Академический Документы

Профессиональный Документы

Культура Документы

V2i6 Ijertv2is60390

Загружено:

praveenОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

V2i6 Ijertv2is60390

Загружено:

praveenАвторское право:

Доступные форматы

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 6, June - 2013

Development of A Sheet-Metal Component With A Forming Die Using CAE

Software Tools For Design Validation and Improvement

Author -Mr. Amit Dattatray Madake(M.E Mech-PDD Appearing,Student of D.K.T.E.Ichalkaranji)

Guide- Dr. V. R. Naik (Head of Mechanical Department,D.K.T.E.Ichalkaranji)

Swapnil Shashikant Kulkarni (Director-Able Technologies India Pvt. Ltd.,Pune)

Abstract:

Sheet-metal die is an inseparable constituent of the development process of any given

automotive or consumer appliance. In most of the cases, this accounts for a high proportion in

the tooling needs of the large size and structural member in any automotive like the chassis and

the BIW. Many other brackets and gussets along with peripheral clips etc are invariably made of

Sheet-metal due to the strength characteristics complimented by this material and the process

of stamping.

RT

IJE

Introduction

A reduction in the number of trials would directly influence the cycle time for development. A

shorter cycle time can be planned with due utilization of software tools that would predict the

trial results without actually conducting the same! The simulation offered by the software

during the process of stamping lends important insights into the modifications needed in the

die and/or the component to effect a simplified and productive die. Normally, a Forming die

(including Draw die) calls for refined design parameters for ensuring a smooth passage through

the trial phase of the developed Die normally accompanied by crucial review inputs over the

Design of the component too.

Literature Review

1) Arash Behrouzi, Bijan Molaee Dariani, Mahmood Shakeri had discussed (1) Shape error due

to elastic recovery of formed part in unloading known as springback, is one of the most

IJERTV2IS60390 www.ijert.org 921

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 6, June - 2013

important problems of tool design in sheet metal forming processes. Many researches have

been performed for proposing an efficient method to decrease or compensate springback error

in sheet forming processes.

2) Juraj HUDAK, Miroslav TOMAS had Presented (2) contribution deals with force parameters

research (drawing and blankholding) in deep-drawing process of flat bottomed cylindrical cup.

Experimental research was realised using steel sheets for enamelling KOSMALT produced by

U.S.Steel Koice, Ltd. Deep drawing process of this steel is complicated due to contradictory

requests from the view of steel structure: good drawability and good enameling.

3) Hakim S. Sultan Aljibori, Abdel Magid Hamouda had done (3) in the study on Minimization

of response times and costs and maximization of the efficiency and quality in producing a

product are imperative for survival in the competitive manufacturing industry. Sheet metal

forming is a widely used and costly manufacturing process, to which these considerations apply.

Aluminum sheet becomes favorable compare to steel regards to some improvement at

RT

aerodynamic designs, increased engine efficiency and fuel economy. Wide range of aluminum

automotive product included doors, fenders, bumpers face bars, seat frames and roof panels

IJE

have been produced. This paper was carried out to study the finite element (elastic-plastic)

analysis of sheet metal forming process using the finite element software.

4) J. S. Colton, Y.Park had discussed (4) the demand for rapid, low-cost die fabrication and

modification technology is greater than ever in the sheet metal forming industry. One category

of rapid tooling technology involves the use of advanced polymers and composite materials to

fabricate metal forming dies. In addition because the mechanisms by which they fail are not

fully understood, the dies are designed on the basis of experience and intuition. This study

investigates the failure of V-bending dies fabricated from an easy-to-machine, polyurethane-

based, composite board stock Based on the mechanical behavior of the die material, several

failure criteria are proposed to predict die failure mode and the corresponding die life.

5) A.Wifi. & A.Mosalam had discussed (5) the complexity and interactive nature of the

parameters affecting the performance of various blank-holding techniques. It has been

demonstrated that certain combinations of such parameters would lead to the most favourable

IJERTV2IS60390 www.ijert.org 922

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 6, June - 2013

working conditions leading to a successful cup drawing. Efforts should be made to develop

effective optimization techniques to control these parameters and optimize the BHF schemes.

