Академический Документы

Профессиональный Документы

Культура Документы

TC 53 Card Layout Design

Загружено:

J.SathishИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TC 53 Card Layout Design

Загружено:

J.SathishАвторское право:

Доступные форматы

2500

2500

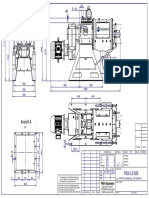

1 3 DK740 - 1No.

Item Qty. Symbol Description Power Frame

1427 width

140 100 1 01 TC 5-1 High Production Card

01 TC-LF Lap Feeding Device 01x 10.18 -

2 01 KH 600 Coiler -

4617

2 01 TC-FB Filter Box 01x 02.50 -

Ribbon Lap - 1No. 1 1 3 01 DFK Directafeed 960

01 TC 5-3 High Production Card 01x 14.20 -

01 KH 600 Coiler -

Sliver Lap - 1No.

280

280

4 01 TC-FB Filter Box 01x 02.50 -

1 1 29.38

MBO

kW mm

300 400

300 Attention:- All Values based on air density = 1.2 kg/m3

1033

2900 4000 4750 2650 - For design of filter installation additional reserve of min. 10 % required

TC 5-3

280

- The absorbed power rating corresponds to approximately 75-80% of the installed

300

power for blow room, cards and draw frames.

280

315

P48 P48

2 280

R28x1.5

1850 DO6 - 1No. 4

550

315

R15x1.5

R15x1.5

RU

R28x1.5

Pos.Nr. Machine P

Air vol./hr Pressure

MONO/DDC

Vmin = 2800 m/h Pst.min = +600 Pa

1 Mat. Feeding : DFK

Vmax = 3500 m/h Pst.max = +1200 Pa

Vmin = 2800m/h Pst.min = -100 Pa

1 Exhaust air : DFK

Vmax = 3500m/h Pst.max = -150 Pa

UNIMIX

2 Exhaust air : KH Vtarget = 250m/h Pst. = -250 Pa

300

1 Vmin = 3700m/h

Waste : TC 5-3/ TC 5-1 Pst.target = -800 Pa

LR Fan

Vmax= 3900m/h

ERM

Pneumatic

P48

SECTION: A-A Sc. 1:50

Connection

Consuming

TC 5-3

Point 280

Compressed air requirement

(without factor of safety) 01 x 1400 1400

280

(l/h)

280

315

100

Necessary pressure at

2475

2475

the consuming point 8

(bar)

DK740 - 1No. Connection at the R15x1.5

1401

3600

3600

3600

Consuming Point

3360

3160

3092

Distribution

2790

R28x1.5

Ducting

TC 5-1

TC 5-3

1900

4642

Ribbon Lap - 1No.

4642

Compressed air must fulfill following conditions:

2

Sliver Lap - 1No. Oil - ISO-class 1 ( oil content 0.01 mg/m)

1 1 3 Dust - ISO-class 1 ( particle density 0.1 mg/m)

MBO

P48 TC-LF

P48 DFK

Water - ISO-class 4 ( dew point + 3C)

High Production Card Filter Box

1033

2900 4000 4750 2650

Comm. No. 01 x TC..... DFK 960 Comm. No. 01 x TC..... TC-FB

01 x TC..... TC 5-3

36 01 x TC..... KH 600

125

1850

2 2

1850 DO6 - 1No.

550

Piping Specification

36

List of conventional signs

550

125 Specification of pipes for material Material : St (Zinc galvanised)

MONO/DDC

transport, exhaust air and waste transport. Truetzschler India scope of supply

Max. pipe length : 1500mm

Piping and connections must be completely airtight. Truetzschler scope of supply

D = <400 400 ... 600 >600 mm

Existing machines

UNIMIX

T = 0.75 1.00 1.25 mm Future extension

D = <400 >=400mm

R = 2xD 1xD Material transport duct for Cotton

SPACE REQUIREMENT AND FLOOR LOAD M1:50 ST 12 Material transport duct for Cotton

TC 5-3 / KH 600 (ZINC galvanised)

