Академический Документы

Профессиональный Документы

Культура Документы

Polycure FT TD

Загружено:

Marius Iana0 оценок0% нашли этот документ полезным (0 голосов)

85 просмотров2 страницыPolycure FT TD

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPolycure FT TD

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

85 просмотров2 страницыPolycure FT TD

Загружено:

Marius IanaPolycure FT TD

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

ACRYLIC POLYMER POLYCURE FT

Curing Agent

Product Name Product Type Uses

POLYCURE FT Acrylic Polymer An all acrylic polymer curing

agent for GRC and other

cementitious systems.

Polycure FT eliminates the need for moist curing of GRC products.

Curing of GRC and other cementitious products

Cementitious products should be moist cured to ensure that there is sufficient retained

moisture for complete hydration of the cement. This is particularly critical for thin skin

GRC products. The recommended curing regime is a wet cure at 95% relative humidity

for 7 days. In many cases this is not practical due insufficient factory space.

POLYCURE FT Curing System

When Polycure FT is added to the mix at the recommended dosage it forms a film

within the matrix during the setting and hardening process. The formation of this film

significantly reduces the permeability and thus lessens the loss of water by evaporation

ensuring that sufficient water is available for complete hydration.

Recommended Dosage

The recommended dosage level for Polycure FT is between 4 and 7 kgs for 50 kgs of

cement. Polycure FT is an emulsion containing a minimum of 50% solids, so a dosage

rate of 5kgs per 50kgs may also be stated as 5% polymer solids by weight of cement.

Mixing Method and Mix Design

The Polycure FT should be added to the mixer after the water has been added and

before the cement and sand. The amount of water should be reduced by the amount of

water in the polymer and further reductions will be possible because of the plasticising

effect of the polymer. Additional plasticisers or super plasticisers can be used and it is

recommended that trial mixes are undertaken to assess their compatibility.

Antifoam

Polycure FT contains an antifoaming agent which is sufficient for most applications but

additional antifoam may be added during mixing.

For further information contact:

Fibre Technologies International Limited : +44 (0)117 9825855

Avonmouth Way Fax: +44 (0)117 9820060

Avonmouth info@fibretech.org

Bristol BS11 9YA www.fibretech.org

MEMBERS OF THE INTERNATIONAL GLASSFIBRE REINFORCED CONCRETE ASSOCIATION

Properties

Compound Type Aqueous Thermoplastic Dispersion

Polymer Type Acrylic

% Solids 50% +-1%

Free Monomer Content Max 0.2%

Appearance Milky White Liquid Free From Lumps

Odour Mild

pH 6.0 7.0 At 25c.

Minimum Film Formation Temp. 11.0c

Particle Size 110 - 210

MALVERN

Ultra Violet Resistance Good

Alkali Resistance Good

Brookfield RVT At 25c SP2/100 RPM 0.0 150.0

Freeze-Thaw Stability Store Above 5c

Specific Gravity 1.055 At 25c

Storage & Shelf Life

Six months when stored in dry warehouse conditions (5 20c)

PROTECT FROM FROST

SUPPLIED BY FIBRE TECHNOLOGIES INTERNATIONAL

For further information contact:

Fibre Technologies International Limited : +44 (0)117 9825855

Avonmouth Way Fax: +44 (0)117 9820060

Avonmouth info@fibretech.org

Bristol BS11 9YA www.fibretech.org

MEMBERS OF THE INTERNATIONAL GLASSFIBRE REINFORCED CONCRETE ASSOCIATION

Вам также может понравиться

- Polymer Additives: Product Solutions From CorbionДокумент8 страницPolymer Additives: Product Solutions From CorbionXuân Giang NguyễnОценок пока нет

- Pure Polyurea Vs HybridДокумент18 страницPure Polyurea Vs HybridTanmay Gor100% (1)

- Polyfoam B-235 PIR pipe insulationДокумент2 страницыPolyfoam B-235 PIR pipe insulationA MahmoodОценок пока нет

- Bond Polymers International BrochureДокумент9 страницBond Polymers International Brochuregabriel oliveira monteiroОценок пока нет

- Polypro VC 17Документ2 страницыPolypro VC 17hauvuОценок пока нет

- Polyurethane CoatingДокумент14 страницPolyurethane CoatingKhalil Rehman100% (3)

