Академический Документы

Профессиональный Документы

Культура Документы

23 IKO Poster Casting Defects

Загружено:

Milica Antic0%(1)0% нашли этот документ полезным (1 голос)

983 просмотров1 страницаOvo predstavlja slikegrešaka livenja.

Оригинальное название

130198699 23 IKO Poster Casting Defects

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документOvo predstavlja slikegrešaka livenja.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0%(1)0% нашли этот документ полезным (1 голос)

983 просмотров1 страница23 IKO Poster Casting Defects

Загружено:

Milica AnticOvo predstavlja slikegrešaka livenja.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

S&B Industrial Minerals GmbH

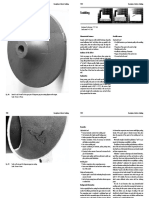

Burn on Broken Mould Erosion

Nature of Defect Nature of Defect Nature of Defect

Thin sand crusts firmly Flash-like metal penetration in The sand is washed away,

adhering to the casting. the mould, sometimes parts of mostly near to the sprue, often

Defect occursmore frequently the mould are included in the accompanied by sand inclu-

with thickwalled castings at casting. sions. Bulges arise on the

high castingtemperature. casting near to the gate.

Remedies

Remedies Add more bentonite to increase Remedies

Increase amount of lustrous green tensile strength. Avoid drying out of the moul-

carbon producers and coke pro- Raise compactability of the ding sand. Increase amount of

ducers in the moulding sand. moulding sand. bentonite in the sand. Increase

Increase amount of new sand milling time of the moulding

if sintering point of the sand is sand. Increase mould com-

low and oolitization is high. paction. Use carbonaceous

additive with a high lustrous

carbon producing ability.

Explosion Penetration Lustrous Carbon Inclusions Fissure Defect

Nature of Defect Nature of Defect Nature of Defect

Extensive penetration, when Formation of surface irregula- Narrow, crack-like cavities

the mould is filled too quickly. rities, inclusions and laps due vertical to the surface. Dendrite

to non-wetting characteristic of formation in the cavities.

Remedies lustrous carbon, often associ-

Reduce amount of free water. ated with the use of Cold-Box Remedies

Increase milling time of the cores. The defect is of a metallurgical

moulding sand. Increase ooliti- nature due to too much nitro-

zation rate of the moulding Remedies gen contained in the iron.

sand. Use dried Cold-Box cores. Reduce the amount of nitrogen

Reduce amount of lustrous in the moulding sand. Use low

carbon producer in the nitrogen containing carbon-

moulding sand. Use carbon- aceous additive. Reduce

aceous additive with a higher addition of carbonaceous

coking residue. additive in the moulding sand.

Moulding Sand

Micro Shrinkage Scarred Surface Blow Holes

Nature of defect Nature of Defect Nature of Defect

Porous structure found in the Scarred casting surface around Cavities with smooth walls,

area of the casting which is last hot spots, particularly with SG singularly or in groups.

to solidify. cast iron.

Remedies

Remedies Remedies Low casting temperatures are

Defect occurs with alloys having Reduce amount of impurities often the cause. Benefits may

a wide solidification range. present in the sand that are be obtained by increasing

Little influencing by the moul- destroying the oxide skin. mould permeability.

ding sand. Reduction of organic Reduce fines or add coarser

material and an increase in the new sand. Reduce organic

moisture level will improve additions to the sand.

thermal conductivity of the

moulding sand.

Penetration Pin Holes Roughness

Nature of Defect Nature of Defect Nature of Defect

Roughness caused by the Accumulation of small sub- Rough casting surface finish

molten metal penetrating the surface rounded holes. due to coarse sand.

immediate sand grains of the Defects appear after annealing

mould surface, particularly in and light machining. Remedies

softly rammed areas. Use finer sand. Increase amount

Remedies of lustrous carbon producing

Remedies Normally the defect is of a material in the moulding sand.