LR Fan

Material transport duct for Blend

Free of oil

and grease Material transport duct for Man Made Fiber

D

ERM

Waste transport duct

Exhaust air duct

3742 900 T

R

15

580 90mm deep for coiler Example for cable duct

215 975 820 1076 under floor

Hole 120 for cable and Free of Burr G Recommended Machine

compressed air piping

84

420

X-X Modification in existing Machine

914

BR-2W 2 Way Distribution BR-MT Magnet Trap

80

X

BR-AC Automatic Change Box LC-HD Heat Detector

880

599

1475

599

585

412

10

450 HWK Manual Change Box LC-SD Spark Detector for Pipes

2000

Details for Cable & Pneumatic Points

152

BR-FA Fresh Air Flap BR-FP Fire Protection Flap

599

599

80

1 Cable outlet 120

880

BR-FF Flexafeed Flap

2-3 Cable connection Point Longitudinal BR-PS Pipe slide -by customer-

G

D

seam pipes

P48 Pneumatic outlet 120 G

Point foundation 200 T ST 12 (ZINC galvanized) Elaborated Vijay 2017.03.04

150mm deep for plug 525 3170 Distribution part Checked Kandge

Floorload approx. 8520 N/m2 3750 Re-checked

Load on each floorplate approx. 33 N/cm2 Name Date

30

All rights reserved Scale Order no.

D1

D2

All Dimensions in mm 1 : 100 BE 612 02, AE 612 03

Customer / Subject Drawing no.

BWR 06712-234591

South India Textile

Replaces BWR 04503-234591

D1 <1.05

= Research Association

(Coimbatore, TML) Replaced for

Вам также может понравиться

- User Manual: Tia Technology India Pvt. LTDДокумент83 страницыUser Manual: Tia Technology India Pvt. LTDRobin PОценок пока нет

- MR - Ranjeet Kumar Kurkure Process Line With PackingДокумент12 страницMR - Ranjeet Kumar Kurkure Process Line With PackingRanjeet BhaiОценок пока нет

- EPI-3522 GRAND - Abian BlisreringДокумент12 страницEPI-3522 GRAND - Abian Blisreringmohammad pirayesh100% (1)

- Meech Web Cleaning Overview Brochure 2015Документ24 страницыMeech Web Cleaning Overview Brochure 2015danceОценок пока нет

- The New: The Best Solution For The New Class of Filter BagДокумент24 страницыThe New: The Best Solution For The New Class of Filter BagThong Kin MunОценок пока нет

- Ce 12p Product ManualДокумент36 страницCe 12p Product ManualHrsDesingОценок пока нет

- Company Profile PT. Kinar Prospek TeknologiДокумент16 страницCompany Profile PT. Kinar Prospek TeknologiOcky Hendrawan LimansagitaОценок пока нет

- Maintenance Manual: FAX: 816-472-1999 PHONE: 816-472-8999 TOLL FREE: 1-800-235-2829 E-MailДокумент303 страницыMaintenance Manual: FAX: 816-472-1999 PHONE: 816-472-8999 TOLL FREE: 1-800-235-2829 E-MailferneyОценок пока нет

- GPL-5545C Manual - NewДокумент30 страницGPL-5545C Manual - NewRocio GimenezОценок пока нет

- Risk Analysis - StretchbanderДокумент14 страницRisk Analysis - StretchbanderEnko ŠatrovićОценок пока нет

- Cartoning C2024Документ70 страницCartoning C2024Imam RidwanОценок пока нет

- IMA Blistering BrochureДокумент8 страницIMA Blistering BrochureTueОценок пока нет

- M4 M6 Q Series ManualДокумент26 страницM4 M6 Q Series ManualAhmet MetinОценок пока нет

