Академический Документы

Профессиональный Документы

Культура Документы

Clean Room Design PDF

Загружено:

marcalpiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Clean Room Design PDF

Загружено:

marcalpiАвторское право:

Доступные форматы

Clean Room

Chapter 5

Design

By the end of this chapter, Introduction

you will be able to: In this chapter we will look at the specific

design of a clean room including the walls,

l Explain the terms positive and ceilings and floors as well as the practical

negative pressure needs of items such as workbenches, storage

cupboards and chairs.

l Name and describe two We will examine how air is filtered to

categories of air flow in a maintain the air quality and how air pressure

clean room prevents contamination of the cleanroom when

people and equipment move into or out of the

l List the main design features clean room.

of a clean room We will also take a brief look at the different

types of clean room using particle counts to

l Explain the different grades

grade areas.

of clean rooms

Chapter 5: Clean Room Design 1

Aseptic Processing

What is a Clean Room? Dirty air from the surrounding area is

prevented from entering the cleanroom by

Cleanrooms are usually self-contained controlling the air pressure in the cleanroom.

facilities with their own dedicated ventilation

systems. These control air quality, temperature l Cleanest room at highest pressure

and humidity. l Air flows from the cleanest to

dirtiest areas

Air is filtered through High Efficiency

Particulate Air (HEPA) filters which have a very Operation is at positive pressure, so ensures

small pore size. The filters collect and remove any airflow is pushed outwards from the room

small particles, before air enters through the and dirty air cannot enter the room by default.

ceiling grilles. The size of the aseptic suite depends on the

maximum number of people who might use it

at any one time.

A fairly large room is more pleasant to work

in, and the overall level of microbes in the

Ceiling HEPA filter environment is less affected by local air

disturbances or contamination produced by

individual workers.

Clean Room Design

Clean rooms fall into two categories,

unidirectional and non-unidirectional.

Build up of contaminants in the cleanroom is Unidirectional clean rooms normally have

prevented by the flow of clean air at a rate of a vertical airflow. Air flows downwards through

minimum of 20 room air changes per hour. HEPA filters located in the ceiling. The air is

extracted through perforated flooring or grilles

mounted on the walls at floor level.

Note: airflow in a unidirectional clean room

can also be horizontal.

2 Chapter 5: Clean Room Design

Chapter 5

Clean Room Design

Non unidirectional clean rooms have air When storage space is required, cupboards

flows from HEPA filters located in various are preferable to drawers because they are

positions and returned through opposite easier to clean. Cupboards should be dust

locations. Filters may be distributed at equal proof and smooth inside. Rounded beading

intervals throughout the room or grouped over may be used to cover dust-retaining angles

critical areas. The distribution and returns in within storage spaces and between fixed

this instance mean that the air flow may be benches and walls. Small units on castors

turbulent in nature. make useful additions to the working surface.

Chairs must be adjustable and comfortable

and covered with an impervious washable

material.

Trolleys should be made from stainless steel

and be easily cleanable.

The floors, walls and ceiling should be made

of a smooth impervious material to ensure no Switches and sockets should be flush fitting

particle shedding and easy cleaning. They and have plastic fingerplates.

should also be chemically resistant. All joins

There should be no

in the covering materials should be welded to

l shelves, window ledges or door frames

ensure that there is no chance of seepage of

where dust might settle.

cleaning fluids under the covering.

l pipes or ductwork. (False ceilings should be

Doors should be easy to open and, where fully sealed with lighting recessed).

necessary, two doors linked together to form

l sinks or drains.

an air lock. This prevents a sudden rush of

air when a door is opened. All doors should

be controlled to prevent unwanted flow of air

from one area to another by opening of doors

simultaneously.

Benches should be made from one complete

sheet of laminate because some liquids attack

the adhesive at the joints and eventually cause

lifting. Where possible made they should be

made from stainless steel, Trespa or Conan

which are impervious. They are usually

wall-mounted to reduce dust collection and

facilitate its detection and removal.