- Flexible Plastic Film Laminates SeminarДокумент58 страницFlexible Plastic Film Laminates SeminarEtHical EmoTionОценок пока нет

- Packaging PDFДокумент48 страницPackaging PDFDebasis Kumar SahaОценок пока нет

- Carbothane 134 HPДокумент4 страницыCarbothane 134 HPsrinath vОценок пока нет

- Polyfoam B250Документ2 страницыPolyfoam B250A MahmoodОценок пока нет

- HF4760 BL3Документ2 страницыHF4760 BL3Niraj HattangdiОценок пока нет

- Polyglass HA VE HAДокумент2 страницыPolyglass HA VE HAGautamОценок пока нет

- Acrilem ST190: Product DescriptionДокумент2 страницыAcrilem ST190: Product DescriptionMachidon OanaОценок пока нет

- Intelligent Films Applications For Daily SupplyДокумент56 страницIntelligent Films Applications For Daily SupplyHabteyes AbateОценок пока нет

- Technical Data Sheet: Anti-OxidantДокумент1 страницаTechnical Data Sheet: Anti-OxidantXuân Giang NguyễnОценок пока нет

- 22866Документ2 страницы22866Majed DawaОценок пока нет

- BindersДокумент4 страницыBindersSariyyaHeydarovaОценок пока нет

- Polyglass: 2/23 A Polyglass VEF 5th June 2007Документ3 страницыPolyglass: 2/23 A Polyglass VEF 5th June 2007Saradhi MedapureddyОценок пока нет

- Techno - Commercial Information On Plastics Industry - News On Plastics IndustryДокумент6 страницTechno - Commercial Information On Plastics Industry - News On Plastics IndustryGufran AhmadОценок пока нет

- Apcotex PT 500Документ1 страницаApcotex PT 500daniele.rosendoОценок пока нет

- Polyglass Polyglass Polyglass Polyglass: Page 1 of 2Документ2 страницыPolyglass Polyglass Polyglass Polyglass: Page 1 of 2aryopnОценок пока нет

- Phenoline 353 PDSДокумент2 страницыPhenoline 353 PDSGerson SuarezОценок пока нет

- RTC Flexible Packaging - EngДокумент25 страницRTC Flexible Packaging - EngthuylienОценок пока нет

- TDS-103 Dispersion Techniques Carbopol PolymersДокумент5 страницTDS-103 Dispersion Techniques Carbopol PolymersMostofa RubalОценок пока нет

- Ambani Organic Pvt. LTD.: Aopl Mura57Документ1 страницаAmbani Organic Pvt. LTD.: Aopl Mura57Manish Chavda AhirОценок пока нет

- Polyken 1019Документ1 страницаPolyken 1019Vijay KumarОценок пока нет

- Research On Packaging MaterialsДокумент48 страницResearch On Packaging MaterialsShahbazAliMemon100% (1)

- C100EДокумент3 страницыC100ESatrio NugrohoОценок пока нет

- Auto Care Formulations - CompressДокумент42 страницыAuto Care Formulations - CompressAnh HoangОценок пока нет

- Submittal - Bitumode Flex-P - Alternative ProposalДокумент25 страницSubmittal - Bitumode Flex-P - Alternative ProposalJason RazatlabОценок пока нет

- Tolonate™ IDT 70 B: Product Data SheetДокумент2 страницыTolonate™ IDT 70 B: Product Data SheetKay ChenОценок пока нет

- Licowax PE 520Документ2 страницыLicowax PE 520Urban Renewal DevelopmentОценок пока нет

- Curran® Granules: Your Biobased Solution For Improved Water Based CoatingsДокумент2 страницыCurran® Granules: Your Biobased Solution For Improved Water Based CoatingsWendell SanchezОценок пока нет

- PRIMAL™ HG-1000 Binder: Technical Data SheetДокумент9 страницPRIMAL™ HG-1000 Binder: Technical Data SheetLong An DoОценок пока нет

- Technical Data Sheet Flexfill TPE 90AДокумент1 страницаTechnical Data Sheet Flexfill TPE 90AAngelОценок пока нет

