Академический Документы

Профессиональный Документы

Культура Документы

Interthane 138: Product Description

Загружено:

SUBHOMOYОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Interthane 138: Product Description

Загружено:

SUBHOMOYАвторское право:

Доступные форматы

Interthane 138

_____________

Polyurethane

_____________

PRODUCT Two component acrylic polyurethane finish giving excellent durability and long term

DESCRIPTION term recoatability.

_______________________________________________________________________

INTENDED USES Suitable for use in both new construction and as a maintenance finish which can be

used in a wide variety of environments including offshore structures, petrochemicals plants,

bridges and in the power industry.

_______________________________________________________________________

PRACTICAL Colour Wide range

INFORMATION FOR Gloss Level Glossy

INTERTHANE 138 Volume Solids 50 +/- 2% (depends on colour)

Typical Thickness 50 - 60 microns (2.0 2.4 mils) dry equivalent to 100 - 120 microns (4

4 .8 mils) wet

Theoretical Coverage 10.0 m2 / litre at 50 microns d.f.t. and at 50% volume solids

Practical Coverage Allow appropriate loss factors

Method of Application Airless spray, Conventional Spray, Brush, Roller

Drying Time

Overcoating Interval with

Interthane 138 by Self

Temperature Touch Dry Hard Dry Minimum Maximum

______________________________________________________________________________

15C (59 F) 3 hours 10 hours 10 hours Extended*

25C (77 F) 2 hour 6 hours 6 hours Extended*

40C (104 F) 1 hour 3 hours 3 hours Extended*

* See International Protective Coatings Definitions and Abbreviations

_____________________________________________________________________________

REGULATORY Flash point Base (Part A) C/A (Part B) Mixed

DATA 34o C (93 F) 49C (120 F) 35 C (95 F)

Interthane 138

Polyurethane

SURFACE All surfaces to be coated should be clean , dry and free from contamination. Prior

PREPARATION to paint application all surfaces should be assessed and treated in accordance with

ISO 8504:1994

Primed Surfaces

Interthane 138 should always be applied over a recommended anti-corrosive coating

Scheme. The primer surface should be dry and free from all contamination., and

Interthane 138 must be applied within the overcoating intervals specified (consult

the relevant product data sheet)

Areas of breakdown, damage etc. should be prepared to the specified standard (e.g.

SA21/2 (ISO 8501-1:1988) or SSPC-SP6, Abrasive Blasting, or SSPC-SP11, Power

Tool Cleaning) and patch primed prior to the application of Interthane 138.

__________________________________________________________________________

APPLICATION Mixing Material is supplied in two containers as a unit. Always mix a

Complete unit in the proportions supplied. Once the unit has

been mixed it must be used within the working pot life specified.

(1) Agitate Base (Part A) with a power agitator.

(2) Combine entire contents of Curing Agent (Part B) with Base

(Part A) and mix thoroughly with power agitator.

Mix Ratio 9.0 parts : 1.0 part by volume

Working Pot 5 C (41F) 15C (59 F) 25C (77F) 40C (104F)

Life 12 hours 4 hours 2 hours 45 minutes

Airless Spray Recommended - Tip range 0.33-0.45 mm(13-18 thou)

- Total output fluid pressure at spray tip not

less than 155 kg / cm2 (2,200 p.s.i.)

Air Spray Recommended Gun DeVilbiss MBC or JGA

(Pressure Pot) Air Cap 704 or 765

Fluid Tip E

Air Spray Suitable Use suitable proprietary equipment.

(Conventional)

Brush Suitable Typically 30 40 microns (1.2 1.6 mils) can be achieved

Roller Suitable Typically 30-40 microns (1.2 1.6 mils ) can be achieved

Thinner International Do not thin more than allowed by local

GTA713or GTA733 environmental legislation.

(or GTA056)

Cleaner International GTA713

(or GTA056) or GTA733

Work Stoppages Do not allow material to remain in hoses, gun or spray equipment.

Thoroughly flush all equipment with International GTA713. Once

units of paint have been mixed they should not be resealed and it

is advised that after prolonged stoppages work commences with

freshly mixed units.

Clean Up Clean all equipment immediately after use with International GTA713

It is good working practice to periodically flush out spray equipment

during the course of the working day. Frequency of cleaning will depend

upon amount sprayed, temperature and elapsed time., including any delays.

