Академический Документы

Профессиональный Документы

Культура Документы

Metrode - P92 WPS PDF

Загружено:

Xing ChenОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Metrode - P92 WPS PDF

Загружено:

Xing ChenАвторское право:

Доступные форматы

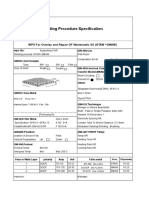

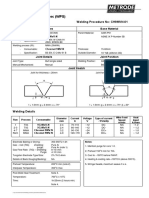

Welding Procedure Specification (WPS)

Welding Procedure No: CH92-01

Consumables Base Material

Welding process (root): TIG (GTAW) Parent Material: A335 P92

- Consumable: 9CrWV

- Specification: -

Welding process (fill): MMA (SMAW)

- Consumable: Chromet 92 Thickness: 15-60mm

- Specification: - Outside Diameter: 16 NB (406mm OD)

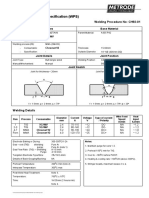

Joint Details Joint Position

Joint Type: Butt single sided Welding Position: ASME: 5G

Manual/Mechanised: Manual BS EN: PF

Joint Sketch

Joint for thickness < 20mm Joint for thickness > 20mm

f g f g

f = 1-3mm; g = 2-4mm; = 70 f = 1-3mm; g = 2-4mm; = 70; = 20

Welding Details

Wire Feed Heat

Diameter Current Voltage Type of current

Run Process Consumable Speed Input

mm A V / Polarity

m/min kJ/mm

1 TIG 9CrWV 2.4 70-110 ~12 DC- NA ~1.2

2-3 TIG 9CrWV 2.4 80-140 ~12 DC- NA ~ 1.2

4-7 MMA Chromet 92 3.2 90-130 ~24 DC+ NA ~ 1.0

Rem MMA Chromet 92 4.0 120-170 ~25 DC+ NA ~ 1.2

Electrode Baking or Drying: 300-350oC/1-2h Notes:

Gas root (TIG) shielding: Pure Ar

1. Maintain purge for runs 1-3.

purge: Pure Ar (note 1)

Gas Flow Rate (TIG) Shielding: 8-15 l/min

2. Preheat 150oC min for TIG.

Purge: 4-10 l/min

Tungsten Electrode Type/Size: 2% Th/2.4mm 3. Cool to ~100oC before PWHT.

Details of Back Gouging/Backing: NA 4. Heating & cooling rate <100oC/h (above 300C).

Preheat Temperature: 200oC min (note 2) 5. Stringer beads, maximum weave 3 x .

o

Interpass Temperature: 300 C max

Post-Weld Heat Treatment: Note 3.

Temperature: 760oC 10oC

Time: 1h/25mm (2 hours min)

Note 4.

N:\Tech\Literature\Technical Profiles\P92\P92 Tech Profile wps.doc

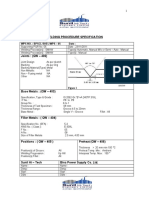

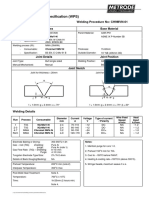

Welding Procedure Specification (WPS)

Welding Procedure No: SCF92-01

Consumables Base Material

Welding process (root): TIG (GTAW) Parent Material: A335 P92

- Consumable: 9CrWV

- Specification: - Thickness: 15-60mm

Welding process (fill): MMA (SMAW) Joint Details

- Consumable: Chromet 92 Joint Type: Single side butt weld

- Specification: - Manual/Mechanised: Manual

Welding process (fill): FCAW Joint Position

- Consumable: Supercore F92 (Note 1) Welding Position: ASME: 6G

- Specification: _ BS EN: HL045

Joint Sketch Welding Sequences

f g

f = 1-2mm; g = 3-4mm; = 75; = 10-20

Welding Details

Diameter Current Voltage Type of Wire Feed Heat

Run Process Consumable current / Speed Input

mm A V

Polarity m/min kJ/mm

1 TIG 9CrWV 2.4 80-120 ~12 DC- NA ~1.4

2-6 MMA Chromet 92 3.2 90-110 ~22 DC+ NA ~1.0

Fill FCW Supercore F92 1.2 160-190 25-27 DC+ (Note 2) ~6-8 ~1.2

Electrode Baking or Drying: 300-350C/1-2h Notes:

Gas root (TIG) shielding: Argon

1. Shielding gas Ar-20%CO2 at 15-25 l/min.

purge: Argon (Note 3)

Gas Flow Rate (TIG) Shielding: 8-12 l/min

2. Electrode stickout 15-25mm.

Purge: 4-10 l/min

Tungsten Electrode Type/Size: 2% Th / 2.4mm 3. Maintain purge for at least first two runs.

