Академический Документы

Профессиональный Документы

Культура Документы

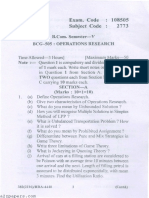

157 37325 EA221 2013 4 2 1 Assignment Practice Problems

Загружено:

MaherKОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

157 37325 EA221 2013 4 2 1 Assignment Practice Problems

Загружено:

MaherKАвторское право:

Доступные форматы

Assignment Practice Problems

Problem No. 1: Refer to the assignment problem on page 63 and solve it (Note: it is a

max problem).

Problem No. 2: Refer to the assignment problem (Sheet No. 2 problem No. 3) and solve

it.

Problem No. 3: Consider the following data of assigning jobs to machines:

Machine A Machine B Machine C Machine D

Job 1 12 16 14 10

Job 2 9 8 13 7

Job 3 15 12 9 11

a. Formulate the mathematical model for the assignment problem

b. Solve the problem using the Hungarian Method to find the minimum cost of

assignment.

Problem 4: Five employees are available to perform four jobs. The time it takes each

person to perform each job is given in the following table.

Time (hours)

Job 1 Job 2 Job 3 Job 4

Person 1 22 18 30 18

Person 2 18 --- 27 22

Person 3 26 20 28 28

Person 4 16 22 ---- 14

Person 5 21 --- 25 28

Note: dashes indicate person cannot do that particular job.

a. Formulate the mathematical model for the assignment problem

b. Determine the assignment of employees to jobs that minimizes the total time

required to perform the four jobs.

Transshipment Practice Problems

Problem No 1: (Solved in the Lecture)

Widgetco manufactures widgets at two factories, one in Memphis and one in Denver. The

Memphis factory can produce up to 150 widgets per day, and the Denver factory can

produce up to 200 widgets per day. Widgets are shipped by air to customers in Los

Angeles and Boston. The customers in each city require 130 widgets per day. Because of

the deregulation of air fares, Widgetco believes that it may be cheaper to first fly some

widgets to New York or Chicago and then fly them to their final destination. The costs of

flying a widget are shown the below table Widgetco wants to minimize the total cost of

shipping the required widgets to its customers.

Problem No. 1 (continued)

To

From Memphi Denver N.Y. Chicago L.A. Boston

s

Memphis $0 --- $8 $13 $25 $28

Denver --- $0 $15 $12 $26 $25

N.Y. --- --- $0 $6 $16 $17

Chicago --- --- $6 $0 $14 $16

L.A. --- --- --- --- $0 ---

Boston --- --- --- --- --- $0

Note: dashes indicate shipments are not allowed

Problem No 2: Sunco Oil produces oil at two wells. Well 1 can produce up to 160,000

barrels per day, and well 2 can produce up to 140,000 barrels per day. It is possible to

ship oil directly from wells to Sunco's customers in Los Angeles and New York.

Alternatively, Sunco could transport oil to the ports of Mobile and Galveston and then

ship it by tanker to New York or Los Angeles. The capacity of Galveston is 150,000

barrels per day and Mobile has a capacity of 180,000 barrels per day. Los Angeles require

requires 150,000 barrels per day and New York 200,000 barrels per day. The costs of

shipping 1000 barrels between two points are shown in the following table. Solve the

problem to minimize the transportation costs. (use northwest corner, max 2 tableaus)

To

From Well 1 Well 2 Mobile Galveston N.Y. L.A.

Well 1 $0 --- $10 $13 $25 $28

Well 2 --- $0 $15 $12 $26 $25

Mobile --- --- $0 $6 $16 $17

Galveston --- --- $6 $0 $14 $16

N.Y. --- --- --- --- $0 ---

L.A. --- --- --- --- $15 $0

Note: dashes indicate shipments are not allowed

Problem No 3: Prepare the initial transportation tableau using the Northwest corner

200 250

Borg Sadat Port

Elarab City Said

6th of

Oct.

