311(1)/00 Page 1 of 11

Page:

METHOD STATEMENT FOR CONCRETING

2 of 11

Project: Rev: Date:

CADANGAN MENYAMBUNG SEMULA KERJA-KERJA PEMBANGUNAN RUMAH PENGINAPAN 00 23/02/2017

DBKL YANG MENGANDUNGI SEBUAH BANGUNAN 2 TINGKAT BLOK PENTADBIRAN,

SEBUAH BANGUNAN 3 TINGKAT, BLOK RUMAH PENGINAPAN DAN SEBUAH KOLAM

RENANG KANAK-KANAK DI ATAS LOT 1018, MUKIM SI RUSA DAERAH PORT DICKSON,

NEGERI SEMBILAN DARUL KHUSUS

4. EQUIPMENT, TOOLS AND RESOURCES

4.1 Machineries and Equipments

4.1.1 Concrete Mixer

4.1.2 Vibrating pokers

4.1.3 Personal Protective Equipments

4.1.4 Transfer Lorries

4.1.5 Mobile crane

4.1.6 Generator

4.2 Tools

4.2.1 Wheelbarrows

4.2.2 Wire brush

4.2.3 Angle grinder

4.2.4 Measuring tapes

4.2.5 Other handy tools.

4.3 Man Power

4.3.1 Project Engineer 1 person

4.3.2 Site Supervisor 1 person

4.3.3 Safety Co ordinator 1 person

4.3.4 Lifting supervisor 1 person

4.3.5 Crane operator 1 person

4.3.6 General worker 2 persons

MEGA BINA SDN. BHD. MS/PD/DBKL#2311(1)/00 Page 2 of 11

Page:

METHOD STATEMENT FOR CONCRETING

3 of 11

Project: Rev: Date:

CADANGAN MENYAMBUNG SEMULA KERJA-KERJA PEMBANGUNAN RUMAH PENGINAPAN 00 23/02/2017

DBKL YANG MENGANDUNGI SEBUAH BANGUNAN 2 TINGKAT BLOK PENTADBIRAN,

SEBUAH BANGUNAN 3 TINGKAT, BLOK RUMAH PENGINAPAN DAN SEBUAH KOLAM

RENANG KANAK-KANAK DI ATAS LOT 1018, MUKIM SI RUSA DAERAH PORT DICKSON,

NEGERI SEMBILAN DARUL KHUSUS

5. METHODOLOGY

5.1 Delivery, storage, handling and protection of materials at site

All formwork and rebar should be transported to site by means of lorry and

unloaded appropriately using a mobile crane. They shall be stored in a

proper stockyard allocated at site. Similarly for aluminium formwork, care

should be taken to ensure that the formwork are properly stacked up as to

avoid damages or dented to the edges or surface of the formwork.

Methods of sampling and testing of materials for concrete shall be as laid

down in the latest edition of the relevant British Standards Frequency of

testing shall be as set out hereunder. All costs associated with testing of

materials shall be borne by the Contractor.

5.2 Pre-installation requirements:

5.2.1 Site clearance and setting out.

Get surveyor to set out the gridline for each R.C. frame to be constructed

before casting (ie from ground floor column right up to roof beam inclusive of

R.C. Staircase)

5.2.2 The coordination of works with other trades.

a) Roofing work

b) Window and steel door works

c) External and infrastructure work

5.3 Execution of work

5.3.1 Structure (RC Works)

a) Generally formwork shall be constructed and followed by the laying of

reinforcement bar according to the approved drawings and specifications as

request for inspection checklist for RC works to Engineer / Site Representative for

comment prior to casting of concrete. Concrete used shall be ready-mix concrete

from a respective supplier. Hoisting of concrete rebar formwork will be carried out

using a mobile crane.

b) Striking of formwork should not be by force or levering against concrete surface.

Prior to concreting, formwork must be thoroughly cleaned out and re-checked.

Provision should be made for cleaning out and draining.

c) Construction joint must be straight, truly vertical formed in the exact position

shown on drawings. For those not specified, construction joint should be well

planned against concrete delivery. Carpenters must be standby during concreting

in case temporary stop ends, correction of shuttering and any other contingencies.