Details of Back Gouging/Backing: NA 4. Preheat 150C min for TIG.

Preheat Temperature: 200C min (note 4) 5. Cool to ~100C before PWHT.

Interpass Temperature: 300C 6. Heating & cooling rate <100C/h (above 300C).

Post-Weld Heat Treatment: Note 5.

Temperature: 760C 10C

Time: 1 h/25mm (4 hours min)

Note 6.

N:\Tech\Literature\Technical Profiles\P92\P92 Tech Profile wps.doc

Welding Procedure Specification (WPS)

Welding Procedure No: SAW-P92-01

Consumables Base Material

Welding process (root): TIG (GTAW) Parent Material: A335 P92

- Consumable: 9CrWV Thickness: 25-75mm

- Specification: - Outside diameter:

Welding process (hot pass): MMA (SMAW) Joint Details

- Consumable: Chromet 92 Joint Type: Butt single sided

- Specification: - Manual/Mechanised: Manual & mechanised

Welding process (fill): SAW Joint Position

- Consumable: 9CrWV + LA491 (flux) Welding Position: ASME, 1G (1GR; note 6).

- Specification: - BS EN, PA (note 6).

Joint Sketch

f g

f = 13mm; g = 2-4mm; = 70; = 20

Welding Details

Diameter Current Voltage Type of Travel Heat

Run Process Consumable current / Speed Input

mm A V

Polarity mm/min kJ/mm

1 TIG 9CrWV 2.4 70-110 ~12 DC- NA ~ 1.0

2-3 TIG 9CrWV 2.4 80-140 ~12 DC- NA ~ 1.2

4-7 MMA Chromet 92 3.2 90-130 ~24 DC+ NA ~ 1.2

Rem SAW (note 1) 9CrWV 2.4 350-450 ~30 DC+ 400-500 ~ 2.0

Electrode & Flux Drying: 300-350oC/1-2h Notes:

Gas root (TIG) shielding: Pure Ar

1. SAW flux LA491.

purge: Pure Ar (note 2)

Gas Flow Rate (TIG) Shielding: 8-15 l/min

~20mm wire extension, ~30mm flux depth.

Purge: 4-10 l/min

Tungsten Electrode Type/Size: 2% Th/2.4mm 2. Maintain purge for runs 1-3.

Details of Back Gouging/Backing: NA 3. Preheat 150oC min for TIG.

Preheat Temperature: 200oC min (note 3) 4. Cool to <100oC before PWHT.

Interpass Temperature: 300oC max 5. Heating & cooling rate <100oC/h (above 300C).

Post-Weld Heat Treatment: Note 4. 6. For rotated pipe, head to be 10 before TDC

o o

Temperature: 760 C 10 C perpendicular to pipe.

Time: 1h/25mm (4 hours min)

Note 5.

N:\Tech\Literature\Technical Profiles\P92\P92 Tech Profile wps.doc

Вам также может понравиться

- Electrode Selection As Per Base Metal With Preheat, Postheat and Hardness DetailsДокумент1 страницаElectrode Selection As Per Base Metal With Preheat, Postheat and Hardness DetailsJlkKumar100% (1)

- STD 1104 - Welding of Pipelines and Related FacilitiesДокумент38 страницSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilОценок пока нет

- Electrode SelectionДокумент1 страницаElectrode SelectionVijayabaraniОценок пока нет

- Metrode Dissimilar Consumable SelectorДокумент7 страницMetrode Dissimilar Consumable SelectorClaudia MmsОценок пока нет

- WPS Format For ASME IX - PQR-AllДокумент3 страницыWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Duplex Ss Welding PDF FreeДокумент8 страницDuplex Ss Welding PDF Freeel_sharkawy2011Оценок пока нет