Chapter 5: Clean Room Design 3

Aseptic Processing

Hand washing facilities should be available Remember: In summary, there should be:

external to changing rooms. Taps should be

l smooth impervious surfaces

elbow or foot operated so that cleaned hands

l no ledges for dust to gather

are not used to turn the water off. Soap should

be conveniently dispensed from a wall or bench l surfaces which are easy to clean

dispenser. Electric hand dryers or high quality l transfer systems/airlocks to prevent

paper towels should be used to dry hands. contamination

l no water sources

Other aspects of design

of the Cleanroom

When designing a clean room there are many

considerations to make.

Here are a few but this is not an exhaustive list

of good and bad practice.

There should be a separate two-way transfer

hatch system for the transfer of goods in and

out of the cleanroom, to prevent contamination Material used in the construction should make

of environments. cleaning and disinfection easy. For example

there should be no joins between walls, floors

and ceiling and all surfaces should be smooth

and easy to clean.

There should be a support room from which

Horizontal surfaces can accumulate particles

materials can be passed into and out of the

and should be maintained by regular cleaning

cleanroom through hatches.

4 Chapter 5: Clean Room Design

Chapter 5

Clean Room Design

Airlocks should be installed between clean This is a close up of a high quality door and

areas and adjoining dirty areas hinge. Glass is easily cleanable and enables

safe access/egress.

Equipment should not reduce the airflow

and should not be placed anywhere it disturbs

the airflow.

Many of the normal routes out of an aseptic

suite can be difficult to access during a fire

alarm due to the number of corridors out of

This image shows an alcohol extraction

the suite.

unit situated in the spraying in zones of

the preparation area. It works as a vacuum This is an example of a specially constructed

extracting the alcohol fumes. fire escape to the outside of the building from

an aseptic suite. The outer door is fabricated

as a standard fire escape door, however it is

sealed behind a sheet of breakable glass.

Chapter 5: Clean Room Design 5

Aseptic Processing

Remember: Here are some other important considerations about the design and use of clean

rooms.

l The equipment should be arranged to minimise the amount of operator movement while

maximising their comfort.

l The number of staff in an aseptic processing room should be kept to a minimum.

l The flow of personnel should be limited to minimise exit and entry especially in the critical

area.

l The number of transfers to the critical area of the clean room or isolator should be

minimised.

l Excessive movement adjacent to the critical area should be restricted.

Test Yourself

Can you list 10 features to take into consideration when designing/fitting out a cleanroom?

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

6 Chapter 5: Clean Room Design

Chapter 5

Clean Room Design

Environmental Control

The highest standard of environmental control will be included in the design of the clean room.

Processes should be designed to give optimal personnel and product flow through the unit. We

will look at this in more detail later.

Aseptic processes in the clean room are designed to minimise the exposure of sterile components

to the potential hazards of the manufacturing process.

There are a maximum number of particles of different sizes allowed in the clean room at rest and

during operation.

Grade Particle count (max particle /m3)

Particle size at rest Particle size in operation

0.5 m 5 m 0.5 m 5 m

A 3,500 1 3,500 1

B 3,500 1 350,000 2,000

C 350,000 2,000 3,500,000 20,000

D 3,500,000 20,000 Not defined Not defined

The table shows the values for the maximum particle count for different particle sizes within the

different grades of clean room (Reference: Orange Guide 2007)

Examples of Cleanroom Grade

Grade A Laminar air flow cabinets and isolators, i.e. the point of fill.

Grade B The aseptic room.

Grade C The preparation room

inner support room.

Grade D Support, filling and isolator rooms.

Information: Isolators may be sited in Grade C or D rooms check your local procedures).

Chapter 5: Clean Room Design 7

Aseptic Processing

Alarm Systems

Fire and smoke alarms must be fitted in all

areas of the facility. Staff must respond to

alarms by evacuating the area immediately.

An air supply alarm should be fitted which

detects if there is a failure in the air supply to

the facility. If this is triggered, work must cease

immediately.

In this simulated image the red lamps would

indicate a problem with the cabinets.