MEGA BINA SDN. BHD. MS/PD/DBKL#2311(1)/00 Page 3 of 11

Page:

METHOD STATEMENT FOR CONCRETING

4 of 11

Project: Rev: Date:

CADANGAN MENYAMBUNG SEMULA KERJA-KERJA PEMBANGUNAN RUMAH PENGINAPAN 00 23/02/2017

DBKL YANG MENGANDUNGI SEBUAH BANGUNAN 2 TINGKAT BLOK PENTADBIRAN,

SEBUAH BANGUNAN 3 TINGKAT, BLOK RUMAH PENGINAPAN DAN SEBUAH KOLAM

RENANG KANAK-KANAK DI ATAS LOT 1018, MUKIM SI RUSA DAERAH PORT DICKSON,

NEGERI SEMBILAN DARUL KHUSUS

d) Avoid having construction joints or temporary stops end at those area need absolute water

tightness for example bath area.

e) Check the verticality of every columns formwork. Be very sure that the formwork are

sufficiently and correctly framed, cramped, and braced so that the columns cast area as

vertical as the formwork before casting. Check the orientation of timber yokes to ensure

forms can be able to resist concrete pressure from both directions.

f) All beams / slabs formwork must be leveled properly with reference to the datum marked

at every column after columns formwork removed. Check every slabs and beams soffit

level before and after casting. Quick check can be done by marking on the casted

columns.

g) Opening for plumbing check to baseline must be provided at each floor. Baseline must be

transferred to upper floor columns etc. before upper floor works can be proceed.

3.0 Precaution In Reinforcement.

a) Upon receipt of steel (round steel bars, deformed bars and welded mesh fabric).

Make sure that it is of the specified type, quantity and grades shown. The bars

should have mill tags identifying in the batch number, mill test result should be

accompanying the D.Os.

b) Steel reinforcement should be stored in clean conditions. It shall be clean and free

from loose rust and loose scale at time of fixing in position and subsequently

concreting.

c) The steel must be installed in accordance to drawing and specifications:-

i) The bars are the required numbers, size and shape and have been placed

within the allowable tolerances.

ii) Spices should have the required lap and must not located at points of

maximum tensile stress.

iii) The reinforcement is being adequately tied and supported to remain in

position when concrete is placed.

iv) The specified cover of concrete for the steel bars is being obtained.

v) Tying wire is not allowed to protrude towards the face concrete.

4.0 Regular Checking of Reinforcement is Essential.

Wastage in construction materials particularly reinforcement should be kept at the

minimum, i.e. rebars should be cut according to the best combination of lengths.

MEGA BINA SDN. BHD. MS/PD/DBKL#2311(1)/00 Page 4 of 11

Page:

METHOD STATEMENT FOR CONCRETING

5 of 11

Project: Rev: Date:

CADANGAN MENYAMBUNG SEMULA KERJA-KERJA PEMBANGUNAN RUMAH PENGINAPAN 00 23/02/2017

DBKL YANG MENGANDUNGI SEBUAH BANGUNAN 2 TINGKAT BLOK PENTADBIRAN,

SEBUAH BANGUNAN 3 TINGKAT, BLOK RUMAH PENGINAPAN DAN SEBUAH KOLAM

RENANG KANAK-KANAK DI ATAS LOT 1018, MUKIM SI RUSA DAERAH PORT DICKSON,

NEGERI SEMBILAN DARUL KHUSUS

5.0 Concrete.

In this project ready-mix concrete are being used

6.0 Mixing of Materials

a) All mixing of concrete materials shall be carried out in a mechanically operated mixer complying

with B.S. 1305 Batch Type Concrete Mixers except in an emergency when hand methods may

be employed as approved by the S.O. The mixer shall be of a type which will ensure an uniform

distribution of materials throughout the mass.

b) The mixer shall be of such capacity that one or more whole bags of cement may be used in the

batch. The volume of he mixed material shall not exceed the makers rated capacity for the

mixer.

c) The mixing time shall be measured from the time when all the materials are in the mixer drum.