Use finer sand. Improve ram- metallurgical nature. Increase the amount of fines

ming of the moulds. Reduce The mould material may have e.g. coke in the sand.

compactability of the moulding a certain effect. In case of pin

sand. Increase amount of holes the moisture, the organic

carbonaceous additive. Increase additions and the amount of

amount of coke in the moul- nitrogen in the moulding sand

ding sand. should be reduced.

Sand inclusions Slag inclusions Scabs

Nature of Defect Nature of Defect Nature of Defect

Irregularly formed sand Non-metallic irregular shaped Mushroom type defect with

inclusions just underneath the inclusions, when occurring, sharp edges parallel to the

casting surface, associated with tend to be on upper casting casting surface.

products from the metal slag surfaces.

reaction in other areas. Remedies

Remedies Increase bentonite level.

Remedies The defects are caused by Use carbonaceous additive with

Keep the moulding sand suffi- slag being present with the a wide softening range.

ciently plastic by good sand molten metal in the pouring Increase the amount of

preparation and sand cooling. ladle. If the formation is due carbonaceous additive in the

Adjust to optimum compac- to eroded sand, reduce the moulding sand.

tability. Reduce the tendency amount of inert fines and use

of the mould to stick to the a more active lustrous carbon

pattern by the use of parting producer. Increase milling time

agents. of the moulding sand.

Swells Metal Penetration Blow Holes at Angles

Nature of Defect Nature of Defect Nature of Defect

Irregular bulges, in most cases Firmly adhering agglomerates Smooth wall cavities at the

widely spread, sometimes with of sand/metal at hot spots and angles of the casting.

rough surface and/or pene- in softly rammed areas.

tration. Remedies

Remedies The cause is insufficient feeding

Remedies Reduce compactability of the and rate of solidification.

Reduce compactability of the sand. Improve ramming of the Influencing by moulding sand

moulding sand. Ram moulds moulds. Increase amount of is possible. Reduce the moisture

better and more evenly. carbonaceous additive and coke content and the organic

Make sand less sensitive to in the moulding sand. additions of the sand.

over- and underramming by Improve the venting of the

increasing the amount of mould.

bentonite.

Вам также может понравиться

- Types of Casting Defects: Admin November 23, 2017 Casting Defect1Документ5 страницTypes of Casting Defects: Admin November 23, 2017 Casting Defect1Nasir SoudagarОценок пока нет

- 23-IKO Poster Casting DefectsДокумент1 страница23-IKO Poster Casting DefectsGopal Jetani50% (2)

- Lecture 3 Casting Surface DefectsДокумент72 страницыLecture 3 Casting Surface DefectsLuis Arturo RamirezОценок пока нет

- Common Metallurgical Defects in Ductile Cast Iron PDFДокумент1 страницаCommon Metallurgical Defects in Ductile Cast Iron PDFsskiitb100% (2)

- 16 ScabbingДокумент4 страницы16 Scabbingvivek13120% (1)

- Casting DefectsДокумент5 страницCasting DefectsGurjinder SinghОценок пока нет

- Casting Defect - Fissure DefectsДокумент3 страницыCasting Defect - Fissure Defectsvivek1312Оценок пока нет

- Casting Inspection NDTДокумент8 страницCasting Inspection NDTdombipinОценок пока нет

- Casting Defects - Sand Mold, Metal CastingДокумент12 страницCasting Defects - Sand Mold, Metal CastingFarhan EllahiОценок пока нет

- Lack of Root Fusion Lack of Root PenetrationДокумент35 страницLack of Root Fusion Lack of Root PenetrationAdil Hasanov100% (1)

- Weld-Defects A - TWI PDFДокумент97 страницWeld-Defects A - TWI PDFMKPashaPasha100% (2)

- Casting DefectsДокумент35 страницCasting DefectsYaser Mohamed AbasОценок пока нет

