Академический Документы

Профессиональный Документы

Культура Документы

Belt Conveyor RFBE-B1800 X 9.7

Загружено:

Mahmoud HanafyАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Belt Conveyor RFBE-B1800 X 9.7

Загружено:

Mahmoud HanafyАвторское право:

Доступные форматы

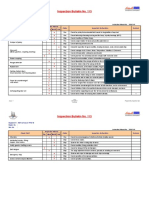

Inspection Bulletin No.

104

Equipment Belt Conveyor RFBE-B1800 X 9.7

Equip. No. :

Item No.

Inspection Interval

Check Point Status Inspection Instruc

Day Week Month Year

Run Check the pulley for mechanical fault, check for irre

Drive Station

Run Check fasteninig of bearing housing and the temp.

Drive Pulley Stop Check Condition of Rubber lining .

Stop Check scraper blades for wear and position adjuste

Scraper of pulley

Stop Check fastening of bolts and nuts

Stop Complete inspection for gear condition, bearing cle

Drive unit Run Check Leakage of oil, Oil level, Noise, Temperature,

(Motor, gearbox, Run Check oil temperature (Measures and record)

coupling, bearing)

Run Check gear box runs smoothly and does not genera

Fludex coupling Stop Check General condition, oil level, oil condition and

Stop Check Movability of the plough deflector on the sus

Plough deflector

Stop Check the rubber strip of the plough deflector

Rubber belt Stop Check belt Tension, belt surface condition, Alignme

Carring, Return Idlers Run Check Rotation of Idlers freely without abnormal No

Shock absorber, Self Run Check damaged, wear, and check the idler center on

Cleaning Idlers Stop Check that the rubber lining on Idlers is intact for th

Structure Run Check General arrangement structure,structure vibr

Inlet/outlet chutes, Stop Check Wear, cracks.

Filling hopper, Side Stop Examine the rubber sealing stips for wear.

Guides Stop Check adjusting of deflector plates.

Safety guards / Netting Run Check condition, fixing, protective effect

Stop Examine wire rope for damage and check rope anch

Emergency Stop

Stop Check operation of emergency switches

Askew switches/Speed Stop Check operation and condition.

Issue: 1 04/15/2017 Prepared By Inspection Dpt.

13:42:37

Instruction Manual No. 39541-98

Inspection Instructions Revision

Check the pulley for mechanical fault, check for irregularities of any kind

Check fasteninig of bearing housing and the temp. in pulley bearings (60C)

Check Condition of Rubber lining .

Check scraper blades for wear and position adjustement.

Check fastening of bolts and nuts

Complete inspection for gear condition, bearing clearance, seals, sleeves,back stop.

Check Leakage of oil, Oil level, Noise, Temperature, Vibration, & Cleanness.

Check oil temperature (Measures and record)

Check gear box runs smoothly and does not generate excessive noise

Check General condition, oil level, oil condition and oil seal

Check Movability of the plough deflector on the suspinsion

Check the rubber strip of the plough deflector

Check belt Tension, belt surface condition, Alignment, damage, general, wear

Check Rotation of Idlers freely without abnormal Noise,check damaged, and wear.

Check damaged, wear, and check the idler center on the shaft.

Check that the rubber lining on Idlers is intact for the shock absorber Idlers

Check General arrangement structure,structure vibration overall.

Check Wear, cracks.

Examine the rubber sealing stips for wear.

Check adjusting of deflector plates. 1

Check condition, fixing, protective effect

Examine wire rope for damage and check rope anchorage

Check operation of emergency switches

Check operation and condition.

Issue: 1 04/15/2017 Prepared By Inspection Dpt.

