Академический Документы

Профессиональный Документы

Культура Документы

Excerpt International Fire Buyer - Shipboard Fire-Fighting

Загружено:

Seba BayramОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Excerpt International Fire Buyer - Shipboard Fire-Fighting

Загружено:

Seba BayramАвторское право:

Доступные форматы

A COMPREHENSIVE ROUND-UP

OF ALL THE LATEST FIRE PRODUCTS

AND GLOBAL INDUSTRY EVENTS

BOAT FIRES

Shipboard fire-fighting: A new solution

The Cutting Extinguisher is a high-pressure water jet system with penetrating

and cutting capabilities that is being revolutionised by the Royal Swedish Navy

Introduction The construction of a lightweight composite insulates heat well, and

Pooling and sharing and Smart Defence have become the does not conduct heat away from the fire room. Even though the

buzzwords of the day among authorities such as the European composite material insulates well , at a certain point of the fire

Defence Agency and NATO. The recent cuts in budgets allover the development, the supporting structure will degenerate and cause

lines require new ways to entangle old problems: Not only are the collapse.

budgets decreasing in an increasing pace, ability to retain capability Shipboard fires onboard ships, or ships with superstructures,

are an undisputed demand from the funders. In addition, demands constructed with composite systems; traditional boundary cooling

on military operations with respect to safety and security are closing has no effect due to the construction material 's insulating properties

in to the demands of the civilian society. - the 'thermos effect '. Instead, one needs to rely on passive

For most operations, this could imply prolonging the life span of protection, early warning systems, automatic fixed installed water

present equipment, finding disruptive and groundbreaking mist systems, etc. For both traditional steel hull and light weight

technologies and methods for doing more with less and work more constructions vessels, fixed installed high pressure water mist

safely and efficiently with the means at hand. Naval operations are systems are often limited to designated high risk fire areas due to

not exempt. cost and limitation of auxiliary emergency power. Breach of such

As someone one said, fire onboard can ruin a good day. systems, or fires caused by external attacks at a non-designated

Traditionally, shipboard fire-fighting on steel hull vessels engage a lot area, would require traditional boundary cooling and/or BA attack;

of crewmembers consumes a lot of water and takes focus off of the both crew and water consuming, high-risk tasks, thus mission

mission. Fires onboard naval vessels will not only impact the vessel, compromising.

but also threaten to compromise the mission as a whole. In addition,

modern composite lightweight material structures require immediate Water mist

intervention in the fire compartment, less the supporting structure Water mist is generally interpreted as sprays with water drops of a

risks to be damaged or collapse. New disruptive technology for size up to 1000 microns , or 1 mm. Recently, research has shown

applying water mist to shipboard fires has recently been developed : that water broken up into small droplets adds a number of features

The Cutting Extinguisher. The Cutting Extinguisher method is proven to it as a fire-fighting media. By atom ising the water into micron size

by on-shore fire-fighting and a number of scientific reports. In the droplets, the surface area of a given volume of water expands

naval setting, the efficiency of water mist introduced to a dramatically. At a droplet size of 1 mm , one litre of water covers the

compartment with a fully developed fire has also been documented area of a third of a soccer goal (6m2). At 1 micron , one litre of water

in various scientific reports. covers an area of approximately 6000 m2, or the area of a football

pitch . The surface area exposed by the atomisation of the water

Vessel constructions and shipboard fire-fighting reduces the time tremendously for the water to transform to steam.

Steel hulls and lightweight construction materials However, experts conclude that, with respect to heat absorption,

Traditionally, a naval ship is constructed with a steel structure. In there is a threshold at a water droplet size at about 1 to 10 microns,

terms of combustion, this it is a good choice. However, steel's ability or 0.001 to 0.01 mm. Given we have a method to transform water to

to conduct heat brings on a number of challenges when it comes to micron size droplets and applying this to fire-fighting , we have a

fire-fighting. When a steel bulkhead or deck is exposed to fire or theoretical possibility to increase the efficiency of water used by up

heat, an intact construction will conduct heat to the adjacent side to approximately 1000%. Suppliers of fixed installed fire-fighting

reasonably fast. Thus, an un-insulated steel panel will not work as a systems such as Hi Fog and Ultra fog are getting close to these

fire shield. To protect the vessel from spreading of fire from the levels. Adopting this feature to a hand held lance with the possibility

incident area, the vessel's construction is separated into insulated to penetrate virtually any construction material, and you will have a

fire zones. A fully developed fire in a fire zone is nevertheless likely to tool that adds safety, swiftness, redundancy and accessibility with a

ruin the content of the complete fire zone. minimal use of water to shipboard fire-fighting.

