Академический Документы

Профессиональный Документы

Культура Документы

CIP 19 - Curling of Concrete Slabs

Загружено:

MaestroColicus100%(1)100% нашли этот документ полезным (1 голос)

94 просмотров2 страницыNrmca Alabeos

Оригинальное название

Curling

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документNrmca Alabeos

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

94 просмотров2 страницыCIP 19 - Curling of Concrete Slabs

Загружено:

MaestroColicusNrmca Alabeos

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

CIP 19 - Curling of Concrete Slabs

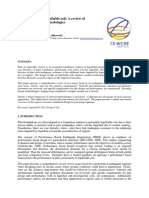

WHAT is Curling? Slab Surface is

Curling is the distortion of a slab into a curved shape Cooler and Drier than Base

by upward or downward bending of the edges. The

occurrence is primarily due to differences in moisture

and/or temperature between the top and bottom sur- A. Upward Curling Typical in Internal Slabs

faces of a concrete slab. The distortion can lift the

edges or the middle of the slab from the base, leaving

an unsupported portion. The slab section can crack

Slab Surface at a Higher Temperature

when loads exceeding its capacity are applied. Slab

and Moisture than Base

edges might chip off or spall due to traffic when the

slab section curls upwards at its edges. In most cases,

curling is evident at an early age. Slabs may, however,

curl over an extended period.

B. Downward Curling

WHY do Concrete Slabs Curl?

Changes in slab dimensions that lead to curling are Curling of Concrete Slabs

most often related to moisture and temperature gradi- age differences from top to bottom in these cases are

ents in the slab. When one surface of the slab changes larger than for slabs on an absorptive subgrade.

size relative to the other, the slab will warp at its edges

in the direction of relative shortening. This curling is Thin slabs and long joint spacing tend to increase curl-

most noticeable at the sides and corners. One pri- ing. For this reason, thin unbonded toppings need to

mary characteristic of concrete that affects curling is have a fairly close joint spacing.

drying shrinkage. Anything that increases drying shrink- In industrial floors, close joint spacing may be unde-

age of concrete will tend to increase curling. sirable because of the increased number of joints and

The most common occurrence of curling is when the increased joint maintenance problems. However, this

top surface of the slab dries and shrinks with respect must be balanced against the probability of interme-

to the bottom. This causes an upward curling of the diate random cracks and increased curling at the joints.

edges of a slab (Figure 1A). Curling of a slab soon The other factor that can cause curling is temperature

after placement is most likely related to poor curing differences between the top and bottom of the slab.

and rapid surface drying. In slabs, excessive bleeding The top part of the slab exposed to the sun will ex-

due to high water content in the concrete or water pand relative to the cooler bottom causing a down-

sprayed on the surface; or a lack of surface moisture ward curling of the edges (Figure 1B). Alternately,

due to poor or inadequate curing can create increased during a cold night when the top surface cools and

surface drying shrinkage relative to the bottom of the contracts relative to the bottom surface in contact with

slab. Bleeding is accentuated in slabs placed directly a warmer subgrade, the curling due to this tempera-

on a vapor retarder (polyethylene sheeting) or when ture differential will add to the upward curling caused

topping mixtures are placed on concrete slabs. Shrink- by moisture differentials.

10.The use of properly designed and placed slab re-

HOW to Minimize Slab Curling?

inforcement may help reduce or eliminate curling.

The primary factors controlling dimensional changes Load transfer devices that minimize vertical move-

of concrete that lead to curling are drying shrinkage, ment should be used across construction joints.

construction practices, moist or wet subgrades, and

11.Certain types of breathable sealers or coatings on

day-night temperature cycles. The following practices

slabs can work to minimize moisture differentials

will help to minimize the potential for curling:

and reduce curling.