13:42:37

Вам также может понравиться

- Belt Conveyor RT45-BДокумент2 страницыBelt Conveyor RT45-BMahmoud HanafyОценок пока нет

- Inspection Bulletin No. 103: Impact Crusher IM - 13RДокумент1 страницаInspection Bulletin No. 103: Impact Crusher IM - 13RMahmoud HanafyОценок пока нет

- Excavator Instructors NotesДокумент31 страницаExcavator Instructors NotesWALTER EMMANUEL FLORES COSCOОценок пока нет

- Grand I10 MaintainanceДокумент10 страницGrand I10 Maintainancerick slyОценок пока нет

- Unloader Check ListДокумент1 страницаUnloader Check ListAnonymous ahdhFMaОценок пока нет

- M.E.M.01.C.EN.00 - Maintenance ManualДокумент10 страницM.E.M.01.C.EN.00 - Maintenance ManualGorazdSklepičОценок пока нет

- Sop Be 2Документ91 страницаSop Be 2abdul subhanОценок пока нет

- Driving Commercial Vehicles Manual Class 4 Unrestricted Pre-Trip InspectionДокумент7 страницDriving Commercial Vehicles Manual Class 4 Unrestricted Pre-Trip InspectionjwОценок пока нет

- Technical Maintain ScheduleДокумент7 страницTechnical Maintain ScheduleHENRYMARINGANОценок пока нет

- M025 DECK CRANE Operation ChecklistДокумент4 страницыM025 DECK CRANE Operation Checklistahmedtaher.at192Оценок пока нет

- 3 ES10-10ES Daily Maintenance List (20171220) - 20181120 - 095019Документ4 страницы3 ES10-10ES Daily Maintenance List (20171220) - 20181120 - 095019Lacatusu MirceaОценок пока нет

- Recommended Trailer Maintenance Schedule: Brake SystemДокумент1 страницаRecommended Trailer Maintenance Schedule: Brake SystemMario Adrian Carrillo ArtalejoОценок пока нет

- LY38 Ops Manual PDFДокумент36 страницLY38 Ops Manual PDForlando chullo llave100% (1)

- How To Inspect A Gearbox PDFДокумент5 страницHow To Inspect A Gearbox PDFsurawutwijarn100% (2)

- Hyundai Elevator Preventive Maintenance ProcedureДокумент19 страницHyundai Elevator Preventive Maintenance ProcedureTrebor Santos100% (2)

- Verif EPI Poulies Procedure ENДокумент3 страницыVerif EPI Poulies Procedure ENaliya azharОценок пока нет

- Maintenance: Rotor Interval Ref. No. NotesДокумент11 страницMaintenance: Rotor Interval Ref. No. NotesEduardo AcostaОценок пока нет

- Suplemen Step Ow Lathe-1Документ18 страницSuplemen Step Ow Lathe-1mochtardida974Оценок пока нет

- During Conductor Paying Out It Is Used For Pulling of ACSR ConductorsДокумент37 страницDuring Conductor Paying Out It Is Used For Pulling of ACSR ConductorsRohit Singh100% (1)

- 05 Turbine Operation MaintenanceДокумент9 страниц05 Turbine Operation Maintenancesakera 88Оценок пока нет

- Impac Vehicle Maintenance Sheet - C, D, EДокумент6 страницImpac Vehicle Maintenance Sheet - C, D, EFranklyn MunroeОценок пока нет

- Crankcase Inspection Safety & Procedure MMD Favourite QuestionsДокумент1 страницаCrankcase Inspection Safety & Procedure MMD Favourite QuestionsAnkit ChatterjeeОценок пока нет

- Elevator PM GuideДокумент19 страницElevator PM GuideJFBD BuildersОценок пока нет

- Check Valve SelectionДокумент1 страницаCheck Valve SelectionramkikkdОценок пока нет

- Crane & Hoist Pre-Use Inspection Checklist: Hook and Chain Assembly - Monthly InspectionДокумент3 страницыCrane & Hoist Pre-Use Inspection Checklist: Hook and Chain Assembly - Monthly InspectionAde KodratОценок пока нет

- BACKHOE LOADER Pre-Operations ChecklistДокумент3 страницыBACKHOE LOADER Pre-Operations Checklistmanny daleonОценок пока нет

- Overhead CranesДокумент50 страницOverhead CraneshamzanusratОценок пока нет

- 3 EPT20-15ET Daily Maintenance List - 20181115 - 133154Документ3 страницы3 EPT20-15ET Daily Maintenance List - 20181115 - 133154Lacatusu MirceaОценок пока нет