Normally, developed shipboard fires in a limited fire zone on steel

hull vessels may be contained and controlled by cooling the Methods and procedures

boundaries, making it possible to wait out the fire before initiating the Standard naval shipboard fire -fighting

reentry procedure. In contrast, lightweight structures are often made Pre action preparations and training is of essence to combat fires

out of combustible materials, such as carbon fibre and PVC foam successfully. Preparations also cover structural protection, fixed fire

combined into carbon reinforced plastic laminate. In case of fire, suppressing systems, equipment control , awareness and readiness .

there is an imminent risk that the lightweight construction will On live incidents, standard procedures for fire-fighting tactics

contribute to the fire development. To protect the construction from on board conventional vessels include four main actions:

fire and heat, intumescent paint or insulation is amended to the 1. Early Detection Alarm,

construction panels. The construction itself may also contain 2. First Attack,

redundant supporting beams, allowing either one to be weakened or 3. Containment, Control,

destroyed by fire without distortion or collapse of the structure itself. 4. BA Attack Safe Re entry Procedure.

038 IFB www.firebuyer.com

BOAT FIRES

Primarily, early detection is of essence to extinguish the fire in its induced by weapon or accident at an area deemed a low or a non

growth stage, before the fire has fully developed. Secondly, fire hazard zone, time to suppress and get in control of the fire is

immediately after detection and alarm, the first attack is made by even less. A shipboard fire on a composite ship is always critical to

personnel detecting the fire. By using fire extinguishers or other mission . The fire must be intervened immediately and from the

means to suffocate the fire and/or removing the fuel, the crew and inside, where the fire develops. Using BA attack in this situation

the ship might avoid a larger incident. Third step, if the initial would induce risks and hazards not acceptable, neither by naval

procedures fail, is to contain the fire in the fire compartment. Sealing standards, nor by the supporting civil society.

off the area to prevent the fire to spread , removing fuel , and to

minimise oxygen supply, is made to buy time for the fourth step to The Cutting Extinguisher

muster. To contain the fire, automatic, semi automatic or manual The Cutting Extinguisher is a mobile high-pressure water jet

fixed installed fire suppression systems, if present and deemed system with penetrating and cutting capabilities. The system ejects

approximately 30 to 60 litres of water through a nozzle mounted in a

hand held lance at approximately 250 bar and 200 metres per

second.

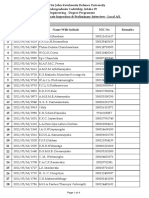

Abrasive

Abra sive

va lve

Bou~y cooling

High pressure

water pump

proper action, should be engaged.

If the fixed installed fire suppression systems fail, boundary

cooling of the ship structure is of essence. Since conventional ships

normally is constructed with mild steel, a highly heat conductive The hand lance is connected through a high-pressure hose to the

construction material, the heat from the original fire is likely to travel main system and is controlled by the lance operator. The system has

through the construction and ignite other cells/compartments. the capability to mix an abrasive, cutting agent, into the water, thus

Boundary cooling requires vast amounts of water applied to the enabling the operator to penetrate or cut through virtually any

decks and bulkheads surrounding the initial fire compartment. construction material. When the water jet combined with abrasive

Depending on the size of the initial fire compartment, a sufficient slurry has cut through the bulkhead or hatch, the water breaks out

number of personnel are required to operate the nozzles applying into an ultra fine mist due to the high velocity the jet receives as it

water for boundary cooling . The fourth step is the re entry passes through the special nozzle. The Cutting Extinguisher

procedure, BA attack on the fire compartment. This cannot be done combines some of the main features of fixed installed ultra high

in a safe way until the fire has been suppressed or reached its decay pressure water mist fire suppression systems with penetrating and

stage. The latter adds time to the total lapsed time to get in control cutting abilities and adds mobility. In addition, to minimise the risk of

of the fire. During this time, boundary cooling must be applied re ignition of fibrous solid fuels, a Class-A detergent may be added

continuously. by the control of the operator. When the water jet enters the fire

room, the water atomises due to its high velocity and cavitation

Composite vessel shipboard fire-fighting when passing through the nozzle. The water mist starts to break up

The tactics for shipboard fire-fighting on composite ships are at about 5 metres from the nozzle and reaches about 15 metres.

initially similar to standard procedures. However, containment is not As the water mist enters the fire room, depending on the fire

relevant since boundary cooling is obsolete - the modern sandwich situation, it is exposed to the hot fire gases, the radiation of the fire

construction itself isolates the desired cooling of the externally and the actual flames . The energy transforms the atomised water to

applied water. Given the fire zone in question is classified , i.e. is steam, and in the process consumes the energy and heat. In the

isolated with fire resisting material and having fixed installed fire process, the steam inerts the fire gas by decreasing the oxygen

suppressing systems or other means, there are some time available fraction. It also cools the fuel surface, and by time, shields the fuel

to suppress the fire prior to constructional damage occur. If the fixed from the surroundings. If the cutting extinguisher is utilised with a

fire suppression systems are breached, or if the actual fire is Class-A detergent, the shielding is even more apparent.