All surplus materials and empty containers should be disposed of in

accordance with appropriate regional regulations / legislation.

Interthane 138

Polyurethane

PRODUCT Level of sheen and surface finish is dependent on application method. Avoid

CHARACTERISTICS using a mixture of application methods whenever possible. Best results in terms

of gloss and appearance will always be obtained with conventional air spray

application.

For brush application, and in some colours, two coats of Interthane 138 May be required to give

uniform coverage, especially when applying Interthane 138 over dark undercoats, and when using

certain lead free bright colours such as yellows and oranges. Best practice is to use a colour

compatible intermediate or anti-corrosive coating under the Interthane 138.

When overcoating after weathering, or ageing, ensure the coating is fully cleaned to

remove all surface contamination such as oil, grease, salt crystals and traffic fumes,

before application of a further coat of Interthane 138.

Absolute measured adhesion of topcoats to aged Interthane 138 is less than that to

fresh material, however, it is adequate for the specified end use.

This product must only be thinned using the recommended International thinners.

The use of alternative thinners, particularly those containing alcohols, can severely

inhibit the curing mechanism of the coating.

Do not apply at steel temperature below 5 C (41 F).

When applying Interthane 138 in confined spaces, ensure adequate ventilation.

Condensation occurring during or immediately after application may result in a matt

finish and an inferior film.

Premature exposure to ponding water will cause colour change, especially in dark

colours and at low temperatures.

This product is not recommended for use in immersion conditions. When severe

chemical or solvent splashing is likely to occur, contact International Protective

Coatings for information regarding suitability.

______________________________________________________________________________

SYSTEMS The following primers / intermediates are recommended for Interthane 138:

COMPATIBILITY

Intergard 475 HS Intergard 410

Intergard 251 Interplus 770

Intergard 269 Interseal 670 HS

Intergard 400 Interzinc 42

Intergard 256 Interzinc 52

Interthane 138 is designed to be topcoated with itself.

For other suitable primers / intermediates, consult International Protective Coatings.

Interthane 138

Polyurethane

ADDITIONAL Further information regarding industry standards, terms and abbreviations used in

INFORMATION this data sheet can be found in the following sections of the International Protective

Coatings data manual :

Definitions & Abbreviations

Surface Preparation

Paint Application

Theoretical & Practical Coverage

Individual copies of these information sections are available upon request.

___________________________________________________________________________

SAFETY This product is intended for use only by professional applicators in industrial

PRECAUTIONS situations in accordance with the advice given on this sheet, the Material Safety Data

Sheet and the container(s), and should not be used without reference to the Material

Safety Data Sheet (MSDS) which International Protective Coatings has provided to its

customers.

All work involving the application and use of this product should be performed in

compliance with all relevant national health, Safety & Environmental standards and

regulations.

In the event welding or flame cutting is performed on metal coated with this product,

Dust and fumes will be emitted which will require the use of appropriate personal

protective equipment and adequate local exhaust ventilation.

If in doubt regarding the suitability of use of this product, consult International

Protective Coatings for further advice.

Warning : Contains isocyanate. Wear air-fed hood for spray application.

______________________________________________________________________________

PACK SIZE 20 litre unit Interthane 138 Base18 litres in a 20 litre container

Interthane 138 Curing Agent 2 litres in a 3.0 litre container

For availability of other pack sizes contact International Protective Coatings.

_______________________________________________________________________

STORAGE

Shelf Life 12 months minimum at 25 C (77 F). Subject to re-inspection .hereafter. Store in dry,

shaded conditions away from sources of heat and ignition.Curing agent is moisture

sensitive. Store in a cool and dry place.

Disclaimer

The information given in this sheet in not intended to be exhaustive and any person using the product for any purpose other than that specifically recommended in this sheet without first

obtaining written confirmation from us as to the suitability of the product for the intended purpose does so at his own risk. Whilst we endeavour to ensure that all advice we give about the

product (whether in this sheet or otherwise) is correct we have no control over either the quality or condition of the substrate or the many factors affecting the use and application of the

product. Therefore, unless we specifically agree in writing to do so, we do not accept any liability whatsoever or howsoever arising for the performance of the product or for any loss or

damage (other than death or personal injury resulting from our negligence) arising out of the use of the product. The information contained in this sheet is liable to modification from time

to time in the light of experience and our policy of continuous product development.

