Академический Документы

Профессиональный Документы

Культура Документы

CEMBRE LUG 90deg Cable Lug - AKBAR TRADING EST - SAUDI ARABIA

Загружено:

GIBUОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CEMBRE LUG 90deg Cable Lug - AKBAR TRADING EST - SAUDI ARABIA

Загружено:

GIBUАвторское право:

Доступные форматы

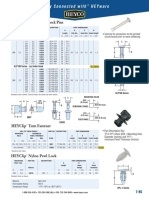

COPPER TUBE CRIMPING LUGS ANGLED 90

for copper conductors A-L

File no. E125401

Cond. Size Dimensions mm

sqmm Stud Ref. Quantity Mechanical Hydraulic

Box/Bag Tools Tools

low

stranded flexible*

mm

i B M N A d A-L series lugs angled 90

6 6 A 1-L 6 3,6 11,0 7,0 6,0 9,5 6,4 2.000/100 are manufactured from

5 A 2-L 5 4,6 10,0 6,5 6,0 10,5 5,3 1.500/100 electrolytic copper tube.

HN1

10 6 A 2-L 6 4,6 11,0 7,0 6,0 10,5 6,4 1.500/100 The dimensions of the tube

8 A 2-L 8 4,6 15,0 9,0 8,0 10,5 8,4 500/100 are designed to obtain the

B 15D

HN5

5 A 3-L 5 5,8 11,5 6,5 6,0 12,0 5,3 1.000/100 most efficient electrical

HN-A25

6 A 3-L 6 5,8 11,5 7,0 6,0 12,0 6,4 1.000/100 conductivity and mechani-

16

8 A 3-L 8 5,8 15,0 9,0 8,0 12,0 8,4 1.000/100 cal strength to resist vibra-

10 A 3-L 10 5,8 18,0 11,0 10,0 12,0 10,5 500/100 tion and pull out.

6 A 5-L 6 7,0 14,0 7,0 6,0 13,0 6,4 500/100

Cembre lugs are annealed

25 8 A 5-L 8 7,0 15,0 9,0 8,0 13,0 8,4 500/100

to guarantee optimum duc-

10 A 5-L 10 7,0 18,0 11,0 10,0 13,0 10,5 500/100

TN 70 SE

tility which is an absolute

6 A 7-L 6 8,9 17,0 7.0 6,0 15,5 6,4 500/100

HT 120 and tools and heads with 130 kN crimping force

25 8 A 7-L 8 8,9 17,0 9,0 8,0 15,5 8,4 300/100

necessity for connectors

35 which will have to withstand

35 10 A 7-L 10 8,9 19,0 11,0 10,0 15,5 10,5 400/100

HT 51 RH 50 B 51 B 55

B 35-45D the severe deformation

TN 120 SE**

B 35-500

HT 45-E

12 A 7-L 12 8,9 21,0 14,0 12,0 15,5 13,2 300/100

arising when compressed

HT 81-U RHU 81

6 A 10-L 6 10,0 19,0 8,0 7,0 18,5 6,4 300/100

35 8 A 10-L 8 10,0 19,0 9,0 8,0 18,5 8,4 300/100 and any bending of the palm

50 during installation.

50 10 A 10-L 10 10,0 20,0 11,5 9,5 18,5 10,5 200/50

ECW-H3D

RHU 520

12 A 10-L 12 10,0 21,0 12,0 12,0 18,5 13,2 200/50 In applications subject to vi-

8 A 14-L 8 11,3 21,0 9,0 8,0 20,0 8,4 200/50 bration, terminals still have

70

50 10 A 14-L 10 11,3 21,0 11,0 10,0 20,0 10,5 200/50 to perform a reliable con-

70 12 A 14-L 12 11,3 22,0 14,0 12,0 20,0 13,2 150/50 nection, annealing plays a

16 A 14-L 16 11,3 26,0 18,0 16,0 20,0 17,0 150/50 vital role in avoiding crack-

8 A 19-L 8 13,5 25,0 9,0 8,0 24,5 8,4 100/25 ing or breaks between the

70

95 10 A 19-L 10 13,5 25,0 11,0 10,0 24,5 10,5 100/25 barrel and palm.