The minimum time of mixing shall be one and one half minutes for mixers of one (1) cubic yard

or less capacity shall have mixing time increased by fifteen (15) seconds for each additional half

cubic yard capacity or part thereof.

d) The drum shall rotate at a peripheral speed of approximately two hundred (200) feet per minute

at a point on the widest section of the drum, or at a speed of twelve (12) c.p.m. whichever is the

slower.

e) The first batch shall contain an excess of cement, sand and water sufficient to coat the inside of

the mixer without reducing the mortar content of the mix below that required.

f) The remixing with or without further addition of water, cement or aggregates, of concrete which

has partially hardened shall not be permitted.

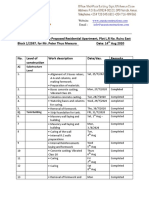

7.0 Method of Proportioning

Nominal Mixes Normal Strength Concrete

MEGA BINA SDN. BHD. MS/PD/DBKL#2311(1)/00 Page 5 of 11

Page:

METHOD STATEMENT FOR CONCRETING

6 of 11

Project: Rev: Date:

CADANGAN MENYAMBUNG SEMULA KERJA-KERJA PEMBANGUNAN RUMAH PENGINAPAN 00 23/02/2017

DBKL YANG MENGANDUNGI SEBUAH BANGUNAN 2 TINGKAT BLOK PENTADBIRAN,

SEBUAH BANGUNAN 3 TINGKAT, BLOK RUMAH PENGINAPAN DAN SEBUAH KOLAM

RENANG KANAK-KANAK DI ATAS LOT 1018, MUKIM SI RUSA DAERAH PORT DICKSON,

NEGERI SEMBILAN DARUL KHUSUS

Nominal Mixes High Strength Concrete

The proportions of the mix as specified in the table above are expected to produce works cube

strengths in excess of the requirements of this specification and a workability sufficient to ensure the

concrete being workable and fully compacted

8.0 Placing, vibrating and finishing Concrete.

Certain precaution should be taken in placing & compaction of concrete to ensure

a satisfactory finish:-

a) Immediately before any concreting is commenced all formwork shall be carefully

examined to ensure that all dirt, shavings, sawdust, etc. has been removed. The

inside of all timber forms, barrows, chutes, etc. shall be wetted prior to the placing

of concrete.

b) All concrete shall be handled from the mixer as rapidly as practicable by methods

which shall prevent segregation. Unless otherwise approved, in no case shall the

time exceed thirty (30) minutes after discharge from the mixer or agitator truck

vehicle. Under no circumstances shall concrete that has partially hardened be

placed in the work.

c) Concrete shall be placed in one continuous operation between the ends of

members and/or construction joints irrespective of meal hours, tea breaks, etc.

The concrete shall be placed so that the coarse aggregate will not be separated

from the rest of the material.

d) The concrete shall be thoroughly worked and consolidated round the steel

reinforcement and into all parts of the formwork, to that the steel is thoroughly

coated and so that no voids or cavities are left.

e) The concrete shall be placed in layers of such thickness and from such heights as

will enable this to be done. The Contractor shall not be permitted to drop concrete

directly into forms where the distance between the end of the concrete exceeds

50.

MEGA BINA SDN. BHD. MS/PD/DBKL#2311(1)/00 Page 6 of 11

Page:

METHOD STATEMENT FOR CONCRETING

7 of 11

Project: Rev: Date:

CADANGAN MENYAMBUNG SEMULA KERJA-KERJA PEMBANGUNAN RUMAH PENGINAPAN 00 23/02/2017

DBKL YANG MENGANDUNGI SEBUAH BANGUNAN 2 TINGKAT BLOK PENTADBIRAN,

SEBUAH BANGUNAN 3 TINGKAT, BLOK RUMAH PENGINAPAN DAN SEBUAH KOLAM

RENANG KANAK-KANAK DI ATAS LOT 1018, MUKIM SI RUSA DAERAH PORT DICKSON,

NEGERI SEMBILAN DARUL KHUSUS

f) All concrete shall be compacted by sufficient numbers of approved type of

mechanical vibrators suitable for the operation for which it is intended. Vibrators

proposed for use shall be approved by the S.O.

g) Sufficient vibrators shall be provided to suit the capacity of the concrete mixer.

h) For each group of four units (or part thereof) in operation, one additional vibrator

shall be provided and kept in readiness for immediate use should a breakdown

occur.

i) Location of all construction joints shall be submitted to the S.O. for approval prior

to commencement of any concreting operations. Before fresh concrete is

deposited upon or against any concrete at a construction joint the surface of the

hardened concrete shall be thoroughly roughened and cleaned of all laitance,

loose and foreign matter. Immediately prior to placing of concrete at any point the

hardened surface shall be dampened and coated with a layer of neat cement

slurry. The layer shall be brushed into the joint surfaces and shall not be allowed

to dry out before placing the fresh concrete.

