Академический Документы

Профессиональный Документы

Культура Документы

Qap PDF

Загружено:

Ravi Bhadani0 оценок0% нашли этот документ полезным (0 голосов)

114 просмотров3 страницыОригинальное название

QAP.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

114 просмотров3 страницыQap PDF

Загружено:

Ravi BhadaniАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

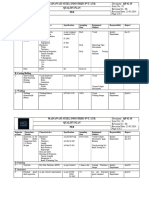

Customer: Geeco Enercon

QUALITY ASSURANCE PLAN Equipment: Oil Cooler

Manufacturer: OMEEL Coils

Component Type/Met Extent Agency Remarks

Sr. Characteristics and Categ Reference Acceptance Format of

s& hod of of

No Checks ory Documents Norms Record P W V

Operation Check Check

1 2 3 4 5 6 7 8 9 10 11

1 Design Design Input Review CR Review 100% Clients Clients Calculation 2 1 Drawing given

Review Review of Design design drawing drawing sheets and by client so

Calculation calculatio drawings manufacturing

n and will be done

1. Area drawings as per the

calculation drawing, there

2. Shell Thickness is no

Calculation interference

3. Dished Head of

Thickness manufacturer.

4. Flange

Standards

5. General

Layout of Oil

Cooler

6. Review of the

Drawing and

BOM

Legends

P: Perform 3: Vendor/Manufacturer MA: Major

W: Witness 2: Customer/Customer Nominated Agency CR: Critical

V: Verification 1: Customer Nominated Agency

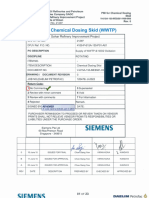

Customer: Geeco Enercon

QUALITY ASSURANCE PLAN Equipment: Oil Cooler

Manufacturer: OMEEL Coils

Type/Met Extent Agency Remarks

Sr. Components Characteristics and Categ Reference Acceptance Format of

hod of of

No & Operation Checks ory Documents Norms Record P W V

Check Check

1 2 3 4 5 6 7 8 9 10 11

2 Raw Material 1. Shell MA Visual, 1 on Material TC

Inspection 2. Dished End MA Mechanic Each TC/Lab

3. Oil Cooler MA al & Lot record

Tubes Chemical

4. Tube Sheet MA

5. Baffle Plates MA Visual &

6. Heat MA Chemical

Exchanger

Supporting

leg MA

7. Nozzles MA

8. Pipes &

Flanges MA

9. Tie Rods MA

10. Hard Wares

3 M/C Dimensional MA Visual & 100% As per As per IR

Component Inspection Measuring Approved Approved

Tubesheet and drawing drawing

End Flange

Legends

P: Perform 3: Vendor/Manufacturer MA: Major

W: Witness 2: Customer/Customer Nominated Agency CR: Critical

V: Verification 1: Customer Nominated Agency

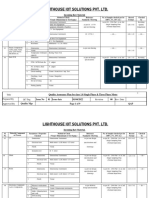

Customer: Geeco Enercon

QUALITY ASSURANCE PLAN Equipment: Oil Cooler

Manufacturer: OMEEL Coils

Type/Met Format Agency Remarks

Sr. Components Characteristics and Categ Extent Reference Acceptance

hod of of

No & Operation Checks ory of Check Documents Norms P W V

Check Record

1 2 3 4 5 6 7 8 9 10 11

4 Layout of Fit up of Tube MA Visual & 100% As per As per IR

Arrangement Dimensional Measuring Approved Approved

Inspections drawing drawing

Mock up For Tube

Expansion

5 In Process 1. Fit up of total MA Visual & 100% As per As per IR

Inspection system Measuring Approved Approved

Dimensional drawing drawing

Inspection

2. Dimensional MA Visual & 100% As per As per IR

Inspection of Measuring Approved Approved

After drawing drawing

Completed

Welding

6 Dimensional Layout & Total MA Visual & 100% As per As per IR

Inspection Assembly Measuring Approved Approved

drawing drawing

7 Hydro Testing Hydro Testing CR Visual & Hydro Test @ PQR IR