Malfunctioning and Problems

Problems should be reported immediately so

that appropriate action can be taken. Anything

unusual should be reported even though it

Work should only restart when the air supply may seem trivial, as it could be a precursor to

has been reinstated and been running a major fault or incident.

constantly for a minimum period. In the

You should report any procedural deviations

absence of a validation exercise of the clean-

or difficulties.

up time, this period should be one hour.

Reports may be filed with the Estates

Here is an example of an alarm panel with

Department at the hospital for any routine

lamps showing the working status of the

work that may need to be done within the

LAFC and Isolator cabinets.

cleanroom or supporting areas. Specialist

cleanroom companies may be required to

carry out more complicated tasks.

Air pressure

The air pressure in clean rooms is highest

in the aseptic filling room (cleanest) and

drops incrementally to the corridors. The usual

practice is to start at 45 Pascals and come

down in 10 Pascals increments, with the final

differential being at least 15 Pascals. This will

depend on the layout of your clean rooms.

The green lamp indicates that the cabinet

is running correctly in this image.

8 Chapter 5: Clean Room Design

Chapter 5

Clean Room Design

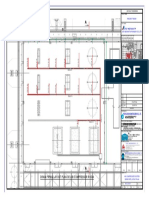

Clean Room Suite Layout

The following plans are examples of clean room suite layouts for Isolators and LAFCs and show

the flow of work and air.

Airflow direction Step over Bench

Workflow direction Transfer Hatches

Isolator Suite Layout Laminar Air Flow Cabinet (LAFC) Suite Layout

Isolator LAFC

EU grade A EU grade A

Clean Room Clean Room

EU Grade D EU Grade B

2nd Change Room 2nd Change Room

EU Grade D at rest EU Grade B at rest

Inner Support Room

Inner Support

Room EU Grade D

(clean room)

1st Change Room Outer Support Room Outer Support Room

1st Change Room

EU Grade D at rest

Chapter 5: Clean Room Design 9

Aseptic Processing

Activity

Make a sketch plan of your unit and mark on it:

l Flow of products

l Flow of people

l Flow of documents

l Air pressures in different parts of the unit.

10 Chapter 5: Clean Room Design

Chapter 5

Clean Room Design

Questions

What is the maximum allowable number of particles in a Grade A and Grade B clean

Q1 room at rest and in operation? Complete the table below to show your answers.

Grade A At rest In operation

Particle size: 0.5 m 5 m 0.5 m 5 m

Max number of

particles allowed:

Grade B At rest In operation

Particle size: 0.5 m 5 m 0.5 m 5 m

Max number of

particles allowed:

Q2 Why are airlocks installed between clean areas and adjoining less clean areas?

(2)

Chapter 5: Clean Room Design 11

Aseptic Processing

Q3 Whats the difference between a unidirectional and a non-unidirectional airflow?

(6)

12 Chapter 5: Clean Room Design

Вам также может понравиться

- Clean RoomДокумент23 страницыClean RoomHumaid Shaikh100% (1)

- Pharmaceutical Facilities: Design, Layouts and ValidationОт EverandPharmaceutical Facilities: Design, Layouts and ValidationРейтинг: 4 из 5 звезд4/5 (6)

- 6 - Clean Room Validation RequirmentsДокумент3 страницы6 - Clean Room Validation Requirmentsvijaysirsat2007100% (1)

- Cleanroom Technology: Fundamentals of Design, Testing and OperationОт EverandCleanroom Technology: Fundamentals of Design, Testing and OperationОценок пока нет

- Validation Part2Документ48 страницValidation Part2gvasОценок пока нет

- Principles and Practices of Contamination Control and CleanroomsОт EverandPrinciples and Practices of Contamination Control and CleanroomsОценок пока нет

- CLEAN ROOM PresentationДокумент54 страницыCLEAN ROOM PresentationSanjay Gade100% (1)

- Cleanroom Design in 10 Easy StepsДокумент5 страницCleanroom Design in 10 Easy StepsWerner SchrammelОценок пока нет

- Hvac For Clean Rooms FacilitiesДокумент54 страницыHvac For Clean Rooms FacilitiesAhmed Sherif100% (3)

- Sterilisation and Disinfection: Pharmaceutical MonographsОт EverandSterilisation and Disinfection: Pharmaceutical MonographsРейтинг: 5 из 5 звезд5/5 (3)

