Академический Документы

Профессиональный Документы

Культура Документы

LT LG400 13 Inspection Maintenance Procedures

Загружено:

Arturo Zavala UrquidesАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

LT LG400 13 Inspection Maintenance Procedures

Загружено:

Arturo Zavala UrquidesАвторское право:

Доступные форматы

OPERATING, INSPECTION AND

MAINTENANCE PROCEDURES

WARNING: Before attempting to operate the landing gear, you must

read and understand the following procedures:

Perform all procedures in lighted area clear of obstacles and other personnel.

Always grip the crank handle securely with both hands.

Maintain proper footing at all times.

Never attempt to shift the landing gear while under load.

Lifting and lowering of the trailer must always be done in LOW GEAR.

DO NOT ATTEMPT TO LIFT OR LOWER TRAILER WITH LANDING GEAR IN HIGH

GEAR, AS SERIOUS PERSONAL INJURY COULD OCCUR.

Always secure the crank handle when not in use.

OPERATING INSTRUCTIONS

Push crank handle in for high gear.

TRAILER

RETRACT Pull crank handle out for low gear.

Turn crank:

LOW

HIGH Counterclockwise - Retract

Clockwise - Extend

EXTEND

FIGURE 1

Note: Both inside and outside mounts crank the same.

The right to alter specifications is reserved. Page 1 of 8

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT LG400-13 RevF

COUPLING PROCEDURES

STEP 1

Inflate tractor air suspension and back up

close to the trailer centering the kingpin TRAILER

with the throat of the fifth wheel and STOP! (TOP)

DO NOT ATTEMPT TO COUPLE UNTIL

STEPS 2 THROUGH 4 ARE

COMPLETED. KINGPIN

STEP 2 3 2

1. Chock trailer wheels.

2. Connect brake lines and light cord.

3. Support slack in lines to prevent

interference.

4. Set trailer brakes.

4 1

STEP 3

Make sure that the landing gear is in low ENGAGED

gear (see figure 1) and engage crank DISENGAGED

handle.

FIFTH WHEEL FIFTH WHEEL

4-6 MUST LIFT WILL NOT LIFT

STEP 4 TRAILER TRAILER

Adjust trailer height so that the fifth

wheel will lift the trailer. USE LOW

GEAR

FIFTH WHEEL

TILTED DOWN

STEP 5

Couple and verify that there is no gap

between fifth wheel and trailer and that

the kingpin is inside the lock. NO GAP KINGPIN INSIDE LOCK

STEP 6

USE LOW GEAR UNTIL

While still in low gear, retract landing PADS JUST COME OFF

gear until pads just come off the THE GROIUND

ground.

STEP 7

Switch to high gear and fully retract, SWITCH TO HIGH GEAR

AND FULLY RETRACT,

secure crank handle. SECURE CRANK HANDLE

The right to alter specifications is reserved. Page 2 of 8

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT LG400-13 RevF

UNCOUPLING PROCEDURES

STEP 1

Position the tractor and trailer on level

ground, clear of persons and

obstacles.

STEP 2 1

1. Set trailer brakes. Slowly back

tractor tightly against trailer.

2. Set tractor brakes.

3. Chock trailer wheels.

2 3

STEP 3

Shift landing gear to high gear ENGAGED

(see figure 1) and engage crank handle. DISENGAGED

STEP 4

Extend landing gear until pads just

touch the ground. USE HIGH GEAR UNTIL PADS

TOUCH THE GROUND

STEP 5

Switch to low gear and crank an SECURE HANDLE

additional 4-8 turns minimum.

Secure crank handle

STEP 6 3

2

1. Pull fifth wheel release handle.

1

2. Disconnect air lines and light cord.

3. Release tractor brakes and slowly drive

away from trailer.

The right to alter specifications is reserved. Page 3 of 8

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT LG400-13 RevF

MAINTENANCE PROCEDURES

IMPORTANT: All steps in this document must be performed at least every 3 months.

STEP 1: INSPECT LEGS AND MOUNTINGS:

Inspection Possible Causes

Cross shaft connection bolts and lock nuts must be 1. Cross shaft bolt too tight

secure, but allow side-to-side play in the cross shaft. 2. Incorrect cross shaft length

1. Bolts not tightened to proper torque

Tighten or replace bolts as necessary.

2. Improper coupling procedures

Inspect the mounting flange for cracks or other signs 1. Overloading

of damage. 2. Improper coupling techniques

1. Legs not fully retracted

Repair or replace any broken or damaged parts of

2. Overloading

the landing gear assembly.

3. Legs damaged by collision

1. Legs not fully retracted when moving trailer

Extend the legs and, using a straightedge, inspect for

2. Improper ground clearance

bent lower leg and damaged footwear.

