Академический Документы

Профессиональный Документы

Культура Документы

Aqua Terre Pamphlet

Загружено:

Craftychemist0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров2 страницыPamphlet for Aqua Terre de-watering system

Оригинальное название

Aqua Terre pamphlet

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPamphlet for Aqua Terre de-watering system

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров2 страницыAqua Terre Pamphlet

Загружено:

CraftychemistPamphlet for Aqua Terre de-watering system

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

Aquaterre

Fed ti at coal washery

way EDwe

Conventional methods fr the

emoval of water from

concentrated fe suspensions oF

Sedmented materials are not ont

iefeen they can Mera take up

te yeas for completion

Commonly employed methods are

unsatisfactory because they re 09

Iara ow, a bulk propery tht

fal ff dramatically wth

decreasing particle and pore siz

In comparison, wth EDW

(Glectradawatering) technology,

‘Sal patcle and pore sels not

negative facie

Experimentation and fd was

have shown that he use of EDW

‘ean and does produce many

Benefits s vel as commeresal

‘and operauonal advantages,

These incl!

(Reduction in operating costs

(© Greater optimization and

Integration of operations

© Help in dispose and

rehebitation

© Recovery of usable water

where supples are searce or

expensive

Excoiton ater EDW

(© Assistance in mesting

‘enronmental needs

Freeing up valuable real estate

‘owing removal of dar

tallngs deposts that curently

sterile esting underving

(© Ging greater retums de to

lower moisture in products

(© Providing additonal revenve

when dewatered sludge or

tangs are saleable or ia

Saleable component can be

wscracted

WHATS EDW AND HOW DOES

ITWoRK?

Electo- dewatering ¢ not new, but

"application to date has been

limited and ts potental not

‘ealzed, ts process that allows

the efficient removel a water from

suspensions, sludges or dures

Containing fin, ulterine oe

oloidal solid partes It

Incorporates ineliget se of

sedimentation and drainage

processes and judclous

ppiiation of size classification

{nd surface chemical

Todicatons to ensure the most

Ccosteffectve result

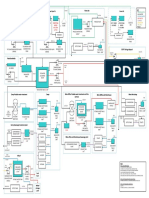

Spied dorm of EDW process Posie nstranspor water molecles toca, Exematlonshoxing stably the

egntvalychatged poces mone to anode (oles canbe rere raga)

EDW dewatering faster and more

‘completely than present

methods.

EDW is basically simple

process which combines the

‘established prinples of

‘ectrophoresis and

‘dectro-osmosis as well as

‘Sectolysis and her

mechanisms such a structural

rearrangement.

DW invaes the transport of

charged particles and ther

‘ssocieted fons ovarde

tectodes of opooste polar.

‘The process is easly

controlled, lenble in operation

and versatile nits many

‘ppliations

EDW comprises technologies for

impoundments tanks and

machines Elecvode separations

tange rom centimetres to several

‘metre with devatering tines

from minutes toyears EDW

techncogies canbe adapted to

‘ost stone and on

Complement esing procedures

ven providing aspera

sheet

WHO CAN BENEFTT FROM

EDWw?

Many industies generate

suspensions of tne or ultafine

Solis, ether as products or as.

‘ste To devater and

Consolidate such surpensions is

‘ten dificult and expensive

Current mechanical devices do not

alnays produce satisfactory results,

EDW can provide an effective and

economical ematve t

‘ommenly employed dewatering

methods or ean asst in

Processing herd to dewoter res,

Indust processes that can

benefit rom EDW technology

include

Coal preparation

1 Sewage sludge dewatering

Sand washing

“Treatment of water purfcaion

residues

Mineral processing

Clay production

Radioave hazardous wastes

Ceri forming

Manufacutng, Food &

Chemicals production

Geotechnical engineering, eg

sol dewotering

‘evatered ean tang

HOW WAS EDW DEVELOPED?

Asnoted herein, electro osmotic

dewatering i not new but there

have been relatively few industia

‘applications Following novel

basic research, Dr N© Lockhart

@F CSIRO (Commonwealth

‘Scientific and Industrial Research

(Organization started applied

research In 1980 on

‘ecto dewatering of fine

“suspensions from mineral and

Coal processing operation. This

‘work was pay sponsored by

‘member companies of AMIRA

(estat Miner! indunties

Research Associaton,

(ver the ensuing years much

tperence was gained of

Important parameters such as

"Properties of colledal systems

(eq she dstibution 2a

Potential, mechanical

horace)

Intuence of pH and salinity

Sedimentation and drainage

‘characteristics

Eectial potential gradients

wotages Currents,

Electrode materials and

‘georeties

Mechanical design and

scale-up fom test ests

Aquaterre

“Typical sand snes dar sil wet

years afer abandonment

Fld tls nvaing in-situ

‘Sevatering of impoundments

‘tere carted ott in tangs ponds

ata coal washery, using

Foriaontalelectoge

arrangements. Some 570 tonnes

‘ttalings were dewatering in 2

weeks toa spadeable

‘Consistency at an electrical

‘eneray consumption of 9 kh per

tone, oF 20 Wht on a dry basa

Had EDW not been employed,

the talings would have required a

‘consolidation time of several!