- Comparison Table of Differential Pressure Rev02Документ4 страницыComparison Table of Differential Pressure Rev02Arshavin Watashi WaОценок пока нет

- Clean ROOM HVACДокумент40 страницClean ROOM HVACAjay Sastry0% (1)

- Clean Room PDFДокумент62 страницыClean Room PDFMuhammad DanishОценок пока нет

- Good Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsОт EverandGood Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsОценок пока нет

- Cleanroom Design PDFДокумент322 страницыCleanroom Design PDFcristina100% (3)

- A Basic Design Guide For Clean Room ApplicationsДокумент61 страницаA Basic Design Guide For Clean Room ApplicationsAlex Chin67% (3)

- Clean Room HandbookДокумент80 страницClean Room HandbookPecingina Dalia DanielОценок пока нет

- Clean Room - Clean Room & HVAC SystemsДокумент74 страницыClean Room - Clean Room & HVAC Systemspchakravarty_2100% (8)

- AirlocksДокумент75 страницAirlocksmarkieboy3650% (2)

- ASHRAE Clean Room Design.Документ98 страницASHRAE Clean Room Design.Vishwajeet Rattan67% (6)

- Cleanrooms and HVAC Systems Design FundamentalsДокумент39 страницCleanrooms and HVAC Systems Design FundamentalsAhmad Ramahi100% (3)

- Class 10000 Iso 7 Cleanroom CleaningДокумент5 страницClass 10000 Iso 7 Cleanroom CleaningBồ Công AnhОценок пока нет

- Validation Presentation SRPДокумент76 страницValidation Presentation SRPRamakrishna Agumbe100% (1)

- DOP Test ProtocolДокумент10 страницDOP Test ProtocolIzi100% (2)

- ISO Class - Clean RoomДокумент11 страницISO Class - Clean RoomBanukumar RajendranОценок пока нет

- Clean Room ValidationДокумент15 страницClean Room ValidationSaifulIslam100% (2)

- Air Handling Systm in Pharmaceutical Manufacturing Pharm R.A. BinitieДокумент86 страницAir Handling Systm in Pharmaceutical Manufacturing Pharm R.A. Binitiemuratguzel100% (2)

- HVAC Design For Pharmaceutical FacilitiesДокумент57 страницHVAC Design For Pharmaceutical FacilitiesShams MInhaz Monzur100% (4)

- Clean RoomДокумент0 страницClean RoompostboxsgОценок пока нет

- Supplementary Training Modules On GMP: Air Handling SystemsДокумент20 страницSupplementary Training Modules On GMP: Air Handling SystemsRambabu komati - QAОценок пока нет

- HVAC Design For Cleanroom FacilitiesДокумент55 страницHVAC Design For Cleanroom FacilitiesMadhu Gajulapalli100% (1)

- What Is A Cleanroom - Cleanroom ClassificationsДокумент2 страницыWhat Is A Cleanroom - Cleanroom ClassificationsMai Phuong Phan TranОценок пока нет

- Clean Room PDFДокумент62 страницыClean Room PDFcaporegime01100% (2)

- Clean RoomДокумент322 страницыClean RoomCalin Truta100% (11)

- Basic Cleanroom ProtocolДокумент33 страницыBasic Cleanroom Protocolsid_calayag100% (2)

- Clean Room DesignДокумент26 страницClean Room Design981048281867% (3)

- Cleanroom Air ChangeДокумент2 страницыCleanroom Air ChangeFlu PlantОценок пока нет

- Clean Room SpecificationsДокумент4 страницыClean Room Specificationsminimoy86Оценок пока нет

- Excel Clean Room TechnologiesДокумент9 страницExcel Clean Room Technologiesxlcleantech100% (2)

- 6513 APM Chapter 5Документ12 страниц6513 APM Chapter 5Reema IshaqОценок пока нет

- Basic Requirements For Clean RoomДокумент6 страницBasic Requirements For Clean Roomsamuel debebeОценок пока нет