- Casting DefectsДокумент60 страницCasting DefectsVaibhav AwacharОценок пока нет

- Casting Defects - Sand Mold, Metal Casting PDFДокумент10 страницCasting Defects - Sand Mold, Metal Casting PDFAbhinav Pratap MauryaОценок пока нет

- Discontinuities and DefectsДокумент12 страницDiscontinuities and DefectsPatrick Dominguez100% (1)

- Welddefects As Per Iso 5817Документ40 страницWelddefects As Per Iso 5817shruthiОценок пока нет

- Common Metallurgical Defects in Grey Iron English (1Документ1 страницаCommon Metallurgical Defects in Grey Iron English (1sateeshkori100% (2)

- Casting DefectsДокумент12 страницCasting Defectssushil.vgiОценок пока нет

- 50 Casting DefectsДокумент49 страниц50 Casting DefectsmohammadОценок пока нет

- Factors Affecting CastingДокумент6 страницFactors Affecting CastingMuhammad BilalОценок пока нет

- (EW-471) - Gas Metal Arc Welding (2012 - 1998, Hobart Institute of Welding Technology)Документ9 страниц(EW-471) - Gas Metal Arc Welding (2012 - 1998, Hobart Institute of Welding Technology)Juan Diego AlvarezОценок пока нет

- Iqi Wire Type BSEN 462-1 PDFДокумент13 страницIqi Wire Type BSEN 462-1 PDFThe Normal HeartОценок пока нет

- Barc L2Документ152 страницыBarc L2gladson67% (3)

- DefectologyДокумент91 страницаDefectologySivasankaran Raju100% (6)

- Casting Processes CompleteДокумент49 страницCasting Processes CompleteRavi KumarОценок пока нет

- Basic Weld MetallurgyДокумент34 страницыBasic Weld Metallurgydaha333Оценок пока нет

- Slide 4 Casting Defects and Heat TreatmentДокумент58 страницSlide 4 Casting Defects and Heat TreatmentgunjanОценок пока нет

- 112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Документ33 страницы112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Carlos Nombela PalaciosОценок пока нет

- SCRATA Casting Surface QualityДокумент43 страницыSCRATA Casting Surface QualityHarold Gill100% (9)

- Fundamentals of Visual InspectionДокумент49 страницFundamentals of Visual InspectionsusanwebОценок пока нет

- Casting DefectsДокумент39 страницCasting DefectsAnup Tigga100% (3)

- Characterization of Casting Defect in Typical Castings of A Directionally Solidified SuperalloyДокумент134 страницыCharacterization of Casting Defect in Typical Castings of A Directionally Solidified SuperalloyChun-Yi LinОценок пока нет

- Foundry DefectsДокумент74 страницыFoundry DefectsdanielsasikumarОценок пока нет

- 350 Master CanДокумент113 страниц350 Master CanSangeeth.KpОценок пока нет

- Chapter-1c-Casting Defects and Remedies PDFДокумент71 страницаChapter-1c-Casting Defects and Remedies PDFakrishu100% (1)

- Casting DefectsДокумент61 страницаCasting DefectsVikas NagarОценок пока нет

- Forging DefectsДокумент12 страницForging DefectsBalram JiОценок пока нет

- Handbook of Casting DefectsДокумент90 страницHandbook of Casting DefectsKamal Thummar100% (1)

- WIS5 Paper 1 Rev 3Документ4 страницыWIS5 Paper 1 Rev 3ghcalotaОценок пока нет

- Effect of Bismuth in Ductile IronДокумент4 страницыEffect of Bismuth in Ductile Ironmarcotulio123100% (2)

- Weld Defects PresentationДокумент80 страницWeld Defects PresentationRen SalazarОценок пока нет

- Cordon Off - 4 (00000003)Документ1 страницаCordon Off - 4 (00000003)Anonymous PlyxbQ3tОценок пока нет

- Standards by Iso Steel CastingsДокумент4 страницыStandards by Iso Steel CastingsrajagopalОценок пока нет