www.firebuyer.com IFS 039

BOAT FIRES

If the fire is not situated immediately opposite to the penetrated wall, Conclusions

the continuous use of the cutting extinguisher water jet will soon Fire hazards and incidents are of great concern to all types of

saturate the immediate volume and travel towards the fire. The vessels. The impact on crew, ship and mission could be disastrous.

speed of the injected water mist will aid in the process. If controlled New constructions, new assignments and societal change have

ventilation is applied (positive pressure ventilation), the effect will triggered the Royal Swedish Navy in searching of safer and more

appear even sooner: The fire will consume the air between the water efficient fire-fighting. Requirements in cost efficiency while

mist and the fire, eventually sucking in the water mist into the flames maintaining the readiness and capability levels with decreasing

and choking itself. number of crew available, has been an issue of great importance on

A typical scenario is a fire room of 75 cubic metres (2.4m x 6.5m the agenda for the supplying agency. Safety and mission focus have

x 5.0m) with a 3.6 MW fire (diesel pool of 3.6 square metres). With a also played a role of great magnitude while evaluating tools and

fully developed fire, the temperature of the room is approximately methods.

600C. By applying a 28 litre per minute cutting extinguisher, the Research made by the Royal Swedish Navy and others has found

temperature will decrease to 100C in 30 seconds, using just short that the cutting extinguisher and its methods supplies or contributes

of 15 litres of water. Examples of penetration abilities are tested and extensively with the following features:

described in various reports. FMV conducted tests at early stages:

4mm mild steel, 10 seconds Safe and rapid re entry procedure at shipboard fire-fighting

Bmm carbon fibre laminates, within 10 seconds through mitigation of backdraft and flashovers, as well as rapid

50mm concrete slab, passed without noticing resilience cooling of fire gases;

The concept require much less crew than standard fire-

The cutting extinguisher is primarily a tool for rapidly and fighting procedures alone, which leaves more crew available

efficiently cooling fire gases produced by solid or liquid fires (Class A for the mission;

and B) from a safe position. By adding a Class A detergent, Boundary cooling from inside the 'thermos';

additional positive effects on solid fibrous fuels will occur. The It is a complement to standard fire-fighting equipment, and is

cutting extinguisher has been tested in accordance with easily introduced to present procedures;

EN 3 7:2004+AI 2007(E), Annex C. According to this standard, the In comparison with boundary cooling, the cutting

current between operator accessed parts (like handle) and earth extinguisher concept uses minimal amount of water - which

must not be greater than 0.5 mA when an alternating voltage of 35 decreases stability issues and collateral damages;

kV is applied to a metallic plate. The cutting exti nguisher fulfills the The concept is easy to understand, and is easy to train;

requirements with the use of water and water and abrasives. The method is easily practiced onboard;

The cutting extinguishing method for Fire & Rescue Services has Excellent system for redundancy on breach of fixed installed

been developed by the Swedish Rescue Service Agency together fire suppression systems;

with SERF, a regional Swedish Fire and Rescue Service, and is ., The cutting extinguisher can be used where fixed installed

being enhanced and refined continuously. The concept includes the fire suppressive systems and other measures don't reach; void

use of thermal imaging cameras and positive pressure ventilation areas, cofferdams and containers for transportation;

(PPV), as well as multiple use of cutting extinguishers in large Self contained diesel engine system works independently of

volume fire rooms. The system is developed by Cold Cut Systems main power systems;

and is presently standard issue on many Fire and Rescue Services Can be used as a clearing tool, especially on composite

in Sweden, Norway, UK, as well as on other markets. The Royal vessels;

Swedish Navy has adopted the system and method for naval use, Retrofitting to comply as an equivalent to new classifications/

as have several other maritime organisations and businesses, such standards are possible and very cost effective.

as the German Central Command for Maritime Emergencies In addition, the cutting extinguisher could be used for third

(Havariekommando) and Smit Salvage. party fires, as a fire and rescue tool.