Testing PSI

8 Surface Shade & DFT MA Visual & 100% at Approved Approved IR

Preparation & Measuring Random Paint Paint

Painting Specification Specification

Legends

P: Perform 3: Vendor/Manufacturer MA: Major

W: Witness 2: Customer/Customer Nominated Agency CR: Critical

V: Verification 1: Customer Nominated Agency

Вам также может понравиться

- QAP CondenserДокумент3 страницыQAP CondenserisaacОценок пока нет

- Technical Specification and PQR - 2022 05 04 11 00 54Документ9 страницTechnical Specification and PQR - 2022 05 04 11 00 54isepcontrolОценок пока нет

- Burj Dubai Development The Dubai Mall: Main Contract Joint Venture: Dbb/Ag&CccДокумент3 страницыBurj Dubai Development The Dubai Mall: Main Contract Joint Venture: Dbb/Ag&CccJoseph DarwinОценок пока нет

- Cable Trays (ITP E 0002)Документ1 страницаCable Trays (ITP E 0002)Avishek ChowdhuryОценок пока нет

- F-075-Check List For Reinforced Concrete WorkДокумент1 страницаF-075-Check List For Reinforced Concrete WorkEshwarОценок пока нет

- FAT Procedure SafePlusДокумент3 страницыFAT Procedure SafePlusharisОценок пока нет

- Quality Assurance PlanДокумент3 страницыQuality Assurance PlanVicky Gautam100% (1)

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteДокумент5 страницQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- Inspection MatrixДокумент2 страницыInspection MatrixFabian BellОценок пока нет

- Quality Assurance Plan For PEBДокумент2 страницыQuality Assurance Plan For PEBBipin Vihari DasОценок пока нет

- Inspection and Test Plan Steel Sheet Pile DriДокумент6 страницInspection and Test Plan Steel Sheet Pile DriSofda Imela100% (1)

- Qap Reciever TanksДокумент6 страницQap Reciever Tanksyamunaengg2011Оценок пока нет

- Sample QAPДокумент3 страницыSample QAPArjun ChouhanОценок пока нет

- Qap - Sail-WbДокумент2 страницыQap - Sail-WbRiyu RathodОценок пока нет

- LG (67) - G3-1007 Fan (Propeller) G v.2Документ10 страницLG (67) - G3-1007 Fan (Propeller) G v.2Anonymous Lta32Ta9Оценок пока нет

- Quality Assurance PlanДокумент3 страницыQuality Assurance PlanNESTOR YUMULОценок пока нет

- List of InspectionДокумент17 страницList of InspectionNQTОценок пока нет

- JMC Projects India Limited Water Business Unit FormworkДокумент4 страницыJMC Projects India Limited Water Business Unit FormworkKumar AbhishekОценок пока нет

- ENMAS EPC Quality Assurance Plan for Piping ComponentДокумент2 страницыENMAS EPC Quality Assurance Plan for Piping ComponentPavul RajОценок пока нет

- CV - Qa.f-038, Concrete Pour CardДокумент3 страницыCV - Qa.f-038, Concrete Pour CardSandip PaulОценок пока нет

- Inspection Plan For Pipe LineДокумент4 страницыInspection Plan For Pipe LineArfanAliОценок пока нет

- Quality Control in Fabricaton 1 Quality Assurance Plan 2 Inspection Report 3 NDT Report 4Документ13 страницQuality Control in Fabricaton 1 Quality Assurance Plan 2 Inspection Report 3 NDT Report 4Varun MalhotraОценок пока нет

- By Sekar - Rajesh at 6:53 PM, Jun 17, 2015Документ23 страницыBy Sekar - Rajesh at 6:53 PM, Jun 17, 2015Rahmat BasukiОценок пока нет

- QAP of FOB AS PER PKG3Документ32 страницыQAP of FOB AS PER PKG3Prasanta Parida100% (1)

- 001 Inspection - Report - INTEC (05 - 07102015) PDFДокумент7 страниц001 Inspection - Report - INTEC (05 - 07102015) PDFfitroh_hzОценок пока нет