3. Improper coupling procedures

Check for interference between powder metal

Holes too small or in incorrect location on mounting

bushing and trailer mounting surface.

Inspect the crank handle bolt and lock nut. Tighten Crank handle bolt too tight (the crank handle bolt

or replace as necessary. must be loose enough to allow free engagement)

Check for proper crank shaft shifting in both high and

Damage to crankshaft due to contact or collision

low gear.

Important: Landing gear with excessive play should be rebuilt or replaced.

STEP 2: INSPECT ALIGNMENT:

Inspection Possible Causes

1. Improper installation

Using a square, check that both legs are square to the

2. Loose bracing bolts

trailer and parallel with each other as shown.

3. Improper coupling techniques

TRAILER END TRAILER

VIEW SIDE VIEW

SQUARE

SQUARE

The right to alter specifications is reserved. Page 4 of 8

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT LG400-13 RevF

MAINTENANCE PROCEDURES

STEP 3: INSPECT FOR PROPER OPERATION : (see Operating Instructions on page 1)

Action Inspection (Look for the following indicators): Possible Causes

1. Bent leg.

Lower leg wobbling or twisting.

2. Bent lift screw.

Lower leg makes a sudden drop (hopping). Damage to lift screw threads.

1. Shift to high gear

2. Extend leg to the ground. Inconsistent torques at different positions of

Bent or damaged screw.

3. Inspect for smooth operation. the crank handle throughout the travel.

Without load in high gear the torque should 1. Damage to lift screw or lift nut.

not exceed approx. 7 lbs at the crank 2. Gear not lubricated at routine

handle. maintenance intervals.

4. Extend leg to the ground. With an empty trailer in low gear the torque

Gear not lubricated at routine

5. Shift to low gear. should not exceed approx. 19 lbs at the

maintenance intervals.

6. Crank an additional 8 to 10 turns. crank handle.

If any of the above indicators are present the landing gear should be disassembled

and inspected for actual wear and/or damage. Replace as required.

STEP 4: LUBRICATE:

The only solution for corrosion problems is regular re-lubing of the legs in both the gearbox (upper

grease zerk) and the screw/nut cavity (lower grease zerk). This action will place a fresh coat of grease

on all the surfaces protecting them from rust.

1. Lubricate at least every 3 months and more frequently in applications where the landing gear are exposed to excessive

moisture (liquid salt water spray), dust, or if they are not used for extended periods.

2. Lubricate with the trailer securely coupled to a tractor (see coupling instructions on page 2).

3. Employ a lubricant compatible with the original type of grease used:

Standard Lithium base 1-2% Moly EP-2 Warning: Do not use any lubricants

Low temperature Arctic-grade, all weather white grease containing Teflon

Bevel Gear Lubrication Instructions:

Lubricate in the top grease fitting as shown. BEVEL GEARS

At least 4oz. (50 pumps on a hand grease gun). (Add 4oz. Every 3 mo.)

Lift Screw/Nut Lubrication Instructions:

It is not required to perform these steps if the direct

LIFT SCREW/NUT

lubrication (outlined in the addendum) were completed

(Add 4oz. Every 3 mo.)

Fully retract the landing gear, then using high gear

extend 7 turns.

Lift Nut

Lubricate in the bottom grease fitting as shown. 7 turns in

At least 4oz. (50 pumps on a hand grease gun). high gear

Extend and retract the landing gear to apply grease

to the entire length of the screw.

The right to alter specifications is reserved. Page 5 of 8

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT LG400-13 RevF

TROUBLE-SHOOTING POINTS

Problem Cause Correction

1. See below for proper crank handle

Hard to crank 1. Turning crank in wrong direction.

rotation.

landing gear

2. Shift to low gear (see figure 1, page1).

2. Attempting to raise or lower trailer in high

DO NOT ATTEMPT TO LIFT OR

gear.

LOWER IN HIGH GEAR.

3. Turn crank in opposite direction to

3. Legs are already fully extended or retracted.

retract or extend.

4. Inspect cross shaft bolts. Back off bolts

4. Cross shaft binding:

to allow lateral (side-to-side) movement

- over-tightened bolts.

of cross shaft. Use self-locking type

- cross shaft bent or too long.

nuts only.

5. Legs must be parallel and extend and

5. Mis-aligned landing gear legs. retract evenly. Remove cross shaft;

adjust landing gear legs to same height.

6. Grease landing gear as directed in

step 4 on page 5. If problem remains,

6. Lack of grease. inspect for corrosion per Addendum A

on page 7, for alternative corrections

prior to dismantling assembly.

