Академический Документы

Профессиональный Документы

Культура Документы

Industrial Revolution 4.0

Загружено:

GRD JournalsАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Industrial Revolution 4.0

Загружено:

GRD JournalsАвторское право:

Доступные форматы

GRD Journals | Global Research and Development Journal for Engineering | National Conference on Computational Intelligence Systems

(NCCIS17) | March 2017

e-ISSN: 2455-5703

Industrial Revolution 4.0

1Kevin

Vishal K J

1

Student

1

Department of Mechanical Engineering

1Loyola-ICAM College of Engineering and Technology(LICET)

Chennai, India

Abstract

This paper deals about how INDUSTRIAL REVOLUTION 4.0 is going to tune our lives based on Artificial Intelligence, Big Data

and Internet of things. Industrial revolution 4.0 is the next phase in digitalization of the manufacturing sector, driven by four

disruptions: the astonishing rise in data volumes, computational power and connectivity, the emergence of analytics and business-

intelligence capabilities; new form of human machine interactions and augmented reality. Even though we get advanced in these

technologies. We should understand its consequences as well as its positive feedback. Wes should get ready to meet its core and

use its fruits only for the goodness of mankind.

Keyword- Technological Revolution, Computational Power, Intelligent Maintenance System

__________________________________________________________________________________________________

I. INTRODUCTION

We stand on the brink of a technological revolution that will fundamentally alter the way we live, work, and relate to one another.

In its scale and complexity, the transformation will be unlike anything humankind has experienced before. We do not yet know

just how it will unfold, but one thing is clear, the response to it must be integrated and comprehensive, involving all stakeholders

of the global polity, from the public and private sectors to academia and civil society.

Fig. 1: (CNC-milling & grinding)

All rights reserved by www.grdjournals.com 58

Industrial Revolution 4.0

(GRDJE / CONFERENCE / NCCIS17 / 010)

II. EVOLUTION OF REVOLUTION

III. BASIC MEANING

The term industry 4.0 was first designed by the German Government and represents the application of Artificial Intelligence, Big

Data and Internet of things. McKinsey defines Industry 4.0 as the next phase in digitalization of the manufacturing sector, driven

by four disruptions: the astonishing rise in data volumes, computational power and connectivity, the emergence of analytics and

business-intelligence capabilities; new form of human machine interactions and augmented reality.

Fig. 2: Assembly line production

IV. PRINCIPLES

A. Interoperability

The ability of machines, devices, sensors, and people to connect and communicate with each other via the Internet of Things (IoT)

or the Internet of People (IoP).

B. Information Transparency

The ability of information systems to create a virtual copy of the physical world by enriching digital plant models with sensor data.

This requires the aggregation of raw sensor data to higher-value context information.

C. Technical Assistance

First, the ability of assistance systems to support humans by aggregating and visualizing information comprehensibly for making

informed decisions and solving urgent problems on short notice. Second, the ability of cyber physical systems to physically suort

humans by conducting a range of tasks that are unpleasant, too exhausting, or unsafe for their human co-workers.

All rights reserved by www.grdjournals.com 59

Industrial Revolution 4.0

(GRDJE / CONFERENCE / NCCIS17 / 010)

D. Decentralized Decisions

The ability of cyber physical systems to make decisions on their own and to perform their tasks as autonomously as possible. Only

in the case of exceptions, interferences, or conflicting goals, are tasks delegated to a higher level.

V. INDUSTRY-SCIENCE RELATION

1) Emphasize consistency in innovation policy.

2) Continue to act boldly in prioritizing research funding.

3) Expand investments in the future.

4) Eliminate legislative obstacles to innovation.

Fig. 3: im-plant gun

5) Craft an innovation-friendly tax system, and provide tax incentives for research and development by business enterprises.

6) Strengthen industry-science cooperation in lasting ways.

7) Ensure acceptance of innovation.

8) Attract people to research and development, and prepare them for R&D careers.