7.0 Rectification Works - Honeycomb

a) Shall be inspected by COW and if the defect is not serious grouting cement shall

be use and the grouting material must be approved by Engineer.

b) If the defect is too serious the defect area shall be hack off which confirm by COW

and Engineer and reconstruct the above defect area.

8.0 Safety & Environmental Programme

All HSSE procedure and regulations shall be complied with.

To provide proper and safe access for inspection and working.

Site personnel must be in proper safety working attire e.g. Safety boots an

helmets must be worn at all times.

Proper and adequate lighting to be provided when working at night.

Water ponding must be constantly pumped out and mosquito infestation checked

and controlled.

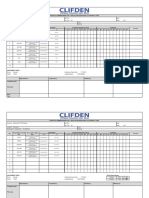

9.0 QA/QC Programme

9.1 Inspections and Test Plan

In order to ensure the quality of honeycomb concrete repair works meet the

requirement, inspection and test shall be carried out as per the Project Quality

Plan (PQP).

Inspection Request Form (IRF) attached with Checklist

MEGA BINA SDN. BHD. MS/PD/DBKL#2311(1)/00 Page 7 of 11

Вам также может понравиться

- Productivity Output For DemolitionДокумент2 страницыProductivity Output For DemolitionAmalina Yani100% (5)

- Productivity Output For Electrical WorksДокумент24 страницыProductivity Output For Electrical WorksAmalina Yani50% (2)

- B Estimate & Check ListДокумент122 страницыB Estimate & Check Listmani0214Оценок пока нет

- Construction Cost Hand Book 2022Документ202 страницыConstruction Cost Hand Book 2022Eng. John MwauraОценок пока нет

- Elemental Cost Analysis ReportДокумент3 страницыElemental Cost Analysis ReportAmalina Yani100% (1)

- Paint Matrix ANGSI BSDPA - BSOEДокумент8 страницPaint Matrix ANGSI BSDPA - BSOEZafarul Naim JamaludinОценок пока нет

- Program Narrative Report - 24 March 2011Документ12 страницProgram Narrative Report - 24 March 2011manoj3090Оценок пока нет

- 30.99.97.1616 Rev. 1 - ITP For Civil WorksДокумент26 страниц30.99.97.1616 Rev. 1 - ITP For Civil Worksshajahan eОценок пока нет

- DCBCP I-2 - Volume IIДокумент207 страницDCBCP I-2 - Volume IIEdmond Bautista100% (1)

- Overhead Crane Pre-Op ChecklistДокумент2 страницыOverhead Crane Pre-Op ChecklistThompson OgborokpaОценок пока нет

- Daily Diary Reports-02Документ1 страницаDaily Diary Reports-02OBERT MASALILAОценок пока нет

- P4508 - Monthly Progress Report - Oct 2017Документ5 страницP4508 - Monthly Progress Report - Oct 2017Anghel CastilloОценок пока нет

- SWMSДокумент22 страницыSWMSNuragus HariyadiОценок пока нет

- FINAL PPT-Aggregate ProductionДокумент77 страницFINAL PPT-Aggregate ProductionLeilani Manalaysay100% (1)

- Analysis of Fleet Replacement Lifecycle: Project #12-14Документ19 страницAnalysis of Fleet Replacement Lifecycle: Project #12-14Juan Carlos Briceño GuevaraОценок пока нет

- NMDC - CHEC - Mukaab - Traffic Management Plan - Rev 00Документ39 страницNMDC - CHEC - Mukaab - Traffic Management Plan - Rev 00imranОценок пока нет

- CV SANDEEP DUBEY Civil Engineer.Документ4 страницыCV SANDEEP DUBEY Civil Engineer.Sandeep dubeyОценок пока нет