95

12 A 19-L 12 13,5 25,0 14,0 12,0 24,5 13,2 100/25 The presence of an inspec-

95 10 A 24-L 10 15,2 28,5 11,0 10,0 25,5 10,5 50/25

120 tion hole facilitates full inser-

120 12 A 24-L 12 15,2 28,5 14,1 12,0 25,5 13,2 50/25

tion of the conductor, whilst

120 10 A 30-L 10 16,7 31,5 13,0 11,0 28,5 10,5 50/25

150 the barrel length has been

150 12 A 30-L 12 16,7 31,5 16,0 14,0 28,5 13,2 50/25

150 10 A 37-L 10 19,2 31,5 13,0 11,0 31,5 10,5 50/25

designed to allow easy and

185 accurate positioning of the

185 12 A 37-L 12 19,2 31,5 16,0 14,0 31,5 13,2 50/25

185

dies during the crimping op-

240 12 A 48-L 12 21,1 39,0 16,0 14,0 33,0 13,2 30/15 eration.

240

Lugs are electrolytically tin-

240

300 12 A 60-L 12 23,7 39,0 20,0 14,0 42,0 13,2 20/10 plated to avoid oxidation.

300

Details of the appropriate

*Actual conductor section may require a larger lug eg for 120mm2 size use A30-... lug. crimping tools and dies

**See page 105 are shown on pages 186

to 187.

25

Вам также может понравиться

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Homac T&B Multi-LugsДокумент3 страницыHomac T&B Multi-LugsallfloridaОценок пока нет

- Schedule No.: Bill of Materials With Pipe Cut LengthsДокумент3 страницыSchedule No.: Bill of Materials With Pipe Cut LengthsIndra HarapanОценок пока нет

- Model 2400-L: Lug WaferДокумент1 страницаModel 2400-L: Lug WaferNicolás FriasОценок пока нет

- Export Price Lists For All HTT Hydraulic Component RangeДокумент68 страницExport Price Lists For All HTT Hydraulic Component RangeHuseyin TASKIN100% (2)

- 2A3 M8 Cembre 16sqmm 11kV 33kV Cable Lug M8 HoleДокумент1 страница2A3 M8 Cembre 16sqmm 11kV 33kV Cable Lug M8 HoleJalal AlbadriОценок пока нет

- ASME Material SpectДокумент46 страницASME Material SpectPankajDhobleОценок пока нет

- PS Eba 280Документ2 страницыPS Eba 280andi takwaОценок пока нет

- Series Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionДокумент2 страницыSeries Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionLuisPortorelliZambranoОценок пока нет

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down Vents - Drains (T 120°C)Документ1 страницаService: Non Corrosive Hydrocarbons - Glycol - Blow Down Vents - Drains (T 120°C)AliZenatiОценок пока нет

- Er-63 1Документ3 страницыEr-63 1Dibyendu ChakrabortyОценок пока нет

- 2A-M 2A-M: Heavy Duty Copper Tube TerminalsДокумент1 страница2A-M 2A-M: Heavy Duty Copper Tube TerminalsJaks JaksОценок пока нет

- Air 03Документ1 страницаAir 03Praveen SubramanianОценок пока нет

- Joint For Side Folding PDFДокумент2 страницыJoint For Side Folding PDFRamy ChaayaОценок пока нет

- Astm A320Документ1 страницаAstm A320huicholeОценок пока нет

- BOQ For Cacl2 and New Tank240Документ2 страницыBOQ For Cacl2 and New Tank240kasvikrajОценок пока нет

- Douglas Chero Catalogue Valve 6-2003Документ89 страницDouglas Chero Catalogue Valve 6-2003Yurizki LhzОценок пока нет

- F15-F30 Model Number Selection GuideДокумент15 страницF15-F30 Model Number Selection GuideHina ImranОценок пока нет

- Series 2700 Maintenance ManualДокумент12 страницSeries 2700 Maintenance ManualLuciusОценок пока нет

- API 602 Forged Steel Valves - Catalog (R1)Документ50 страницAPI 602 Forged Steel Valves - Catalog (R1)Jose Angel GonzalezОценок пока нет

- Upgrading of Existing Fuel Storage and New Truck Loading Facilities Piping Material SpecificationДокумент5 страницUpgrading of Existing Fuel Storage and New Truck Loading Facilities Piping Material SpecificationvinodОценок пока нет

