Академический Документы

Профессиональный Документы

Культура Документы

Corrosion Behavior of Ti-6Al-4V Alloys in Differents Media - Abdulmageed

Загружено:

JulioОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Corrosion Behavior of Ti-6Al-4V Alloys in Differents Media - Abdulmageed

Загружено:

JulioАвторское право:

Доступные форматы

Al-

Khwarizmi

Engineering

Al-Khwarizmi Engineering Journal, Vol. 6, No. 3, PP 77 - 84 (2010) Journal

Corrosion Behavior of Ti-6Al-4V Alloy in Different Media

Majid H. Abdulmageed* Slafa I. Ibrahim **

* Department of Materials Engineering/ University of Technology

Email: majed_hamed60@yahoo.com

** Energy and Fuel Research Center/ University of Technology

(Received 25 October 2009; Accepted 27 July 2010)

Abstract

In this work the corrosion behavior of Ti-6Al-4V alloy was studied by using galvanostatic measurements at room

temperature in different media which includ sodium chloride (food salt), sodium tartrate (presence in jellies, margarine,

and sausage casings,etc.), sodium oxalate (presence in fruits, vegetables,etc.), acetic acid (presence in vinegar),

phosphoric acid (presence in drink), sodium carbonate (presence in 7up drink,etc.), and sodium hydroxide in order to

compare.

Corrosion parameters were interpreted in these media which involve corrosion potential( Ecorr) and corrosion current

density (icorr), since the results of (Ecorr) indicate that Oxalate ions are more corrosive than other materials while the

results of (icorr) indicate that NaCl is more corrosive than other materials. Cathodic and Anodic Tafel slopes that were

used to calculate the polarization resistance (Rp) to know which materials effect on Ti-6Al-4V alloy uses in dental

materials and the results of (Rp) were: Na2CO3 >Oxalate >H3PO4 >CH3COOH >NaOH >Tartrate >NaCl.

The change in free energy (G) and rate of corrosion in (mpy) were calculated, and the results of rate indicate that

increasing in the following sequences: NaCl>Tartrate >NaOH >Oxalate> CH3COOH> H3PO4> Na2CO3.

Keywords: Corrosion, titanium alloy, free energy, tafel method.

1. Introduction is present because of titaniums strong affinity for

oxygen.

Titanium and its alloy provide excellent Anhydrous conditions in the absence of a

resistance to general and localized attack under source of oxygen should be avoided since the

most oxidizing, neutral and inhibited reducing protective film may not be regenerated if

conditions in aqueous environments and remain damaged. Figure (1) shows the pourbaix diagram

passive under mildly reducing conditions, of Ti/H2O system.

although they may be attacked by strongly There are many studies about corrosion of Ti-

reducing or complexing media . Titanium is alloy from many authors, Smith BJ and co-

especially known for its outstanding resistance to workers studies of fretting corrosion experiments

chlorides and other halides generally present in were performed on Ti-6Al-4V similar metal, pin-

most process streams. [1] on-flat fretting couple, relative displacement

A study of the corrosion resistance of titanium amplitudes between the fretting specimens were

is basically a study of the properties of the oxide directly measured using LVDT`s. [2]

film. The oxide film on titanium is very stable and Latifa Kinani, Abdelilah Chtani and co-

is attacked only by a few substances including hot workers studies the effect of eugenol on the

concentration reducing acids, most notably, titanium corrosion in artificial saliva enriched

hydrofluoric acid. Titanium is capable of healing with eugenol at different concentration. The

this film almost instantaneously in every corrosion behavior and titanium surface

environment where a trace of moisture or oxygen characterization were investigated by

electrochemical measurements. [3]

This page was created using Nitro PDF trial software.

To purchase, go to http://www.nitropdf.com/

Majid H. Abdulmageed Al-Khwarizmi Engineering Journal, Vol. 6, No. 3, PP 77 - 84 (2010)

M.Nakagaw and co-workers studies titanium capillary for connection with an SCE reference

which is used as a metal for biocompatible electrode.

materials such as dental implants or restorations

because of its excellent chemical stability [4].

Chohayeb A.A. and co-workers studies the

corrosion behavior of couples consisting of

titanium and one of the dental casting alloys, Ni-

Cr, Co-Cr, Au-Pd-Ag or Pd-Ag. Alloys and Ti

were studied using materials in the cast condition.

Potentiodynamic polarization techniques were

used for making electrochemical measurements

on the alloys and couples in artificial saliva at

37oC. Corrosion potentials, corrosion rates and

general corrosion behavior, including passivation

range and breakdown potentials, were determined

for all materials and couples. [5]

In this study we choose some media which

have an effect on the titanium alloy in the field of (a)

dentistry such as NaCl, Oxalate, Tartrate,

Hole to electrical

Carbonate, Acetic acid, Phosphoric acid and connection

NaOH.