- CS 5200 Operating ManualДокумент15 страницCS 5200 Operating ManualJoan LamedaОценок пока нет

- Operation Manual: FWM1200 FWM1200AДокумент27 страницOperation Manual: FWM1200 FWM1200AnicolasОценок пока нет

- GE 6500 SX 35640-gb - 12-12 PDFДокумент50 страницGE 6500 SX 35640-gb - 12-12 PDFArdi NuaryОценок пока нет

- Bouwpaco Powder Dosing & PackingДокумент33 страницыBouwpaco Powder Dosing & PackingAlexander AeromodelistaОценок пока нет

- DQ BlisteadoraДокумент15 страницDQ Blisteadorasami2210Оценок пока нет

- Pama - Product Pasteurization, Heating and Cooling Systems PDFДокумент9 страницPama - Product Pasteurization, Heating and Cooling Systems PDFCar MiguelОценок пока нет

- Smigroup enДокумент30 страницSmigroup enSNОценок пока нет

- Catalogo CAM 2017 EspanaДокумент68 страницCatalogo CAM 2017 Espanameriem.rssfОценок пока нет

- Mexico, Solanum, V6Plus, HP140401 3,140411Документ7 страницMexico, Solanum, V6Plus, HP140401 3,140411Humberto GonzálezОценок пока нет

- XWZ-120A Operation Manual: Full Automatic Cartoning MachineДокумент35 страницXWZ-120A Operation Manual: Full Automatic Cartoning MachinealexjoelОценок пока нет

- AU5847E AVL Smokemeter415SE PGДокумент274 страницыAU5847E AVL Smokemeter415SE PGViktor DilberОценок пока нет

- Qpro 8P ENGLS 121201Документ4 страницыQpro 8P ENGLS 121201MdОценок пока нет

- HFTF-2023 Operation Manual ModificadoДокумент52 страницыHFTF-2023 Operation Manual ModificadoAndrew RamirezОценок пока нет

- نافخهДокумент136 страницنافخهmohamedОценок пока нет

- Sim Tab FeederДокумент2 страницыSim Tab FeederMusab HashmiОценок пока нет

- SomatecДокумент123 страницыSomatecAdi kurniantoОценок пока нет

- Modular Labelling System, Labeling Equipment - Tronics America Series S1000 Brochure, CatalogДокумент2 страницыModular Labelling System, Labeling Equipment - Tronics America Series S1000 Brochure, CatalogtronicsamericaОценок пока нет

- INDOSA Technology: The World's No. 1 in Can MachineryДокумент25 страницINDOSA Technology: The World's No. 1 in Can Machinery高金辉Оценок пока нет

- Hitachi Printer: Technical Manual Ink Jet Printer For Industrial MarkingДокумент164 страницыHitachi Printer: Technical Manual Ink Jet Printer For Industrial MarkingRodrigoОценок пока нет

- Manual Profile Library Editor EnuДокумент68 страницManual Profile Library Editor Enupopaciprian27Оценок пока нет

- Profil Venelteko 02 enДокумент36 страницProfil Venelteko 02 enguillermomolteniОценок пока нет

- Advent Product CatalogДокумент64 страницыAdvent Product CatalogmiculinicОценок пока нет

- PSS 3.2 - 520 - 5,5kW - DrawingДокумент1 страницаPSS 3.2 - 520 - 5,5kW - DrawingCentrifugal SeparatorОценок пока нет

- Information On The Safe Operation of Starlinger MachinesДокумент29 страницInformation On The Safe Operation of Starlinger MachinesThaigroup CementОценок пока нет

- HS SLSMAN 01 Rev.W - Pasteurizer 520 115V Operation ManualДокумент33 страницыHS SLSMAN 01 Rev.W - Pasteurizer 520 115V Operation ManualErick LoganОценок пока нет

- Tube Filling Machines: TFS 80-1 TFS 80-2Документ8 страницTube Filling Machines: TFS 80-1 TFS 80-2mhafizanОценок пока нет