VI. CLOUD BASED DESIGN & MANU

Fig. 4: Cloud communication

All rights reserved by www.grdjournals.com 60

Industrial Revolution 4.0

(GRDJE / CONFERENCE / NCCIS17 / 010)

Cloud-based design and manufacturing (CBDM) refers to a service-oriented networked product development model in which

service consumers are able to configure products or services and reconfigure manufacturing systems through Infrastructure-as-a-

Service (IaaS), Platform-as-a-Service (PaaS), Hardware-as-a-Service (HaaS), and Software-as-a-Service (SaaS)

Today's manufacturing companies are undergoing a transformation towards increased digitalization, automation of

manufacturing processes and as well new forms of manufacturing organization and business models. While large-size

manufacturing companies are able to follow the pace of such technological developments, small-to mid-size manufacturing

companies (SME) often experience substantial problems in adopting technologically and organizationally far reaching concepts as

for example propagated by Industry 4.0.

Fig. 5: SIEMENS manufacturing using stimulation

VII. ROLE OF DATA & ANALYTICS

Big Data Analytics consists of 6Cs in the integrated Industry 4.0:

a) Connection (sensor and networks)

b) Cloud (computing and data on demand)

Fig. 6: Hierarchy of Data Analytics

c) Cyber (model & memory)

d) Content/context (meaning and correlation)

e) Community (sharing & collaboration)

f) Customization (personalization and value).

All rights reserved by www.grdjournals.com 61

Industrial Revolution 4.0

(GRDJE / CONFERENCE / NCCIS17 / 010)

VIII. MACHINE TO MACHINE RELATION

Machine to machine refers to direct communication between devices using any communications channel, including wired and

wireless.

Fig. 7: Automatic manufacturing of charger head using CNC

Machine to machine communication can include industrial instrumentation, enabling a sensor or meter to communicate the data it

records (such as temperature, inventory level, etc.) to application software that can use it (for example, adjusting an industrial

process based on temperature or placing orders to replenish inventory). Such communication was originally accomplished by

having a remote network of machines relay information back to a central hub for analysis, which would then be rerouted into a

system like a personal computer.

IX. INTELLIGENT MAINTENANCE SYSTEM

An intelligent maintenance system (IMS) is a system that utilizes the collected data from the machinery in order to predict and

prevent the potential failures in them. The occurrence of failures in the machinery can be costly and even catastrophic.

Fig. 8: Intelligent cooling system in manufacturing plant

All rights reserved by www.grdjournals.com 62

Industrial Revolution 4.0

(GRDJE / CONFERENCE / NCCIS17 / 010)

In order to avoid them, there needs to be a system which analyses the behaviour of the machine and provides alarms and

instructions for preventive maintenance. Analysing the behaviour of the machines has become possible by means of advanced

sensors, data collection systems, data storage/transfer capabilities and data analytic tools developed for such purpose.

X. IMPACT OF 4.0

The impact on Industry4.0s notable areas:

1) Services and business models

2) Reliability and continuous productivity

3) IT security

4) Machine safety

5) Product lifecycles

6) Industry value chain

7) Workers' education and skills

8) Socio-economic factors.

XI. CHALLENGES

1) IT security issues, which are greatly aggravated by the inherent need to open up those previously closed production shops.

2) Reliability and stability needed for critical machine-to-machine communication (M2M), including very short and stable

latency times.

3) Need to maintain the integrity of production processes.

4) Need to avoid any IT snags, as those would cause expensive production outages.

5) Need to protect industrial knowhow (contained also in the control files for the industrial automation gear).

6) Lack of adequate skill-sets to expedite the march towards fourth industrial revolution.

7) Loss of many jobs to automatic processes and IT-controlled processes, society.

XII. CONCLUSION

Even though we get advanced in these technologies. We should understand its consequences as well as its positive feedback. We

should get ready to meet its core and use its fruits only for the goodness of mankind. I just ask everyone to remember that.

WE ARE THE MASTERS OF THESE MACHINES, THEY SHOULD NOT MASTER US!