100 125

Amrey Ismalya

a 10th of

Ramadan

Вам также может понравиться

- Arabic PhrasesДокумент15 страницArabic PhrasesFaridOrahaОценок пока нет

- B767 Electrical SystemsДокумент11 страницB767 Electrical SystemsRC Agulay100% (1)

- Box Culvert Limit StateДокумент52 страницыBox Culvert Limit StateMahadev Sastry88% (8)

- Xt600e 3tb-3uw 90-95Документ46 страницXt600e 3tb-3uw 90-95Kenneth SynnesОценок пока нет

- Container CargoДокумент20 страницContainer Cargoajantha31100% (1)

- Final Sol 4O03 16Документ4 страницыFinal Sol 4O03 16MaherKОценок пока нет

- Twi Industries VSMДокумент12 страницTwi Industries VSMChe CruzОценок пока нет

- hsg94 PDFДокумент40 страницhsg94 PDFbtjajadiОценок пока нет

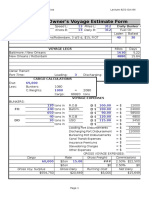

- Owner's Voyage Estimate Form: Daily Bunker ConsumptionДокумент2 страницыOwner's Voyage Estimate Form: Daily Bunker ConsumptionJuan Ramón FuentesОценок пока нет

- A Highly Unlikely Bicycle Tourist - Stephen PeelДокумент24 страницыA Highly Unlikely Bicycle Tourist - Stephen PeelStephen PeelОценок пока нет

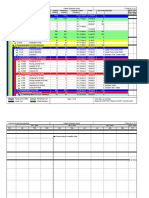

- Equipment Plan & BGT Calculation: Base Calculation Planned Calculation PC 200 PC 300 PC 300Документ13 страницEquipment Plan & BGT Calculation: Base Calculation Planned Calculation PC 200 PC 300 PC 300Iwan DermawanОценок пока нет

- Practice 1 SolutionsДокумент2 страницыPractice 1 SolutionsLin Lin Kanokkorn67% (3)

- New Supervisor Skills For SuccessДокумент26 страницNew Supervisor Skills For SuccessMaherKОценок пока нет

- Question Book 2Документ24 страницыQuestion Book 2Daniel Butler100% (2)

- AIR LAW Study Guide: Part 1 - DefinitionsДокумент90 страницAIR LAW Study Guide: Part 1 - DefinitionsGirish SreeneebusОценок пока нет

- Use of Foamed Concrete in Construction: Ravindra K. DhirДокумент12 страницUse of Foamed Concrete in Construction: Ravindra K. DhirzaswanthОценок пока нет

- History of The Serene Republic: Venetian Wing Lion On The Pediment of The St. Mark Basilica, VeniceДокумент28 страницHistory of The Serene Republic: Venetian Wing Lion On The Pediment of The St. Mark Basilica, VeniceEric LefrançaisОценок пока нет

- Transshipme NT Method: Prepared By: Justine Louisse R. AgpalasinДокумент27 страницTransshipme NT Method: Prepared By: Justine Louisse R. AgpalasinDon ValleОценок пока нет

- P403 5webДокумент2 страницыP403 5webAna Gabriela Rivero CerrutoОценок пока нет

- Exercises On Integer Programming FormulationsДокумент4 страницыExercises On Integer Programming FormulationsRajvardhan KaviОценок пока нет

- Lesson Topics: B.1 Transportation Review QuestionsДокумент7 страницLesson Topics: B.1 Transportation Review QuestionsJeannette VillenaОценок пока нет

- Assignment - 3 - TPДокумент3 страницыAssignment - 3 - TPsohilamohsen46Оценок пока нет

- INDE2001 StudyQuestions6Документ2 страницыINDE2001 StudyQuestions6Hakkı Anıl AksoyОценок пока нет