- Ebp 650 - 2Документ52 страницыEbp 650 - 2Lau AlexОценок пока нет

- Shanghai - Kaili Yarn Splicer: - Working Manual. - Spares Parts Catalogue.Документ27 страницShanghai - Kaili Yarn Splicer: - Working Manual. - Spares Parts Catalogue.Deepak Kumar0% (1)

- Boost 1d3d CouplingДокумент42 страницыBoost 1d3d CouplingAdrian FerrerОценок пока нет

- TC3 - Op - Man - Rev B 2011-04-15allДокумент91 страницаTC3 - Op - Man - Rev B 2011-04-15alljosue nievesОценок пока нет

- Complete Water and Syrup Filling Line 3000bph at 1000ml: To: Matic Gdańsk 11.04.2023 Offer No: 074 - 04 - 2023 - MKДокумент49 страницComplete Water and Syrup Filling Line 3000bph at 1000ml: To: Matic Gdańsk 11.04.2023 Offer No: 074 - 04 - 2023 - MKAlija IbrisevicОценок пока нет

- Staubli - Mould Clamping SystemsДокумент8 страницStaubli - Mould Clamping SystemsRuben PauwelsОценок пока нет

- Chapter-7 Transport and Handling: 7.1 The PackageДокумент6 страницChapter-7 Transport and Handling: 7.1 The PackageKatana JijtsuОценок пока нет

- Dbe 04568bengДокумент74 страницыDbe 04568bengElectronic RampolytexОценок пока нет

- 201F Packer Safety - TroubleshootingДокумент155 страниц201F Packer Safety - TroubleshootingVSreenuvasuluReddyОценок пока нет

- Dbe 04567aengДокумент111 страницDbe 04567aengElectronic RampolytexОценок пока нет

- VisioChrom UK 2 90my 037Документ132 страницыVisioChrom UK 2 90my 037clizas100% (1)

- Use and Maintenance Manual-Shrink WrapperДокумент48 страницUse and Maintenance Manual-Shrink WrapperJacintaShiОценок пока нет

- Ipinium Meat Rounders Manual Maintenance PDFДокумент38 страницIpinium Meat Rounders Manual Maintenance PDFalvaroОценок пока нет

- Technical Handbook: Four Nozzles Vacuum Filling MachineДокумент12 страницTechnical Handbook: Four Nozzles Vacuum Filling MachineAshish MishraОценок пока нет

- Use and Instruction Manual: Headquarters C.so Alba 81/83 - 12043 Canale (CN) ITALYДокумент52 страницыUse and Instruction Manual: Headquarters C.so Alba 81/83 - 12043 Canale (CN) ITALYGabriel SimbañaОценок пока нет

- Cartoning Machines: by Shailesh JadhavДокумент9 страницCartoning Machines: by Shailesh JadhavShailesh Jadhav100% (1)

- Sealer Closer-Instruction ManualДокумент111 страницSealer Closer-Instruction Manualsuberec100% (1)

- SDNF InterfaceДокумент11 страницSDNF Interfacepopaciprian27Оценок пока нет

- Precision Gage Solutions: Thread Check IncДокумент51 страницаPrecision Gage Solutions: Thread Check IncAngel Alvarez CarrilloОценок пока нет

- Legrand 630A Rising Main Busduct Layout DWGДокумент2 страницыLegrand 630A Rising Main Busduct Layout DWGAjay Babu MОценок пока нет

- Ick Work - Partition Layout (Basement Floor)Документ1 страницаIck Work - Partition Layout (Basement Floor)Shubham PokhriyalОценок пока нет

- Rieter Robospin Brochure 3306 v4 97549 enДокумент4 страницыRieter Robospin Brochure 3306 v4 97549 enJ.SathishОценок пока нет