It is the users responsibility to check that this sheet is current prior to using the product. Issue date : December 2000

Вам также может понравиться

- P Peaking BandingДокумент4 страницыP Peaking BandingSUBHOMOYОценок пока нет

- 10 5382@econgeo 4722 PDFДокумент15 страниц10 5382@econgeo 4722 PDFAlfredo StevenОценок пока нет

- BIOL1018 Lab Manual 2016Документ40 страницBIOL1018 Lab Manual 2016Kayla HendersonОценок пока нет

- Hospital Housekeeping ManualДокумент14 страницHospital Housekeeping ManualphilipОценок пока нет

- External Floating RoofДокумент14 страницExternal Floating RoofAjeetKumarОценок пока нет

- 870 UkДокумент4 страницы870 UkAhmed IbrahimОценок пока нет

- Interthane 990 en O-FДокумент4 страницыInterthane 990 en O-Fapde06Оценок пока нет

- Interthane 990Документ4 страницыInterthane 990Harekrushna PradhanОценок пока нет

- Internationa Paint MSDSДокумент4 страницыInternationa Paint MSDStsoheil100% (1)

- Interthane 990: PolyurethaneДокумент4 страницыInterthane 990: Polyurethaneyugesh mrОценок пока нет

- Interline 983+ds+eng PDFДокумент4 страницыInterline 983+ds+eng PDFMohamed NouzerОценок пока нет

- Paint Specification DatasheetДокумент4 страницыPaint Specification DatasheetSUBHOMOYОценок пока нет

- 975p Interline PDFДокумент4 страницы975p Interline PDFRicardo Correa ColoradoОценок пока нет

- 331 UkДокумент4 страницы331 UkAhmed IbrahimОценок пока нет

- Interthane 990: Product DescriptionДокумент4 страницыInterthane 990: Product Descriptionsorion61Оценок пока нет

- Chartek 8E: Epoxy IntumescentДокумент4 страницыChartek 8E: Epoxy IntumescentSubham SahuОценок пока нет

- E Program Files An ConnectManager SSIS TDS PDF Interfine 629 Eng A4 20151012Документ4 страницыE Program Files An ConnectManager SSIS TDS PDF Interfine 629 Eng A4 20151012Theophilus ThistlerОценок пока нет

- Protective Coating-3Документ0 страницProtective Coating-3Sivaratnam NavatharanОценок пока нет

- TDS-PDF-Interzone 485 Eng A4 20220127Документ4 страницыTDS-PDF-Interzone 485 Eng A4 20220127kousick sundararajanОценок пока нет

- Chartek 8 Epoxy IntumescentДокумент4 страницыChartek 8 Epoxy IntumescentAhmed IbrahimОценок пока нет

- PDS Intergard 906Документ4 страницыPDS Intergard 906SUBHOMOYОценок пока нет

- E Program Files An ConnectManager SSIS TDS PDF Interzone 485 Eng A4 20160321Документ4 страницыE Program Files An ConnectManager SSIS TDS PDF Interzone 485 Eng A4 20160321orbit ServiceОценок пока нет

- Interthane 990Документ4 страницыInterthane 990DuongthithuydungОценок пока нет

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interprime - 198 - Eng - Usa - LTR - 20150205Документ4 страницыE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interprime - 198 - Eng - Usa - LTR - 20150205Roberta RamosОценок пока нет

- 329 UkДокумент4 страницы329 UkAhmed IbrahimОценок пока нет

- Pages From E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interthane - 990 - Eng - Usa - LTR - 20190227-2Документ1 страницаPages From E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interthane - 990 - Eng - Usa - LTR - 20190227-2Hajarath AliОценок пока нет

- TDS Intergard® 269epoxyДокумент4 страницыTDS Intergard® 269epoxySyamsul MaripОценок пока нет

- Interzinc 52: Epoxy Zinc-RichДокумент4 страницыInterzinc 52: Epoxy Zinc-RichSagar BhosaleОценок пока нет