- CVS ValvulasДокумент20 страницCVS ValvulasDaniel AcostaОценок пока нет

- Pulse Emitting Water Meters 2Документ2 страницыPulse Emitting Water Meters 2Omar SaaedОценок пока нет

- Series 20 Knife Gate Valve: Product DescriptionДокумент2 страницыSeries 20 Knife Gate Valve: Product DescriptionDhananjay BhaldandОценок пока нет

- Bomba Sumergible DX PDFДокумент2 страницыBomba Sumergible DX PDFJuan Carlos Gonzales PreiraОценок пока нет

- Rocore Shell Tube Catalog PDFДокумент8 страницRocore Shell Tube Catalog PDFOBUS1976Оценок пока нет

- Heyclip Nylon Snap Lock Pins: "Stay Connected With" HeywareДокумент1 страницаHeyclip Nylon Snap Lock Pins: "Stay Connected With" HeywareBaihaki StОценок пока нет

- Pipe Line and MRO Surplus InventoryДокумент42 страницыPipe Line and MRO Surplus InventoryHANIF AKBARОценок пока нет

- Data Sheet: HCPL-0370, HCPL-3700, HCPL-3760Документ14 страницData Sheet: HCPL-0370, HCPL-3700, HCPL-3760Adnan RafiqueОценок пока нет

- ROOFTOP - TEMPBLUE - 20210210 - Opt - Ficha TécnicaДокумент4 страницыROOFTOP - TEMPBLUE - 20210210 - Opt - Ficha TécnicaPablo Andres Espin MartinОценок пока нет

- Machinists Tools by Williams 1944Документ32 страницыMachinists Tools by Williams 1944OSEAS GOMEZОценок пока нет

- Balanced Pressure Thermostatic Steam Trap RTA-125 RTH-125 RTV - Technical InformationДокумент2 страницыBalanced Pressure Thermostatic Steam Trap RTA-125 RTH-125 RTV - Technical InformationcentricolltdaОценок пока нет

- Flow-Tek Part Number Selection GuideДокумент18 страницFlow-Tek Part Number Selection GuideAmanda50% (2)

- Insulated Cable Lugs: Product InformationДокумент4 страницыInsulated Cable Lugs: Product InformationNiteshОценок пока нет

- PH-2732-SPFR Jack StandДокумент3 страницыPH-2732-SPFR Jack StandveliquedОценок пока нет

- Connection TorquesДокумент1 страницаConnection TorquesGharib HashemОценок пока нет

- AIV Line SheetДокумент3 страницыAIV Line Sheetajee doОценок пока нет

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)Документ1 страницаService: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)AliZenatiОценок пока нет

- CT113030 ImДокумент2 страницыCT113030 ImFranklin LibreОценок пока нет

- Al SeriesДокумент4 страницыAl SeriesABC - Angela GomezОценок пока нет

- Maximum Fastener Torque For ANSI Flange Attached To Ariel Cylinder NozzleДокумент1 страницаMaximum Fastener Torque For ANSI Flange Attached To Ariel Cylinder NozzleJeff LОценок пока нет

- ABK4-RM-ERS-24-016 For Hoses and ClampДокумент5 страницABK4-RM-ERS-24-016 For Hoses and ClampKasarachi AmadiОценок пока нет

- Cable ManagementДокумент60 страницCable ManagementrakeshsinghsisodiaОценок пока нет

- View Looking S View Looking E: Primary Support Material ListДокумент1 страницаView Looking S View Looking E: Primary Support Material ListJeremy GutiérrezОценок пока нет

- Pressure Relief ValveДокумент4 страницыPressure Relief ValveDiky AfriantОценок пока нет

- ElicaДокумент58 страницElicaDorin ȘuvariОценок пока нет

- Ficha Tecnica Bornes - ConnectwellДокумент1 страницаFicha Tecnica Bornes - ConnectwellMijail Ivan Sotomayor HuariОценок пока нет

- Toyo Gate Valve PricelistДокумент1 страницаToyo Gate Valve PricelistLaurence Arcon BanalОценок пока нет

- 8J101-3655G ST 1xTAL850 TB AHДокумент1 страница8J101-3655G ST 1xTAL850 TB AHOktovianus TeguhОценок пока нет

- TC21Документ2 страницыTC21Pierrat0% (1)