- TA Advance FormДокумент1 страницаTA Advance FormJ.SathishОценок пока нет

- Lead Time Reduction Machine Interference Problem Impact On Lead TimeДокумент124 страницыLead Time Reduction Machine Interference Problem Impact On Lead TimeJ.SathishОценок пока нет

- Statistics For TextilesДокумент11 страницStatistics For TextilesJ.SathishОценок пока нет

- Boards ReportДокумент61 страницаBoards ReportJ.SathishОценок пока нет

- Ceklist ISO 17021-2Документ6 страницCeklist ISO 17021-2Ade Haris MustafaОценок пока нет

- Textiles CommitteeДокумент12 страницTextiles CommitteeJ.SathishОценок пока нет

- News Clippings 02022023Документ40 страницNews Clippings 02022023J.SathishОценок пока нет

- ICF Newsletter Feb 2 2023Документ22 страницыICF Newsletter Feb 2 2023J.SathishОценок пока нет

- Daily-Rates-16 02 2023Документ2 страницыDaily-Rates-16 02 2023J.SathishОценок пока нет

- Hra For Armed Force RuleДокумент4 страницыHra For Armed Force RuleDevi Prasad PandaОценок пока нет

- T A Rules and Reimbursement Allowance - May 2022Документ7 страницT A Rules and Reimbursement Allowance - May 2022J.SathishОценок пока нет

- Key Highlights of FTP 2023 Booklet - 230331 - 122255Документ13 страницKey Highlights of FTP 2023 Booklet - 230331 - 122255J.SathishОценок пока нет

- Daily-Rates-16 02 2023Документ2 страницыDaily-Rates-16 02 2023J.SathishОценок пока нет

- Tuid Mill DetailsДокумент94 страницыTuid Mill DetailsJ.SathishОценок пока нет

- News Clippings 01022023Документ43 страницыNews Clippings 01022023J.SathishОценок пока нет

- News Clippings 06022023Документ25 страницNews Clippings 06022023J.SathishОценок пока нет

- Daily-Rates-16 02 2023Документ2 страницыDaily-Rates-16 02 2023J.SathishОценок пока нет

- Receipt DocДокумент1 страницаReceipt DocJ.Sathish100% (1)

- Pulse of Cotton 24-01-2023Документ8 страницPulse of Cotton 24-01-2023J.SathishОценок пока нет

- News Clippings 11022023Документ28 страницNews Clippings 11022023J.SathishОценок пока нет

- Receipt DocДокумент1 страницаReceipt DocJ.SathishОценок пока нет

- News Clippings 10022023Документ24 страницыNews Clippings 10022023J.SathishОценок пока нет

- Pulse of Cotton 31-01-2023Документ9 страницPulse of Cotton 31-01-2023J.SathishОценок пока нет

- F2007548-18 Nep HisДокумент1 страницаF2007548-18 Nep HisJ.SathishОценок пока нет

- Pulse of Cotton 27-01-2023Документ11 страницPulse of Cotton 27-01-2023J.SathishОценок пока нет

- SpinningДокумент5 страницSpinningJ.SathishОценок пока нет

- Pulse of Cotton 07-02-2023Документ13 страницPulse of Cotton 07-02-2023J.SathishОценок пока нет

- Pulse of Cotton 11-02-2023Документ12 страницPulse of Cotton 11-02-2023J.SathishОценок пока нет

- F2007548-17 Nep HisДокумент1 страницаF2007548-17 Nep HisJ.SathishОценок пока нет

- A Ongc HRM Summer ProjectДокумент58 страницA Ongc HRM Summer ProjectAmit SunsaraОценок пока нет

- Seismic Isolation For Buildings Catalog 2013 by Bridgestone Corp - Multi Rubber BearingДокумент44 страницыSeismic Isolation For Buildings Catalog 2013 by Bridgestone Corp - Multi Rubber BearingitetejacОценок пока нет

- Ecological Fire MGMT Guidelines V5Документ40 страницEcological Fire MGMT Guidelines V5MeОценок пока нет