Experience suggests that using the finite element method as an evaluation engine of the

objective function used in optimization is very powerful, but unfortunately very time

consuming. No claim is made here that the presented work is complete.

6) Se-Ho Kim, Seung-Ho Kim, Hoon Huh had discussed (6) in his journal is the tool design is

carried out for a multi-stage deep drawing and ironing process of a rectangular cup with the

large aspect ratio using the result of the finite element analysis. The analysis incorporates

three-dimensional continuum elements for an elasto-plastic finite element method with the

explicit time integration scheme using LS-DYNA3D. The analysis simulates the five-stage deep

drawing and ironing process with the thickness control of the cup wall. Simulation is performed

in order to investigate the failure by tearing during the forming process at the initial state of

tool design.

RT

7) Peter Kostka,Peter Cekan had discussed (7) the ability to predict different process

conditions in deep drawing is essential for die face designers, tooling stamping & manufacturing

IJE

engineers. These predictions in turn affect the speed, accuracy and cost of the final produced

poduct.This paper briefly discusses the possibilities of controlling the blankholding pressure

distribution and shows some computer simulations done in DYNAFORM, with the result being

experimentally verified with tooling designed by the authors.

Objective:

Forming involves plastic deformation (3) while material is constrained to conform to

given contour or shape. This operation poses challenges for modeling using the mathematical

or analytical (1) model. The size, thickness, material properties, features, direction of form and

the changes in the direction for the features, depth of the forming, etc influence the complexity

and affect the quality of the component.

IJERTV2IS60390 www.ijert.org 923

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 6, June - 2013

For this dissertation work the scope can be recorded as below:

Understanding the design intent of the component

Die Design for the subject component

Steel material like HCHcr (High carbon High Chromium) & OHNS (Oil Hardening non

Shrinkage) grade for both punch and die block to suit the components having EDD (Extra

Deep Draw) would be used for experimentation.

Analysis to identify the defects & best methodology of processing the part &

comparison would be reviewed.

Trials and validation.

Documentation and review.

Recommendation with final design output.

Software Used: M.S.EXCEL/ UNIGRAPHICS NX-6/ HYPERFORM/ OPTRIX

RT

1. Software CAD/ CAE facility is available at Able Technologies (I) Pvt. Ltd, Pune/

IdeaMaps, Pune. The popular software used for `forming analysis to be used for this

IJE

software would be any of the following HyperForm / AutoForm/ MD-Marc/ D-Form/

Optrix.

Experimentation/ Validation:

The standard or reference data available for the past design/ validation as standards or

reference normally proves to be very useful while considering experimentation. The die once

manufactured would be subjected to trials for checking the output (the component). The

experimentation would be carried out using a Press Machine of a suitable type and tonnage.

Normally, a hydraulic press is used for Form and Draw that involve stretching/ thinning of the

component with a high draw ratio. The Die is set up over the machine and the component is fed

manually or automatic during the trial run.

IJERTV2IS60390 www.ijert.org 924

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 6, June - 2013

The trials are conducted in a very controlled environment with focus on

the variables influencing the generation of defects. A number of trial runs are conducted to

ensure consistency/ repeatability of the stamping process.

The methodology to be adopted for this development phase would include the determination

of blank size, Analysis for identifying the defects and the best course of processing the part,

optimized operating parameters for the hydraulic press, setting for tuning the variables on the

forming die like blank-holding pressure, experimentation over varying thickness within a given

range and so on.

The virtual validation of the die (simulation using software) should address the given problem

during the design stage. While the die is manufactured, the trials and testing would address the

phase of validation as the physical tool (die) would be tried-out for checking the nature of the

physical component as an outcome of the developmental process.

RT

The die would be considered as validated upon inspecting the physical trial components for the

presence and magnitude of defects. Low occurrence and consistency in the desirable

IJE

characteristics in the physical part produced would be considered as a basis for validation of the

Die.