040 IFB www.firebuyer.com

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Top 100 WaifusДокумент3 страницыTop 100 WaifusFirman Anugraha Islamy100% (1)

- SkyBaron's Enigma M4 Manual 1.02Документ15 страницSkyBaron's Enigma M4 Manual 1.02Chem Draw WebdesignerОценок пока нет

- The Analysis of Casablanca MovieДокумент7 страницThe Analysis of Casablanca Movieapi-461285807Оценок пока нет

- Gheorghe Curinschi Vorona Istoria Arhitecturii in RomaniaДокумент207 страницGheorghe Curinschi Vorona Istoria Arhitecturii in RomaniaRaluca Diaconescu100% (1)

- The State News - Wednesday, September 12, 2001Документ14 страницThe State News - Wednesday, September 12, 2001The State NewsОценок пока нет

- Published EPJPДокумент23 страницыPublished EPJPSeba BayramОценок пока нет

- Chap 1Документ17 страницChap 1Seba BayramОценок пока нет

- Turbuent Pipe FlowsДокумент5 страницTurbuent Pipe FlowsSeba BayramОценок пока нет

- 20 FireonBoardДокумент98 страниц20 FireonBoardSeba BayramОценок пока нет

- STW 44-3-4 - Model Course AE Chief and Second Engineer Officer Secretariat1Документ204 страницыSTW 44-3-4 - Model Course AE Chief and Second Engineer Officer Secretariat1Seba BayramОценок пока нет

- Vortical Flow Over A 3-D Backward-Facing Step: Numerical Heat Transfer, Part A: ApplicationsДокумент27 страницVortical Flow Over A 3-D Backward-Facing Step: Numerical Heat Transfer, Part A: ApplicationsSeba BayramОценок пока нет

- BL-GE-6300-LEC-1933T LIFE AND WORKS of Jose RizalДокумент27 страницBL-GE-6300-LEC-1933T LIFE AND WORKS of Jose RizalApple CamaliganОценок пока нет

- Cleopatra PDFДокумент205 страницCleopatra PDFlordmiguel100% (1)

- ISLAMIC PAKISTAN GoodДокумент293 страницыISLAMIC PAKISTAN Goodaishaumair0% (1)

- HistorydylaneditДокумент6 страницHistorydylaneditapi-19858424Оценок пока нет

- Identities and Inequalities Exploring The Intersections of Race Class Gender and Sexuality 3rd Edition Newman Solutions ManualДокумент25 страницIdentities and Inequalities Exploring The Intersections of Race Class Gender and Sexuality 3rd Edition Newman Solutions ManualLindaBrownoaeg100% (58)

- Summary of Art of War by Sun TzuДокумент6 страницSummary of Art of War by Sun TzuJoel LenamingОценок пока нет

- El Filibusterismo (Summary)Документ4 страницыEl Filibusterismo (Summary)Nestor Bong Bordaje NemeñoОценок пока нет

- Documents of The 1898 Declaration of The Philippine IndependenceДокумент33 страницыDocuments of The 1898 Declaration of The Philippine IndependencemyelОценок пока нет

- John Wick - Shadow of The Demon LordДокумент1 страницаJohn Wick - Shadow of The Demon LordAllan NicolauОценок пока нет

- ACLU Fusion Center Report - 20071212Документ27 страницACLU Fusion Center Report - 20071212BillLudley5Оценок пока нет

- Technical ManualДокумент970 страницTechnical Manualdeniz taylanОценок пока нет

- Lyautey Battle 1942Документ8 страницLyautey Battle 1942pachagro100% (1)

- Surface WarfareДокумент65 страницSurface WarfareLobbyist_Myo100% (5)

- ENG 1st Interview Name List MaleДокумент4 страницыENG 1st Interview Name List MaleNaveen DananjayaОценок пока нет

- Ihl Reviewer PDFДокумент8 страницIhl Reviewer PDFAnthony AlonzoОценок пока нет

- Military Engineering: Military Engineering Is Loosely Defined As The Art, Science, andДокумент8 страницMilitary Engineering: Military Engineering Is Loosely Defined As The Art, Science, andTun Hlaing WinОценок пока нет

- mỗi phần nghe có tín hiệu. nhạc kết thúc bài nghe.: DESO26 A. LISTENING (40 points)Документ10 страницmỗi phần nghe có tín hiệu. nhạc kết thúc bài nghe.: DESO26 A. LISTENING (40 points)Gà ĐạtОценок пока нет

- Nct-Avery DoumaДокумент4 страницыNct-Avery DoumaAvery DoumaОценок пока нет

- OTO Melara Mod 56: History OperatorsДокумент4 страницыOTO Melara Mod 56: History OperatorsMark MarasiganОценок пока нет

- Ames Family Esm-Elint System 0Документ4 страницыAmes Family Esm-Elint System 0portainsОценок пока нет

- AnzioДокумент28 страницAnzioBob Andrepont100% (2)

- NDAA Chairman S MarkДокумент389 страницNDAA Chairman S MarkyaswabiОценок пока нет

- The French and Indian War 1Документ2 страницыThe French and Indian War 1api-265371560Оценок пока нет

- Jedi Knights: Clone Wars Fan SourcebookДокумент18 страницJedi Knights: Clone Wars Fan SourcebookThe_Dream100% (1)

- Annals of Tacitus B 00 Tac I RichДокумент320 страницAnnals of Tacitus B 00 Tac I RichHrco Žnj100% (1)