- Cantece Copii in EnglezaДокумент10 страницCantece Copii in EnglezaGeorgi Neacşa100% (1)

- Patel, Anita - Super Indian Snack and Street Food Recipes PDFДокумент117 страницPatel, Anita - Super Indian Snack and Street Food Recipes PDFBella ImèneОценок пока нет

- SMAW Health Hazards of g12 Students During Laboratory ActivitiesДокумент25 страницSMAW Health Hazards of g12 Students During Laboratory ActivitiesPaul Patrick Guanzon100% (1)

- GOLDEN DAWN 1 10 The Banishing Ritual of HexagramДокумент4 страницыGOLDEN DAWN 1 10 The Banishing Ritual of HexagramF_RC86% (7)

- GTE LAB MANUAL Ver 4 - 1Документ135 страницGTE LAB MANUAL Ver 4 - 1akhilaОценок пока нет

- Internship ReportДокумент50 страницInternship ReportSachinОценок пока нет

- Elements of HardscapingДокумент57 страницElements of HardscapingNathar ShaОценок пока нет

- User Manual For Emvólio: WWW - Blackfrog.InДокумент22 страницыUser Manual For Emvólio: WWW - Blackfrog.InmariaОценок пока нет

- School of Chemical Engineering - 20Документ372 страницыSchool of Chemical Engineering - 20biroutiОценок пока нет

- Mat11 PDFДокумент13 страницMat11 PDFRaquel Martins E SilvaОценок пока нет

- Turnitin Originality ReportДокумент20 страницTurnitin Originality ReportNaomi Deirdre ReyesОценок пока нет

- Nokia 6131 NFCДокумент5 страницNokia 6131 NFCvetvetОценок пока нет

- Govind S Rajan - ResumeДокумент1 страницаGovind S Rajan - ResumeGovind RajanОценок пока нет

- 4mb/01r-Que-2023 Jun Edexcel PastpaperДокумент24 страницы4mb/01r-Que-2023 Jun Edexcel Pastpaperaugust.shwanОценок пока нет

- What Makes A Cup of NESCAFÉ So Special? The Best Coffee Beans andДокумент4 страницыWhat Makes A Cup of NESCAFÉ So Special? The Best Coffee Beans andYenny YanyanОценок пока нет

- Honda Bikes and ScootersДокумент6 страницHonda Bikes and ScootersShamrjit AgrahariОценок пока нет

- JNTU Old Question Papers 2007Документ8 страницJNTU Old Question Papers 2007Srinivasa Rao GОценок пока нет

- 13 - Oxygen Removal From Boiler WaterДокумент12 страниц13 - Oxygen Removal From Boiler Waterarunkumar23101100% (1)

- Biology: Higher Tier Paper 1HДокумент28 страницBiology: Higher Tier Paper 1HkaruneshnОценок пока нет

- .Cancer DiseaseДокумент10 страниц.Cancer DiseasejanakrajchauhanОценок пока нет

- (Complete) BLC 201 Assignment Intro Logistics SCM Sep 2021 - McdonaldДокумент12 страниц(Complete) BLC 201 Assignment Intro Logistics SCM Sep 2021 - McdonaldHf CreationОценок пока нет

- Newton Interviews - Tookie AngusДокумент12 страницNewton Interviews - Tookie AngusPeter BellОценок пока нет

- Design and Modelling of Internal Permanent Magnet Motor (#764846) - 1189475Документ25 страницDesign and Modelling of Internal Permanent Magnet Motor (#764846) - 1189475Tejas PanchalОценок пока нет

- GIRBESДокумент6 страницGIRBESMiguel LópezОценок пока нет

- Nuitration in Human 3Документ2 страницыNuitration in Human 3Usman AmeenОценок пока нет

- Rangtong Shentong ViewДокумент19 страницRangtong Shentong Viewlongjim31100% (1)