Академический Документы

Профессиональный Документы

Культура Документы

180 Ohm Resistor

Загружено:

Nidhi PanditИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

180 Ohm Resistor

Загружено:

Nidhi PanditАвторское право:

Доступные форматы

CRCW-HP e3

www.vishay.com

Vishay Draloric

Pulse Proof, High Power Thick Film Chip Resistors

FEATURES

Excellent pulse load capability

Enhanced power rating

Double side printed resistor element

AEC-Q200 qualified

Material categorization: for definitions of compliance

please see www.vishay.com/doc?99912

The pulse proof, high power thick film chip resistors series APPLICATIONS

is the perfect choice for most fields of power measurement Automotive

electronics where reliability, stability, high power rating and

excellent pulse load performance are of major concern. Industrial

Typical applications include battery management systems

in automotive appliances.

TECHNICAL SPECIFICATIONS

CRCW0402- CRCW0603- CRCW0805- CRCW1206- CRCW1210- CRCW1218- CRCW2010- CRCW2512-

DESCRIPTION

HP e3 HP e3 HP e3 HP e3 HP e3 HP e3 HP e3 HP e3

Imperial size 0402 0603 0805 1206 1210 1218 2010 2512

Metric size code RR1005M RR1608M RR2012M RR3216M RR3225M RR3246M RR5025M RR6332M

Resistance range 1 to 1 M jumper (0)

Resistance tolerance 5 %; 1 %; 0.5 %

Temperature coefficient 200 ppm/K; 100 ppm/K

Rated dissipation, P70 (1) 0.2 W (2) 0.25 W 0.5 W 0.75 W (3) 0.75 W 1.5 W 1.0 W 1.5 W

Operating voltage,

50 V 75 V 150 V 200 V 200 V 200 V 400 V 500 V

Umax. ACRMS/DC

Permissible film

155 C

temperature, F max. (1)

Operating temperature

-55 C to +155 C

range

Max. resistance change

at P70 for resistance

range, |R/R| after:

1000 h 2.0 %

8000 h 4.0 %

Permissible voltage

against ambient

(insulation):

1 min, Uins 75 V 100 V 200 V 300 V 300 V 300 V 300 V 300 V

Notes

Marking: See document Surface Mount Resistor Marking (www.vishay.com/doc?20020).

(1) Please refer to APPLICATION INFORMATION below.

(2) CRCW0402-HP resistors feature a single side printed resistive layer only.

(3) Specified power rating requires a thermal resistance of R = 110 K/W.

th

APPLICATION INFORMATION

When the resistor dissipates power, a temperature rise above the ambient temperature occurs, dependent on the thermal

resistance of the assembled resistor together with the printed circuit board. The rated dissipation applies only if the permitted

film temperature is not exceeded.

These resistors do not feature a limited lifetime when operated within the permissible limits. However, resistance value drift

increasing over operating time may result in exceeding a limit acceptable to the specific application, thereby establishing a

functional lifetime.

Revision: 16-Sep-16 1 Document Number: 20043

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

CRCW-HP e3

www.vishay.com

Vishay Draloric

TEMPERATURE COEFFICIENT AND RESISTANCE RANGE

TYPE / SIZE TCR TOLERANCE RESISTANCE E-SERIES

200 ppm/K 5% 1 to 1 M E24

1%

CRCW0402-HP e3 100 ppm/K 1 to 1 M E24; E96

0.5 %

Jumper, Imax. = 3 A 10 m 0 -

200 ppm/K 5% 1 to 1 M E24

1%

CRCW0603-HP e3 100 ppm/K 1 to 1 M E24; E96

0.5 %

Jumper, Imax. = 5 A 8 m 0 -

200 ppm/K 5% 1 to 1 M E24

1%

CRCW0805-HP e3 100 ppm/K 1 to 1 M E24; E96

0.5 %

Jumper, Imax. = 6 A 5 m 0 -

200 ppm/K 5% 1 to 1 M E24

1%

CRCW1206-HP e3 100 ppm/K 1 to 1 M E24; E96

0.5 %

Jumper, Imax. = 10 A 5 m 0 -

200 ppm/K 5% 1 to 1 M E24

1%

CRCW1210-HP e3 100 ppm/K 1 to 1 M E24; E96

0.5 %

Jumper, Imax. = 12 A 4 m 0 -

200 ppm/K 5% 1 to 1 M E24

1%

CRCW1218-HP e3 100 ppm/K 1 to 1 M E24; E96

0.5 %

Jumper, Imax. = 20 A 4 m 0 -

200 ppm/K 5% 1 to 1 M E24

1%

CRCW2010-HP e3 100 ppm/K 1 to 1 M E24; E96

0.5 %

Jumper, Imax. = 12 A 5 m 0 -

200 ppm/K 5% 1 to 1 M E24

1%

CRCW2512-HP e3 100 ppm/K 1 to 1 M E24; E96

0.5 %

Jumper, Imax. = 16 A 5 m 0 -

Note

The temperature coefficient of resistance (TCR) is not specified for 0 jumpers.