- Formulating Polyurea Coatings and CaulksДокумент5 страницFormulating Polyurea Coatings and CaulksAhmed TahaОценок пока нет

- Atlas Copco Roto Inject Fluid JECДокумент2 страницыAtlas Copco Roto Inject Fluid JECアラファト イスラム教Оценок пока нет

- Polyurethane Self Adhesive AДокумент5 страницPolyurethane Self Adhesive Arehmat aliОценок пока нет

- FloArm Coat EFG Ver 5Документ3 страницыFloArm Coat EFG Ver 5praveenpatel.pp7143Оценок пока нет

- Phenolic FoamДокумент20 страницPhenolic FoamkenandyouОценок пока нет

- Film Formation in Coatings - Properties, Mechanisms, and ApplicationsДокумент10 страницFilm Formation in Coatings - Properties, Mechanisms, and ApplicationsAadhi InnovativesОценок пока нет

- ข่าว1 pdf-notes flattened 201307151439Документ4 страницыข่าว1 pdf-notes flattened 201307151439khala1391@gmail.comОценок пока нет

- PVC: ChemistryДокумент55 страницPVC: ChemistryAnjumol Salim100% (2)

- Corrocoat FlexiresДокумент2 страницыCorrocoat FlexiresstelioskoОценок пока нет

- 100% Solids Polyurethane and Polyurea Coatings TechnologyДокумент10 страниц100% Solids Polyurethane and Polyurea Coatings TechnologymohsennorooziОценок пока нет

- 95-1132-01 - Formulation Dowanol PDFДокумент40 страниц95-1132-01 - Formulation Dowanol PDFNeli Arias100% (1)

- Carboguard 1340 PDSДокумент4 страницыCarboguard 1340 PDSSaefuddin OrtegaОценок пока нет

- Tds Uniqflow 372s enДокумент1 страницаTds Uniqflow 372s enm daneshpourОценок пока нет

- Tds Uniqflow 372s enДокумент1 страницаTds Uniqflow 372s enm daneshpourОценок пока нет

- General Properties Rheological Properties: PVC Paste Resin (Homopolymer)Документ2 страницыGeneral Properties Rheological Properties: PVC Paste Resin (Homopolymer)AminulIslamОценок пока нет

- Technical Data Sheet Chemitac 11: DescriptionДокумент3 страницыTechnical Data Sheet Chemitac 11: DescriptionPhuong The NguyenОценок пока нет

- Piopoxy AF Tie Coat - TDSДокумент2 страницыPiopoxy AF Tie Coat - TDSIsabelo AbaoОценок пока нет

- Polycon Water Tanks for Every Home & ConditionДокумент32 страницыPolycon Water Tanks for Every Home & ConditionMohamd LabeabОценок пока нет

- Ceilcote 242mr FlakelineДокумент3 страницыCeilcote 242mr FlakelineBoris CardenasОценок пока нет

- Silicone Technical TextilesДокумент39 страницSilicone Technical TextilesRahul Oza100% (4)

- Richards PDFДокумент26 страницRichards PDFsurendraОценок пока нет

- Loctite Liofol BC 1580-EnДокумент3 страницыLoctite Liofol BC 1580-EnCharly DtОценок пока нет

- Polymers-Prep, Props, UsesДокумент7 страницPolymers-Prep, Props, UsesHarshal A ShahОценок пока нет

- Specialty Acrylics Various TDS FormulationsДокумент2 страницыSpecialty Acrylics Various TDS Formulationsfranchise.adajanОценок пока нет

- Program Liga 3 2017-2018 PDFДокумент1 страницаProgram Liga 3 2017-2018 PDFMarius IanaОценок пока нет

- Program Liga 3 2017-2018 PDFДокумент1 страницаProgram Liga 3 2017-2018 PDFMarius IanaОценок пока нет

- Eta 08 - 0379Документ15 страницEta 08 - 0379YYOUNOS_MAОценок пока нет

- Ctr. Rcs Rds Arcadia ENG PDFДокумент7 страницCtr. Rcs Rds Arcadia ENG PDFMarius IanaОценок пока нет

- Program Liga 3 2017-2018Документ1 страницаProgram Liga 3 2017-2018Marius IanaОценок пока нет