- Inspection and Test Plan (ITP) Sample IPAL PalembangДокумент3 страницыInspection and Test Plan (ITP) Sample IPAL PalembangBudi TooleeОценок пока нет

- QCR W 2016Документ1 страницаQCR W 2016Madhan KannanОценок пока нет

- Suria Engineering Dossier for GF-304CR StructureДокумент35 страницSuria Engineering Dossier for GF-304CR Structuresuria qaqcОценок пока нет

- Itp For Fabn. & Erection of Structural WorksДокумент4 страницыItp For Fabn. & Erection of Structural Workscrm 2Оценок пока нет

- ITP For Boiler ErectionДокумент6 страницITP For Boiler ErectionUmair Awan100% (2)

- QAP of MCC_A1_14-12-12_SRДокумент9 страницQAP of MCC_A1_14-12-12_SRsriram.5230Оценок пока нет

- Quality Assurance PlanДокумент9 страницQuality Assurance PlanQAD LotusОценок пока нет

- Jash Engineering LTD.: Quality Assurance PlanДокумент3 страницыJash Engineering LTD.: Quality Assurance PlanShree ConstructionОценок пока нет

- QIP of Boiler For ErectionДокумент6 страницQIP of Boiler For ErectionUmair Awan100% (2)

- FQP For Chimney 3 MechanicalДокумент4 страницыFQP For Chimney 3 MechanicalKuldeep ChakerwartiОценок пока нет

- Cathodic Protection & AC/DC Interference Mitigation Installation, Inspection & Test Plan (ITP)Документ10 страницCathodic Protection & AC/DC Interference Mitigation Installation, Inspection & Test Plan (ITP)wei gao100% (1)

- PIPING R04 101022 DraftДокумент2 страницыPIPING R04 101022 DraftPavul RajОценок пока нет

- ISRO EOT Crane QAPДокумент17 страницISRO EOT Crane QAPSuleman Khan100% (1)

- PART 38 CSWIP 3.1 Noted Points - Part 2Документ7 страницPART 38 CSWIP 3.1 Noted Points - Part 2ravindra_jivaniОценок пока нет

- MDR List of Content for PIPEДокумент1 страницаMDR List of Content for PIPED S Sagar TripuramalluОценок пока нет

- K.P.Mondal & Sons: Quality Assurance PlanДокумент1 страницаK.P.Mondal & Sons: Quality Assurance PlanTanmoy DuttaОценок пока нет

- ELECT-TIC-1.3 (WireCable Laying & Pulling)Документ2 страницыELECT-TIC-1.3 (WireCable Laying & Pulling)Muhammad IrfanОценок пока нет

- First Article Inspection Report: Purchase Order Number Supplier NameДокумент8 страницFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityОценок пока нет

- 00257650-0000-33EG-0001 - Rev PB - Attachment A - ITP ExampleДокумент4 страницы00257650-0000-33EG-0001 - Rev PB - Attachment A - ITP ExampleSubrata Das100% (1)

- QAP_M030128-00 (1)Документ19 страницQAP_M030128-00 (1)Pinki Mitra DasОценок пока нет

- Adobe Scan 25-Oct-2022Документ6 страницAdobe Scan 25-Oct-2022himanshu koleyОценок пока нет

- Quality Assurance Plan For TWSДокумент1 страницаQuality Assurance Plan For TWSsukumar bhowmickОценок пока нет

- Methodology For FabricationДокумент35 страницMethodology For FabricationBhushan KumarОценок пока нет

- Shuttering Check-List For TWDДокумент2 страницыShuttering Check-List For TWDMohammed Shabbir LunawadiОценок пока нет

- Concrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17Документ1 страницаConcrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17mahesh naikОценок пока нет

- Qcpi 5Документ2 страницыQcpi 5Hausland Const. Corp.Оценок пока нет

- Quality Control PlanДокумент13 страницQuality Control Plandadz mingiОценок пока нет

- Cable GlandingДокумент5 страницCable GlandingSourav RanaОценок пока нет

- Danem Engineering Works - WLL.: Quality Control & Inspection Test PlanДокумент11 страницDanem Engineering Works - WLL.: Quality Control & Inspection Test PlanRejoy babyОценок пока нет