- Interthane 990 HS DatasheetДокумент4 страницыInterthane 990 HS DatasheetBalasubramanian AnanthОценок пока нет

- 212 UkДокумент4 страницы212 UkAhmed IbrahimОценок пока нет

- SSIS TDS PDF Interline 982 EngДокумент4 страницыSSIS TDS PDF Interline 982 EngAhmad BarriehОценок пока нет

- Chartek 1709: Epoxy Intumescent CoatingДокумент4 страницыChartek 1709: Epoxy Intumescent CoatingvegaamercasОценок пока нет

- Interzinc 2280 Product BrochureДокумент4 страницыInterzinc 2280 Product BrochureAshish Raul CIEОценок пока нет

- Intergard 291Документ4 страницыIntergard 291MohammadAseefОценок пока нет

- Interchar 404 Fire GreyДокумент4 страницыInterchar 404 Fire GreyaymanОценок пока нет

- Interchar 2090: Acrylic IntumescentДокумент4 страницыInterchar 2090: Acrylic IntumescentEngTamerОценок пока нет

- E Program Files An ConnectManager SSIS TDS PDF Enviroline 378 Eng Usa LTR 20150205Документ4 страницыE Program Files An ConnectManager SSIS TDS PDF Enviroline 378 Eng Usa LTR 20150205Manikanta Sai KumarОценок пока нет

- Interzinc 2280 UkДокумент4 страницыInterzinc 2280 UkTài Đỗ VănОценок пока нет

- Interprime 198: Product DescriptionДокумент4 страницыInterprime 198: Product DescriptionAndri AjaОценок пока нет

- Interprime 198Документ4 страницыInterprime 198Andri AjaОценок пока нет

- Enviroline 376F 60Документ4 страницыEnviroline 376F 60Ahmet GözübüyükОценок пока нет

- Intergard 251Документ4 страницыIntergard 251Engr Saeed AnwarОценок пока нет

- 821 UkДокумент4 страницы821 UkAhmed IbrahimОценок пока нет

- F 2 Pentathane 4510Документ3 страницыF 2 Pentathane 4510Gunjan GaganОценок пока нет

- High Build Epoxy Tank Lining CoatingДокумент3 страницыHigh Build Epoxy Tank Lining CoatingSiDdu Kalashetti0% (1)

- Inorganic Zinc-Rich Silicate: IS 14946: Protective Coating World Wide ProductsДокумент4 страницыInorganic Zinc-Rich Silicate: IS 14946: Protective Coating World Wide ProductsSubham SahuОценок пока нет

- InternationДокумент4 страницыInternationRauf AliyevОценок пока нет

- Intercure 99Документ4 страницыIntercure 99Doby YuniardiОценок пока нет

- Interseal 547: Surface Tolerant EpoxyДокумент4 страницыInterseal 547: Surface Tolerant EpoxyTài Đỗ VănОценок пока нет

- Interzone 101 Eng A4 20150205Документ4 страницыInterzone 101 Eng A4 20150205Wale OyeludeОценок пока нет

- Interzone 101: EpoxyДокумент4 страницыInterzone 101: Epoxyjamjam75Оценок пока нет

- Enviroline 2405: Hybrid EpoxyДокумент4 страницыEnviroline 2405: Hybrid EpoxyMuthuKumarОценок пока нет

- Chartak 2218 DatasheetДокумент4 страницыChartak 2218 DatasheetRubi SinghОценок пока нет

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intertherm - 3350 - Eng - A4 - 20150818Документ4 страницыE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intertherm - 3350 - Eng - A4 - 20150818vtnhoemОценок пока нет

- aE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interchar - 1260 - Eng - A4 - 20150205Документ4 страницыaE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interchar - 1260 - Eng - A4 - 20150205Annas QahharОценок пока нет

- Intergard 251HS - MDSДокумент4 страницыIntergard 251HS - MDSSahanОценок пока нет

- TDS-PDF-Interzinc 22 EngДокумент4 страницыTDS-PDF-Interzinc 22 Engapde06Оценок пока нет

- Interplate 997: Inorganic Zinc SilicateДокумент4 страницыInterplate 997: Inorganic Zinc SilicateRoshan AravinthОценок пока нет