1. Use the lowest practical water content in the con-

When curling in a concrete slab application cannot be

crete.

tolerated alternate options include the use of shrink-

2. Use the largest practical maximum size aggregate age reducing admixtures, shrinkage-compensating

and/or the highest practical coarse aggregate con- concrete, post tensioned slab construction or vacuum

tent to minimize drying shrinkage. dewatering. These options should be decided before

3. Take precautions to avoid excessive bleeding. In the construction and could increase the initial cost of

dry conditions place concrete on a damp, but ab- the project.

sorptive, subgrade so that all the bleed water is Some methods of remedying slab curling include

not forced to the top of the slab. This may not be ponding the slab to reduce curl followed by sawing

appropiate for interior slabs on which a moisture additional contraction joints, grinding slab joints where

sensitive floor covering would be placed. curling has occurred to restore serviceability and in-

4. Avoid using polyethylene vapor retarders unless jecting a grout to fill voids under the slab to restore

covered with at least four inches (100 mm) of a support and prevent break-off of uplifted edges.

trimable, compactible granular fill (not sand). If a

moisture-sensitive floor covering will be placed

on interior slabs, the concrete will generally be References

1. Guide for Concrete Floor and Slab Construction, ACI

placed directly on a vapor retarder (see CIP29) 302.1R American Concrete Institute, Farmington Hills,

and other procedures may be necessary. MI www.concrete.org

5. Avoid a higher than necessary cement content. Use 2. Slabs on Grade, ACI Concrete Craftsman Series, CCS-

of pozzolan or slag is preferable to very high ce- 1 American Concrete Institute, Farmington Hills, MI.

3. Shrinkage and Curling of Slabs on Grade, Series in

ment content.

three parts, R. F. Ytterberg, ACI Concrete International,

6. Cure the concrete thoroughly, including joints and April, May and June 1987, American Concrete Insti-

edges. If membrane-curing compounds are used, tute.

apply at twice the recommended rate in two ap- 4. Concrete Slab Surface Defects: Causes, Prevention,

plications at right angles to each other. Repair, IS177, Portland Cement Association, Skokie,

IL, www.cement.org

7. When minimizing curling is critical, use a joint spac- 5. Pavement Design, Transportation Research Record

ing not exceeding 24 times the thickness of the 1207, National Research Council, Washington, D.C.,

slab. 1988, p. 44.

6. Controlling Curling and Cracking in Floors to Re-

8. For thin toppings, clean the base slab to ensure ceive Coverings, J. Holland and W. Walker, Concrete

bond and consider use of studs and wire around Construction, July 1998, www.worldofconcrete.com.

the edges and particularly in the slab corners. 7. Where to Place the Vapor Retarder, B. Suprenant and

9. Use a thicker slab, or increase the thickness of W. Malisch, Concrete Construction, May 1998.

the slab at edges. 8. Repairing Curled Slabs, B. Suprenant, Concrete Con-

struction, May 1999.

9. Residential Concrete, National Association of Home

Builders, Washington, DC, www.nahb.com.

1990, 2002, 2004

Вам также может понравиться

- ACI 336 - 2002 - ATF - Sections 2 - 6.1 - 6.9Документ20 страницACI 336 - 2002 - ATF - Sections 2 - 6.1 - 6.9Alice MuYun XuОценок пока нет

- ACI 222.3R-11 - Guide To Desig PDFДокумент32 страницыACI 222.3R-11 - Guide To Desig PDFMaestroColicus100% (2)

- Innovative Ways To Reinforce Slabs On GroundДокумент8 страницInnovative Ways To Reinforce Slabs On GroundScooby DooОценок пока нет

- Ground Engineering SystemsДокумент76 страницGround Engineering SystemsAfendi AriffОценок пока нет

- Cementitious Grouts: A Comprehensive GuideДокумент65 страницCementitious Grouts: A Comprehensive GuideDavidQОценок пока нет

- Sprayed Concrete TechnologyДокумент318 страницSprayed Concrete TechnologyoltaiyrxОценок пока нет

- 211.7R-15 Guide For Proportioning Concrete Mixtures With Ground Limestone and Other Mineral FillersДокумент20 страниц211.7R-15 Guide For Proportioning Concrete Mixtures With Ground Limestone and Other Mineral FillersYAZAN ALFARRAОценок пока нет