References:

1) Die Shape Design in Channel Forming Process by Compensation of Springback Error

Arash Behrouzi, Bijan Molaee Dariani, Mahmood Shakeri Department of Mechanical

Engineering, Amirkabir University of Technology,Tehran, Iran,Majlesi Journal of Mechanical

Engineering,vol.3/No.2/winter 2010 Page No.17-26.

2) Analysis Of Forces in Deep Drawing Process, Juraj HUDAK,Miroslav TOMAS, Department

of Technologies & materials, Technical University of Kosics, Annals of faculty Engg.Hunedoara-

International Journal Of Engineering,TOM IX (Year 2011) Fascicule 1.

( ISSN-1584-2665) Page No.219-221

IJERTV2IS60390 www.ijert.org 925

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 6, June - 2013

3) Finite Element Analysis of Sheet Metal Forming Process,Hakim S. Sultan Aljibori

Mechanical Engineering Department, Faculty of Engineering University Malaya, 50603, Kuala

Lumpur, Malaysia, Abdel Magid Hamouda Mechanical and industrial Engineering

Department,Faculty of Engineering, Qatar University, Doha, Qatar,European Journal of

Scientific Reasearch ISSN 1450-216X Vol.33 No.1 (2009),PP.57-69.

4) Failure Analysis of Rapid Prototyped Tooling in Sheet Metal Forming -Cylindrical Cup

Drawing,Y. Park1 J. S. Colton Professor, Fellow ASME the George W. Woodruff School of

Mechanical Engineering, Georgia Institute of Technology, Atlanta, GA 30332-0405, Vol.127,Feb

2005, Page No.126-137.

5) Some aspects of blank-holder force schemes in deep drawing Process, A.Wifi, A.Mosallam

Department of mechanical Design & production, Faculty of Engg, Cariro University, Giza12316,

RT

Egypt,Vol.24 Issue 1 Sept.2007, Page No.315-321.

IJE

6) Tool design in a multi-stage drawing and ironing process of a rectangular cup with a large

aspect ratio using finite element analysis , Se-Ho Kim, Seung-Ho Kim, Hoon Huh,Department

of Mechanical Engineering, Korea Advanced Institute of Science and Technology, Science Town,

Taejon, 305-701 South Korea Received 16 October 2001; accepted 3 January 2002, Page

No.863-875.

7) Computer Simulated and Experimental Verification of Tooling for Progressive Deep

Drawing,Peter Kostka,Peter Cekan,Slovak University of Technology in Bratislava, Faculty of

Mechanical Engineering, Department of Materials & Technologies, 8 th International LS- DYNA

Users conference Metal Forming (1),Page No.9-59 to 9-65.

IJERTV2IS60390 www.ijert.org 926

Вам также может понравиться

- 009 Installation of Pumps Risk AssessmentДокумент2 страницы009 Installation of Pumps Risk Assessmentgangadharan000100% (13)

- A Comparative Study of Conventional Steel Building and Pre-Engineered Steel Building Structure Using STAAD PROДокумент7 страницA Comparative Study of Conventional Steel Building and Pre-Engineered Steel Building Structure Using STAAD PROIJRASETPublicationsОценок пока нет

- Aluminium Alloy GDC & ProblemsДокумент11 страницAluminium Alloy GDC & ProblemsN.B.PОценок пока нет

- TRB CatalogДокумент836 страницTRB CatalogDiana LazariОценок пока нет

- Dynamic Analysis On RCC and Composite Structure For Uniform and Optimized SectionДокумент16 страницDynamic Analysis On RCC and Composite Structure For Uniform and Optimized SectionIJRASETPublicationsОценок пока нет

- Dynamic Postioning SystemДокумент50 страницDynamic Postioning Systempraveen_meo1Оценок пока нет

- Procast 2009 Steel ExampleДокумент11 страницProcast 2009 Steel ExampleKimberly KingОценок пока нет