Fig. 9: International Airport Maintained by Intelligent Operation Performance System-iOPS

All rights reserved by www.grdjournals.com 63

Industrial Revolution 4.0

(GRDJE / CONFERENCE / NCCIS17 / 010)

XIII. CNC MACHINES USED FOR MANUFACTURING PARTS WHICH IS CONTROLLED BY COMPUTERS

Fig. 10:

Fig. 11:

REFERENCES

[1] Hermann, Pentek, Otto, 2016: Design Principles for Industrie 4.0 Scenarios. Published in: System Sciences (HICSS), 2016

49th Hawaii International Conference on 5-8 Jan 2016

[2] Kagermann, H., W. Wahlster and J. Helbing, eds., 2013:: Recommendations for implementing the strategic initiative Industrie

4.0: Final report of the Industrie 4.0 Working Group.

[3] BMBF-Internetredaktion (2016-01-21). "Zukunftsprojekt Industrie 4.0 - BMBF", M. Waidner and M. Kasper, "Security in

industrie 4.0 - challenges and solutions for the fourth industrial revolution," 2016 Design, Automation & Test in Europe

Conference & Exhibition (DATE), Dresden, 2016, pp. 1303-1308.

All rights reserved by www.grdjournals.com 64

Industrial Revolution 4.0

(GRDJE / CONFERENCE / NCCIS17 / 010)

[4] Die Evolution zur Industrie 4.0 in derProduction. https://www.siemens.com/de/de/home/unternehmen/themenfelder/ingenuity-

for-life/optima-consumer.html.

[5] "With the coming of intra-atomic energy and supersonic stratosphere aviation we face an even more staggering fourth

Industrial Revolution." Harry Elmer Barnes, Historical Sociology: Its Origins and Development: Theories of Social Evolution

from Cave Life to Atomic Bombing (New York, 1948).

[6] "After World War II, we entered a fourth industrial revolution, with great advancement in electronics." Rose, Arnold M.

"Automation and the Future Society."

[7] "What is the Digital Revolution? - Definition from Techopedia". Techopedia.com.

[8] "What is the fourth industrial revolution? World Economic Forum.

[9] Marr, Bernard. "Why Everyone Must Get Ready For The 4th Industrial Revolution". Forbes (blog).

[10] Mr. Prabhu Shankar B.E, M.E, PGDM, Asst.Professor, Loyola-ICAM College of Engineering & Technology.

All rights reserved by www.grdjournals.com 65

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Wire Line Operation and EquipmentДокумент122 страницыWire Line Operation and Equipmentmissaoui100% (3)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Hustler Mini Z 44/52 Parts ManualДокумент125 страницHustler Mini Z 44/52 Parts ManualGary0% (1)

- FRAP AssayДокумент2 страницыFRAP AssayMayank Tandon94% (17)

- A Study On Various Grades of Triple Blended High Strength Concrete Using GGBS and Silica Fume As Partial Replacement of CementДокумент4 страницыA Study On Various Grades of Triple Blended High Strength Concrete Using GGBS and Silica Fume As Partial Replacement of CementGRD JournalsОценок пока нет

- Study On Disposal and Treatment of Pharmaceutical WastesДокумент8 страницStudy On Disposal and Treatment of Pharmaceutical WastesGRD JournalsОценок пока нет

- Design and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankДокумент5 страницDesign and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankGRD JournalsОценок пока нет

- Effect of Various Lateral Load Resisting Systems On Buildings With Flat Slab SystemsДокумент16 страницEffect of Various Lateral Load Resisting Systems On Buildings With Flat Slab SystemsGRD JournalsОценок пока нет

- Value Based Education The Need For The Present Indian Education SystemДокумент6 страницValue Based Education The Need For The Present Indian Education SystemGRD JournalsОценок пока нет

- Study and Implementation of Project Management Principles in New Product Development in The Automobile Manufacturing IndustryДокумент11 страницStudy and Implementation of Project Management Principles in New Product Development in The Automobile Manufacturing IndustryGRD JournalsОценок пока нет

- Image Based Virtual Try On NetworkДокумент4 страницыImage Based Virtual Try On NetworkGRD JournalsОценок пока нет

- A Study On Measurement of Service Quality in Public & Private Hospitals of ChhattisgarhДокумент6 страницA Study On Measurement of Service Quality in Public & Private Hospitals of ChhattisgarhGRD JournalsОценок пока нет