PACKAGING

PACKAGING

TYPE / SIZE CODE QUANTITY PACKAGING STYLE WIDTH PITCH

DIMENSIONS

ED = ET7 10 000 180 mm / 7"

CRCW0402-HP e3 2 mm

EE = EF4 50 000 330 mm / 13"

EI = ET2 5000 180 mm / 7"

ED = ET3 10 000 180 mm / 7"

2 mm

EL = ET4 20 000 285 mm / 11.25"

CRCW0603-HP e3 EE = ET8 20 000 330 mm / 13"

EA = ET1 5000 180 mm / 7"

EB = ET5 10 000 4 mm 285 mm / 11.25"

EC = ET6 20 000 Paper tape acc. to 330 mm / 13"

8 mm

EA = ET1 5000 IEC 60286-3, Type 1a 180 mm / 7"

CRCW0805-HP e3 EB = ET5 10 000 4 mm 285 mm / 11.25"

EC = ET6 20 000 330 mm / 13"

EA = ET1 5000 180 mm / 7"

CRCW1206-HP e3 EB = ET5 10 000 4 mm 285 mm / 11.25"

EC = ET6 20 000 330 mm / 13"

EA = ET1 5000 180 mm / 7"

CRCW1210-HP e3 EB = ET5 10 000 4 mm 285 mm / 11.25"

EC = ET6 20 000 330 mm / 13"

CRCW1218-HP e3 EK = ET9 4000 4 mm 180 mm / 7"

EF = E02 4000 4 mm 180 mm / 7"

CRCW2010-HP e3 Blister tape acc. to

EJ = E08 16 000 12 mm 4 mm 330 mm / 13"

IEC 60286-3, Type 2a

EG = E67 2000 8 mm

CRCW2512-HP e3 180 mm / 7"

EH = E82 4000 4 mm

Revision: 16-Sep-16 2 Document Number: 20043

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

CRCW-HP e3

www.vishay.com

Vishay Draloric

PART NUMBER AND PRODUCT DESCRIPTION

Part Number: CRCW0603562RFKEAHP

Part Number: CRCW06030000Z0EAHP

C R C W 0 6 0 3 5 6 2 R F K E A H P

TYPE / SIZE VALUE TOLERANCE TCR PACKAGING SPECIAL

CRCW0402 R = decimal D = 0.5 % K = 100 ppm/K EA up to 2 digits

CRCW0603 K = thousand F=1% N = 200 ppm/K EB HP = pulse proof,

CRCW0805 M = million J=5% 0 = jumper EC high power

CRCW1206 0000 = jumper Z = jumper ED

CRCW1210 EE

CRCW1218 EF

CRCW2010 EG

CRCW2512 EI

EJ

EH

EK

EL

Product Description: CRCW0603-HP 100 562R 1 % ET1 e3

Product Description: CRCW0603-HP 0R0 ET1 e3

CRCW0603-HP 100 562R 1% ET1 e3

TYPE / SIZE TCR RESISTANCE VALUE TOLERANCE PACKAGING LEAD (Pb)-FREE

CRCW0402-HP 100 ppm/K 10R = 10 0.5 % ET1, ET2, e3 = pure tin

CRCW0603-HP 200 ppm/K 562R = 562 1% ET3, ET4, termination

CRCW0805-HP 10K = 10 k 5% ET5, ET6, finish

CRCW1206-HP 1M = 1 M ET7, ET8,

CRCW1210-HP 0R0 = jumper ET9, EF4,

CRCW1218-HP E02, E08,

CRCW2010-HP E67, E82

CRCW2512-HP

Revision: 16-Sep-16 3 Document Number: 20043

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

CRCW-HP e3

www.vishay.com

Vishay Draloric

DESCRIPTION The products do not contain any of the banned

Production is strictly controlled and follows an extensive set substances as per IEC 62474, GADSL, or the SVHC list,

of instructions established for reproducibility. A cermet film see www.vishay.com/how/leadfree.

layer and a glass-over are deposited on both sides of a high Hence the products fully comply with the following

grade (Al2O3) ceramic substrate with its prepared inner directives:

contacts on both sides. A special laser is used to achieve 2000/53/EC End-of-Life Vehicle Directive (ELV) and

the target value by smoothly fine trimming the resistive layer Annex II (ELV II)

without damaging the ceramics. The resistor elements are 2011/65/EU Restriction of the Use of Hazardous

covered by a protective coating designed for electrical, Substances Directive (RoHS) with amendment

mechanical and climatic protection. The terminations 2015/863/EU

receive a final pure tin on nickel plating. A three or

2012/19/EU Waste Electrical and Electronic Equipment

four-character code marking designates the resistance

Directive (WEEE)

values in accordance with IEC 60062. The three-character

code system is applicable to values from E24 series only, Vishay pursues the elimination of conflict minerals from its

while the four-character code system is applicable to values supply chain, see the Conflict Minerals Policy at

from E96 and E24 series. www.vishay.com/doc?49037.

The result of the determined production is verified by an

APPROVALS

extensive testing procedure on 100 % of the individual chip

resistors. Only accepted products are laid directly into the The resistors are qualified according to AEC-Q200.

tape in accordance with IEC 60286-3 Type 1a and Where applicable, the resistors are tested in accordance

Type 2a (1). with EN 140401-802 which refers to EN 60115-1,

EN 60115-8 and the variety of environmental test

ASSEMBLY procedures of the IEC 60068 (1) series.

The resistors are suitable for processing on automatic SMD

assembly systems. They are suitable for automatic

soldering wave, reflow or vapor phase as shown in RELATED PRODUCTS

IEC 61760-1 (1). The encapsulation is resistant to all For more information about products with superior surge

cleaning solvents commonly used in the electronics and pulse performance please refer to datasheet:

industry, including alcohols, esters and aqueous solutions. D/CRCW-IF e3, Pulse Proof Thick Film Chip Resistors

The suitability of conformal coatings, potting compounds www.vishay.com/doc?20024.

and their processes, if applied, shall be qualified by For thick film resistors with standard requirements for power

appropriate means to ensure the long-term stability of the rating, please refer to datasheet:

whole system. D/CRCW e3, Standard Thick Film Chip

The resistors are RoHS-compliant, the pure tin plating www.vishay.com/doc?20035.

provides compatibility with lead (Pb)-free and For anti-surge products and high power rating, please refer

lead-containing soldering processes. Solderability is to datasheet:

specified for 2 years after production or requalification. The RCS e3, Anti-Surge High Power Thick Film Chip Resistors

permitted storage time is 20 years. The immunity of the www.vishay.com/doc?20065.

plating against tin whisker growth has been proven under

extensive testing.