- What To Know When Considering A Cleanroom: by Simplex Technical StaffДокумент10 страницWhat To Know When Considering A Cleanroom: by Simplex Technical Staffmhk665Оценок пока нет

- Aseptic Processing of Parenteral ProductsДокумент50 страницAseptic Processing of Parenteral ProductsHanuma KanthetiОценок пока нет

- An Air Handling UnitДокумент4 страницыAn Air Handling UnitDono WayОценок пока нет

- Production Facilities: Aseptic Area: This Area Is The Heart of Sterile Product OperationДокумент18 страницProduction Facilities: Aseptic Area: This Area Is The Heart of Sterile Product Operationmonoj5859100% (1)

- Cleanroom Ensures Product Quality: Source: DIN EN ISO 14644-1:2016-06Документ9 страницCleanroom Ensures Product Quality: Source: DIN EN ISO 14644-1:2016-06Kritarth JaiswalОценок пока нет

- Concept Residential Bfloorplan (Color The Hallway or Corridor)Документ6 страницConcept Residential Bfloorplan (Color The Hallway or Corridor)Chi De LeonОценок пока нет

- Design of Aseptic AreaДокумент5 страницDesign of Aseptic AreaSayyeda SumaiyahОценок пока нет

- D B I C: Clean Air Technology, Inc. Esigns, Uilds and Nstalls LeanroomsДокумент2 страницыD B I C: Clean Air Technology, Inc. Esigns, Uilds and Nstalls LeanroomsRajeshОценок пока нет

- Aseptic Area:: DefinitionДокумент4 страницыAseptic Area:: DefinitionNon.d AlmalkiОценок пока нет

- Istructe Ec2 (Concrete) Design Manual 11Документ2 страницыIstructe Ec2 (Concrete) Design Manual 11Bertin BakariОценок пока нет

- Estimation Excel SheetДокумент11 страницEstimation Excel SheetManojОценок пока нет

- Effect of Using Saturated Lime Water in The Production of Concrete Using Pozzolanic Cement Cem II B-PДокумент18 страницEffect of Using Saturated Lime Water in The Production of Concrete Using Pozzolanic Cement Cem II B-PKellymax olakitarОценок пока нет

- IIIB RICE Digital Audit ProgramsFromAuditNetДокумент100 страницIIIB RICE Digital Audit ProgramsFromAuditNetspicychaitu0% (1)

- 31003Документ4 страницы31003Elliott RussellОценок пока нет

- Legacy Chiller Systems Model PZAT9S SubmittalДокумент18 страницLegacy Chiller Systems Model PZAT9S SubmittalStefan WeissОценок пока нет

- Electric Duct HeatersДокумент13 страницElectric Duct HeatersKhizerОценок пока нет

- Hydraulic Construction EquipmentДокумент24 страницыHydraulic Construction EquipmentAYUSH PARAJULIОценок пока нет

- Existing Vessel To Transitional VesselДокумент2 страницыExisting Vessel To Transitional VesselcarsicocnflatuoОценок пока нет

- Drain Piping Layout Plan of Air Compressor RoomДокумент1 страницаDrain Piping Layout Plan of Air Compressor RoomTôn Huỳnh ĐoànОценок пока нет

- Types of Plumbing FittingsДокумент8 страницTypes of Plumbing FittingsDanica Deloa50% (2)

- Spherical and Spherical Thrust BearingsДокумент21 страницаSpherical and Spherical Thrust BearingsSumit GhosalОценок пока нет

- Method Statement For PRE-ENGINEERED BUILDING ASSEMBLYДокумент39 страницMethod Statement For PRE-ENGINEERED BUILDING ASSEMBLYStephanie EmersonОценок пока нет

- ENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)Документ4 страницыENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)m khaeronОценок пока нет

- 3-1-4common Tools For OCS 3Документ35 страниц3-1-4common Tools For OCS 3ewnetu kassaОценок пока нет

- Concrete Pumping Cop 2019 PDFДокумент59 страницConcrete Pumping Cop 2019 PDFaung moe tunОценок пока нет

- Category Business Name Phone CityДокумент24 страницыCategory Business Name Phone CityMadhav PatilОценок пока нет