- Technologies in Educational Practice As A Tool For AthletesДокумент10 страницTechnologies in Educational Practice As A Tool For AthletesGRD JournalsОценок пока нет

- GRDJEV06I060005Документ7 страницGRDJEV06I060005GRD JournalsОценок пока нет

- Chronic Kidney Disease Stage Prediction in HIV Infected Patient Using Deep LearningДокумент8 страницChronic Kidney Disease Stage Prediction in HIV Infected Patient Using Deep LearningGRD JournalsОценок пока нет

- Environmental Awareness, Sustainable Consumption and Social Responsibility in The Context of The Covid-19 PandemicДокумент12 страницEnvironmental Awareness, Sustainable Consumption and Social Responsibility in The Context of The Covid-19 PandemicGRD JournalsОценок пока нет

- Driver Distraction, Alcohol and Obstacle Detection Through Machine Learning: A ReviewДокумент5 страницDriver Distraction, Alcohol and Obstacle Detection Through Machine Learning: A ReviewGRD JournalsОценок пока нет

- Metrics For Validation and Traceability of Project Management RequirementsДокумент13 страницMetrics For Validation and Traceability of Project Management RequirementsGRD JournalsОценок пока нет

- Optimization of Xanthan Gum Fermentation Utilizing Food WasteДокумент11 страницOptimization of Xanthan Gum Fermentation Utilizing Food WasteGRD JournalsОценок пока нет

- COVID - 19 VirusДокумент3 страницыCOVID - 19 VirusGRD JournalsОценок пока нет

- Automatic Face Recognition Attendance System Using Python and OpenCvДокумент7 страницAutomatic Face Recognition Attendance System Using Python and OpenCvGRD Journals100% (1)

- Potential of Post-Industrial Waste Landscape in Addressing Floods in Coastal Urban SlumsДокумент5 страницPotential of Post-Industrial Waste Landscape in Addressing Floods in Coastal Urban SlumsGRD JournalsОценок пока нет

- Parking Policy For Vadodara City, Gujarat, IndiaДокумент5 страницParking Policy For Vadodara City, Gujarat, IndiaGRD JournalsОценок пока нет

- Spectrophotometric Determination of Protonation Constants of L-Dopa in Dimethylformamide-Water MixturesДокумент4 страницыSpectrophotometric Determination of Protonation Constants of L-Dopa in Dimethylformamide-Water MixturesGRD JournalsОценок пока нет

- Touch Less Elevator Panel For Prevention of CoronavirusДокумент8 страницTouch Less Elevator Panel For Prevention of CoronavirusGRD JournalsОценок пока нет

- Quantification of Busulfan in Pharmaceutical Formulations by Analytical HPLCДокумент6 страницQuantification of Busulfan in Pharmaceutical Formulations by Analytical HPLCGRD JournalsОценок пока нет

- Designing of Flexible Pavement by Using Geosynthetic Material (Cotton Fiber)Документ5 страницDesigning of Flexible Pavement by Using Geosynthetic Material (Cotton Fiber)GRD JournalsОценок пока нет

- Covid-19 and Its Global Impact On Various SectorsДокумент3 страницыCovid-19 and Its Global Impact On Various SectorsGRD JournalsОценок пока нет

- Evaluate The Performance of MongoDB NoSQL Database Using PythonДокумент5 страницEvaluate The Performance of MongoDB NoSQL Database Using PythonGRD JournalsОценок пока нет

- Elements of Probabilistic Graphical Models For Machine LearningДокумент11 страницElements of Probabilistic Graphical Models For Machine LearningGRD JournalsОценок пока нет

- An Efficient Comparison Neural Network Methods To Evaluate Student PerformanceДокумент4 страницыAn Efficient Comparison Neural Network Methods To Evaluate Student PerformanceGRD JournalsОценок пока нет

- Potential Waste Water ReuseДокумент10 страницPotential Waste Water ReuseGRD JournalsОценок пока нет

- M20 Grade Concrete Subjected To Elevated TemperatureДокумент8 страницM20 Grade Concrete Subjected To Elevated TemperatureGRD JournalsОценок пока нет