- ASME 9 - CalculatorДокумент2 страницыASME 9 - CalculatorEmel Besir100% (1)

- PWHT, HT, Igc, MawpДокумент40 страницPWHT, HT, Igc, Mawpsachinshirnath100% (1)

- WPS-PQR (Er309l Mo)Документ4 страницыWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- Wps p91 - BhelДокумент2 страницыWps p91 - BhelAshish Gupta100% (4)

- 19403955-WPS M.S. Is 2062Документ10 страниц19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- 6GR RequirementsДокумент1 страница6GR Requirementswalitedison100% (1)

- Wps Gtaw Monel b127 b164Документ2 страницыWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- Hardox 450Документ3 страницыHardox 450Marko RisticОценок пока нет

- WPS - 017Документ12 страницWPS - 017MAT-LIONОценок пока нет

- WPS Resrvoire Sous Pression Smaw SawДокумент6 страницWPS Resrvoire Sous Pression Smaw SawDanem HalasОценок пока нет

- How To Read PWHTchartДокумент10 страницHow To Read PWHTchartAkhilesh Kumar100% (3)

- Preheat and Interpass TempДокумент2 страницыPreheat and Interpass TempUche UrchОценок пока нет

- WPS 2014-002 006 - 6G PipeДокумент3 страницыWPS 2014-002 006 - 6G PipejeswinОценок пока нет

- 004 Gtaw P5aДокумент16 страниц004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- ASME IX Interpretation-Part7Документ37 страницASME IX Interpretation-Part7kevin herryОценок пока нет

- Asme WPS Demo PWHT PDFДокумент3 страницыAsme WPS Demo PWHT PDFGanesh rohitОценок пока нет

- Welding& Inspection WPS& WelderДокумент112 страницWelding& Inspection WPS& WelderNitesh Garg100% (7)

- Piping Inspection 22.01.2020Документ72 страницыPiping Inspection 22.01.2020KarthikОценок пока нет

- ASME 9 Multi Process Welding Procedures QW200Документ2 страницыASME 9 Multi Process Welding Procedures QW200Teodor EzaruОценок пока нет

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsДокумент6 страницOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketОценок пока нет

- WeldingДокумент9 страницWeldingkiraneluruОценок пока нет

- WPS BhelДокумент2 страницыWPS BhelpradhankruhsnaОценок пока нет

- Multiple PQR QualificationДокумент4 страницыMultiple PQR QualificationKarthikeyan ShanmugavelОценок пока нет

- IIW World OverrviewДокумент4 страницыIIW World OverrviewAnonymous hBBam1nОценок пока нет

- All Materials DocumentsДокумент1 страницаAll Materials DocumentsRonit PatelОценок пока нет

- Welding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Документ1 страницаWelding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Lipika GayenОценок пока нет

- Eil WPSДокумент28 страницEil WPSRanjan Kumar0% (1)

- 202 1sp 0 Saw Cs CsДокумент8 страниц202 1sp 0 Saw Cs CskrishimaОценок пока нет

- Asme Sec 9 - AДокумент144 страницыAsme Sec 9 - Anidhinchandranvs67% (3)

- CV-AIT KOUFI Metallurgist Engineer - QAQC Welding NDT Coating Head DPT - EnGДокумент3 страницыCV-AIT KOUFI Metallurgist Engineer - QAQC Welding NDT Coating Head DPT - EnGait.koufiОценок пока нет

- Definition of Buttering From ASME Section IXДокумент2 страницыDefinition of Buttering From ASME Section IXsanket100% (3)

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationДокумент8 страницQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীОценок пока нет

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateДокумент2 страницыWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanОценок пока нет

- Welding Procedure Qualification Record: Shipyard LogoДокумент4 страницыWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- WPSASMEДокумент76 страницWPSASMERama TamaОценок пока нет

- Welding Consumable ChartДокумент2 страницыWelding Consumable ChartAfetОценок пока нет

- BohlerThyssen PDFДокумент386 страницBohlerThyssen PDFElMacheteDelHuesoОценок пока нет

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Документ2 страницыWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- P 91 - Welding WPSДокумент2 страницыP 91 - Welding WPSSuhailshah123475% (4)