MATERIALS

Vishay acknowledges the following systems for the

regulation of hazardous substances:

IEC 62474, Material Declaration for Products of and for the

Electrotechnical Industry, with the list of declarable

substances given therein (2)

The Global Automotive Declarable Substance List

(GADSL) (3)

The REACH regulation (1907/2006/EC) and the related list

of substances with very high concern (SVHC) (4) for its

supply chain

Notes

(1) The quoted IEC standards are also released as EN standards with the same number and identical contents.

(2) The IEC 62474 list of declarable substances is maintained in a dedicated database, which is available at http://std.iec.ch/iec62474.

(3) The Global Automotive Declarable Substance List (GADSL) is maintained by the American Chemistry Council and available at

www.gadsl.org.

(4) The SVHC list is maintained by the European Chemical Agency (ECHA) and available at http://echa.europa.eu/candidate-list-table.

Revision: 16-Sep-16 4 Document Number: 20043

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

CRCW-HP e3

www.vishay.com

Vishay Draloric

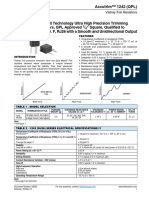

FUNCTIONAL PERFORMANCE

Single Pulse

Axis Title

10 000 10000

Pmax. - Pulse Load (W)

2 nd line

2512

1218

1000 2010

1210

1206

100 0805 1000

0603

2nd line

1st line

0402

10

^

1 100

0.1

0.01 10

0.000001 0.00001 0.0001 0.001 0.01 0.1 1 10 100

ti - Pulse Duration (s)

2nd line

Maximum pulse load, single pulse; applicable if P 0 and n < 1000 and max.;

for permissible resistance change equivalent to 8000 h operation

Continuous Pulse

Axis Title

10 000 10000

Pmax. - Continuous Pulse Load (W)

2 nd line

2512

1218

1000 2010

1210

1206

100 0805 1000

0603

2nd line

1st line

0402

10

1 100

0.1

^

0.01 10

0.000001 0.00001 0.0001 0.001 0.01 0.1 1 10 100

ti - Pulse Duration (s)

2nd line

Maximum pulse load, continuous pulses; applicable if P P (amb) and max.;

for permissible resistance change equivalent to 8000 h operation

Revision: 16-Sep-16 5 Document Number: 20043

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

CRCW-HP e3

www.vishay.com

Vishay Draloric

Pulse Voltage

Axis Title

2000 10000

Umax. - Pulse Voltage (V)

2 nd line

1800 2512

1600

2010

1400

1000

1200

2nd line

1st line

1000

^

800 1206, 1210, 1218

100

600 0805

400

0603

200

0402

0 10

0.000001 0.00001 0.0001 0.001 0.01 0.1 1 10

ti - Pulse Duration (s)

2nd line

Maximum pulse voltage, single and continuous pulses; applicable if P P max . ;

for permissible resistance change equivalent to 8000 h operation

Derating

Axis Title 70

1.8 10000

P - Power Dissipation (W)

CRCW1218-HP, CRCW2512-HP

1.6 CRCW2010-HP

CRCW1206-HP, CRCW1210-HP

CRCW0805-HP

1.4 CRCW0603-HP

2nd line

CRCW0402-HP

1.2 1000

2nd line

1st line

1

0.8

0.6 100

0.4

0.2

0 10

-50 0 50 100 150

amb - Ambient Temperature (C)

2nd line

Revision: 16-Sep-16 6 Document Number: 20043

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

CRCW-HP e3

www.vishay.com

Vishay Draloric

TESTS AND REQUIREMENTS

All executed tests are carried out in accordance with the The testing also covers most of the requirements specified

following specifications: by EIA/IS-703 and JIS-C-5201-1.

EN 60115-1, generic specification The tests are carried out under standard atmospheric

EN 60115-8 (successor of EN 140400), sectional conditions in accordance with IEC 60068-1, 4.3, whereupon

specification the following values are applied:

EN 140401-802, detail specification Temperature: 15 C to 35 C

IEC 60068-2-xx, test methods Relative humidity: 25 % to 75 %

The parameters stated in the Test Procedures and Air pressure: 86 kPa to 106 kPa (860 mbar to 1060 mbar).

Requirements table are based on the required tests A climatic category LCT / UCT / 56 is applied, defined by the

and permitted limits of EN 140401-802. The table presents lower category temperature (LCT), the upper category

only the most important tests, for the full test schedule refer temperature (UCT), and the duration of exposure in the

to the documents listed above. However, some additional damp heat, steady state test (56 days).

tests and a number of improvements against those The components are mounted for testing on boards in

minimum requirements have been included. accordance with EN 60115-8, 2.4.2 unless otherwise

specified.