- 1st Grading Exam Perdev With TosДокумент4 страницы1st Grading Exam Perdev With Toshazel malaga67% (3)

- (Herbert Kitschelt, Steven I. Wilkinson) Patrons, PDFДокумент387 страниц(Herbert Kitschelt, Steven I. Wilkinson) Patrons, PDFClemente Tomás Sánchez BarjaОценок пока нет

- Analysis and Optimization of Cutting ParДокумент7 страницAnalysis and Optimization of Cutting Parpintakaning rungssitОценок пока нет

- Modelling and Analysis of Drilling Jig For MountinДокумент5 страницModelling and Analysis of Drilling Jig For MountinHarsha MetiОценок пока нет

- Kuo2021 Article CharacterizationsOfPolymerInjeДокумент18 страницKuo2021 Article CharacterizationsOfPolymerInjeAsad UllahОценок пока нет

- AFDEX Simulation of Connecting RodДокумент7 страницAFDEX Simulation of Connecting RodKumar SatyamОценок пока нет

- Ijapie 2017 02 220Документ7 страницIjapie 2017 02 220Rui MatiasОценок пока нет

- Design and Fabrication of Portable Drilling and Boring MachineДокумент4 страницыDesign and Fabrication of Portable Drilling and Boring MachineVIVA-TECH IJRIОценок пока нет

- Comparative Study of Casting Simulation Packages Used in FoundriesДокумент4 страницыComparative Study of Casting Simulation Packages Used in FoundriesPrasad AnandОценок пока нет

- 10 Viii August 2022Документ19 страниц10 Viii August 2022IJRASETPublicationsОценок пока нет

- Cad Modelling of Combination Tool For End Mill and ReamerДокумент6 страницCad Modelling of Combination Tool For End Mill and ReamerIJRASETPublicationsОценок пока нет

- Design and Fabrication of Multipurpose Mechanical MachineДокумент12 страницDesign and Fabrication of Multipurpose Mechanical MachineIJRASETPublicationsОценок пока нет

- Design & Fabrication of Metal Scrap Bailing PressДокумент4 страницыDesign & Fabrication of Metal Scrap Bailing PressReyazul HaqueОценок пока нет

- Geometrical Metrology For Metal Additive ManufacturingДокумент24 страницыGeometrical Metrology For Metal Additive ManufacturingPhilipe Saraiva CruzОценок пока нет

- Minimizing Shrinkage Porosity by Optimizing Some Parameters of Al Alloy (6061T6) Using DOEДокумент11 страницMinimizing Shrinkage Porosity by Optimizing Some Parameters of Al Alloy (6061T6) Using DOEIJRASETPublicationsОценок пока нет

- Investigation of Progressive Die Tool For Electrical AppliancesДокумент7 страницInvestigation of Progressive Die Tool For Electrical Appliancesmis2hijosОценок пока нет

- Additively Manufacturing An Indexable Insert: IOP Conference Series: Materials Science and EngineeringДокумент6 страницAdditively Manufacturing An Indexable Insert: IOP Conference Series: Materials Science and Engineeringsiva kumarОценок пока нет

- PROJECT REVIEW 1 FinalДокумент23 страницыPROJECT REVIEW 1 FinalNani DatrikaОценок пока нет

- 1 s2.0 S2212827122001159 MainДокумент6 страниц1 s2.0 S2212827122001159 MainSUBHASHISH SAHOOОценок пока нет

- Comparative Analysis of Face Milling in Dry and Wet Condition of Al 8011 For Minimum Surface Roughness in Face MillingДокумент10 страницComparative Analysis of Face Milling in Dry and Wet Condition of Al 8011 For Minimum Surface Roughness in Face MillingIJRASETPublicationsОценок пока нет

- PROJECT REVIEW 2 FinalДокумент23 страницыPROJECT REVIEW 2 FinalNani DatrikaОценок пока нет

- Determination of Forming Limit Diagram For Aisi 1008 Steel Sheet by Theoratical, Experimental and Fea MethodДокумент7 страницDetermination of Forming Limit Diagram For Aisi 1008 Steel Sheet by Theoratical, Experimental and Fea Methodnsk143446Оценок пока нет