- MM y ServicioДокумент82 страницыMM y Serviciojesus francoОценок пока нет

- Pre Operational InspectionДокумент89 страницPre Operational InspectionGustavo ArancibiaОценок пока нет

- Brake System InspectionДокумент6 страницBrake System Inspectioncarlos pilcoОценок пока нет

- Maintenance of GBДокумент46 страницMaintenance of GBAnoop Tiwari100% (4)

- Kia-Carnival 2008 en Manual de Mantenimiento C6b3ec5b7aДокумент48 страницKia-Carnival 2008 en Manual de Mantenimiento C6b3ec5b7aAmelia Sofía Sanhueza GrandónОценок пока нет

- Troubleshooting Guide For Butterfly ValvesДокумент1 страницаTroubleshooting Guide For Butterfly Valvesjomar bonhayagОценок пока нет

- Gear InspectionДокумент6 страницGear Inspectionbh hbОценок пока нет

- PM Inspection SheetДокумент4 страницыPM Inspection SheetYogeshОценок пока нет

- Crane and Hoist Pre Use Inspection ChecklistДокумент3 страницыCrane and Hoist Pre Use Inspection ChecklistKingsley Phang67% (3)

- Maintenance ESC & TRV FujiДокумент4 страницыMaintenance ESC & TRV Fujikhadavi kulonОценок пока нет

- Mariners Repository - Propeller Inspection, Defects and RepairsДокумент13 страницMariners Repository - Propeller Inspection, Defects and RepairsATT2016Оценок пока нет

- 5.19 JSP Power Transformer High Voltage TestДокумент4 страницы5.19 JSP Power Transformer High Voltage Testmuhammad.younisОценок пока нет

- Class4 Pre Trip InspectionДокумент3 страницыClass4 Pre Trip Inspection法璋Оценок пока нет

- Alternator Overhaul SK-KD 18.4Документ25 страницAlternator Overhaul SK-KD 18.4Opu RoteОценок пока нет

- Mine Canadian Royalties: Excavator TrainingДокумент72 страницыMine Canadian Royalties: Excavator Trainingotak04Оценок пока нет

- 3 EPT20-15EHJ Daily Maintenance List - 20181115 - 154241Документ2 страницы3 EPT20-15EHJ Daily Maintenance List - 20181115 - 154241Fabricio ArteagaОценок пока нет

- Asphalt Plant Inspection ItemДокумент2 страницыAsphalt Plant Inspection ItemsacsewОценок пока нет

- HGДокумент6 страницHGlaxman JoshiОценок пока нет

- IFT Forklift Inspection 1Документ1 страницаIFT Forklift Inspection 1HSE ENL GCLOUDОценок пока нет

- Maintenance Interval CaymanДокумент4 страницыMaintenance Interval CaymanJZM GulfОценок пока нет

- 900 Liter Wheeled Water Cum Foam MonitorДокумент2 страницы900 Liter Wheeled Water Cum Foam MonitorvivekvpsfeОценок пока нет

- Aspen Dental Mechanical Service Requirements: NotesДокумент2 страницыAspen Dental Mechanical Service Requirements: NotesMon DoceОценок пока нет

- SGT - Le.014 Crane Inspection Type 1Документ10 страницSGT - Le.014 Crane Inspection Type 1ryangillespie100% (1)

- Tufting Maintenance PlanДокумент22 страницыTufting Maintenance PlanSimphiwe Mathe100% (1)

- GoMog Service ListДокумент7 страницGoMog Service ListPaper-FaceОценок пока нет

- Pre-Trip Inspection FormДокумент1 страницаPre-Trip Inspection Form• kylīīę •Оценок пока нет

- ZHENJIANG MARINE AUXILIARY MACHINERY WORKS - Ops & Maint - SH70 - 16Документ19 страницZHENJIANG MARINE AUXILIARY MACHINERY WORKS - Ops & Maint - SH70 - 16Amanda ViverosОценок пока нет