- Defects in Fusion WeldingДокумент83 страницыDefects in Fusion WeldingBalakumar100% (1)

- PT Theory English New 2014Документ44 страницыPT Theory English New 2014CRISTIAN SILVIU IANUCОценок пока нет

- AMCOL - MCST - TR - HeviSand - Chromite - Double - Skin Defect - On - Heavy - Steel - Casting PDFДокумент12 страницAMCOL - MCST - TR - HeviSand - Chromite - Double - Skin Defect - On - Heavy - Steel - Casting PDFSUNDRAMNAGAОценок пока нет

- NDT Procedure Casting 17.03.13Документ16 страницNDT Procedure Casting 17.03.13Jiten Karmakar100% (1)

- Casting Defects, Causes, and RemediesДокумент33 страницыCasting Defects, Causes, and Remediesahmedenghesham100% (1)

- Sand Casting Defects PosterДокумент1 страницаSand Casting Defects Posterleh antОценок пока нет

- 05 Lustrous Carbon Incl PDFДокумент2 страницы05 Lustrous Carbon Incl PDFbvphimanshuОценок пока нет

- Burnt-On SandДокумент2 страницыBurnt-On SandJOHNSONОценок пока нет

- 20 Green Sand Casting Defects and Their Suggested RemediesДокумент4 страницы20 Green Sand Casting Defects and Their Suggested RemediesPatil Amol PandurangОценок пока нет

- Defectos Soluciones PDFДокумент9 страницDefectos Soluciones PDFCaballero RrzОценок пока нет

- Casting Defects: Defects Due To Evolution of GasesДокумент3 страницыCasting Defects: Defects Due To Evolution of GasesRathodVijayОценок пока нет

- 20020203a PDFДокумент4 страницы20020203a PDFtalk2sumantaОценок пока нет

- Casting - Processes - and - Defects 1Документ1 страницаCasting - Processes - and - Defects 1Nunya ByznisОценок пока нет

- Infographic: Common Drilling Mud Problems - Causes and SolutionsДокумент1 страницаInfographic: Common Drilling Mud Problems - Causes and SolutionsPegasus Vertex, Inc.Оценок пока нет

- Carbonitrided Rolling BearingsДокумент8 страницCarbonitrided Rolling BearingsRodrigo Jechéla BarriosОценок пока нет

- Dokumen - Tips - 28 Elkemposter Common Metallurgical Defects in Ductile Irons PDFДокумент2 страницыDokumen - Tips - 28 Elkemposter Common Metallurgical Defects in Ductile Irons PDFMD ISMAILОценок пока нет

- Green Sand Casting Defect!: NameДокумент8 страницGreen Sand Casting Defect!: Namekarthick rajaОценок пока нет

- PT Kurs AmerickiДокумент68 страницPT Kurs AmerickiMilica AnticОценок пока нет

- Standardi Za IbrДокумент16 страницStandardi Za IbrMilica AnticОценок пока нет

- P91 Bez PWHTДокумент12 страницP91 Bez PWHTMilica AnticОценок пока нет

- Din 17175 PDFДокумент22 страницыDin 17175 PDFMilica Antic0% (1)

- MT Skripta EngleskiДокумент28 страницMT Skripta EngleskiMilica AnticОценок пока нет

- Ultrasonic Inspection Velocity TableДокумент2 страницыUltrasonic Inspection Velocity TableCesar Tochukwu NwokoОценок пока нет

- P91 Bez PWHTДокумент12 страницP91 Bez PWHTMilica AnticОценок пока нет

- V-1523-12 Prevod Method To Calculate Ultrasonic Wave VelocityДокумент15 страницV-1523-12 Prevod Method To Calculate Ultrasonic Wave VelocityMilica AnticОценок пока нет