- Method Statement For Kamoa CampДокумент28 страницMethod Statement For Kamoa CampAdam MulengaОценок пока нет

- Method Statement Striking FormworkДокумент3 страницыMethod Statement Striking FormworkSurya HeriwijayaОценок пока нет

- 082 Sustainable BuildingДокумент10 страниц082 Sustainable BuildingArya WardhanaОценок пока нет

- FortnightlyProgressReport 04 MRCatAlAmratДокумент52 страницыFortnightlyProgressReport 04 MRCatAlAmratAbdulaziz Al-FarsiОценок пока нет

- Basics of Project Scheduling: Create A Schedule Using CPMДокумент11 страницBasics of Project Scheduling: Create A Schedule Using CPMWali RahmanОценок пока нет

- Mobilization Construction Equipment & ToolsДокумент1 страницаMobilization Construction Equipment & ToolsallОценок пока нет

- Fence InstallationДокумент10 страницFence InstallationanoopyohОценок пока нет

- Dredging Work ScheduleДокумент1 страницаDredging Work SchedulejeorgeОценок пока нет

- Executive Summary-P-5 181.450 To 222Документ14 страницExecutive Summary-P-5 181.450 To 222sat palОценок пока нет

- Method Statement For Drainange Construction Work: Document/Drawing Number: TNEC-STSB-KLIA-CS-MS-013 Revision: AДокумент9 страницMethod Statement For Drainange Construction Work: Document/Drawing Number: TNEC-STSB-KLIA-CS-MS-013 Revision: AAishah AliasОценок пока нет

- DEWATERINGДокумент5 страницDEWATERINGAmalОценок пока нет

- Section J: Structural Steel and Metal Works: @hakcipta JKR MalaysiaДокумент8 страницSection J: Structural Steel and Metal Works: @hakcipta JKR MalaysiaZAHRUDIN ZAHIRUDDIN DAUD MoeОценок пока нет

- Site Manager Job DescriptionДокумент4 страницыSite Manager Job DescriptionAmalina YaniОценок пока нет

- Epoxy Painting MethodДокумент3 страницыEpoxy Painting MethodKaram MoatasemОценок пока нет

- GMD Company Profile - January 2015Документ18 страницGMD Company Profile - January 2015rajeshОценок пока нет

- Daily Site Progress ReportДокумент15 страницDaily Site Progress ReportOmoge Oluwole TemitopeОценок пока нет

- 05-EL - FTR - Insulation & Continuity TestДокумент3 страницы05-EL - FTR - Insulation & Continuity Testben sullivanОценок пока нет

- 3B - Method Statement - StructuresДокумент123 страницы3B - Method Statement - Structuressreesailam100% (2)

- Thomas Model 4 Wiley Mill ManualДокумент10 страницThomas Model 4 Wiley Mill ManualErik RMОценок пока нет

- 2x150mw Dmci CWP 001 EarthworksДокумент12 страниц2x150mw Dmci CWP 001 EarthworksBenjo FaustoОценок пока нет

- Methodology Montclair Interchange - FINALДокумент12 страницMethodology Montclair Interchange - FINALJoseph Gomez0% (1)

- Contoh Report IkhwanДокумент35 страницContoh Report IkhwanzairulОценок пока нет

- Tutorial 2 ConcreteДокумент1 страницаTutorial 2 ConcretepangkaiyunОценок пока нет

- GMD Company ProfileДокумент8 страницGMD Company ProfileRajesh GajjarОценок пока нет

- Pre-Feasibility Report: Tata Steel LimitedДокумент10 страницPre-Feasibility Report: Tata Steel LimitedLokendra Singh RathoreОценок пока нет

- Attachment 4 Scope of WorkДокумент5 страницAttachment 4 Scope of WorkMathias OnosemuodeОценок пока нет

- SR (1) .Quantity SurveyorДокумент4 страницыSR (1) .Quantity SurveyorpoplinuiytОценок пока нет

- Hindustan Construction CompanyДокумент18 страницHindustan Construction CompanySudipta BoseОценок пока нет

- Gimpa Meeting Minutes For 4TH Technical MeetingДокумент3 страницыGimpa Meeting Minutes For 4TH Technical MeetingNana BarimaОценок пока нет