- Milton Cat Preventive Maintenance PM 1 and PM 2 Marketing PieceДокумент2 страницыMilton Cat Preventive Maintenance PM 1 and PM 2 Marketing PieceEdwin AlexОценок пока нет

- Maint ScheduleДокумент2 страницыMaint Schedulekeithfrost84Оценок пока нет

- Troubleshooting CentriДокумент5 страницTroubleshooting CentriDou BadaОценок пока нет

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementОт EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Limestone Crusher PM Plan - 30.01.23Документ2 страницыLimestone Crusher PM Plan - 30.01.23Mahmoud HanafyОценок пока нет

- Cement Mill 1 Planned Stoppage - 28.01.23 UpdateДокумент2 страницыCement Mill 1 Planned Stoppage - 28.01.23 UpdateMahmoud HanafyОценок пока нет

- Cement Mill 1 Planned Stoppage - 26.01.23 UpdateДокумент2 страницыCement Mill 1 Planned Stoppage - 26.01.23 UpdateMahmoud HanafyОценок пока нет

- Cement Mill 1 Planned Stoppage - 26.01.2023 UpdateДокумент2 страницыCement Mill 1 Planned Stoppage - 26.01.2023 UpdateMahmoud HanafyОценок пока нет

- Cement Mill 1 Planned StoppageДокумент3 страницыCement Mill 1 Planned StoppageMahmoud HanafyОценок пока нет

- Cement Mill 1 Planned Stoppage - 26.01.2023 UpdateДокумент3 страницыCement Mill 1 Planned Stoppage - 26.01.2023 UpdateMahmoud HanafyОценок пока нет

- Packer Operating ManualДокумент127 страницPacker Operating ManualMahmoud HanafyОценок пока нет

- Adeco: Project Engineering BVДокумент30 страницAdeco: Project Engineering BVMahmoud HanafyОценок пока нет

- Mahmoud Hanafy: Professional SummaryДокумент3 страницыMahmoud Hanafy: Professional SummaryMahmoud HanafyОценок пока нет

- LinksДокумент2 страницыLinksMahmoud HanafyОценок пока нет

- Mahmoud Hanafy CV 2020Документ2 страницыMahmoud Hanafy CV 2020Mahmoud HanafyОценок пока нет

- PM WNCC - Sep. 2019 OM Monthly ReportДокумент6 страницPM WNCC - Sep. 2019 OM Monthly ReportMahmoud HanafyОценок пока нет

- Forward Side Backward Side Forward Side Backward Side 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 B H B H B H B HДокумент2 страницыForward Side Backward Side Forward Side Backward Side 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 B H B H B H B HMahmoud HanafyОценок пока нет

- Bo Bo: Forward Side Backward Side Forward Side Backward Side 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 B H B H B H B HДокумент2 страницыBo Bo: Forward Side Backward Side Forward Side Backward Side 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 B H B H B H B HMahmoud HanafyОценок пока нет

- Book1Документ3 страницыBook1Mahmoud HanafyОценок пока нет

- Alignment ProtocolДокумент1 страницаAlignment ProtocolMahmoud Hanafy100% (1)

- Kiln Shutdown Report Sep-2019Документ14 страницKiln Shutdown Report Sep-2019Mahmoud Hanafy0% (1)

- PM Department: 1-Infrared Hand PyrometerДокумент1 страницаPM Department: 1-Infrared Hand PyrometerMahmoud HanafyОценок пока нет

- Inspection Report For Raw Mill's Internal Parts.: ObjectiveДокумент3 страницыInspection Report For Raw Mill's Internal Parts.: ObjectiveMahmoud HanafyОценок пока нет

- Geometric Dimensioning and Tolerancing Presented To: Dr. Ahmed Mahrous Report By: Mahmoud Hanafy MahmoudДокумент3 страницыGeometric Dimensioning and Tolerancing Presented To: Dr. Ahmed Mahrous Report By: Mahmoud Hanafy MahmoudMahmoud HanafyОценок пока нет