- MS Project Tutorial for Software Project ManagementДокумент36 страницMS Project Tutorial for Software Project ManagementBilal Ahmed Barbhuiya100% (3)

- Guide ENДокумент294 страницыGuide ENMarius IanaОценок пока нет

- Datex-Ohmeda Tec7 - Service ManualДокумент48 страницDatex-Ohmeda Tec7 - Service ManualCarlos Alberto SacsaОценок пока нет

- Maurice Nicoll The Mark PDFДокумент4 страницыMaurice Nicoll The Mark PDFErwin KroonОценок пока нет

- Decorative Concrete Overlays Offer Growth OpportunitiesДокумент23 страницыDecorative Concrete Overlays Offer Growth OpportunitiesMarius IanaОценок пока нет

- Start 0.00 Lei Plan 0.00 Lei Design 0.00 Lei Build 400.00 Lei Test 0.00 Lei Install 0.00 Lei Handover 0.00 Lei Finish 0.00 LeiДокумент1 страницаStart 0.00 Lei Plan 0.00 Lei Design 0.00 Lei Build 400.00 Lei Test 0.00 Lei Install 0.00 Lei Handover 0.00 Lei Finish 0.00 LeiMarius IanaОценок пока нет

- Scanned Image 31Документ9 страницScanned Image 31Marius IanaОценок пока нет

- Autocad 2015 What Is New Guide PDFДокумент47 страницAutocad 2015 What Is New Guide PDFLuis Carlos Ayllón EscobarОценок пока нет

- Ps10000a GRC Spray Station For GRCДокумент2 страницыPs10000a GRC Spray Station For GRCMarius IanaОценок пока нет

- MTS Masina Universala ElectromecanicaДокумент20 страницMTS Masina Universala ElectromecanicaMarius IanaОценок пока нет

- MTS Masina Universala ElectromecanicaДокумент20 страницMTS Masina Universala ElectromecanicaMarius IanaОценок пока нет

- T 10A T10MAIlluminanceMeters ManualДокумент60 страницT 10A T10MAIlluminanceMeters ManualMarius IanaОценок пока нет

- Brosura Foundry Master XlineДокумент2 страницыBrosura Foundry Master XlineMarius IanaОценок пока нет

- X-Strata920 Brochure 2014Документ4 страницыX-Strata920 Brochure 2014Marius IanaОценок пока нет

- Series: Illuminance MeterДокумент6 страницSeries: Illuminance MeterMarius IanaОценок пока нет

- XRF IntroducereДокумент53 страницыXRF IntroducereMihaela VecaОценок пока нет

- Safety Data Sheet SectionsДокумент8 страницSafety Data Sheet SectionsMarius IanaОценок пока нет

- Harta BucurestiДокумент1 страницаHarta BucurestialberttimoteiОценок пока нет

- MTS Criterion Universal Test SystemsДокумент24 страницыMTS Criterion Universal Test SystemsMarius IanaОценок пока нет

- WindTurbineFactbook SinglePagesДокумент49 страницWindTurbineFactbook SinglePagesMarius IanaОценок пока нет

- Citologia ConvencionalДокумент10 страницCitologia ConvencionalMarius IanaОценок пока нет

- Exemple Tehnica CombinataДокумент1 страницаExemple Tehnica CombinataMarius IanaОценок пока нет

- CEMENT RESEARCH: Changes in Hydration of Cement Components and AdmixturesДокумент17 страницCEMENT RESEARCH: Changes in Hydration of Cement Components and AdmixturesNam HuynhОценок пока нет

- Guide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodsДокумент24 страницыGuide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodsPushkar NathОценок пока нет

- Concrete - Complementary British Standard To BS EN 206: BSI Standards PublicationДокумент7 страницConcrete - Complementary British Standard To BS EN 206: BSI Standards Publicationاسماعيل جودةОценок пока нет

- An Investigation Into The Effect of Rice Husk ASh On Mortar When Added in Varying Proportions - Andrew WoodДокумент73 страницыAn Investigation Into The Effect of Rice Husk ASh On Mortar When Added in Varying Proportions - Andrew WoodNarayan Singhania100% (1)