TEST PROCEDURES AND REQUIREMENTS

IEC

EN 60115-1 60068-2 (1) REQUIREMENTS

TEST PROCEDURE

CLAUSE TEST PERMISSIBLE CHANGE (R)

METHOD

Stability for product types: STABILITY CLASS 2 OR BETTER

CRCW-HP e3 1 to 1 M

4.5 - Resistance - 0.5 %; 1 %; 5 %

Temperature (20 / -55 / 20) C and

4.8 - 100 ppm/K; 200 ppm/K

coefficient (20 / 155 / 20) C

U = P 70 x R or U = Umax.;

whichever is the less severe;

1.5 h on; 0.5 h off

4.25.1 - Endurance at 70 C

70 C; 1000 h (2 % R + 0.1 )

70 C; 8000 h (4 % R + 0.1 )

Endurance at

4.25.3 - upper category 155 C, 1000 h (2 % R + 0.1 )

temperature

Damp heat, (40 2) C; 56 days;

4.24 78 (Cab) (1 % R + 0.05 )

steady state (93 3) % RH;

Damp heat, (85 2) C; (85 5) % RH;

4.37 67 (Cy) steady state, U = 0.1 x P 85 x R 100 V; (2 % R + 0.1 )

accelerated 1000 h

4.23 - Climatic sequence: -

4.23.2 2 (Bb) dry heat 125 C; 16 h

55 C; 24 h; 90 % RH;

4.23.3 30 (Db) damp heat, cyclic

1 cycle

4.23.4 1 (Ab) cold -55 C; 2 h

(2 % R + 0.1 )

4.23.5 13 (M) low air pressure 8.5 kPa; 2 h; (25 10) C

55 C; 24 h;

4.23.6 30 (Db) damp heat, cyclic 90 % RH;

5 cycles

4.23.7 - DC load U= P 70 x R Umax.; 1 min

- 1 (Aa) Cold -55 C; 2 h (0.5 % R + 0.05 )

Revision: 16-Sep-16 7 Document Number: 20043

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

CRCW-HP e3

www.vishay.com

Vishay Draloric

TEST PROCEDURES AND REQUIREMENTS

IEC

EN 60115-1 60068-2 (1) REQUIREMENTS

TEST PROCEDURE

CLAUSE TEST PERMISSIBLE CHANGE (R)

METHOD

Stability for product types: STABILITY CLASS 2 OR BETTER

CRCW-HP e3 1 to 1 M

30 min at -55 C and

Rapid change of (1 % R + 0.05 )

4.19 14 (Na) 30 min at 125 C;

temperature no visible damage

1000 cycles

U = 2.5 x P 70 x R 2 x Umax.;

4.13 - Short time overload whichever is the less severe; (2 % R + 0.05 )

5s

Severity no. 4:

U = 10 x P 70 x R or

Single pulse high (1 % R + 0.05 )

4.27 - U = 2 x Umax.;

voltage overload no visible damage

whichever is the less severe;

10 pulses 10 s/700 s

U= 15 x P 70 x R or

U = 2 x Umax.;

Periodic electric (1 % R + 0.05 )

4.39 - whichever is the less severe;

overload no visible damage

0.1 s on; 2.5 s off;

1000 cycles

Electrostatic IEC 61340-3-1 (1);

4.38 - discharge 3 pos. + 3 neg. discharges; (1 % R + 0.05 )

(human body model) ESD voltage acc. to the size

Endurance by sweeping;

10 Hz to 2000 Hz;

no resonance; (0.5 % R + 0.05 )

4.22 6 (Fc) Vibration

amplitude 1.5 mm or no visible damage

200 m/s2;

7.5 h

Solder bath method;

Sn60Pb40

non-activated flux;

(235 5) C;

(2 0.2) s Good tinning ( 95 % covered)

4.17 58 (Td) Solderability

Solder bath method; no visible damage

Sn96.5Ag3Cu0.5

non-activated flux;

(245 5) C;

(3 0.3) s

Solder bath method

Resistance to

4.18 58 (Td) (260 5) C; (0.5 % R + 0.05 )

soldering heat

(10 1) s

Component solvent Isopropyl alcohol;

4.29 45 (XA) No visible damage

resistance +50 C; method 2

CRCW0402-HP and

Shear CRCW0603-HP: 9 N

4.32 21 (Uu3) No visible damage

(adhesion) CRCW0805-HP to

CRCW2512-HP: 45 N

Depth 2 mm; (0.25 % R + 0.05 )

4.33 21 (Uu1) Substrate bending

3 times no visible damage, no open circuit in bent position

4.7 - Voltage proof U = 1.4 x Uins; 60 s No flashover or breakdown

Flammability, IEC 60695-11-5 (1);

4.35 - No burning after 30 s

needle flame test 10 s

Note

(1) The quoted IEC standards are also released as EN standards with the same number and identical contents.

Revision: 16-Sep-16 8 Document Number: 20043

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

CRCW-HP e3

www.vishay.com

Vishay Draloric

DIMENSIONS

DIMENSIONS AND MASS

L W H T1 T2 MASS

TYPE / SIZE

(mm) (mm) (mm) (mm) (mm) (mg)