- 03-2 PSME Code On Fire ProtectionДокумент23 страницы03-2 PSME Code On Fire ProtectionDessa GuditoОценок пока нет

- Nozzle Reinforcement Calculation Excel SheetДокумент3 страницыNozzle Reinforcement Calculation Excel Sheetramesh punjabiОценок пока нет

- 4687 - Carrier 30 GF 120Документ36 страниц4687 - Carrier 30 GF 120ชัยณรงค์ เทียนบุตรОценок пока нет

- Section - 11356 - Dewatered Sludge Storage SilosДокумент24 страницыSection - 11356 - Dewatered Sludge Storage SilosjufrejjОценок пока нет

- A Guide To Ventilation Exhaust FansДокумент4 страницыA Guide To Ventilation Exhaust FansLoter BelautОценок пока нет

- MEB18010-Test 3Документ15 страницMEB18010-Test 3MustafaОценок пока нет

- 1.Chiều dài ống gió mềm-SMACNA 1995Документ4 страницы1.Chiều dài ống gió mềm-SMACNA 1995Long MaiОценок пока нет

- Single-Chamber Type, Inlet and Outlet Area Have The Same SizeДокумент6 страницSingle-Chamber Type, Inlet and Outlet Area Have The Same SizeSathishkumarОценок пока нет

- Greene Tweed o Ring Catalog en PBДокумент29 страницGreene Tweed o Ring Catalog en PBDaniel Villaflor100% (1)

- Elasto-Seal-Pro Bullbond Tds 2017rДокумент4 страницыElasto-Seal-Pro Bullbond Tds 2017rMark VillafloresОценок пока нет

- LEVEL GAUGE DATASHEET-Rev.AДокумент8 страницLEVEL GAUGE DATASHEET-Rev.Asugeng wahyudiОценок пока нет

- GRUNDFOS Heating-Handbook-2020Документ132 страницыGRUNDFOS Heating-Handbook-2020Τζίνα ΓιαννοπούλουОценок пока нет

- Project Report (Phase 1) PDFДокумент38 страницProject Report (Phase 1) PDFvikki100% (3)

- An Applied Guide to Water and Effluent Treatment Plant DesignОт EverandAn Applied Guide to Water and Effluent Treatment Plant DesignРейтинг: 5 из 5 звезд5/5 (4)

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)

- Process Plant Equipment: Operation, Control, and ReliabilityОт EverandProcess Plant Equipment: Operation, Control, and ReliabilityРейтинг: 5 из 5 звезд5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОт EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОценок пока нет

- Piping Engineering Leadership for Process Plant ProjectsОт EverandPiping Engineering Leadership for Process Plant ProjectsРейтинг: 5 из 5 звезд5/5 (1)

- Distillation Design and Control Using Aspen SimulationОт EverandDistillation Design and Control Using Aspen SimulationРейтинг: 5 из 5 звезд5/5 (2)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyОт EverandSodium Bicarbonate: Nature's Unique First Aid RemedyРейтинг: 5 из 5 звезд5/5 (21)

- Guidelines for Chemical Process Quantitative Risk AnalysisОт EverandGuidelines for Chemical Process Quantitative Risk AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlОт EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlРейтинг: 4 из 5 звезд4/5 (4)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersОт EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОт EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОценок пока нет

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОт EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОценок пока нет

- The Perfumed Pages of History: A Textbook on Fragrance CreationОт EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationРейтинг: 4 из 5 звезд4/5 (1)

- Fundamentals of Risk Management for Process Industry EngineersОт EverandFundamentals of Risk Management for Process Industry EngineersОценок пока нет

- A New Approach to HAZOP of Complex Chemical ProcessesОт EverandA New Approach to HAZOP of Complex Chemical ProcessesОценок пока нет

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksОт EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksОценок пока нет

- Fun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksОт EverandFun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksОценок пока нет

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsОт EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottРейтинг: 4 из 5 звезд4/5 (6)

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionОт EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionОценок пока нет

- Bioinspired Materials Science and EngineeringОт EverandBioinspired Materials Science and EngineeringGuang YangОценок пока нет