Alloy

2. Experimental Part

2.1. Materials and Chemicals Epoxy resin

(b)

Ti-6Al-4V alloy was cut into square shape

with (1cm2) area and (1cm) thickness, and made Fig.2. (a)-The Standard Corrosion Cell (ASTM) [7].

into electrode by pressing a copper wire into a (b)- Working Electrode.

hole on one side and then insulating all but one

side with an epoxy resin (Fig. 1). Many materials were used in this work such as

materials that have effects on Ti-alloy in dentistry

field and some of them have general effect. These

materials are shown in table (1).

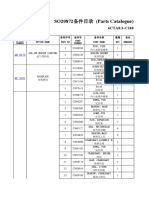

Table 1,

The Molecular Weight and Purity of Materials.

Materials M. wt Concentration

(g.mol-1)

Sodium 40.00 0.1M

hydroxide

Sodium 58.44 0.1M

chloride

Potassium 188.18 0.1M

hydrogen

Tartrate

Fig.1. Pourbaix Diagram of Ti/H2O System. Acetic acid 60.0 10%M

Phosphoric 68 4%M

The exposed area was grinding on emery acid

papers 400,600 and 1000-mesh grit. A braiding

Sodium 106 0.1M

was done by power-driven wheels. The carbonate

electrochemical cell was of the usual type (Fig. 2)

with provision for working electrode (Ti-alloy), Sodium 134 0.1M

auxiliary electrode (Pt electrode), and a Luggin oxalate

This page was created using Nitro PDF trial software.

78

To purchase, go to http://www.nitropdf.com/

Majid H. Abdulmageed Al-Khwarizmi Engineering Journal, Vol. 6, No. 3, PP 77 - 84 (2010)

2.2. Galvanostatic Measurement

The galvanostatic was measured using

WENKING M Lab. from BANK ELEKTRONIK

(Germany). The galvanostatic scan started about

Potential (mV)

hour after the electrode immersion in the test

popo

solution, the range of voltage depending on OCP

value versus the saturated calomel electrode.

Both the cathodic and anodic curves were

obtained with decreasing and increasing

polarization, and this was repeated several times.

The polarization curve obtained involved the

cathodic and anodic regions. Extensive data could

be derived from the detailed analysis of each

polarization region using extrapolated method to

determine both the corrosion current density (icorr) Fig.3. Polarization Curve of Ti-6Al-4V Alloy in

and corrosion potential (Ecorr) . NaCl Solution at Room Temperature.

3. Results and Discussion

3.1. Corrosion Behavior

The study of polarization behavior of Ti-6Al-

4V alloy in different media involves the active

Potential (mV)

region which consists of cathodic and anodic

region to calculate the corrosion potentials and

corrosion current densities by using linear Tafel

method.

Figs. (3) to (9) show the polarization curves of

Ti-6Al-4V in different media. The corrosion

parameters of Ti-6Al-4V in different media were

listed in table (2).

The cathodic region represents the reduction

reaction which occurs on the surface of alloy Fig.4. Polarization Curve of Ti-6Al-4V Alloy in

according to the medium of corrosion. Sodium Tartrate Solution at Room Temperature.

2H+ +2e H2 (in the acidic medium) (1)

O2 + H2O +2e 2OH-

(in the neutral and basic solution ) (2)

While the anodic region represent the

dissolution of metal or metals in alloy to ions

according to the following reactions:

Potential (mV)

Ti Ti2+ + 2e (3)

Fig.5. Polarization Curve of Ti-6Al-4V Alloy in

Sodium Hydroxide Solution at Room Temperature.

This page was created using Nitro PDF trial software.

79

To purchase, go to http://www.nitropdf.com/

Majid H. Abdulmageed Al-Khwarizmi Engineering Journal, Vol. 6, No. 3, PP 77 - 84 (2010)

Potential (mV)

Potential (mV)

Potential

Potential

Fig.6. Polarization Curve of Ti-6Al-4V Alloy in Fig.8. Polarization curve of Ti-6Al-4V Alloy in

Sodium Oxalate Solution at Room Temperature. H3PO4 Solution at Room Temperature.

Potential (mV)

Potential (mV)

Potential

Potential

Fig.7. Polarization Curve of Ti-6Al-4V Alloy in Fig.9. Polarization Curve of Ti-6Al-4V Alloy in

CH3COOH Solution at Room Temperature. Na2CO3 Solution at Room Temperature.

Table 2,

The Corrosion Parameters of Ti-6Al-4V in Different Media.