- Eq Linear Stiffness and Damping in Rocking of Circular and Strip FoundationsДокумент25 страницEq Linear Stiffness and Damping in Rocking of Circular and Strip FoundationseiudkОценок пока нет

- Specifications of Concrete WorksДокумент45 страницSpecifications of Concrete Worksnicoleta_cristian4798Оценок пока нет

- Carpet Languages PeoplesДокумент1 557 страницCarpet Languages PeoplespronaturaalОценок пока нет

- Reported by ACI Committee 315: Keywords: Beams (Supports) Bending (Reinforcing Steels) Bridges (StrucДокумент44 страницыReported by ACI Committee 315: Keywords: Beams (Supports) Bending (Reinforcing Steels) Bridges (StrucXakiОценок пока нет

- Aisc Bolting and Welding 190606215451 PDFДокумент73 страницыAisc Bolting and Welding 190606215451 PDFthet naingОценок пока нет

- A New Method For Designing Floor Slabs On GradeДокумент9 страницA New Method For Designing Floor Slabs On GradePGSОценок пока нет

- Lightweight Steel Framing Details: General & Axial LoadbearingДокумент7 страницLightweight Steel Framing Details: General & Axial Loadbearingrmsa17Оценок пока нет

- 53 - Butt-Weld Pipe FittingsДокумент13 страниц53 - Butt-Weld Pipe Fittingsjoni_capelletoОценок пока нет

- SL No IS Codes Name of The Code 1 2 3 Building MeasurementsДокумент9 страницSL No IS Codes Name of The Code 1 2 3 Building MeasurementsRajesh BabuОценок пока нет

- Carbon Structural Steel: Standardspecification ForДокумент4 страницыCarbon Structural Steel: Standardspecification ForlinaОценок пока нет

- Urban Planning PDFДокумент187 страницUrban Planning PDFMaestroColicusОценок пока нет

- Navdac DM 7.02Документ271 страницаNavdac DM 7.02Muhammad Yodha AdityaОценок пока нет

- Reinforced ring foundations spread silo load over soilДокумент6 страницReinforced ring foundations spread silo load over soiljeovanОценок пока нет

- ACI 229 Enhanced CLSM 20160415 PDFДокумент30 страницACI 229 Enhanced CLSM 20160415 PDFerosОценок пока нет

- Filler SlabДокумент3 страницыFiller SlabSanjay RaoОценок пока нет

- What, Why, How PDFДокумент2 страницыWhat, Why, How PDFEnrique PasquelОценок пока нет

- Cracking Concrete SurfacesДокумент2 страницыCracking Concrete SurfacesCivilEngClubОценок пока нет

- Ischebeck Titan Ground Engineering Systems 0523Документ32 страницыIschebeck Titan Ground Engineering Systems 0523Thomas GlasbyОценок пока нет

- Brace Forces in Steel Box Girders With Single Diagonal Lateral Bracing SystemsДокумент12 страницBrace Forces in Steel Box Girders With Single Diagonal Lateral Bracing Systemserky arkvathonejhОценок пока нет

- Curling of Concrete Slabs On GradeДокумент6 страницCurling of Concrete Slabs On GradeBennet Kuriakose100% (1)

- Reinforcing Steel Members and The Effects of WeldingДокумент3 страницыReinforcing Steel Members and The Effects of WeldingaldifmvОценок пока нет

- Lime Based MortarДокумент39 страницLime Based MortarAparna Kumar100% (2)

- ACI Committee 533-ACI 533R-11 - Guide For Precast Concrete Wall Panels-American Concrete Institute (ACI) (2011)Документ52 страницыACI Committee 533-ACI 533R-11 - Guide For Precast Concrete Wall Panels-American Concrete Institute (ACI) (2011)iGedeASОценок пока нет

- Tips For Designers PDFДокумент5 страницTips For Designers PDFSushil DhunganaОценок пока нет