- Interline 399Документ4 страницыInterline 399pinky_y2kОценок пока нет

- Interplate 937 TDSДокумент4 страницыInterplate 937 TDSGilberto ZamudioОценок пока нет

- Intergard 966: Product DescriptionДокумент4 страницыIntergard 966: Product DescriptionSUBHOMOYОценок пока нет

- Interline 982+ds+eng PDFДокумент4 страницыInterline 982+ds+eng PDFMohamed NouzerОценок пока нет

- Amercoat 385Документ4 страницыAmercoat 385Nelly GarcíaОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- Quality Assurance Plan For Is 2062 E250 GR BRДокумент2 страницыQuality Assurance Plan For Is 2062 E250 GR BRSUBHOMOYОценок пока нет

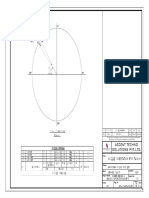

- Nozzle Orientation DrawingДокумент1 страницаNozzle Orientation DrawingSUBHOMOYОценок пока нет

- Design Analysis and Optimization of Double Wall Vacuum Vessel-A Review PaperДокумент3 страницыDesign Analysis and Optimization of Double Wall Vacuum Vessel-A Review PaperSUBHOMOYОценок пока нет

- PDS Intergard 906Документ4 страницыPDS Intergard 906SUBHOMOYОценок пока нет

- Deadstock Volume Tankwise 24.12.15 in DetailДокумент2 страницыDeadstock Volume Tankwise 24.12.15 in DetailSUBHOMOYОценок пока нет

- Load Data of TanksДокумент3 страницыLoad Data of TanksSUBHOMOYОценок пока нет

- Final Energy Balance-Vizag DT 9-6-18Документ6 страницFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYОценок пока нет

- Interseal 547 PDFДокумент4 страницыInterseal 547 PDFSUBHOMOYОценок пока нет

- Final Energy Balance-Vizag DT 9-6-18Документ6 страницFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYОценок пока нет

- WPS 01Документ3 страницыWPS 01SUBHOMOYОценок пока нет

- Intergard 966: Product DescriptionДокумент4 страницыIntergard 966: Product DescriptionSUBHOMOYОценок пока нет

- Final Energy Balance-Vizag DT 9-6-18Документ6 страницFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYОценок пока нет

- Technical Specifications for Furnace Oil Transfer PumpДокумент1 страницаTechnical Specifications for Furnace Oil Transfer PumpSUBHOMOYОценок пока нет

- Bangladesh National Building Code-2015 Vol - 3 - 3 (Draft) PDFДокумент518 страницBangladesh National Building Code-2015 Vol - 3 - 3 (Draft) PDFQuetaste ArtisatОценок пока нет

- WPS 01Документ8 страницWPS 01SUBHOMOYОценок пока нет

- Final Energy Balance-Vizag DT 9-6-18Документ6 страницFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYОценок пока нет

- Final Energy Balance-Vizag DT 9-6-18Документ14 страницFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYОценок пока нет

- Draft Piping LayoutДокумент1 страницаDraft Piping LayoutSUBHOMOYОценок пока нет

- M K Roy - HPCL Kota Terminal - Tank Foundation Drawing R2Документ1 страницаM K Roy - HPCL Kota Terminal - Tank Foundation Drawing R2SUBHOMOYОценок пока нет

- PMS A1aДокумент1 страницаPMS A1aSUBHOMOYОценок пока нет

- SeatringДокумент4 страницыSeatringSUBHOMOYОценок пока нет

- MTC For Rawmaterial of ValvesДокумент17 страницMTC For Rawmaterial of ValvesSUBHOMOYОценок пока нет

- AFB HIN MN MEC 001 (T 06 07 08 09) ModelДокумент1 страницаAFB HIN MN MEC 001 (T 06 07 08 09) ModelSUBHOMOYОценок пока нет

- Lab Test ReportДокумент3 страницыLab Test ReportSUBHOMOYОценок пока нет

- 110012130-81 3 Nos. LotДокумент16 страниц110012130-81 3 Nos. LotSUBHOMOYОценок пока нет

- MTC For ValvesДокумент18 страницMTC For ValvesSUBHOMOYОценок пока нет

- Soil Bearing CapacityДокумент1 страницаSoil Bearing CapacitySUBHOMOYОценок пока нет