- Manufacturing Traveler - ASME U Stamp Vessel - 2Документ8 страницManufacturing Traveler - ASME U Stamp Vessel - 2Muhammad ZubairОценок пока нет

- QAPДокумент3 страницыQAPRavi BhadaniОценок пока нет

- 3 - Hdpe - Itp Pipe WeldingДокумент2 страницы3 - Hdpe - Itp Pipe WeldingAttiq Ahmad Choudhry89% (9)

- Check List For Sub Main Distribution Board InstallationДокумент2 страницыCheck List For Sub Main Distribution Board InstallationNaing Win TunОценок пока нет

- Prds & Piping QapДокумент2 страницыPrds & Piping QapPavul RajОценок пока нет

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsОт EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsРейтинг: 5 из 5 звезд5/5 (1)

- Scan Doc by CamScannerДокумент1 страницаScan Doc by CamScannerRavi BhadaniОценок пока нет

- Indian Boiler Regulations Form Iii-A Certificate of Manufacture and Test (Regulation 4 (E) )Документ1 страницаIndian Boiler Regulations Form Iii-A Certificate of Manufacture and Test (Regulation 4 (E) )Ravi BhadaniОценок пока нет

- Tubebundle Drawing Uri NHPCLДокумент1 страницаTubebundle Drawing Uri NHPCLRavi BhadaniОценок пока нет

- Performance Watch May 2018 1526879473Документ23 страницыPerformance Watch May 2018 1526879473Ravi BhadaniОценок пока нет

- Acmcc 132Документ29 страницAcmcc 132mghodkeОценок пока нет

- Industrial Refrigeration CompressorДокумент8 страницIndustrial Refrigeration Compressorr_sridhar20064780100% (2)

- Shell and Tube Heat Exchanger DesignДокумент41 страницаShell and Tube Heat Exchanger DesignAhmad Budiman100% (2)

- Iict Niper 2960 17Документ81 страницаIict Niper 2960 17Ravi BhadaniОценок пока нет

- Technical DetailsДокумент2 страницыTechnical DetailsRavi BhadaniОценок пока нет

- Air Fin Cooler (Description)Документ4 страницыAir Fin Cooler (Description)Ravi BhadaniОценок пока нет

- View-X technical specificationsДокумент1 страницаView-X technical specificationsRavi BhadaniОценок пока нет

- Catpdf en 26Документ6 страницCatpdf en 26Nooruddin SheikОценок пока нет

- Pipe Chart PDFДокумент2 страницыPipe Chart PDFCarlos Rivera0% (1)

- QAPДокумент3 страницыQAPRavi BhadaniОценок пока нет

- Lecture4 TorsionДокумент27 страницLecture4 Torsionshilton1989Оценок пока нет

- IRISNewsRI mrz10Документ79 страницIRISNewsRI mrz10Ravi BhadaniОценок пока нет

- 1st Review SynopsisДокумент3 страницы1st Review SynopsisRavi BhadaniОценок пока нет

- RCДокумент20 страницRCRavi BhadaniОценок пока нет

- 1st Review SynopsisДокумент3 страницы1st Review SynopsisRavi BhadaniОценок пока нет

- Schedule September 2013Документ1 страницаSchedule September 2013Ravi BhadaniОценок пока нет

- Schedule September 2013Документ1 страницаSchedule September 2013Ravi BhadaniОценок пока нет

- Camless Engine PresentationДокумент20 страницCamless Engine PresentationRavi Bhadani80% (10)

- Expanding rural energy access in IndiaДокумент51 страницаExpanding rural energy access in IndiaRavi BhadaniОценок пока нет

- GFRC Glass Fibre Reinforced ConcreteДокумент9 страницGFRC Glass Fibre Reinforced ConcreteMohd ShahrizanОценок пока нет

- D-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011Документ255 страницD-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011ganesan 00110% (1)

- Building material thermal properties tableДокумент19 страницBuilding material thermal properties tablehansleyОценок пока нет