7. Check landing gear for signs of impact

(accident) damage. Disconnect cross

7. Damaged lift screw or lift nut. shaft and crank legs individually to

determine which leg is damaged.

Replace damaged leg.

8. Interference between powder metal bushing 8. Hole in trailer mounting surface may

and trailer mounting surface need to be enlarged.

1. Replace broken bolt(s) and shaft as

Shaft turns but 1. Broken shaft or shaft bolt.

needed.

legs do not

operate 2. Broken pinion gear or bevel gear or

2. Replace broken gear(s) or pin.

gear pins.

1. Broken gear teeth. 1. Replace broken gear(s).

Shaft does not

turn 2. Replace inner leg or entire landing gear

2. Damaged lift screw.

leg.

3. Replace inner leg or entire landing gear

3. Seized lift screw or nut

leg.

4. Replace bent inner leg or outer leg, or

4. Bent inner or outer leg tube.

entire landing gear leg.

Crank shaft

skips when 1. Broken gear teeth. 1. Replace broken gear(s).

cranking

The right to alter specifications is reserved. Page 6 of 8

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT LG400-13 RevF

ADDENDUM A: FOR SERIOUS CORROSION ISSUES

INSPECT FOR CORROSION:

Vehicle components are getting over exposed to road salts due to the very corrosive melting agents

being used on the roads. If your vehicle operates in these environments consider the following:

Action:

1. Remove the cross shaft

2. Turn each leg by hand to find out if one or both legs are exhibiting the problem.

3. Determine the best solution by using the chart below.

Inspection (Corrosion indicators): Suggested Solution

If torque is 9 ft-lbs or less Re-lubricate as described in step 4 on page 5.

1. Remove the leg cover

2. Push the grease away from the screw

1. If torque is between 10-20 ft-lbs 3. Pour 2-3 oz of 90-180 weight gear lube as close to

2. The grease is NOT rusty brown the screw as possible

4. Let the leg stand over night

5. Run the legs up and down to break any rust loose

6. Re-lubricate as outlined in step 4 on page 5.

1. Remove the leg cover

2. Push the grease away from the screw

1. If torque is between 10-20 ft-lbs 3. Pour 2-3 oz of 10W30 motor oil as close to the

2. The grease IS rusty brown screw as possible

4. Let the leg stand over night

5. Run the legs up and down to break any rust loose

6. Re-lubricate as outlined in step 4 on page 5.

1. Remove the bottom drive fit grease fitting by

clamping w/vise grip pliers and moving up and

down and side-to-side while pulling

2. Spray Kroil or PB Blaster penetrating oil into the

grease fitting hole. Direct the spray toward the

If the Leg is completely seized

screw for 30 seconds

3. Let the leg stand over night

4. Put the landing gear in low gear and extend and

retract the legs to break them free

5. Re-lubricate as outlined in step 4 on page 5.

If problem persists, follow the steps in Addendum B on page 8.

The right to alter specifications is reserved. Page 7 of 8

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT LG400-13 RevF

ADDENDUM B: FOR SERIOUS CORROSION ISSUES

PREPARATION FOR DIRECT LUBE:

Direct Lube Preparation Instructions: Trailer Front

1) Fully retract the landing gear

(so chips will fall out - see figure on right). 1 2

Fully 5/8 dia. hole saw

2) Drill a 5/8 diameter hole (6 from the bottom retract leg through upper leg only

and located in the center of the upper tube). DO

NOT drill into the lower leg.

Continue to the direct lubrication Instructions

below. 6

Chips

DIRECT LUBRICATION:

Direct Lube Instructions:

3) Extend the landing gear to FULL extension to Trailer Front

expose the lubrication hole.

4) Insert the grease gun through the hole. Apply

4oz of grease onto the screw (50 pumps on a

hand grease gun). Use grease compatible with a

3 4 Apply 4 oz.

Lithium base 1-2% Moly EP-2

of grease

5) Retract and extend the landing gear to apply Fully

onto the

grease to the entire length of the screw. Extend leg

screw

Go to step 4 on page 5 and perform the Bevel

5

Gear Lubrication only.