- Appendix 5 Foundation Method StatementДокумент15 страницAppendix 5 Foundation Method StatementTAHER AMMARОценок пока нет

- Sns Company ProfileДокумент37 страницSns Company ProfilesalmanОценок пока нет

- Lansing BWL: Kramer Management Group RFPДокумент122 страницыLansing BWL: Kramer Management Group RFPLansingStateJournalОценок пока нет

- Clearing, Grubbing and ExcavationДокумент25 страницClearing, Grubbing and ExcavationArah Louise ApostolОценок пока нет

- Generalprocedure Export PDFДокумент20 страницGeneralprocedure Export PDFUTTAL RAYОценок пока нет

- Preamble For SBOQДокумент5 страницPreamble For SBOQsanthosh kumar t mОценок пока нет

- Quotation-Minor Civil WorksДокумент2 страницыQuotation-Minor Civil WorksAntonioNicalaОценок пока нет

- Ashok Kumar (Contracts Engineer)Документ2 страницыAshok Kumar (Contracts Engineer)bolsamirОценок пока нет

- SGM - Struct SpecДокумент112 страницSGM - Struct SpecabdouОценок пока нет

- 81 - L&S - Reply To Your Response Letter On Commencement of Construction Works at Saris-Abo 2Документ2 страницы81 - L&S - Reply To Your Response Letter On Commencement of Construction Works at Saris-Abo 2Adyam YonasОценок пока нет

- CP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01Документ6 страницCP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01tarekОценок пока нет

- (L&S) Response To Your Letter On Submission of Shop DrawingsДокумент2 страницы(L&S) Response To Your Letter On Submission of Shop DrawingsAdyam YonasОценок пока нет

- Upgrade of Muldersdrift Sports Complex Project Charter 23.09.2014Документ14 страницUpgrade of Muldersdrift Sports Complex Project Charter 23.09.2014Michael BenhuraОценок пока нет

- Common-Prequalification ChecklistДокумент3 страницыCommon-Prequalification Checklistbureau servicesОценок пока нет

- Legal Cases of Importance To Quantity SurveyorsДокумент3 страницыLegal Cases of Importance To Quantity SurveyorsRoshan de Silva100% (2)

- Health, Safety & EnvironmentДокумент7 страницHealth, Safety & EnvironmentAhsan AfzaalОценок пока нет

- Membina Tembok Gabion Di Jalan Stadium Kuching, DB Kuching UtaraДокумент16 страницMembina Tembok Gabion Di Jalan Stadium Kuching, DB Kuching Utararacing.phreakОценок пока нет

- Apron Concrete Repair Method R01Документ19 страницApron Concrete Repair Method R01ayhanarmanОценок пока нет

- API - A Specialist in Precast Concrete ProductsДокумент3 страницыAPI - A Specialist in Precast Concrete Productsalgebra1975100% (1)

- Method Statement For Exposed ColumnsДокумент12 страницMethod Statement For Exposed ColumnsdeviesrigatiОценок пока нет

- Welder 2Документ1 страницаWelder 2Fahad AhmadОценок пока нет

- Road Project Data SheetДокумент23 страницыRoad Project Data Sheetapi-26419872Оценок пока нет

- NIWI-2654.1 Technical Specification For Supply of BallastДокумент3 страницыNIWI-2654.1 Technical Specification For Supply of BallastCK TangОценок пока нет

- Modul Etika 2010Документ5 страницModul Etika 2010Amalina YaniОценок пока нет

- SBEC4514 EForm Peer Review - 16172Документ1 страницаSBEC4514 EForm Peer Review - 16172Amalina YaniОценок пока нет

- Brief Sbec4514 1Документ14 страницBrief Sbec4514 1Amalina YaniОценок пока нет

- PC No.19 Updated 1Документ661 страницаPC No.19 Updated 1Amalina YaniОценок пока нет

- CO SBEC4514 2016.17-2 VetДокумент5 страницCO SBEC4514 2016.17-2 VetAmalina YaniОценок пока нет

- Productivity Output For PreliminariesДокумент2 страницыProductivity Output For PreliminariesAmalina YaniОценок пока нет