CRCW0402-HP e3 1.0 0.05 0.5 0.05 0.3 0.10 0.25 0.10 0.2 0.10 0.65

CRCW0603-HP e3 1.6 0.10 0.85 0.10 0.45 0.10 0.3 0.20 0.3 0.20 2

CRCW0805-HP e3 2.0 0.15 1.25 0.15 0.5 0.10 0.4 0.20 0.35 0.20 5.5

CRCW1206-HP e3 3.1 0.20 1.6 0.15 0.5 0.15 0.5 0.20 0.45 0.20 10

CRCW1210-HP e3 3.2 0.20 2.5 0.20 0.6 0.10 0.45 0.20 0.4 0.20 18

CRCW1218-HP e3 3.1 0.20 4.6 0.20 0.6 0.10 0.45 0.20 0.4 0.20 31

CRCW2010-HP e3 5.0 0.15 2.5 0.15 0.6 0.10 0.6 0.20 0.6 0.20 25.5

CRCW2512-HP e3 6.3 0.20 3.15 0.15 0.6 0.10 0.6 0.20 0.6 0.20 42

SOLDER PAD DIMENSIONS

G X

Y

Z

RECOMMENDED SOLDER PAD DIMENSIONS

WAVE SOLDERING REFLOW SOLDERING

TYPE / SIZE G Y X Z G Y X Z

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

CRCW0402-HP e3 - - - - 0.45 0.6 0.6 1.65

CRCW0603-HP e3 0.65 1.10 1.25 2.85 0.75 0.75 1.00 2.25

CRCW0805-HP e3 0.90 1.30 1.60 3.50 1.00 0.95 1.45 2.90

CRCW1206-HP e3 1.40 1.40 1.95 4.20 1.50 1.05 1.8 3.60

CRCW1210-HP e3 1.80 1.45 2.95 4.70 1.70 1.10 2.80 4.90

CRCW1218-HP e3 1.60 1.50 5.10 4.60 1.70 1.10 4.90 4.90

CRCW2010-HP e3 3.60 1.65 2.85 6.90 3.70 1.20 2.70 6.10

CRCW2512-HP e3 4.90 1.60 3.50 8.10 5.00 1.25 3.35 7.50

Notes

The given solder pad dimensions reflect the considerations for board design and assembly as outlined e.g in standards IEC 61188-5-x (1) or

in publication IPC-7351.

Still, the given solder pad dimensions will be found adequate for most general applications.

(1) The quoted IEC standards are also released as EN standards with the same number and identical contents.

Revision: 16-Sep-16 9 Document Number: 20043

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

Vishay), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishays knowledge of

typical requirements that are often placed on Vishay products in generic applications. Such statements are not binding

statements about the suitability of products for a particular application. It is the customers responsibility to validate that a

particular product with the properties described in the product specification is suitable for use in a particular application.

Parameters provided in datasheets and / or specifications may vary in different applications and performance may vary over

time. All operating parameters, including typical parameters, must be validated for each customer application by the customers

technical experts. Product specifications do not expand or otherwise modify Vishays terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk.

Please contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for

such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document

or by any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

Revision: 13-Jun-16 1 Document Number: 91000

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Vishay:

CRCW12062K00FKEAHP CRCW120610K0FKEAHP CRCW201010R0FKEFHP CRCW1206100KFKEAHP

CRCW120615K0FKEAHP CRCW12061R00JNEAHP CRCW120610R0FKEAHP CRCW12061K00FKEAHP

CRCW04020000Z0EDHP CRCW06030000Z0EAHP CRCW12060000Z0EAHP CRCW08050000Z0EAHP

CRCW0603100KFKEAHP CRCW121012R0JNEAHP CRCW1210510RJNEAHP CRCW1210240RJNEAHP

CRCW12103K30FKEAHP CRCW1210750RFKEAHP CRCW1210150RFKEAHP CRCW06032M49DHEAP

CRCW04021K00FKEDHP CRCW040210K0FKEDHP CRCW060310K0FKEAHP CRCW06031K00FKEAHP

CRCW08051K00FKEAHP CRCW080510K0FKEAHP CRCW251210R0FKEGHP CRCW2512100RFKEGHP

CRCW201010K0FKEFHP CRCW2010100RFKEFHP CRCW20101K00FKEFHP CRCW25121K00FKEGHP

CRCW080520K0FKEAHP CRCW20102K21FKEFHP CRCW08051R00FKEAHP CRCW080515R0FKEAHP

CRCW12061R00FKEAHP CRCW0402100KFKEDHP CRCW0402100KJNEDHP CRCW0402100RFKEDHP

CRCW0402100RJNEDHP CRCW040210K0JNEDHP CRCW040210R0FKEDHP CRCW040210R0JNEDHP

CRCW040215K0FKEDHP CRCW04021K00JNEDHP CRCW04021K50FKEDHP CRCW04021M00FKEDHP

CRCW04021M00JNEDHP CRCW04021R00FKEDHP CRCW04021R00JNEDHP CRCW040220K0FKEDHP

CRCW0402220KJNEDHP CRCW0402220RJNEDHP CRCW040222K0JNEDHP CRCW040222R0FKEDHP

CRCW040222R0JNEDHP CRCW040222R1FKEDHP CRCW04022K00FKEDHP CRCW04022K20JNEDHP

CRCW04022R20JNEDHP CRCW040233R0FKEDHP CRCW040233R2FKEDHP CRCW0402470KJNEDHP

CRCW0402470RJNEDHP CRCW040247K0FKEDHP CRCW040247K0JNEDHP CRCW040247R0JNEDHP

CRCW0402499RFKEDHP CRCW040249K9FKEDHP CRCW040249R9FKEDHP CRCW04024K70FKEDHP

CRCW04024K70JNEDHP CRCW04024K75FKEDHP CRCW04024K99FKEDHP CRCW04024R70JNEDHP

CRCW040275R0FKEDHP CRCW0603100KJNEAHP CRCW0603100RFKEAHP CRCW0603100RJNEAHP

CRCW060310K0JNEAHP CRCW060310R0FKEAHP CRCW060310R0JNEAHP CRCW060315K0FKEAHP

CRCW06031K00JNEAHP CRCW06031K50FKEAHP CRCW06031M00FKEAHP CRCW06031M00JNEAHP

CRCW06031R00FKEAHP CRCW06031R00JNEAHP CRCW060320K0FKEAHP CRCW0603220KJNEAHP

CRCW0603220RJNEAHP CRCW060322K0JNEAHP CRCW060322R0JNEAHP CRCW06032K00FKEAHP

CRCW06032K20JNEAHP CRCW06032R20JNEAHP CRCW060330K9FKEAHP CRCW060333R0FKEAHP

Вам также может понравиться

- RCS E3: VishayДокумент10 страницRCS E3: VishayMae MegumiОценок пока нет

- D/CRCW E3: VishayДокумент10 страницD/CRCW E3: VishayBenyamin Farzaneh AghajarieОценок пока нет

- RCA-HP E3: Vishay DraloricДокумент10 страницRCA-HP E3: Vishay DraloricMohendra PatiОценок пока нет