- Stable Ionic Liquid-Based Polymer Inclusion Membranes For Lithium and Magnesium SeparationДокумент10 страницStable Ionic Liquid-Based Polymer Inclusion Membranes For Lithium and Magnesium SeparationShivansh MishraОценок пока нет

- Waterjet Cutting Systems: A Versatile Cutting ProcessДокумент2 страницыWaterjet Cutting Systems: A Versatile Cutting ProcessRamin SobatiОценок пока нет

- Secondary Physics Temp NotesДокумент3 страницыSecondary Physics Temp NotesHarish PrabhuОценок пока нет

- Webasto Heater Remote Control: Here Is The Climate Control Unit J255 That Is Going To Be ModifiedДокумент8 страницWebasto Heater Remote Control: Here Is The Climate Control Unit J255 That Is Going To Be ModifiedAlexanderОценок пока нет

- Byk Bykjet 9170Документ2 страницыByk Bykjet 9170ankitleedsОценок пока нет

- MIDEL 7131 Technical Information Pack USДокумент15 страницMIDEL 7131 Technical Information Pack USkatherine100% (1)

- SF026a-Flow Chart Portal Frame Apex ConnectionДокумент3 страницыSF026a-Flow Chart Portal Frame Apex ConnectiondvelchevОценок пока нет

- UK Gate Valves Brochure High Res 02 - 2017Документ20 страницUK Gate Valves Brochure High Res 02 - 2017Sivasubramanian PalaniappanОценок пока нет

- US10985368Документ43 страницыUS10985368LeofodãoОценок пока нет

- MSDS PVCДокумент9 страницMSDS PVCDharu AbdulОценок пока нет

- Muncie - Understanding Truck Mounted Hydraulic SystemsДокумент40 страницMuncie - Understanding Truck Mounted Hydraulic SystemsStarchyLittleOleMe100% (2)

- Balancing Redox ReactionsДокумент2 страницыBalancing Redox ReactionsblobmarleyОценок пока нет

- Flowrox ValveDimensions ENGДокумент32 страницыFlowrox ValveDimensions ENGAlberto DiazОценок пока нет

- Coaching MDSP 02Документ10 страницCoaching MDSP 02jay dubouzetОценок пока нет

- Template For Preparing TANSCST ProposalДокумент6 страницTemplate For Preparing TANSCST ProposalAntony88% (8)

- MCP 101 Product Realization Lab ManualДокумент75 страницMCP 101 Product Realization Lab ManualjasvindersinghsagguОценок пока нет

- Operations Management Assignment - Lean Flow Design StudyДокумент20 страницOperations Management Assignment - Lean Flow Design StudyRachit SrivastavaОценок пока нет

- Materials Question PackДокумент20 страницMaterials Question PackSuper Dila12Оценок пока нет

- 6063 Aluminium Alloy - WikipediaДокумент3 страницы6063 Aluminium Alloy - WikipediaNinad PawarОценок пока нет

- Moment ConnectionДокумент15 страницMoment Connectionnitin400Оценок пока нет

- Annex Details of ValidityДокумент5 страницAnnex Details of ValidityAbhishek GoelОценок пока нет

- Republic of the Philippines Department of Education Region VI Summative Test in Science 7Документ1 страницаRepublic of the Philippines Department of Education Region VI Summative Test in Science 7Laysa FalsisОценок пока нет

- Project 4 Ethylene OxideДокумент12 страницProject 4 Ethylene OxideNhan Nguyen Van100% (4)

- Phase Transitions: Lectures in Physical Chemistry 4Документ8 страницPhase Transitions: Lectures in Physical Chemistry 4Farah AnjumОценок пока нет

- Vulcan LIBS Analyser For QA QC - 2Документ6 страницVulcan LIBS Analyser For QA QC - 2Trần Văn LộcОценок пока нет

- Swatch Case AnalysisДокумент3 страницыSwatch Case Analysisgunjanbihani100% (1)

- pd10196 Tetra Alsafe PDFДокумент2 страницыpd10196 Tetra Alsafe PDFEusebio NavarroОценок пока нет