- WPS PQR 12Документ9 страницWPS PQR 12Ranjan KumarОценок пока нет

- PWHTДокумент79 страницPWHTnguyenОценок пока нет

- Form 167Документ239 страницForm 167Kumar Navneet SinghОценок пока нет

- WPS-Tube To Tube Sheet (SS-SS)Документ2 страницыWPS-Tube To Tube Sheet (SS-SS)suria qaqcОценок пока нет

- Chapter-17 Weldability ....Документ6 страницChapter-17 Weldability ....shahid khanОценок пока нет

- Electrode Selection ChartДокумент4 страницыElectrode Selection Chartsunitbhaumik100% (2)

- Dss 2205 Wps PQR WPQДокумент8 страницDss 2205 Wps PQR WPQAnand KesarkarОценок пока нет

- Welding Procedure Specification (WPS)Документ3 страницыWelding Procedure Specification (WPS)Jignasa ShahОценок пока нет

- Welding Procedure Specification (WPS)Документ6 страницWelding Procedure Specification (WPS)Mohamad Marwan HamwiОценок пока нет

- P91 Profile WpsДокумент6 страницP91 Profile WpsZead Ali Adal100% (2)

- P91 ProfileДокумент6 страницP91 ProfilesrinivasanОценок пока нет

- QW 482 WPSДокумент2 страницыQW 482 WPSsmit patelОценок пока нет

- Weld in G P Ro Cedu Re SP Ecifica Tio N (WP S)Документ2 страницыWeld in G P Ro Cedu Re SP Ecifica Tio N (WP S)almasrizalОценок пока нет

- Welding Procedure Specification: ST NDДокумент1 страницаWelding Procedure Specification: ST NDMaung SleeperОценок пока нет

- BS en 12516-2-2014+a1-2021Документ142 страницыBS en 12516-2-2014+a1-2021Xing ChenОценок пока нет

- Asme B16.11-2021Документ34 страницыAsme B16.11-2021Xing Chen75% (8)

- MSS - SP 155 2018Документ18 страницMSS - SP 155 2018Денис Пекшуев100% (1)

- Iso+11114 5 2022Документ22 страницыIso+11114 5 2022Xing ChenОценок пока нет

- BS en 15081-2007Документ22 страницыBS en 15081-2007Xing Chen100% (1)

- ARTICLE Damage Scenarios For Valves Identifying The Potential ForДокумент5 страницARTICLE Damage Scenarios For Valves Identifying The Potential ForXing ChenОценок пока нет

- Piping Codes, Valve Standards and Ball Valve Selection: Ron Manson, March 2015Документ37 страницPiping Codes, Valve Standards and Ball Valve Selection: Ron Manson, March 2015shameer_febiОценок пока нет

- SPO HighTempДокумент10 страницSPO HighTempXing ChenОценок пока нет

- KF Ball Iom Series WBДокумент10 страницKF Ball Iom Series WBXing ChenОценок пока нет

- KAT A 2014 RIKO Handwheel EN 01 01 01 06 10Документ7 страницKAT A 2014 RIKO Handwheel EN 01 01 01 06 10Xing ChenОценок пока нет

- Klipno Prstenasti ZatvaraciДокумент7 страницKlipno Prstenasti ZatvaraciНебојша РадићОценок пока нет

- (Edau12-722) Super Multi NX, R410a, (3mxs-Evma, Ftxs-Evma)Документ428 страниц(Edau12-722) Super Multi NX, R410a, (3mxs-Evma, Ftxs-Evma)Phanhai KakaОценок пока нет

- 2 Annual Power and Desalination Summit: 17 - 18 March 2013 Bader M Al-SaleemДокумент16 страниц2 Annual Power and Desalination Summit: 17 - 18 March 2013 Bader M Al-Saleemcvolkan1100% (1)

- Moussa 2019Документ14 страницMoussa 2019Abhimanyu YadavОценок пока нет

- Z Source ConverterДокумент12 страницZ Source Converterravirnjn88Оценок пока нет

- Hoppecke Fnceh PDFДокумент7 страницHoppecke Fnceh PDFkamal_khan85Оценок пока нет

- Advantages and Disadvantages of Green Technology Goals, Challenges and StrengthsДокумент13 страницAdvantages and Disadvantages of Green Technology Goals, Challenges and StrengthsBasyirah Mohd ZawawiОценок пока нет