- CRCW-HP E3: Vishay DraloricДокумент10 страницCRCW-HP E3: Vishay DraloricMohendra PatiОценок пока нет

- SMDДокумент6 страницSMDJose SCОценок пока нет

- Bourns CRM2512 DatasheetДокумент5 страницBourns CRM2512 DatasheetbarisОценок пока нет

- Sfr16S/25/25H: Vishay BccomponentsДокумент11 страницSfr16S/25/25H: Vishay BccomponentsMuhammad BilalОценок пока нет

- Resistor DatasheetДокумент10 страницResistor DatasheetEndradno KurniaОценок пока нет

- CRCW0201 E3: VishayДокумент5 страницCRCW0201 E3: VishaycuperiniОценок пока нет

- ETEC225 Lecture 9Документ22 страницыETEC225 Lecture 9none of urОценок пока нет

- Componete ElectronicoДокумент5 страницComponete ElectronicoStuxnetОценок пока нет

- D/CRCW-P E3: VishayДокумент6 страницD/CRCW-P E3: VishayMohendra PatiОценок пока нет

- Bourns CRM0805 DatasheetДокумент5 страницBourns CRM0805 DatasheetbarisОценок пока нет

- Stackpole RNCP Series High Power Anti-Sulfur Thin Film Chip ResistorsДокумент4 страницыStackpole RNCP Series High Power Anti-Sulfur Thin Film Chip ResistorsGabriel VargasОценок пока нет

- Inbound 1310313221Документ2 страницыInbound 1310313221freedownОценок пока нет

- Carbon Composition ResistorДокумент2 страницыCarbon Composition ResistorEmmanuelSanzОценок пока нет

- HVR 2537Документ7 страницHVR 2537Damián PastreОценок пока нет

- Thick Film Chip Resistors: DescriptionДокумент1 страницаThick Film Chip Resistors: DescriptionAutor AutorОценок пока нет

- Accutrim™ 1242 (QPL) : Vishay Foil ResistorsДокумент5 страницAccutrim™ 1242 (QPL) : Vishay Foil ResistorsDaniel HubencuОценок пока нет

- SFR 25Документ9 страницSFR 25Jose Normando SoaresОценок пока нет

- Vishay Beyschlag: FeaturesДокумент11 страницVishay Beyschlag: FeaturesBích Trâm Đào HoàngОценок пока нет

- MPT 221Документ3 страницыMPT 221marina anastasovaОценок пока нет

- Vishay Foil Resistors: FeaturesДокумент7 страницVishay Foil Resistors: FeaturesMahemehr MehrОценок пока нет

- Kem F3050 C44P Radial-1103058Документ9 страницKem F3050 C44P Radial-1103058Alexander MedinaОценок пока нет

- Thick Film Chip Resistor - General PurposeДокумент8 страницThick Film Chip Resistor - General PurposeDarwin SipayungОценок пока нет

- Rogers MaterialДокумент4 страницыRogers MaterialRobert ZmrzliОценок пока нет

- Resistor SMD SizesДокумент11 страницResistor SMD Sizescarlos.antouryОценок пока нет

- Aluminum Single-Point Load Cell Aluminum Single-Point Load CellДокумент3 страницыAluminum Single-Point Load Cell Aluminum Single-Point Load CellMakhis RifaiОценок пока нет

- Lead (Pb)-Bearing Thick Film Chip ResistorsДокумент8 страницLead (Pb)-Bearing Thick Film Chip ResistorsManu MathewОценок пока нет

- PHC Series PDFДокумент3 страницыPHC Series PDFguruh anindraОценок пока нет

- Error Code Captiva P700Документ4 страницыError Code Captiva P700Sudjono BroОценок пока нет

- AWCCA-48R32 Series: Moisture Sensitivity Level (MSL) - MSL 1Документ2 страницыAWCCA-48R32 Series: Moisture Sensitivity Level (MSL) - MSL 1cbdk71Оценок пока нет

- UMA 0204, UMB 0207: Vishay BeyschlagДокумент11 страницUMA 0204, UMB 0207: Vishay BeyschlagManu MathewОценок пока нет

- Célula de Carga Balança IkeaДокумент3 страницыCélula de Carga Balança IkeatrutleptОценок пока нет

- SM6S10 Thru SM6S36A: High Temperature Stability and High Reliability ConditionsДокумент5 страницSM6S10 Thru SM6S36A: High Temperature Stability and High Reliability ConditionsStuxnetОценок пока нет

- 1N6267 Fagor PDFДокумент8 страниц1N6267 Fagor PDFHyacinthe Bertrand RazafindramenaОценок пока нет

- Tabela ResistoreДокумент13 страницTabela Resistorewillian GaldinoОценок пока нет

- MCF 0.5W 1M MCF 0.5W 470K MCF 0.5W 820R MCF 1W 1R5 MCF 1W 330K MCF 1W 33K MCF 1W 680K MCF 1W 68K MCF 1W 68R MCF 2W 150K MCF 2W 470K MCF 2W 680K 287-11040 287-11050 287-11080Документ13 страницMCF 0.5W 1M MCF 0.5W 470K MCF 0.5W 820R MCF 1W 1R5 MCF 1W 330K MCF 1W 33K MCF 1W 680K MCF 1W 68K MCF 1W 68R MCF 2W 150K MCF 2W 470K MCF 2W 680K 287-11040 287-11050 287-11080willian GaldinoОценок пока нет

- 250rd Datasheet - 021753Документ6 страниц250rd Datasheet - 021753amr elnawamОценок пока нет

- CMP Series High Power Anti-Surge Chip Resistors: Features ApplicationsДокумент8 страницCMP Series High Power Anti-Surge Chip Resistors: Features ApplicationsRachmad syahputra SyzgОценок пока нет