- Meng4440 HW3Документ3 страницыMeng4440 HW3AbdelRahman BahieldinОценок пока нет

- Presentation By:-Shubham Gupta Sumit Malik Vishal GohanДокумент41 страницаPresentation By:-Shubham Gupta Sumit Malik Vishal GohanKamal KumarОценок пока нет

- Redbrand Shipping Model Unit Shipping Costs To From Range Names UsedДокумент1 страницаRedbrand Shipping Model Unit Shipping Costs To From Range Names UsedJuan Carlos CabreraОценок пока нет

- S Eventh Semester B.E. Degree Examination, December 201 : Operations ResearchДокумент7 страницS Eventh Semester B.E. Degree Examination, December 201 : Operations ResearchBhimappa YadahalliОценок пока нет

- Distribution Network Models and Case StudyДокумент9 страницDistribution Network Models and Case Studyyellow fishОценок пока нет

- Tutorial 3: Assignment Combinatorial OptimizationДокумент7 страницTutorial 3: Assignment Combinatorial OptimizationMarco Polo Elizais CastilloОценок пока нет

- Solution To IFRS 3rd EditionДокумент11 страницSolution To IFRS 3rd Editionalexander kwabena amoakoОценок пока нет

- hw#2Документ6 страницhw#2Omoyemi Oluwaseyi FrancisОценок пока нет

- Group Assignment #9: Balanced Transportation ProblemДокумент5 страницGroup Assignment #9: Balanced Transportation ProblemKarl Simone EsmillaОценок пока нет

- hw06p0383n02 JMKДокумент4 страницыhw06p0383n02 JMKFranciscoОценок пока нет

- Problem Set 3Документ3 страницыProblem Set 3avinashk1Оценок пока нет

- Transportation and AssignmentДокумент20 страницTransportation and Assignmentbinzidd007Оценок пока нет

- "Case Study On Distribution System Design " (Darby Company)Документ29 страниц"Case Study On Distribution System Design " (Darby Company)Anchit AgrawalОценок пока нет

- Ias 36 - Impairment of Assets Case Studies 1 - 2: C K 03 M C) 'RZB) V D - W RCCVDC RCV KdeuzvcДокумент3 страницыIas 36 - Impairment of Assets Case Studies 1 - 2: C K 03 M C) 'RZB) V D - W RCCVDC RCV KdeuzvcHernan EleОценок пока нет

- ECON2001 - 1G 22-23 Group Quiz QuestionsДокумент11 страницECON2001 - 1G 22-23 Group Quiz QuestionskeithОценок пока нет

- Plant Maximum Capacity (Tons) Cost Per Ton: Case 1Документ4 страницыPlant Maximum Capacity (Tons) Cost Per Ton: Case 1HEM BANSALОценок пока нет

- TUT 3 SolutionДокумент33 страницыTUT 3 SolutionP o o P o o H e a dОценок пока нет

- Answer All QuestionsДокумент3 страницыAnswer All QuestionsDisha KothariОценок пока нет

- QA Assignment 02-15A - 14BДокумент3 страницыQA Assignment 02-15A - 14BZinegnaw MekonnenОценок пока нет

- Cal SheetДокумент14 страницCal SheetMohamed KhedrОценок пока нет

- Ieor 3Документ2 страницыIeor 3Clash GodОценок пока нет

- Staad Pro ReportДокумент33 страницыStaad Pro ReportAbdul khaliquОценок пока нет

- Structural Design Calculations AtriumДокумент31 страницаStructural Design Calculations AtriumBadr AmmarОценок пока нет

- QABD Assignment Selected ModifiedДокумент6 страницQABD Assignment Selected Modifiedhbtmynsat88Оценок пока нет

- END 395 Lecture 5 HandoutДокумент5 страницEND 395 Lecture 5 HandoutFerda ÇetikОценок пока нет