- Design and Fabrication of Welding Fixtures and PositionersДокумент5 страницDesign and Fabrication of Welding Fixtures and PositionersVIVA-TECH IJRIОценок пока нет

- Karthik BN Technical Seminar PresentationДокумент18 страницKarthik BN Technical Seminar PresentationKIRAN TG 1SI19CS063Оценок пока нет

- Thermal Stress Analysis and Optimization of FSW Process On UHMWPE by Using Hexagonal Tool ProfileДокумент10 страницThermal Stress Analysis and Optimization of FSW Process On UHMWPE by Using Hexagonal Tool ProfileIJRASETPublicationsОценок пока нет

- A Review On Stereo-LithographyДокумент4 страницыA Review On Stereo-LithographyGRD JournalsОценок пока нет

- Materials Today: Proceedings: K. Bintu Sumanth, V. SrinivasanДокумент6 страницMaterials Today: Proceedings: K. Bintu Sumanth, V. SrinivasananshuОценок пока нет

- Automated Pressing MachineДокумент7 страницAutomated Pressing MachineIJRASETPublicationsОценок пока нет

- Fracture Toughness of ABS AdditivelДокумент10 страницFracture Toughness of ABS AdditivelsvfОценок пока нет

- Design and Modification of Forming Tool in Press MachineДокумент11 страницDesign and Modification of Forming Tool in Press MachineIJRASETPublicationsОценок пока нет

- Solidification Analysis of Investment Cast Knee Joint ImplantДокумент7 страницSolidification Analysis of Investment Cast Knee Joint ImplantijsretОценок пока нет

- Study On The Shear Characteristics of Perforated Lean Duplex Stainless Steel Rectangular Hollow BeamsДокумент9 страницStudy On The Shear Characteristics of Perforated Lean Duplex Stainless Steel Rectangular Hollow BeamsIJRASETPublicationsОценок пока нет

- Comparative Study Between Hydroforming and Hot StampingДокумент6 страницComparative Study Between Hydroforming and Hot StampingIJRASETPublicationsОценок пока нет

- GFRP NCODE Designlife DigimatДокумент11 страницGFRP NCODE Designlife DigimatKruthika K CОценок пока нет

- V6i2 1316Документ5 страницV6i2 1316ARVINDKOUSHIKОценок пока нет

- Excel Detail DesignДокумент7 страницExcel Detail DesignKishore KrishnanОценок пока нет

- The Influence of Operational Settings On The Tensile Strength of An FDM-Printed Abs ComponentДокумент12 страницThe Influence of Operational Settings On The Tensile Strength of An FDM-Printed Abs ComponentIJRASETPublicationsОценок пока нет

- SMiRT 25 Special Session Kobe Cerisano KovacevicДокумент10 страницSMiRT 25 Special Session Kobe Cerisano KovacevicbaizidffffОценок пока нет

- Forming Simulation and Die Design in Sheet Metal FormingДокумент8 страницForming Simulation and Die Design in Sheet Metal FormingALBERTUS DEОценок пока нет

- Materials Today: Proceedings: C.S. Choudhari, S.S. KhasbageДокумент7 страницMaterials Today: Proceedings: C.S. Choudhari, S.S. KhasbageN. P. JAGANОценок пока нет

- 23 - Steel - 29 - IISTE Call For Paper, HTTP://WWW - Iiste.org/journalsДокумент35 страниц23 - Steel - 29 - IISTE Call For Paper, HTTP://WWW - Iiste.org/journalsiisteОценок пока нет

- Hama Etal J.Comp - Sci.Tech 2008 JST - Go.jpДокумент14 страницHama Etal J.Comp - Sci.Tech 2008 JST - Go.jpMohammed LaamiriОценок пока нет

- Modified Formwork System For Slab ElementДокумент5 страницModified Formwork System For Slab ElementIJRASETPublicationsОценок пока нет