- Baumer PBMN-Flush DS EN 1304 PDFДокумент4 страницыBaumer PBMN-Flush DS EN 1304 PDFJose Vicente CentellesОценок пока нет

- Tension Compression Load Cell Tension Compression Load Cell: Model 614Документ3 страницыTension Compression Load Cell Tension Compression Load Cell: Model 614Juan Carlos BallinariОценок пока нет

- Specification Sheet for Samsung Multi-layer Ceramic CapacitorДокумент3 страницыSpecification Sheet for Samsung Multi-layer Ceramic Capacitorelias rangelОценок пока нет

- MCS 0402, MCT 0603, MCU 0805, MCA 1206 - Professional: Vishay BeyschlagДокумент13 страницMCS 0402, MCT 0603, MCU 0805, MCA 1206 - Professional: Vishay BeyschlaglalithkumartОценок пока нет

- SBSM Data SheetДокумент4 страницыSBSM Data SheetAlex JonesОценок пока нет

- Digi SM300 ManualДокумент3 страницыDigi SM300 ManualWilly Bracamonte TellesОценок пока нет

- High-Resistance High-Voltage Decade Subs - Tuter: HRRS 5kV and 10kV SeriesДокумент2 страницыHigh-Resistance High-Voltage Decade Subs - Tuter: HRRS 5kV and 10kV SeriesAlberto Mendoza ReséndizОценок пока нет

- RGP30A Thru RGP30M: Vishay General SemiconductorДокумент4 страницыRGP30A Thru RGP30M: Vishay General SemiconductorRohit SumanОценок пока нет

- Polypropylene Ppa 684d47baceДокумент6 страницPolypropylene Ppa 684d47baceRafael PaivaОценок пока нет

- Item 108 (Pressure Switch MBC 5100)Документ3 страницыItem 108 (Pressure Switch MBC 5100)AlexDor100% (1)

- OneMountShearB HISBH04Документ4 страницыOneMountShearB HISBH04Emmanuel SidesОценок пока нет

- CMP AДокумент8 страницCMP AFotos WD DiacoОценок пока нет

- 2864 VT DS 2864-EN 614 LoresДокумент3 страницы2864 VT DS 2864-EN 614 Lorestulio enrique leon ayalaОценок пока нет

- TNPW E3-1761965Документ15 страницTNPW E3-1761965João JoséОценок пока нет

- Ac, Ac-At: Vishay DraloricДокумент12 страницAc, Ac-At: Vishay Draloricjns1606Оценок пока нет

- DC/DC Converter Isolation 3000V 1W SIP RoHSДокумент4 страницыDC/DC Converter Isolation 3000V 1W SIP RoHSBahman Pour JafariОценок пока нет

- DatasheetДокумент5 страницDatasheetAliTronic1972Оценок пока нет

- CRCW25123K30JNTG DatasheetzДокумент8 страницCRCW25123K30JNTG DatasheetzVadim ZorinОценок пока нет

- RT/duroid 6006/6010LM High Frequency Laminates: FeaturesДокумент2 страницыRT/duroid 6006/6010LM High Frequency Laminates: FeaturesyyryОценок пока нет

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesОт EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesОценок пока нет

- PDFДокумент4 страницыPDFNidhi PanditОценок пока нет

- 06855351Документ4 страницы06855351Nidhi PanditОценок пока нет

- Microwave Transistor Amplifiers Analysis and DesignДокумент516 страницMicrowave Transistor Amplifiers Analysis and DesignSudip95% (37)

- Introduction To Digital Communications and Information TheoryДокумент8 страницIntroduction To Digital Communications and Information TheoryRandall GloverОценок пока нет

- CDF 2Документ7 страницCDF 2himaanshu09Оценок пока нет

- Random Processes: Version 2, ECE IIT, KharagpurДокумент8 страницRandom Processes: Version 2, ECE IIT, KharagpurHarshaОценок пока нет

- Design of Microstrip Patch Antenna Using Slotted Partial Ground and Addition of Stairs and Stubs For UWB ApplicationДокумент8 страницDesign of Microstrip Patch Antenna Using Slotted Partial Ground and Addition of Stairs and Stubs For UWB ApplicationNidhi PanditОценок пока нет

- M 2 L 5Документ9 страницM 2 L 5RupaShawОценок пока нет

- PDFДокумент19 страницPDFNidhi PanditОценок пока нет

- Planar Band-Notched Ultra-Wideband Antenna With Square-Looped and End-Coupled ResonatorДокумент7 страницPlanar Band-Notched Ultra-Wideband Antenna With Square-Looped and End-Coupled ResonatorNidhi PanditОценок пока нет

- M 1 L 2Документ14 страницM 1 L 2Sandeep AngaraОценок пока нет

- PDFДокумент4 страницыPDFNidhi PanditОценок пока нет

- Digital Communication NotesДокумент12 страницDigital Communication Notesravindarsingh50% (2)

- M 1 L 3Документ9 страницM 1 L 3sakthirsivarajanОценок пока нет

- EC 2014 SolvedДокумент30 страницEC 2014 SolvedTapasRout0% (1)

- Gatepapers GATE2015 New EC-GATE-15-Paper-03 New2Документ31 страницаGatepapers GATE2015 New EC-GATE-15-Paper-03 New2raja_4uОценок пока нет

- EC 2003 UnsolvedДокумент20 страницEC 2003 Unsolvedsreekantha2013Оценок пока нет

- Ec 2001Документ19 страницEc 2001Smit MajithiaОценок пока нет

- EC GATE 15 Paper 01 - New PDFДокумент33 страницыEC GATE 15 Paper 01 - New PDFVikas PsОценок пока нет