‘eneraly have lead toa spadesble

Eonsistency

‘larger field til was conducted

‘ta sand washery, using

‘erical anodes nd cathode

Gans. About 4500 tonnes of

Sand talings were deuatering toa

Spadeable consisteny in ony

te months at an energy

consumption of approximately 0.7

reh/ton a ty base

Without EDW, dewatering and

‘consolidation to spadesble

‘consistency would require

Several yeas

Aquaterre

~AQUATERRE

EDW

DEWATERING

TECHNOLOGY

“Type pete of snd algs afer desiring by EDW

LET Us HELP You!

sgaere is backed by CSIRO wih test facies, research and technology development and ty Dany

Pacie Py Lid with its exensive work vige engineering experise Aquatre offers assistance and

‘tic help You achieve mesimum perormance in fe dewatering of our parc susprsons

« Efficient

Although we specialize in EDW, our expertise extends beyond EDW to all elated aspects of dewatering

problems, eveluation of current systems and assistance with new technology. « Fast

‘Give Aquaterre a cal, we could have the answer to your dewatering problem!

« Cost-effective

e. |

AQUATERRE PTY. LTD. |

Irsorget igor)

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Beltmaster Berekeningen-Transport PDFДокумент16 страницBeltmaster Berekeningen-Transport PDFyaidragonОценок пока нет

- Correlating The Chemical Engineering Plant Cost Index With Macro-Economic IndicatorsДокумент10 страницCorrelating The Chemical Engineering Plant Cost Index With Macro-Economic IndicatorsCraftychemist100% (1)

- The Economic Geology of Iran - Mineral Deposits and Natrual Resources PDFДокумент581 страницаThe Economic Geology of Iran - Mineral Deposits and Natrual Resources PDFCraftychemist100% (1)

- c2Документ54 страницыc2CraftychemistОценок пока нет

- Treliver-Anglosaxony MiningДокумент28 страницTreliver-Anglosaxony MiningCraftychemistОценок пока нет

- CEPCI May2016Документ6 страницCEPCI May2016CraftychemistОценок пока нет

- Visio - Water Balance - Woodlark IslandДокумент1 страницаVisio - Water Balance - Woodlark IslandCraftychemistОценок пока нет

- Saxore Bergbau Technical Report Jun 2016 Amended PDFДокумент67 страницSaxore Bergbau Technical Report Jun 2016 Amended PDFCraftychemistОценок пока нет

- Ajax Fastener HandbookДокумент132 страницыAjax Fastener Handbookandrew_ferrier9390Оценок пока нет

- Tank Volume Calculator FormulaДокумент1 страницаTank Volume Calculator FormulaCraftychemistОценок пока нет

- Bendigo Creek - Figure - Cip PlantДокумент1 страницаBendigo Creek - Figure - Cip PlantCraftychemistОценок пока нет

- Lecture 4 Notes - SupplementaryДокумент8 страницLecture 4 Notes - SupplementaryCraftychemistОценок пока нет

- Kidston gold mine startup details SEO optimized titleДокумент5 страницKidston gold mine startup details SEO optimized titleCraftychemistОценок пока нет

- Pub-3000 Chapter 27 - Cranes, Hoists, and Rigging Safety - Revised 07 - 15Документ15 страницPub-3000 Chapter 27 - Cranes, Hoists, and Rigging Safety - Revised 07 - 15CraftychemistОценок пока нет

- Budgetary Prices For Mills 15kw-630kw 10-3-15Документ1 страницаBudgetary Prices For Mills 15kw-630kw 10-3-15CraftychemistОценок пока нет

- Budgetary Prices For Mills-ARC-VantureДокумент2 страницыBudgetary Prices For Mills-ARC-VantureCraftychemistОценок пока нет

- Newspaper Scan - Digger StoryДокумент1 страницаNewspaper Scan - Digger StoryCraftychemistОценок пока нет

- Electrochemistry Revision LectureДокумент23 страницыElectrochemistry Revision LectureCraftychemistОценок пока нет

- As 2419Документ93 страницыAs 2419Craftychemist100% (2)

- Grundfosliterature 288192Документ64 страницыGrundfosliterature 288192CraftychemistОценок пока нет

- Electrochemistry Lecture 2 - NotesДокумент17 страницElectrochemistry Lecture 2 - NotesCraftychemistОценок пока нет

- Electrochemistry Lecture 5 - NotesДокумент17 страницElectrochemistry Lecture 5 - NotesCraftychemistОценок пока нет

- Actual and Standard VolumesДокумент1 страницаActual and Standard VolumesCraftychemistОценок пока нет

- Genetically Engineered Bacteriophage For Diagnosis of Whooping CoughДокумент32 страницыGenetically Engineered Bacteriophage For Diagnosis of Whooping CoughCraftychemistОценок пока нет

- Electrochemistry Lecture 4 - NotesДокумент20 страницElectrochemistry Lecture 4 - NotesCraftychemistОценок пока нет

- Electrochemistry Lecture 1Документ25 страницElectrochemistry Lecture 1CraftychemistОценок пока нет

- HF - Book - PolarographyДокумент36 страницHF - Book - PolarographyCraftychemistОценок пока нет

- Food Chemistry - Carrots V 02Документ3 страницыFood Chemistry - Carrots V 02CraftychemistОценок пока нет

- Electrochemistry Lecture 3 - NotesДокумент14 страницElectrochemistry Lecture 3 - NotesCraftychemistОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)