- WD 110000 EngДокумент1 страницаWD 110000 EngAxel mikeОценок пока нет

- Tanque de HidroterapiaL-105-SДокумент2 страницыTanque de HidroterapiaL-105-SVictor EspinozaОценок пока нет

- BOM Tidrev2Документ5 страницBOM Tidrev2JoseОценок пока нет

- Weld Procedure Matrix: Job Number: Prepared By: Customer: Date: Technical Contact: Revision: 0Документ3 страницыWeld Procedure Matrix: Job Number: Prepared By: Customer: Date: Technical Contact: Revision: 0RobОценок пока нет

- MINIPOWERPACK-Ver 6 0 PDFДокумент208 страницMINIPOWERPACK-Ver 6 0 PDFBruno CecattoОценок пока нет

- ABN103 CДокумент1 страницаABN103 CSergio FelipeОценок пока нет

- Abbey Q-Parts Catalogue Section 7Документ38 страницAbbey Q-Parts Catalogue Section 7AbbeyMachineryОценок пока нет

- ASP SST Fittings DataCatalog-1013Документ16 страницASP SST Fittings DataCatalog-1013JMОценок пока нет

- E 7016 Product-SheetДокумент1 страницаE 7016 Product-SheetAlireza TakrimiОценок пока нет

- CMP A2F Metric Akbar TradingДокумент1 страницаCMP A2F Metric Akbar TradingGIBUОценок пока нет

- ABB BREAKER-STOCK-LIST-AKBAR-TRADING-SAUDI-ARABIA, Mail@Документ10 страницABB BREAKER-STOCK-LIST-AKBAR-TRADING-SAUDI-ARABIA, Mail@GIBUОценок пока нет

- Eaton Bussmann STOCK AKBAR TRADING SAUDI ARABIAДокумент2 страницыEaton Bussmann STOCK AKBAR TRADING SAUDI ARABIAGIBUОценок пока нет

- CMP E1FW Akbar TradingДокумент1 страницаCMP E1FW Akbar TradingGIBUОценок пока нет

- CMP A2 Single Seal Industrial Cable Gland-AKBAR TRADINGДокумент1 страницаCMP A2 Single Seal Industrial Cable Gland-AKBAR TRADINGGIBUОценок пока нет

- Stock Details-Saudi ArabiaДокумент1 482 страницыStock Details-Saudi ArabiaGIBUОценок пока нет

- Schneider Electric Stock Details Akbar Trading Saudi-170920182124Документ50 страницSchneider Electric Stock Details Akbar Trading Saudi-170920182124GIBUОценок пока нет

- Ane-Pin Type Cembre - AKBAR TRADING EST - SAUDI ARABIAДокумент1 страницаAne-Pin Type Cembre - AKBAR TRADING EST - SAUDI ARABIAGIBUОценок пока нет

- 3M STOCK LIST - AKBAR TRADING-3M Electrical Materials Promotion - Mail@Документ2 страницы3M STOCK LIST - AKBAR TRADING-3M Electrical Materials Promotion - Mail@GIBUОценок пока нет

- Cembre Die Set - AKBAR TRADING EST - SAUDI ARABIAДокумент36 страницCembre Die Set - AKBAR TRADING EST - SAUDI ARABIAGIBUОценок пока нет

- Cembre C Connector - AKBAR TRADING EST - SAUDI ARABIAДокумент2 страницыCembre C Connector - AKBAR TRADING EST - SAUDI ARABIAGIBUОценок пока нет

- Breaker LUGS CEMBRE - AKBAR TRADING EST - SAUDI ARABIAДокумент1 страницаBreaker LUGS CEMBRE - AKBAR TRADING EST - SAUDI ARABIAGIBUОценок пока нет

- Cembre High Voltage Lugs - AKBAR TRADING EST - SAUDI ARABIAДокумент2 страницыCembre High Voltage Lugs - AKBAR TRADING EST - SAUDI ARABIAGIBUОценок пока нет

- General Cat LTD (13V029E) PDFДокумент218 страницGeneral Cat LTD (13V029E) PDFGIBUОценок пока нет

- RF-PPL-30 - Akbar Trading Est - Saudi ArabiaДокумент1 страницаRF-PPL-30 - Akbar Trading Est - Saudi ArabiaGIBUОценок пока нет