- General FormulaДокумент26 страницGeneral FormulaHabtamu HaileОценок пока нет

- Cement Plants Cogeneration SD2002Документ10 страницCement Plants Cogeneration SD2002Leonidas VeraОценок пока нет

- Civil Works Rate List 2021Документ407 страницCivil Works Rate List 2021Akshay VachhaniОценок пока нет

- DOW DLP BrochureДокумент32 страницыDOW DLP BrochureJose MarckwordtОценок пока нет

- PT Semen Indonesia Procedures ListingДокумент284 страницыPT Semen Indonesia Procedures ListingHery KurniawanОценок пока нет

- TCC StructuralConcreteBrief 2023Документ12 страницTCC StructuralConcreteBrief 2023Amro Akram MetwallyОценок пока нет

- Boscoflex: Flexible Cementitious Waterprofing MembraneДокумент2 страницыBoscoflex: Flexible Cementitious Waterprofing MembraneCLENTH FLORentinoОценок пока нет

- Maple Leaf Cement FactoryДокумент290 страницMaple Leaf Cement FactorySarfraz AliОценок пока нет

- High-Performance Cement Matrices Based On Calcium Sulfoaluminate-Belite CompositionsДокумент6 страницHigh-Performance Cement Matrices Based On Calcium Sulfoaluminate-Belite CompositionsraviОценок пока нет

- International Journal of Chemtech Research: P Abhilash, C.Sashidhar, I.V.Ramana ReddyДокумент8 страницInternational Journal of Chemtech Research: P Abhilash, C.Sashidhar, I.V.Ramana Reddyknight1729Оценок пока нет

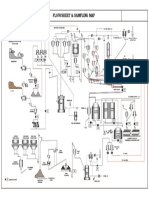

- Flow sheet & sampling map cement plant processesДокумент1 страницаFlow sheet & sampling map cement plant processesOkta RiaОценок пока нет

- P.R. Cements LTD Fixed Assets ManagementДокумент71 страницаP.R. Cements LTD Fixed Assets ManagementPochender vajrojОценок пока нет

- Concept Paper: ENG-FO-032Документ3 страницыConcept Paper: ENG-FO-032mnmusorОценок пока нет

- Utilization of Coconut Shell As Greener ConcreteДокумент9 страницUtilization of Coconut Shell As Greener ConcreteIJRASETPublicationsОценок пока нет

- Issb - CollectedДокумент19 страницIssb - CollectedBrhane Gadiyon100% (1)

- Building Assets Internship ReportДокумент38 страницBuilding Assets Internship ReportNIL. NIL.Оценок пока нет

- Material ListДокумент36 страницMaterial ListSachin PawarОценок пока нет

- Masonry and Concrete: Reporter: Delos Santos, Roxette April AДокумент54 страницыMasonry and Concrete: Reporter: Delos Santos, Roxette April ARoxette AprylleОценок пока нет

- 14 Building Materials used in constructionДокумент10 страниц14 Building Materials used in constructionM ShahidОценок пока нет

- Autoclaved Aerated Concrete (AAC) Blocks Project - Brief ReportДокумент12 страницAutoclaved Aerated Concrete (AAC) Blocks Project - Brief ReportVishal Kansagra77% (31)

- Al Helal 2014Документ6 страницAl Helal 2014Julian OngОценок пока нет

- UltraTech 43 Cement Test CertificateДокумент1 страницаUltraTech 43 Cement Test CertificatelavekushОценок пока нет

- Materials Engineering Directorate Cement and Products Pre-Qualification ListДокумент5 страницMaterials Engineering Directorate Cement and Products Pre-Qualification ListshajbabyОценок пока нет

- Undergraduate Civil Engineering Thesis TopicsДокумент4 страницыUndergraduate Civil Engineering Thesis TopicsKi KiethОценок пока нет

- Asbestos Cement Pipe Condition Assessment and Remaining Service LДокумент119 страницAsbestos Cement Pipe Condition Assessment and Remaining Service LEnrique BonetОценок пока нет

- Auramix 400: Advanced Low Viscosity High Performance Superplasticiser, Based On Polycarboxylic TechnologyДокумент2 страницыAuramix 400: Advanced Low Viscosity High Performance Superplasticiser, Based On Polycarboxylic TechnologyABHI MITRAОценок пока нет