- On Seismic Design of Retaining Walls: Yingwei Wu Shamsher Prakash Vijay K. PuriДокумент8 страницOn Seismic Design of Retaining Walls: Yingwei Wu Shamsher Prakash Vijay K. PuriAnand JadoenathmisierОценок пока нет

- AISC-EJ Unreinforced Web Openings in Steel BeamsДокумент14 страницAISC-EJ Unreinforced Web Openings in Steel BeamsBala SrikanthОценок пока нет

- Corrosion - Degradation of Soil ReinforcementsДокумент104 страницыCorrosion - Degradation of Soil ReinforcementsWan Jailani Wan HussinОценок пока нет

- 503 6R-97 PDFДокумент4 страницы503 6R-97 PDFsaeidcivil89Оценок пока нет

- Libro Concreto PcaДокумент326 страницLibro Concreto Pcaemilio_castelblanc_1Оценок пока нет

- CI3907 GranosikДокумент3 страницыCI3907 GranosikdeviationzОценок пока нет

- Materials System SpecificationДокумент6 страницMaterials System SpecificationAjeetKumarОценок пока нет

- Construction Contractors Survival Guide PDFДокумент160 страницConstruction Contractors Survival Guide PDFMaestroColicus100% (2)

- Deformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementДокумент7 страницDeformed and Plain Low-Alloy Steel Bars For Concrete Reinforcementjose moralesОценок пока нет

- EFFECT OF SOIL ON STRUCTURAL RESPONSEДокумент18 страницEFFECT OF SOIL ON STRUCTURAL RESPONSERamesh GantiОценок пока нет

- Agile in ConstructionДокумент67 страницAgile in ConstructionbabaktavousiОценок пока нет

- Design of Piles in Liquefiable Soil: A Review of Design Codes and MethodologiesДокумент10 страницDesign of Piles in Liquefiable Soil: A Review of Design Codes and MethodologiesHossein DoudiОценок пока нет

- Precast ManualДокумент236 страницPrecast ManualugurОценок пока нет

- Post-Tensioned Slab On GroundДокумент3 страницыPost-Tensioned Slab On GroundstkhedakarОценок пока нет

- Solar DyeingДокумент3 страницыSolar Dyeingwitsg100% (1)

- Use of Shear Lugs For Anchorage To Concrete: January 2009Документ9 страницUse of Shear Lugs For Anchorage To Concrete: January 2009Sandeep BhatiaОценок пока нет

- Designing Concrete For Exposure To Seawater - tcm45-342265Документ3 страницыDesigning Concrete For Exposure To Seawater - tcm45-342265Ignatius Samraj100% (2)

- Cssbi B13-19Документ81 страницаCssbi B13-19Jose L MexiaОценок пока нет

- 2 BlumeДокумент184 страницы2 BlumeCarlos Alberto Acuña AsenjoОценок пока нет

- Design and Behavior of Gusset Plate ConnectionsДокумент11 страницDesign and Behavior of Gusset Plate ConnectionsEmil ParangueОценок пока нет

- Concrete Construction Article PDF - Mechanical vs. Lap SplicingДокумент4 страницыConcrete Construction Article PDF - Mechanical vs. Lap SplicingGilven MedinaОценок пока нет

- Modelling Bonded Post-Tensioned Concrete Slabs in FireДокумент13 страницModelling Bonded Post-Tensioned Concrete Slabs in Firerahulgehlot2008Оценок пока нет

- Transfloor CatalogДокумент56 страницTransfloor Catalogbappy01_cuet9921Оценок пока нет

- ACiДокумент9 страницACiMarcel SteoleaОценок пока нет

- 6446 Gibson PBD - HR WebДокумент192 страницы6446 Gibson PBD - HR WebKoke Colil Benavente100% (1)

- Shear Strength of Reinforced Concrete Deep BeamsДокумент4 страницыShear Strength of Reinforced Concrete Deep Beamsnevinkoshy100% (1)