- U.S. Offshore Wind Industry: NovemberДокумент2 страницыU.S. Offshore Wind Industry: NovemberKOMATSU SHOVELОценок пока нет

- 1KW Project in On GrideДокумент5 страниц1KW Project in On GrideRAKESH PRADHANОценок пока нет

- Microsoft Word - Smart Grid Initiatives in India - Final PaperДокумент15 страницMicrosoft Word - Smart Grid Initiatives in India - Final PaperE.AvinashОценок пока нет

- 2012 2030 PEP Executive Summary PDFДокумент12 страниц2012 2030 PEP Executive Summary PDFraul_bsuОценок пока нет

- IRENA Renewable Energy in Cities 2016Документ64 страницыIRENA Renewable Energy in Cities 2016Ramanditya WimbardanaОценок пока нет

- EM6400 QSG V01.d18 (Web) PDFДокумент4 страницыEM6400 QSG V01.d18 (Web) PDFGillala RamakanthОценок пока нет

- Reactive Power Generation and Control by Thyristor CircuitsДокумент11 страницReactive Power Generation and Control by Thyristor Circuitsrakeshee2007Оценок пока нет

- Bioenergy Conversion FactorsДокумент4 страницыBioenergy Conversion FactorsAhmet SeçenОценок пока нет

- Communication Engineering Research ProposalДокумент3 страницыCommunication Engineering Research ProposalDevОценок пока нет

- ERKE Group, IHC Fundex F2200 Hydraulic Foundation MachineДокумент2 страницыERKE Group, IHC Fundex F2200 Hydraulic Foundation MachineerkegroupОценок пока нет

- Electrical Machine Lab ManualДокумент61 страницаElectrical Machine Lab ManualPrem SharmaОценок пока нет

- Calculating Solar Reflectance Index of Horizontal and Low-Sloped Opaque SurfacesДокумент3 страницыCalculating Solar Reflectance Index of Horizontal and Low-Sloped Opaque SurfacesAbuAhmedQuazi100% (1)

- Lee - 2023 - Net-Zero Transitions For All Considering ApplicatДокумент6 страницLee - 2023 - Net-Zero Transitions For All Considering ApplicatAthena SonОценок пока нет

- Solar Project ReportДокумент16 страницSolar Project ReportGagan SharmaОценок пока нет

- Solar Analysis: Prepared For: Prepared byДокумент10 страницSolar Analysis: Prepared For: Prepared byCesarОценок пока нет

- SF LGBT Community Center 2008-2010 Biennial ReportДокумент28 страницSF LGBT Community Center 2008-2010 Biennial Reportingridt6006Оценок пока нет

- Flywheel Energy FormulaДокумент9 страницFlywheel Energy Formulaalexbusinesss100% (1)

- 01 - Introduction To TrnsysДокумент18 страниц01 - Introduction To TrnsysAnonymous 73gEYyEtLОценок пока нет

- Assignment Ac Vs DC Power PointДокумент4 страницыAssignment Ac Vs DC Power Pointapi-295212665Оценок пока нет

- Installation Instructions For Axial Fans For Bathroom, Toilets, Utility Rooms and KitchensДокумент2 страницыInstallation Instructions For Axial Fans For Bathroom, Toilets, Utility Rooms and KitchenstylerdurdaneОценок пока нет

- Jaipur Vidut Vitran Nigam LTD.: (A) Meter Reading & ConsumptionДокумент1 страницаJaipur Vidut Vitran Nigam LTD.: (A) Meter Reading & ConsumptionSangwan ParveshОценок пока нет

- Modern Electric, Hybrid Electric & Fuel Cell Vehicles - Mehrdad EhsaniДокумент8 страницModern Electric, Hybrid Electric & Fuel Cell Vehicles - Mehrdad EhsaniPunit100% (2)

- Fundamentals and Application of Solar PhotovoltaicsДокумент24 страницыFundamentals and Application of Solar PhotovoltaicsEmmanuel OgoloОценок пока нет

- 9 5in Modular Motor - MMTR 70 01 003Документ2 страницы9 5in Modular Motor - MMTR 70 01 003Qiang ZhangОценок пока нет