- Raychem Saudi Arabia Ltd. High Voltage, Medium Voltage & Low Voltage Cable Joints, Termination Kits & Heat Shrinkable TubingДокумент4 страницыRaychem Saudi Arabia Ltd. High Voltage, Medium Voltage & Low Voltage Cable Joints, Termination Kits & Heat Shrinkable TubingGIBUОценок пока нет

- RAYCHEM - RPG - CABLE - TIE - COATED - SS - BALL - LOCK-AKBAR TRADING-mail@Документ32 страницыRAYCHEM - RPG - CABLE - TIE - COATED - SS - BALL - LOCK-AKBAR TRADING-mail@GIBUОценок пока нет

- Raychem Kits Adjacent To This Range Both Overlap This Range-170211200514Документ6 страницRaychem Kits Adjacent To This Range Both Overlap This Range-170211200514GIBUОценок пока нет

- Pke - End Sleeves - Cembre (1) - AKBAR TRADING EST - SAUDI ARABIAДокумент2 страницыPke - End Sleeves - Cembre (1) - AKBAR TRADING EST - SAUDI ARABIAGIBUОценок пока нет

- Raychem Kits Adjacent To This Range Both Overlap This Range-170211200514Документ6 страницRaychem Kits Adjacent To This Range Both Overlap This Range-170211200514GIBUОценок пока нет

- RAYCHEM - RPG - CABLE - TIE - COATED - SS - BALL - LOCK-AKBAR TRADING-mail@Документ32 страницыRAYCHEM - RPG - CABLE - TIE - COATED - SS - BALL - LOCK-AKBAR TRADING-mail@GIBUОценок пока нет

- Raychem Saudi Arabia Ltd. High Voltage & Low Voltage Cable Joints, Termination Kits & Heat Shrinkable TubingДокумент4 страницыRaychem Saudi Arabia Ltd. High Voltage & Low Voltage Cable Joints, Termination Kits & Heat Shrinkable TubingGIBUОценок пока нет

- RAYCHEM SAUDI ARABIA LTD. (TYCO ELECTRONICS) - AKBAR TRADING EST. SAUDI ARABIA - TE Termination KIT- RAYCHEM/TYCO TERMINATION KIT- TE CONNECTIVITY 케이블 종단-거-瑞侃工具包电缆终端-阿克巴交易 -ชุด การเลิกจ้างДокумент8 страницRAYCHEM SAUDI ARABIA LTD. (TYCO ELECTRONICS) - AKBAR TRADING EST. SAUDI ARABIA - TE Termination KIT- RAYCHEM/TYCO TERMINATION KIT- TE CONNECTIVITY 케이블 종단-거-瑞侃工具包电缆终端-阿克巴交易 -ชุด การเลิกจ้างGIBUОценок пока нет

- AXIS Cable Lugs - AKBAR TRADING EST - SAUDI ARABIA - Mail@Документ33 страницыAXIS Cable Lugs - AKBAR TRADING EST - SAUDI ARABIA - Mail@GIBUОценок пока нет

- AXIS Cable Glands - AKBAR TRADING EST - SAUDI ARABIA - Mail@Документ20 страницAXIS Cable Glands - AKBAR TRADING EST - SAUDI ARABIA - Mail@GIBU100% (1)

- Hawke Saudi Arabia - Stock List - Akbar Trading Est. - Mail@Документ27 страницHawke Saudi Arabia - Stock List - Akbar Trading Est. - Mail@GIBUОценок пока нет

- Raychem Saudi Arabia - Akbar Trading Est. - Mail@Документ5 страницRaychem Saudi Arabia - Akbar Trading Est. - Mail@GIBUОценок пока нет

- Análisis de La Formabilidad de Láminas de Acero AISI 304 Con Diferentes Espesores Mediante Sus Propiedades de TracciónДокумент9 страницAnálisis de La Formabilidad de Láminas de Acero AISI 304 Con Diferentes Espesores Mediante Sus Propiedades de TracciónLuis Carlos Moscote AtencioОценок пока нет

- 9 TLS Final-Portion Feb-2023 Cl-IX PDFДокумент2 страницы9 TLS Final-Portion Feb-2023 Cl-IX PDFDarsh AgarwalОценок пока нет

- IB Chem2 5 Assess T8Документ3 страницыIB Chem2 5 Assess T8Trúc Hồ100% (3)