- CHP 10Документ32 страницыCHP 10Camila Martins SaporettiОценок пока нет

- ECON306: Class Test 1, 16 March 2009 Solution Guide: Cultural AffinityДокумент6 страницECON306: Class Test 1, 16 March 2009 Solution Guide: Cultural AffinitySandile DayiОценок пока нет

- 3850 - Mathematics - Stage - 3 - Question - Paper - Sample 3Документ19 страниц3850 - Mathematics - Stage - 3 - Question - Paper - Sample 3ShellyОценок пока нет

- Ap 3 Merge 3-1234Документ4 страницыAp 3 Merge 3-1234api-295670758Оценок пока нет

- Operations Research For Management-25.04.2017-III PDFДокумент4 страницыOperations Research For Management-25.04.2017-III PDFShivam KapoorОценок пока нет

- SC2KCHT2Документ1 страницаSC2KCHT2reyzahasanudinОценок пока нет

- University of Engineering and Technology: Subject:Erts Submitted byДокумент11 страницUniversity of Engineering and Technology: Subject:Erts Submitted byprvzОценок пока нет

- Problem Set #3 Submit Via Gradescope by Tuesday October 13, 10:00pmДокумент4 страницыProblem Set #3 Submit Via Gradescope by Tuesday October 13, 10:00pmAskIIT IanОценок пока нет

- hw#2 PDFДокумент5 страницhw#2 PDFEkta VaswaniОценок пока нет

- Building Transportation at Over 10,000 Feet:: Narrow Gauge Railroads in The San Juan Mountains of ColoradoДокумент13 страницBuilding Transportation at Over 10,000 Feet:: Narrow Gauge Railroads in The San Juan Mountains of ColoradoMalvareen SohtunОценок пока нет

- Model QPДокумент3 страницыModel QPKarthik Kudroli JKSHIMОценок пока нет

- Bba 2002 NewДокумент21 страницаBba 2002 NewyonghuiОценок пока нет

- Practice Set Transportation ModelsДокумент15 страницPractice Set Transportation ModelsSarah DeviОценок пока нет

- ECON 1102-Paper-F20Документ3 страницыECON 1102-Paper-F20Shah ZeeshanОценок пока нет

- Equipment Plan & BGT Calculation: Base Calculation Planned Calculation PC 200 PC 300 PC 300Документ13 страницEquipment Plan & BGT Calculation: Base Calculation Planned Calculation PC 200 PC 300 PC 300Iwan DermawanОценок пока нет

- Worksheet One For Agricultural Economics III Year StudentsДокумент14 страницWorksheet One For Agricultural Economics III Year StudentsasnaketemuyeОценок пока нет

- Practice Testexam 1 Fall 2014Документ11 страницPractice Testexam 1 Fall 2014Bear CooporОценок пока нет

- BCG-5: S A CH - V: 05 Operation Rese RДокумент4 страницыBCG-5: S A CH - V: 05 Operation Rese RGeeta GuptaОценок пока нет

- EMV and EOL ExercisesДокумент3 страницыEMV and EOL Exercisesbianx villaОценок пока нет

- DurationДокумент28 страницDurationMohammed redaОценок пока нет

- Christmas Fun!, Grades 1 - 3: Activities to Prepare Children’s Hearts for ChristmasОт EverandChristmas Fun!, Grades 1 - 3: Activities to Prepare Children’s Hearts for ChristmasОценок пока нет

- Djatoka InstallationДокумент3 страницыDjatoka InstallationMaherKОценок пока нет

- QueueingДокумент1 страницаQueueingMaherKОценок пока нет

- Book 1Документ1 страницаBook 1MaherKОценок пока нет

- Mean 55 165 STD 30 51.9615 20 Deep/facing L 2 281.4667 14.07334 15 0.801441 3.868206 0.1986 Expected Sales 161.1318 Expcted Leftover 58.86821Документ1 страницаMean 55 165 STD 30 51.9615 20 Deep/facing L 2 281.4667 14.07334 15 0.801441 3.868206 0.1986 Expected Sales 161.1318 Expcted Leftover 58.86821MaherKОценок пока нет