- Theory of Elastic Stability: Stephen Timoshenko James GereДокумент2 страницыTheory of Elastic Stability: Stephen Timoshenko James GereNhân NguyễnОценок пока нет

- Design of Reinforcing Piles To Increase Slope Stability (H.G.poulos)Документ11 страницDesign of Reinforcing Piles To Increase Slope Stability (H.G.poulos)TaiCheong Lee100% (1)

- Profis Engineering Suite: EnglishДокумент36 страницProfis Engineering Suite: Englishkamenos_manosОценок пока нет

- Roberts 1991Документ18 страницRoberts 1991guojie zhouОценок пока нет

- ICBO CIA-7000 Anchor SystemДокумент16 страницICBO CIA-7000 Anchor SystemDon RockwellОценок пока нет

- 870 43 18 Technical Documentation Sika AnchorFix 3030 (06 2018) 1Документ15 страниц870 43 18 Technical Documentation Sika AnchorFix 3030 (06 2018) 1Lucian BogorodeaОценок пока нет

- A Method of Analysis For Infilled Frames - Smith - 1969Документ18 страницA Method of Analysis For Infilled Frames - Smith - 1969ravi100% (1)

- Shear KeyДокумент43 страницыShear KeyMd Shamsul IslamОценок пока нет

- Analysis and Design of Prestressed Concrete SleepersДокумент25 страницAnalysis and Design of Prestressed Concrete SleeperspoezpietaОценок пока нет

- AISC Design Guide 1 - Errata-Column Base Plates - 2nd Edition PDFДокумент6 страницAISC Design Guide 1 - Errata-Column Base Plates - 2nd Edition PDFसौरव डेОценок пока нет

- E1960 PDFДокумент5 страницE1960 PDFdannychacon27Оценок пока нет

- Design of Steel and Composite Beams With Web OpeningsДокумент19 страницDesign of Steel and Composite Beams With Web OpeningsAngelica Gamiz ArciniegaОценок пока нет

- Typical Sizes and Shapes of Concrete Masonry Units: TEK 2-1BДокумент4 страницыTypical Sizes and Shapes of Concrete Masonry Units: TEK 2-1BfostbarrОценок пока нет

- Connection HCS PDFДокумент25 страницConnection HCS PDFPranay UpadhyayОценок пока нет

- CIP 4 - How to Prevent Concrete CrackingДокумент2 страницыCIP 4 - How to Prevent Concrete CrackingKhaleelОценок пока нет

- CrackingДокумент2 страницыCrackingdeinaОценок пока нет

- Reja - Waste Center - RV00Документ1 страницаReja - Waste Center - RV00MaestroColicusОценок пока нет

- Eco WiseДокумент1 страницаEco WiseMaestroColicusОценок пока нет

- Visual Basic Userform 8Документ4 страницыVisual Basic Userform 8Celin Hernández PérezОценок пока нет

- 4 - Stego - V1propДокумент2 страницы4 - Stego - V1propMaestroColicusОценок пока нет

- Ds Precast HBДокумент168 страницDs Precast HBJoeОценок пока нет

- Ds Condensed Chemical HBДокумент28 страницDs Condensed Chemical HBMaestroColicusОценок пока нет

- Ds Tilt-Up HBДокумент120 страницDs Tilt-Up HBMaestroColicusОценок пока нет

- Inspection Checklist: Concrete Floor: Summary Card)Документ2 страницыInspection Checklist: Concrete Floor: Summary Card)MaestroColicusОценок пока нет

- Earned Value Management Tutorial Module 1: Introduction To Earned Value ManagementДокумент25 страницEarned Value Management Tutorial Module 1: Introduction To Earned Value ManagementMaestroColicusОценок пока нет

- Accounting - What Is Cost AccountingДокумент3 страницыAccounting - What Is Cost Accountingapi-3723568Оценок пока нет