- Agacita John PaulДокумент10 страницAgacita John PaulCarlo Dela CruzОценок пока нет

- Master Thesis Subsea 7Документ5 страницMaster Thesis Subsea 7dwt29yrp100% (2)

- Ductile Errors in StaadДокумент2 страницыDuctile Errors in Staadsitaram gvОценок пока нет

- Chapter 6 Composite BeamsДокумент10 страницChapter 6 Composite BeamsDem Austria EspinoОценок пока нет

- A Lateral Theory of Phonology. What Is CVCV and Why Should It Be? Tobias Scheer, Berlin: Mouton de Gruyter (2004) - 854 Pp. + Lix, ISBN 3 11 017871 0Документ11 страницA Lateral Theory of Phonology. What Is CVCV and Why Should It Be? Tobias Scheer, Berlin: Mouton de Gruyter (2004) - 854 Pp. + Lix, ISBN 3 11 017871 0Lazhar HMIDIОценок пока нет

- Quantum Physics Manifestation SuperguideДокумент53 страницыQuantum Physics Manifestation SuperguideQC Rapoo67% (3)

- An Intuitive Guide To Linear Algebra - BetterExplainedДокумент25 страницAn Intuitive Guide To Linear Algebra - BetterExplainedvkk intensiveОценок пока нет

- ST-1 2Документ8 страницST-1 2Omar Dr.Оценок пока нет

- Temperature Is The Degree of Hotness or Coldness of An ObjectДокумент4 страницыTemperature Is The Degree of Hotness or Coldness of An ObjectJohnreeОценок пока нет

- 04.0. Seepage Through Earth DamsДокумент26 страниц04.0. Seepage Through Earth DamsEbrahim AskerОценок пока нет

- NG Flow Meters Why Calibrate Terry GrimleyДокумент59 страницNG Flow Meters Why Calibrate Terry GrimleyPrayogo WibisonoОценок пока нет

- Pipe Reinforcing at SupportДокумент12 страницPipe Reinforcing at SupportSeungmin Paek100% (3)

- Mathematics Solved TestДокумент10 страницMathematics Solved TestShayan FarrukhОценок пока нет

- Tyco Quality Manual 1654241-1CrimpBroGBДокумент28 страницTyco Quality Manual 1654241-1CrimpBroGBdamirОценок пока нет

- Putting Energy To WorkДокумент1 страницаPutting Energy To WorkMicah KlugОценок пока нет

- General Physics Phys 1011 Module Freshman CourseДокумент202 страницыGeneral Physics Phys 1011 Module Freshman Coursetirunehawoke8Оценок пока нет

- Aspen Flare System Analyzer V10 - AspenoneДокумент7 страницAspen Flare System Analyzer V10 - AspenoneMiftah MasrurОценок пока нет

- Productattachments Files e - E-T-Humidefs 10 PDFДокумент4 страницыProductattachments Files e - E-T-Humidefs 10 PDFNeelakandan DОценок пока нет

- Corning Gorilla Glass 5 - PI SheetДокумент2 страницыCorning Gorilla Glass 5 - PI SheetJ. RagaОценок пока нет

- 1.3 Atomic Mass Atomic Number and Isotopes PDFДокумент23 страницы1.3 Atomic Mass Atomic Number and Isotopes PDFMARVIN DELA CRUZОценок пока нет

- R1116010-00000-CI-SPC-0003-0-Anchor BoltДокумент16 страницR1116010-00000-CI-SPC-0003-0-Anchor BoltLОценок пока нет

- Architecture and Its Close Relationship With PhysicsДокумент7 страницArchitecture and Its Close Relationship With PhysicsMarco AponteОценок пока нет

- Assessment 3: Bearing Stress: InstructionsДокумент5 страницAssessment 3: Bearing Stress: InstructionsRaynier LigayaОценок пока нет

- Module 2Документ8 страницModule 2Angiela ConcepcionОценок пока нет

- Low Temperature ApplicationsДокумент411 страницLow Temperature ApplicationsjawaharsorpioОценок пока нет

- Collision of Two Balls in A GrooveДокумент8 страницCollision of Two Balls in A GrooveHanif Daffa BramantyoОценок пока нет

- Basic Aerodynamics BasicsДокумент86 страницBasic Aerodynamics BasicsElvis ParvoiОценок пока нет