- ABC Analysis - DataДокумент1 страницаABC Analysis - DataMaherKОценок пока нет

- Crew Scheduling Model Flight InformationДокумент4 страницыCrew Scheduling Model Flight InformationMaherKОценок пока нет

- TempДокумент1 страницаTempMaherKОценок пока нет

- Rent CarДокумент2 страницыRent CarMaherKОценок пока нет

- Shortest Path Model Network Structure and Flows Flow Balance ConstraintsДокумент1 страницаShortest Path Model Network Structure and Flows Flow Balance ConstraintsMaherKОценок пока нет

- Project Planning and ManagementДокумент26 страницProject Planning and ManagementMaherKОценок пока нет

- Workdesign Jobanalysis ManagersДокумент12 страницWorkdesign Jobanalysis ManagersMaherKОценок пока нет

- DSpace Installation GuideДокумент5 страницDSpace Installation GuideMaherKОценок пока нет

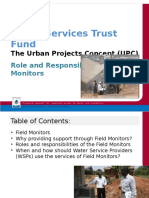

- Roles & Responsibilities of FMsДокумент11 страницRoles & Responsibilities of FMsMaherKОценок пока нет

- Tools For Estimating VMT Reductions From Built Environment ChangesДокумент36 страницTools For Estimating VMT Reductions From Built Environment ChangeskahtanОценок пока нет

- Ready Mix ConcreteДокумент15 страницReady Mix ConcreteSharukh KhanОценок пока нет

- PR Sava Intensa Uhp 26102009 English F Upd Tcm2382-72613Документ3 страницыPR Sava Intensa Uhp 26102009 English F Upd Tcm2382-72613mac1677Оценок пока нет

- D4.1 Hynds Manhole SystemДокумент8 страницD4.1 Hynds Manhole SystemSam LeungОценок пока нет

- International LawДокумент4 страницыInternational Lawaa teohОценок пока нет

- Shipyard Practices: By-Cadet - Aditya Prasad SarangiДокумент71 страницаShipyard Practices: By-Cadet - Aditya Prasad SarangiDINESH YADAVОценок пока нет

- Slips Trips Falls Mod 1Документ27 страницSlips Trips Falls Mod 1feroz khanОценок пока нет

- 6B Advanced Gas Path (AGP) : Output, Efficiency, and Availability SolutionДокумент1 страница6B Advanced Gas Path (AGP) : Output, Efficiency, and Availability SolutionMahesh MishraОценок пока нет

- Baggage Claims and Proration: Classroom and In-Company Course (3 Days/24 Hours)Документ2 страницыBaggage Claims and Proration: Classroom and In-Company Course (3 Days/24 Hours)mohammad hossein mosshafiОценок пока нет

- Case Study ThirteenДокумент6 страницCase Study ThirteenDiljot SinghОценок пока нет

- StockДокумент38 страницStockdalemanukОценок пока нет

- Gta Vice City CheatbookДокумент73 страницыGta Vice City CheatbookDolly Panchal100% (3)

- Pricelist LuzonДокумент7 страницPricelist LuzonKattie ValerioОценок пока нет

- Fire Safety Nomes of Greater NoidaДокумент11 страницFire Safety Nomes of Greater NoidaRajput AnshulОценок пока нет

- CODE3013 Course Outline 2021Документ13 страницCODE3013 Course Outline 2021Grier KershawОценок пока нет

- Traffic Volume Study: Jalan Permatang PauhДокумент5 страницTraffic Volume Study: Jalan Permatang PauhEmir Harith100% (1)

- Q 117R2Документ2 страницыQ 117R22791957Оценок пока нет

- HLMT Panel Hospital ListingДокумент4 страницыHLMT Panel Hospital ListingAiriz IsmailОценок пока нет

- Minutes MGNREGAДокумент3 страницыMinutes MGNREGASaurav KumarОценок пока нет