- Ko Ordinator IДокумент3 страницыKo Ordinator IMilica AnticОценок пока нет

- 4 1Документ8 страниц4 1Milica AnticОценок пока нет

- (E) Basic Study Pack - Optics - Sol - ch01Документ13 страниц(E) Basic Study Pack - Optics - Sol - ch01jeannieqintszyanОценок пока нет

- Datasheet Feroform T814Документ1 страницаDatasheet Feroform T814njsmith5Оценок пока нет

- Figure 8.2 Double Effect Evaporator - Forward FeedДокумент4 страницыFigure 8.2 Double Effect Evaporator - Forward FeedDorie KartikaОценок пока нет

- Tutorial Week 3 PDFДокумент17 страницTutorial Week 3 PDFAfiq RamliОценок пока нет

- Strut and Tie Design ExampleДокумент18 страницStrut and Tie Design Exampleabuzach11100% (2)

- ELECTROMAGNETIC INDUCTION-06-Subjective UnSolvedДокумент4 страницыELECTROMAGNETIC INDUCTION-06-Subjective UnSolvedRaju SinghОценок пока нет

- Axial StopДокумент4 страницыAxial Stopanurag7878Оценок пока нет

- Design SheetsДокумент18 страницDesign SheetsMuraleedharanОценок пока нет

- Emissivity - WikipediaДокумент12 страницEmissivity - WikipediaOmer TokhОценок пока нет

- Ec1402 Optical CommunicationДокумент3 страницыEc1402 Optical CommunicationsubhazОценок пока нет

- Biochemistry 6th Edition Garrett Test BankДокумент29 страницBiochemistry 6th Edition Garrett Test Banklantautonomyurbeiu100% (43)

- Passive Energy Dissipation Systems For StructuralДокумент12 страницPassive Energy Dissipation Systems For StructuralMichael Jhoan Rodriguez RomeroОценок пока нет

- Icml Mla IДокумент3 страницыIcml Mla IDeepak100% (1)

- Previous Year UPTU End Sem Exam Papers - SOM / MOS Paper 7Документ3 страницыPrevious Year UPTU End Sem Exam Papers - SOM / MOS Paper 7nitin_johri0% (1)

- A Study of Scrap Rubber Devulcanization and PDFДокумент216 страницA Study of Scrap Rubber Devulcanization and PDFalfiharadisОценок пока нет

- Journal Bearing LubricationДокумент5 страницJournal Bearing LubricationYorman Hernandez100% (1)

- Piping Stress Handbook - by Victor Helguero - Part 1Документ264 страницыPiping Stress Handbook - by Victor Helguero - Part 1namdq-1Оценок пока нет

- Day 14 Heat Treatments of SteelДокумент20 страницDay 14 Heat Treatments of Steelعزت عبد المنعمОценок пока нет

- Quantum DevicesДокумент132 страницыQuantum DevicesAritra LahiriОценок пока нет

- Si PMДокумент10 страницSi PMKremi TakovaОценок пока нет

- Verification of Norton TheoremДокумент3 страницыVerification of Norton TheoremImam Mehedi HasanОценок пока нет

- Raman ScatteringДокумент8 страницRaman Scatteringk.rahul.gОценок пока нет

- Agitation and MixingДокумент77 страницAgitation and MixingKolliparaDeepak100% (1)

- Viscosity of Newtonian and Non-Newtonian FluidsДокумент9 страницViscosity of Newtonian and Non-Newtonian FluidsAinsssОценок пока нет

- Strength of Materials (9024) PDFДокумент6 страницStrength of Materials (9024) PDFzamanОценок пока нет

- Sensors SyllabusДокумент2 страницыSensors Syllabusdirector.sportssrmistОценок пока нет

- Department of Mechanical Engineering Machine Design Objective QuestionДокумент211 страницDepartment of Mechanical Engineering Machine Design Objective QuestionSushant TiwariОценок пока нет

- Mistery of RZДокумент5 страницMistery of RZzlatkoОценок пока нет

- Practice QuesДокумент6 страницPractice QuesAndyОценок пока нет