- DIN 18202 1997 Tolerances For Building Structures PDFДокумент8 страницDIN 18202 1997 Tolerances For Building Structures PDFMaestroColicusОценок пока нет

- Design of Composite SlabsДокумент130 страницDesign of Composite SlabsMaestroColicusОценок пока нет

- STS130Документ252 страницыSTS130MaestroColicus0% (1)

- DIN 18202 1997 Tolerances For Building Structures PDFДокумент8 страницDIN 18202 1997 Tolerances For Building Structures PDFMaestroColicusОценок пока нет

- 2 Vdma enДокумент17 страниц2 Vdma enEfthymios TatsisОценок пока нет

- Aci 555R-01Документ26 страницAci 555R-01MaestroColicusОценок пока нет

- Aci 555R-01Документ26 страницAci 555R-01MaestroColicusОценок пока нет

- CNC Wood Turning Lathe Cutters Bits Knife ToolsДокумент5 страницCNC Wood Turning Lathe Cutters Bits Knife ToolsSalce SmithОценок пока нет

- Textile Industry in India Project ReportДокумент16 страницTextile Industry in India Project ReportmitОценок пока нет

- Sika MonoTop 615 PDS (CE)Документ6 страницSika MonoTop 615 PDS (CE)Virah Sammy ChandraОценок пока нет

- Bluestar Silicones Emulsion BD PDFДокумент4 страницыBluestar Silicones Emulsion BD PDFSergio Daniel GonzalezОценок пока нет

- Technical ProgrammeДокумент60 страницTechnical ProgrammeAmy FitzgeraldОценок пока нет

- Natural Iron Oxide Product BrochureДокумент4 страницыNatural Iron Oxide Product BrochureNew Riverside Ochre Company, Inc.Оценок пока нет

- Effect of Nodule CountДокумент5 страницEffect of Nodule Countdinesh529Оценок пока нет

- 30 7 2016 Last Updated InvoiceДокумент35 страниц30 7 2016 Last Updated InvoiceHaymanAHMEDОценок пока нет

- Asphalt LectureДокумент11 страницAsphalt LectureKeesh Marlon Repatacodo TabalОценок пока нет

- CBB1443 How To Timber DeckДокумент2 страницыCBB1443 How To Timber DeckTuroyОценок пока нет

- Rubbing - AatccДокумент13 страницRubbing - AatccAjith SatyapalaОценок пока нет

- History of Cement & Concrete: 3000 BC - Egyptian PyramidsДокумент4 страницыHistory of Cement & Concrete: 3000 BC - Egyptian Pyramidssatishkumarkolluru9809Оценок пока нет

- Ecss e HB 32 20 Part5aДокумент435 страницEcss e HB 32 20 Part5avahid030951Оценок пока нет

- Reinforcement Against Punching Failure of Slabs: Technical ManualДокумент20 страницReinforcement Against Punching Failure of Slabs: Technical ManualAnonymous 5VwQ0KC3Оценок пока нет

- TR Fastenings Engineering Guide for Plastic ScrewsДокумент2 страницыTR Fastenings Engineering Guide for Plastic ScrewsAndrew GrimesОценок пока нет

- Nitotile LM GroutДокумент2 страницыNitotile LM GroutVenkata RaoОценок пока нет

- NMP 3Документ17 страницNMP 3kalai dossanОценок пока нет

- Basf Masterrheobuild 1000 TdsДокумент3 страницыBasf Masterrheobuild 1000 TdsDevendraОценок пока нет

- GB Catalog Update 2013-1 Inlay LRДокумент296 страницGB Catalog Update 2013-1 Inlay LRsaotinhyeu307783Оценок пока нет

- Application of Pentron ProdДокумент3 страницыApplication of Pentron ProdBabar AkbarОценок пока нет

- Qcs 2010 Section 16 Part 10 Protective TreatmentДокумент5 страницQcs 2010 Section 16 Part 10 Protective Treatmentbryanpastor106Оценок пока нет

- Conplast SP480Документ2 страницыConplast SP480Tori SmallОценок пока нет