Retract and

extend leg

The right to alter specifications is reserved. Page 8 of 8

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT LG400-13 RevF

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- 995-T System Alignament HunterДокумент12 страниц995-T System Alignament HunterArturo Zavala UrquidesОценок пока нет

- Dryparts TodcoДокумент4 страницыDryparts TodcoArturo Zavala UrquidesОценок пока нет

- Morgan Parts Catalog 44p LRДокумент27 страницMorgan Parts Catalog 44p LRArturo Zavala UrquidesОценок пока нет

- Truck Tire Service Manual 062011 MichelinДокумент154 страницыTruck Tire Service Manual 062011 MichelinArturo Zavala UrquidesОценок пока нет

- Caterpillar Mid Range Catalog 2013 LRДокумент28 страницCaterpillar Mid Range Catalog 2013 LRArturo Zavala Urquides100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Euroncap Serie 5 E39Документ2 страницыEuroncap Serie 5 E39Juan Ramon JMОценок пока нет

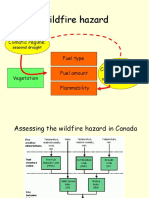

- Wildfire Hazard: Climatic Regime: Fuel Type Fuel Amount Flammability VegetationДокумент65 страницWildfire Hazard: Climatic Regime: Fuel Type Fuel Amount Flammability VegetationIvan Barać100% (1)

- The Making of The TitanicДокумент33 страницыThe Making of The TitanicthethingsyoucanreadОценок пока нет

- Insurance DigestДокумент3 страницыInsurance DigestKatherinePolinasSadioaОценок пока нет

- Word Building 2 BtoДокумент8 страницWord Building 2 BtovericliОценок пока нет

- E11 WI VFD ManualДокумент146 страницE11 WI VFD Manualkamal_khan85Оценок пока нет

- Digital Smart Lock and Anti-Accident System: Amruta Kumbhar, Rajashri KulkarniДокумент5 страницDigital Smart Lock and Anti-Accident System: Amruta Kumbhar, Rajashri Kulkarnifakeacc18Оценок пока нет

- If I Was Your Girl - 230801 - 193848Документ37 страницIf I Was Your Girl - 230801 - 193848p1520067Оценок пока нет

- Analytical Report of Wenzhou Rail DisasterДокумент3 страницыAnalytical Report of Wenzhou Rail DisasterSam TangОценок пока нет

- D1.2 - Unsafe Unhealthy Acts - ConditionДокумент66 страницD1.2 - Unsafe Unhealthy Acts - ConditionDJОценок пока нет

- Fernando vs. CAДокумент2 страницыFernando vs. CAPia SarconОценок пока нет

- LFI 2 Wuye LTI Incident August 2023Документ1 страницаLFI 2 Wuye LTI Incident August 2023MUHAMMAD SANIОценок пока нет

- Continuous MinerДокумент9 страницContinuous MinergopalОценок пока нет

- Difference Between Defect, Error, Bug, Failure and Fault: VerificationДокумент4 страницыDifference Between Defect, Error, Bug, Failure and Fault: VerificationAnil KumarОценок пока нет

- Manual For Alfa Romeo 156Документ358 страницManual For Alfa Romeo 156Jean Machuca100% (2)

- Coefficient of RestitutionДокумент13 страницCoefficient of RestitutionDivina Mercedes FernandoОценок пока нет

- Cap 642Документ272 страницыCap 642afrodizzyОценок пока нет

- The Gaseous StateДокумент6 страницThe Gaseous StateDaniel ChuОценок пока нет

- TPM Awareness Process BriefДокумент28 страницTPM Awareness Process BriefmandapatiharishОценок пока нет

- Omni 2Документ1 страницаOmni 2ty391988Оценок пока нет

- Causes of Death: Medico-Legal Masquerade - Violent Deaths May Be Accompanied by Minimal or NoДокумент3 страницыCauses of Death: Medico-Legal Masquerade - Violent Deaths May Be Accompanied by Minimal or NoIrish WahidОценок пока нет

- XtxtnbregДокумент13 страницXtxtnbregalicorpanaoОценок пока нет

- Safety - Defensive Driving Presentation ExcelinsafetyДокумент51 страницаSafety - Defensive Driving Presentation ExcelinsafetyPrestoneОценок пока нет

- Move MasterДокумент126 страницMove MasterManu VenegasОценок пока нет

- HSE Risk Assessment (UTM)Документ1 страницаHSE Risk Assessment (UTM)kamalОценок пока нет

- Rail Safety CanadaДокумент26 страницRail Safety CanadaBruno ThiemeОценок пока нет

- Structural Analysis of Truck Chassis FrameДокумент11 страницStructural Analysis of Truck Chassis FramedailywaziОценок пока нет

- Dodge DGF Gear Couplings: Instruction ManualДокумент2 страницыDodge DGF Gear Couplings: Instruction ManualTony_Black99Оценок пока нет

- SCAT Systematic Cause Analysis Technique PDFДокумент36 страницSCAT Systematic Cause Analysis Technique PDFAndi Saputra100% (1)

- Multi Format Assessment Paper 4 MarkingДокумент13 страницMulti Format Assessment Paper 4 MarkingSafety OfficerОценок пока нет