- Machine Learning Algorithms To Improve The Performance Metrics of Breast Cancer DiagnosisДокумент4 страницыMachine Learning Algorithms To Improve The Performance Metrics of Breast Cancer DiagnosisGRD JournalsОценок пока нет

- NexstarcommprotДокумент8 страницNexstarcommprotskirmixОценок пока нет

- Formula Notes For Cracking Fluid Mechanics For Gate by Jain SirДокумент27 страницFormula Notes For Cracking Fluid Mechanics For Gate by Jain SirSachin Saini93% (27)

- A Mini Unmanned Aerial Vehicle (Uav) : System Overview and Image AcquisitionДокумент7 страницA Mini Unmanned Aerial Vehicle (Uav) : System Overview and Image AcquisitionhougieОценок пока нет

- Protection For HV Line BayДокумент3 страницыProtection For HV Line BayhasaladОценок пока нет

- Application of Theory of Constraints in Health SystemsДокумент10 страницApplication of Theory of Constraints in Health SystemszafarОценок пока нет

- Aluminium Aluminum 6070 Alloy (UNS A96070)Документ2 страницыAluminium Aluminum 6070 Alloy (UNS A96070)HARIPRASATH PОценок пока нет

- WAHLER Imagebroschuere SERIE enДокумент16 страницWAHLER Imagebroschuere SERIE ensagarpatel337Оценок пока нет

- Difference Between Forging and CastingДокумент2 страницыDifference Between Forging and CastingMOHAMMAD ALIОценок пока нет

- PPTДокумент24 страницыPPTAbhishek jain80% (5)

- SDHP CataloguesДокумент12 страницSDHP CataloguesPuppala Laxmana PrasadОценок пока нет

- MK Conveyor Technology 5.0Документ484 страницыMK Conveyor Technology 5.0Samuel Getaneh TОценок пока нет

- Interurban RMC Rail Bus ManualДокумент4 страницыInterurban RMC Rail Bus ManualSteven GardnerОценок пока нет

- Voltage DetectorsДокумент4 страницыVoltage DetectorsKarthik SriramakavachamОценок пока нет

- How Iso 27001 Compliance Is Impossible Without Privileged Management Technical Brief 17076Документ8 страницHow Iso 27001 Compliance Is Impossible Without Privileged Management Technical Brief 17076George VardangalosОценок пока нет

- 3D Printing Research Paper - Various Aspects PDFДокумент6 страниц3D Printing Research Paper - Various Aspects PDFhipovemicОценок пока нет

- 5 Process SynchronizaionДокумент58 страниц5 Process SynchronizaionLokesh SainiОценок пока нет

- SA35AC E01 MergedДокумент87 страницSA35AC E01 MergedClassyОценок пока нет

- Z4 Multi-Function Button Retrofit KitДокумент12 страницZ4 Multi-Function Button Retrofit KitgioioioiОценок пока нет

- Iam MicroprojectДокумент2 страницыIam MicroprojectGabber IsbackОценок пока нет

- Intro To Neutron ScatteringДокумент191 страницаIntro To Neutron ScatteringEleni MitsiОценок пока нет

- FM 3e SI Chap09 LectureДокумент111 страницFM 3e SI Chap09 LectureRuben SegarОценок пока нет

- ML10 OwnersManualДокумент16 страницML10 OwnersManualSalvador OlivasОценок пока нет

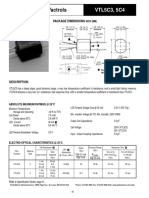

- Low Cost Axial Vactrols: VTL5C3, 5C4Документ2 страницыLow Cost Axial Vactrols: VTL5C3, 5C4sillyОценок пока нет

- Security For VPNs With IPsec Configuration Guide - 15.2MTДокумент166 страницSecurity For VPNs With IPsec Configuration Guide - 15.2MTAnonymous fIXhrYSmОценок пока нет

- Hydrulic Hose and FittingДокумент66 страницHydrulic Hose and FittingMamdouhAlhanafyОценок пока нет

- Pulveriser-Power PlantДокумент67 страницPulveriser-Power PlantARUNGREESMAОценок пока нет

- Bosch Video Management System - Configuration ManualДокумент260 страницBosch Video Management System - Configuration Manualvsuneelg100% (1)