- Revised Foundation Drawing 22.05.2010-ModelДокумент1 страницаRevised Foundation Drawing 22.05.2010-ModelSUBHOMOYОценок пока нет

- Non Destructive Testing (NDT) : by Mr. H.P.VaradeДокумент42 страницыNon Destructive Testing (NDT) : by Mr. H.P.Varaderaj6062Оценок пока нет

- Is 2830 2012 PDFДокумент13 страницIs 2830 2012 PDFK.s. Raghavendra KumarОценок пока нет

- Rice FtirДокумент15 страницRice FtirRavindra AgarwalОценок пока нет

- Boiler Section - 400 To 800HP RSДокумент79 страницBoiler Section - 400 To 800HP RSmynor8josh8juarezОценок пока нет

- Ht-Discharge Pipes and Fittings (PPS) : KunststoffeДокумент35 страницHt-Discharge Pipes and Fittings (PPS) : Kunststoffeluis eduardo ramos rebataОценок пока нет

- Fire Clay Composition & PropertiesДокумент4 страницыFire Clay Composition & PropertiestaghdirimОценок пока нет

- G 21 - 96 R02 - RzixДокумент5 страницG 21 - 96 R02 - RzixjayakumarОценок пока нет

- Msds of LiOHДокумент6 страницMsds of LiOHmunawar786Оценок пока нет

- QO390-SS200025 Technical Sheet (Actuated On Off Valve & RESDVForel Bronang)Документ2 страницыQO390-SS200025 Technical Sheet (Actuated On Off Valve & RESDVForel Bronang)Iqbal MatondangОценок пока нет

- IMA MCQsДокумент18 страницIMA MCQsPCOP Pharmacy100% (1)

- O-Ring Design Considerations - Marco Rubber & Plastics - Custom O-Rings SupplierДокумент4 страницыO-Ring Design Considerations - Marco Rubber & Plastics - Custom O-Rings SupplierMorteza ShakerienОценок пока нет

- Sheet 1 - Introduction To Heat Transfer MechanismsДокумент2 страницыSheet 1 - Introduction To Heat Transfer MechanismsAhmed YousryОценок пока нет

- 05.09.21 OSR - CO-SC Jee Adv 2020 P1 GTA-28 (P-I) QPДокумент17 страниц05.09.21 OSR - CO-SC Jee Adv 2020 P1 GTA-28 (P-I) QPRahul RanjanОценок пока нет

- APPENDIX C Typical Properties of MaterialsДокумент18 страницAPPENDIX C Typical Properties of MaterialsMAT-LIONОценок пока нет

- ACGДокумент15 страницACGIolanda VeronicaОценок пока нет

- Chapter 1 - Oils and Fats - Part 2Документ42 страницыChapter 1 - Oils and Fats - Part 22022627178Оценок пока нет

- Valve Weight PDFДокумент10 страницValve Weight PDFPrabha KaranОценок пока нет

- Calibration of UVДокумент8 страницCalibration of UVMuhammad Abdul BariОценок пока нет

- Grizzly G0758 Mill-Drill ManualДокумент52 страницыGrizzly G0758 Mill-Drill ManualGerard SandersОценок пока нет

- Isolation and Hydrolysis of Casein From MilkДокумент4 страницыIsolation and Hydrolysis of Casein From MilkMurielle SantiagoОценок пока нет

- Denisa - 2 Exemplare - AN - F-VДокумент93 страницыDenisa - 2 Exemplare - AN - F-VAdrian PetrosОценок пока нет

- LT Power & Control Cables GuideДокумент4 страницыLT Power & Control Cables GuideamiteshОценок пока нет

- Ds About Magnesium OilДокумент2 страницыDs About Magnesium OilMark Dingle100% (1)

- VMP Manual PDFДокумент106 страницVMP Manual PDFkikiОценок пока нет

- The Theory Of Emulsification In 40 CharactersДокумент4 страницыThe Theory Of Emulsification In 40 CharactersRuben Masashi SamaОценок пока нет

- Companyprofile For Executives15pagesR1Документ15 страницCompanyprofile For Executives15pagesR1Venus AndromadagalaxyОценок пока нет

- 3DT177Документ11 страниц3DT177dalton2004Оценок пока нет