- Materials Today: Proceedings: R. Kumar, S. Madhu, K. Aravindh, V. Jayakumar, G. Bharathiraja, A. MuniappanДокумент7 страницMaterials Today: Proceedings: R. Kumar, S. Madhu, K. Aravindh, V. Jayakumar, G. Bharathiraja, A. Muniappanชนพัทธ์ คงพ่วงОценок пока нет

- Design of Fatigue Testing Machine For Composite Leaf SpringДокумент30 страницDesign of Fatigue Testing Machine For Composite Leaf SpringIJRASETPublicationsОценок пока нет

- Electrochemical DeburringДокумент8 страницElectrochemical DeburringraulОценок пока нет

- Experimental Investigation of Mustard Oil Based Nano Cutting Fluid On CNC Turning OperationДокумент13 страницExperimental Investigation of Mustard Oil Based Nano Cutting Fluid On CNC Turning OperationIJRASETPublicationsОценок пока нет

- PUBLISHPAPERIJISET V3 I11 03ImpactofPost-WeldHeatTreatmentPWHTontheHardnessandДокумент12 страницPUBLISHPAPERIJISET V3 I11 03ImpactofPost-WeldHeatTreatmentPWHTontheHardnessandYKAGARWALОценок пока нет

- AM92 MAurya N. E.A. Comparative Study and Measurement of Form Errors For The Component Printed by FDM en PJ Process. 2019. Science Direct 336796193Документ8 страницAM92 MAurya N. E.A. Comparative Study and Measurement of Form Errors For The Component Printed by FDM en PJ Process. 2019. Science Direct 336796193markvanderstaay70Оценок пока нет

- Ijmet 06 12 002Документ9 страницIjmet 06 12 002subramanianОценок пока нет

- Modeling and Analysis of An Injection MOULD Deploying CREO Parametric and Analysis SystemДокумент8 страницModeling and Analysis of An Injection MOULD Deploying CREO Parametric and Analysis SystemN. P. JAGANОценок пока нет

- An Investigation On Cut Quality of Aluminum Matrix Composites Cut by Abrasive WaterjetДокумент11 страницAn Investigation On Cut Quality of Aluminum Matrix Composites Cut by Abrasive WaterjetIJRASETPublicationsОценок пока нет

- Computer-Aided Design of Tooling For Casting Process: August 1999Документ11 страницComputer-Aided Design of Tooling For Casting Process: August 1999didoОценок пока нет

- Design and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050Документ8 страницDesign and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050The ash Designe GalaryОценок пока нет

- Investigations For Deducing Wall Thickness of Aluminium Shell Casting Using Three Dimensional PrintingДокумент5 страницInvestigations For Deducing Wall Thickness of Aluminium Shell Casting Using Three Dimensional PrintingR Moses KrupavaramОценок пока нет

- A Review of Soft Computing Techniques in Materials Engineering PDFДокумент17 страницA Review of Soft Computing Techniques in Materials Engineering PDFqoriОценок пока нет

- A Review On Plastic Moulding Manufacturing Process and ParametersДокумент9 страницA Review On Plastic Moulding Manufacturing Process and ParametersIJAERS JOURNALОценок пока нет

- Venue: Logistics For TEQIP Workshop On FEMДокумент1 страницаVenue: Logistics For TEQIP Workshop On FEMpraveenОценок пока нет

- Mechanical and Water Absorption Properties of Sisal-Fibre-Reinforced Polypropylene Composites For Ceiling ApplicationsДокумент7 страницMechanical and Water Absorption Properties of Sisal-Fibre-Reinforced Polypropylene Composites For Ceiling ApplicationspraveenОценок пока нет

- Mechanical Property Analysis of Kenaf-Glass Fibre Reinforced Polymer Composites Using Finite Element AnalysisДокумент11 страницMechanical Property Analysis of Kenaf-Glass Fibre Reinforced Polymer Composites Using Finite Element AnalysispraveenОценок пока нет