- Report Case StudyДокумент1 страницаReport Case StudyAmalina YaniОценок пока нет

- Water and Sediment ControlДокумент5 страницWater and Sediment ControlAmalina YaniОценок пока нет

- SBEC 2823 Construction Measurement 2: Topic: Demolition & Alteration Project: Double Storey Office Building Group 3Документ38 страницSBEC 2823 Construction Measurement 2: Topic: Demolition & Alteration Project: Double Storey Office Building Group 3Amalina YaniОценок пока нет

- Risk Involved in Construction Works.Документ10 страницRisk Involved in Construction Works.Shaibal AhmedОценок пока нет

- Schedule - A: (See Clause 10.1)Документ78 страницSchedule - A: (See Clause 10.1)rupanta74100% (1)

- Fire Alarm System Abbreviations Lighting Receptacles: Electrical Sheet IndexДокумент1 страницаFire Alarm System Abbreviations Lighting Receptacles: Electrical Sheet IndexSuren VelletheryОценок пока нет

- 4WCE-600500 PdfFile 3 1 59Документ25 страниц4WCE-600500 PdfFile 3 1 59MGNMОценок пока нет

- Status of Pile Caps & Girders Piles Caps GirdersДокумент1 страницаStatus of Pile Caps & Girders Piles Caps GirdersAlone TimeОценок пока нет

- Compressive Strength of Concrete Using Sawdust As AggregateДокумент5 страницCompressive Strength of Concrete Using Sawdust As AggregateMohammedОценок пока нет

- Tensegrity March2024Документ19 страницTensegrity March2024Robel Yibra BogaleОценок пока нет

- Nationtech Communications Ltd. (Rate of Civil Works) For Hasan (Final Doc) - 2Документ9 страницNationtech Communications Ltd. (Rate of Civil Works) For Hasan (Final Doc) - 2helalОценок пока нет

- DSS Module-4 Backbencher - ClubДокумент97 страницDSS Module-4 Backbencher - ClubPuneeth hr2Оценок пока нет

- C-1 CTFSgenДокумент19 страницC-1 CTFSgenhansleyОценок пока нет

- International Pte LTD: Technical Specifications For Perfex Set Mounted Radiator (Rev1)Документ1 страницаInternational Pte LTD: Technical Specifications For Perfex Set Mounted Radiator (Rev1)bacОценок пока нет

- Reinforced Concrete Culvert PipesДокумент3 страницыReinforced Concrete Culvert PipesAbdurezak AbdurehimОценок пока нет

- Progress Report For Construction Work at RuiruДокумент2 страницыProgress Report For Construction Work at RuiruJOSEPH MWANGIОценок пока нет

- Fumagalli General Catalogue 2021Документ4 страницыFumagalli General Catalogue 2021RosmiОценок пока нет

- Use of Waste Plastic Use of Waste PlastiДокумент8 страницUse of Waste Plastic Use of Waste PlastiRayhan MazumderОценок пока нет

- Laticrete 290 TDS - 1Документ4 страницыLaticrete 290 TDS - 1Dilon FernandoОценок пока нет

- Comparative Study of Steel Structure With and Without Floating Columns in EtabsДокумент13 страницComparative Study of Steel Structure With and Without Floating Columns in EtabsBehroz BehzadОценок пока нет

- राष ्ट्रीयराजमार्गएवंअवसंरचनाववकासवनर्मविवमट्ेड National Highways & Infrastructure Development Corporation LimitedДокумент2 страницыराष ्ट्रीयराजमार्गएवंअवसंरचनाववकासवनर्मविवमट्ेड National Highways & Infrastructure Development Corporation LimitedAli Asghar ShahОценок пока нет

- White Book C05 S03 Specialist Partitions FireWallДокумент11 страницWhite Book C05 S03 Specialist Partitions FireWallpictura sticlaОценок пока нет

- Failure of Liquid Applied MembraneДокумент20 страницFailure of Liquid Applied MembranepankajОценок пока нет

- Tank 300 DRGДокумент1 страницаTank 300 DRGShovit GautamОценок пока нет

- A Good City Has IndustryДокумент52 страницыA Good City Has IndustrySandra FremОценок пока нет