- EC GATE'14 Paper 04Документ30 страницEC GATE'14 Paper 04SanyaRoyОценок пока нет

- Ec 1993 PDFДокумент19 страницEc 1993 PDFarunathangamОценок пока нет

- EC GATE'14 Paper 03 PDFДокумент33 страницыEC GATE'14 Paper 03 PDFTkschandra SekharОценок пока нет

- EC 2014 SolvedДокумент30 страницEC 2014 SolvedTapasRout0% (1)

- Gatepapers GATE2015 New EC-GATE-15-Paper-02 New2Документ36 страницGatepapers GATE2015 New EC-GATE-15-Paper-02 New2raja_4uОценок пока нет

- EC 2004 Unsolved PDFДокумент21 страницаEC 2004 Unsolved PDFNidhi PanditОценок пока нет

- Gate 2002 Exam Question KeysДокумент20 страницGate 2002 Exam Question KeysAman AnandОценок пока нет

- YUMMY TUMMY - Beef Biryani Recipe - Beef Dum Biryani RecipeДокумент48 страницYUMMY TUMMY - Beef Biryani Recipe - Beef Dum Biryani RecipeWilliam Cj LyngdohОценок пока нет

- Hiv MCQДокумент89 страницHiv MCQEliza Spark80% (5)

- Types of Industrial DisputesДокумент12 страницTypes of Industrial DisputesAntony MwangiОценок пока нет

- Duties and Responsibilities of Housekeeping Staff:-1) Executive Housekeeper/Director of HousekeepingДокумент8 страницDuties and Responsibilities of Housekeeping Staff:-1) Executive Housekeeper/Director of HousekeepingsachinОценок пока нет

- DSI-DYWIDAG Geotechnics Rock Bolts enДокумент6 страницDSI-DYWIDAG Geotechnics Rock Bolts enTomás Nunes da SilvaОценок пока нет

- Deutz-Fahr Workshop Manual for AGROTRON MK3 ModelsДокумент50 страницDeutz-Fahr Workshop Manual for AGROTRON MK3 Modelstukasai100% (1)

- SKC EPAM-5000 Instruction Manual PDFДокумент90 страницSKC EPAM-5000 Instruction Manual PDFmegacobОценок пока нет

- GEK_30375M Lubrication SpecificationsДокумент34 страницыGEK_30375M Lubrication SpecificationsMARITZA GABRIELA ARIZABAL MEDINAОценок пока нет

- Full Test 14 (Key) PDFДокумент4 страницыFull Test 14 (Key) PDFhoang lichОценок пока нет

- Multiple Choice RadioactivityДокумент4 страницыMultiple Choice RadioactivityGodhrawala AliasgerОценок пока нет

- O-Rings & SealsДокумент10 страницO-Rings & SealsPartsGopher.comОценок пока нет

- Periodic Table of Personality ElementsДокумент1 страницаPeriodic Table of Personality Elementslilian_vera_1Оценок пока нет

- A Lesson Design in HELE 6 Chapter 2Документ6 страницA Lesson Design in HELE 6 Chapter 2Jestoni Paragsa100% (5)

- Crosbys Molasses and MoreДокумент37 страницCrosbys Molasses and MoreShaikh MeenatullahОценок пока нет

- HemophiliaДокумент62 страницыHemophiliamuhirwa Samuel100% (1)

- Pathway StemiДокумент2 страницыPathway StemiIntan Nurulita SariОценок пока нет

- Original Instruction Manual: Hypro Series 9303Документ24 страницыOriginal Instruction Manual: Hypro Series 9303vandoОценок пока нет

- Crypto Hash Algorithm-Based Blockchain Technology For Managing Decentralized Ledger Database in Oil and Gas IndustryДокумент26 страницCrypto Hash Algorithm-Based Blockchain Technology For Managing Decentralized Ledger Database in Oil and Gas IndustrySIMON HINCAPIE ORTIZОценок пока нет

- Unit 23 The Interior LandscapeДокумент21 страницаUnit 23 The Interior LandscapesОценок пока нет

- ITC's diverse businesses: cigarettes, packaging, hotels, paperboards, stationery, matches, incense sticks, retail, food, exportsДокумент1 страницаITC's diverse businesses: cigarettes, packaging, hotels, paperboards, stationery, matches, incense sticks, retail, food, exportsShashank JainОценок пока нет

- Different Types of Volcanic HazardsДокумент5 страницDifferent Types of Volcanic HazardsJohn Carlo BañasОценок пока нет

- Non Ferrous AlloysДокумент45 страницNon Ferrous AlloysDeepak NegiОценок пока нет

- Geoheritage of Labuan Island: Bulletin of The Geological Society of Malaysia December 2016Документ14 страницGeoheritage of Labuan Island: Bulletin of The Geological Society of Malaysia December 2016songkkОценок пока нет

- Police Log January 23, 2016Документ9 страницPolice Log January 23, 2016MansfieldMAPoliceОценок пока нет

- Philippine STEM Module Explains Photoelectric EffectДокумент12 страницPhilippine STEM Module Explains Photoelectric EffectJp menorОценок пока нет

- 700 - 900 Error Codes PDFДокумент1 страница700 - 900 Error Codes PDFIsai Lara OsoriaОценок пока нет

- Lesson Plan The Food: TH THДокумент8 страницLesson Plan The Food: TH THFeraru FlorinОценок пока нет

- Effects of Climate ChangeДокумент10 страницEffects of Climate ChangeJan100% (1)

- DIAGEO2Документ12 страницDIAGEO2Tatiana Zuleta RojasОценок пока нет

- 02-Plant Morphology (Exercise)Документ5 страниц02-Plant Morphology (Exercise)varshavishuОценок пока нет