- Flight TicketДокумент4 страницыFlight TicketpraveenОценок пока нет

- Tcps 2 Final WebДокумент218 страницTcps 2 Final WebBornaGhannadiОценок пока нет

- EnglishFile4e Intermediate Plus TG PCM Vocab 1BДокумент1 страницаEnglishFile4e Intermediate Plus TG PCM Vocab 1Bayşe adaliОценок пока нет

- Henderson 1Документ4 страницыHenderson 1danielОценок пока нет

- HS ĐỀ CƯƠNG KIỂM TRA GIỮA KỲ I KHOI 10 NH 23 24Документ6 страницHS ĐỀ CƯƠNG KIỂM TRA GIỮA KỲ I KHOI 10 NH 23 24Ngô Hiểu NhiênОценок пока нет

- Money, Sex, and Power: Toward A Feminist Historical MaterialismДокумент2 страницыMoney, Sex, and Power: Toward A Feminist Historical MaterialismddwererОценок пока нет

- LG 55lw5600 Chassis La12c SMДокумент29 страницLG 55lw5600 Chassis La12c SMwandag2010Оценок пока нет

- Potential Application of Orange Peel (OP) As An Eco-Friendly Adsorbent For Textile Dyeing EffluentsДокумент13 страницPotential Application of Orange Peel (OP) As An Eco-Friendly Adsorbent For Textile Dyeing EffluentsAnoif Naputo AidnamОценок пока нет

- Gear Whine Prediction With CAE For AAMДокумент6 страницGear Whine Prediction With CAE For AAMSanjay DeshpandeОценок пока нет

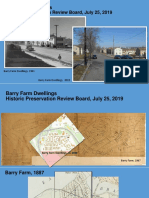

- Barry Farm Powerpoint SlidesДокумент33 страницыBarry Farm Powerpoint SlidessarahОценок пока нет

- Practical Means For Energy-Based Analyses of Disproportionate Collapse PotentialДокумент13 страницPractical Means For Energy-Based Analyses of Disproportionate Collapse PotentialNhut NguyenОценок пока нет

- New Text Document 22Документ90 страницNew Text Document 22Marija SerifovskaОценок пока нет

- JavaScript ArraysДокумент5 страницJavaScript Arraysursu_padure_scrОценок пока нет

- JAIM InstructionsДокумент11 страницJAIM InstructionsAlphaRaj Mekapogu100% (1)

- Unification of Euler and Werner Deconvolution in Three Dimensions Via The Generalized Hilbert TransformДокумент6 страницUnification of Euler and Werner Deconvolution in Three Dimensions Via The Generalized Hilbert TransformMithunОценок пока нет

- IBRO News 2004Документ8 страницIBRO News 2004International Brain Research Organization100% (1)

- Fichas Slate HoneywellДокумент1 страницаFichas Slate HoneywellING CARLOS RAMOSОценок пока нет

- Mmims5elesson BiomesДокумент3 страницыMmims5elesson Biomesapi-490524730100% (1)

- Evolution of Management TheoriesДокумент20 страницEvolution of Management TheoriesKanishq BawejaОценок пока нет

- B.tech - Non Credit Courses For 2nd Year StudentsДокумент4 страницыB.tech - Non Credit Courses For 2nd Year StudentsNishant MishraОценок пока нет

- Semi-Conductor Laboratory - MohaliДокумент4 страницыSemi-Conductor Laboratory - MohalimanjnderОценок пока нет

- Proposal Defense Form Chapter 1 3Документ3 страницыProposal Defense Form Chapter 1 3Jason BinondoОценок пока нет

- INV201 ReadParameterДокумент3 страницыINV201 ReadParameterRaul ArbaniesОценок пока нет

- D027B OmronДокумент141 страницаD027B OmronirfanWPKОценок пока нет

- Biology FileДокумент10 страницBiology FileMichael KorsОценок пока нет

- 500 Grammar Based Conversation Question12Документ16 страниц500 Grammar Based Conversation Question12Ivo Barry Ward100% (1)