Medium Corrosion Potential Corrosion Current -bc +ba Rpx10-7

-Ecorr(mV) Density (mV.dec-1) (mV.dec-1) (.cm-2)

(SCE) icorr (A.cm-2) *10-3

NaCl 148.26 1357.6 113.0 206.6 0.2330

Sodium tartarate 1317.3 160.68 199.3 666.5 4.1460

NaOH 1029.2 114.83 221.7 741.3 6.4530

Sodium Oxalate 1324.2 75.48 261.7 678.9 10.866

Acetic acid 736.8 63.95 171.5 333.5 7.6900

Phosphoric acid 639.9 63.91 216.3 452.5 9.9420

Na2CO3 1319.9 61.43 225.9 862.0 12.652

This page was created using Nitro PDF trial software.

80

To purchase, go to http://www.nitropdf.com/

Majid H. Abdulmageed Al-Khwarizmi Engineering Journal, Vol. 6, No. 3, PP 77 - 84 (2010)

3.2. Corrosion Parameters Another parameter can be calculated from

corrosion measurement is the polarization

The corrosion potential (Ecorr) of material in a resistance (Rp) which represent the measure of the

certain medium at a constant temperature is a resistance of the metal to corrosion in the solution

thermodynamic parameter which is a criterion for in which the metal is immersed.

the extent of the corrosion feasibility under the The polarization resistance (Rp) can be

equilibrium potential (in opposite sign) of the cell determined from Stern- Geary equation [6]:

consisting of the working electrode and the

auxiliary electrode when the rate of anodic dE ba bc

dissolution of working electrode material becomes Rp ...(6)

di i 0 2.303(ba bc )icorr

equal to the rate of the cathodic process that take

place on the same electrode surface. From the

results of (Ecorr) in Table (2), it can be shown that: Where E is the applied potential (Volt) , i is the

current density (A.cm-2) and bc, ba are cathodic

-Ecorr (mV) Oxalate>Na2CO3>Tartrate>NaOH> and anodic Tafel slops respectively.

CH3COOH>H3PO4>NaCl The values of Rp are presented in table (2)

which

It is shown that (Ecorr) value is a measure for indicates that the corrosion in the sodium

the carbonate (Na2CO3) solution resists more than the

extent of the feasibility of the corrosion reaction other solutions. The values of polarization

on purely thermodynamic basis. resistance in the other solution take the following

The corrosion current density (icorr) is a kinetic sequence:

parameter and represents the rate of corrosion

under specified equilibrium condition. At constant Rp (.cm-2) Na2CO3 >Oxalate >H3PO4>

temperature for Ti-6Al-4V alloy, (icorr) values vary CH3COOH >NaOH >Tartrate >NaCl

with variation of ions present in medium and take

the following sequences: 3.3. The Free-Energy Change (G)

icorr (A/cm2) NaCl> Tartrate >NaOH>Oxalate> The free-energy change accompanying an

CH3COOH> H3PO4>Na2CO3 electrochemical reaction can be calculated by the

following equation [7]:

From deep analysis of the cathodic and anodic

regions of the polarization curves for Ti-6Al-4V G = -nFE (7)

alloy in different media, it was possible to derive

data concerning the cathodic and anodic Tafel Where G is the free-energy change, n is the

slopes. From the results which shown in table (2), number of electrons involved in the reaction, F is

values of Tafel slopes (bc & ba) for both cathodic the faraday constant, and E equals the cell

and anodic reactions were generally close to or potential.

higher than 120 mV/decade. Under standard conditions, the standard free

A cathodic Tafel slope of -120 mV/decade in energy of the cell reaction G is directly related to

general diagnostic of a discharge chemical the standard potential difference across the cell, E0

desorption mechanism for hydrogen evolution

reaction of the cathode in which the proton G0= -nFE0 (8)

discharge is the rate determining step.

Where the two basic reactions paths for Electrode potential can be combined

hydrogen evolution reaction are: algebraically to give cell potential.

For a galvanic cell, which operates spontaneously,

Diffusion

H3O+ (Bulk solution) H3O+ (Metal/solution interface)

a positive cell voltage will be obtained if the

(4) difference is taken in the usual way, as

This is followed by the discharge step: Ecell = Ecathode Eanode .(9)

H3O+ + M + e MH + H2O (5) The free energy change in a galvanic cell, or in

a spontaneous cell reaction, is negative and the

cell voltage is positive. In electrolytic cell, the

This page was created using Nitro PDF trial software.

81

To purchase, go to http://www.nitropdf.com/

Majid H. Abdulmageed Al-Khwarizmi Engineering Journal, Vol. 6, No. 3, PP 77 - 84 (2010)

reaction is driven in the non spontaneous icorr : is corrosion current density (A/cm2).

direction by an external electrical force. The free e: equivalent weight of metal or alloy (gm).

energy change in an electrolytic cell, or in a non p: density of metal or alloy (gm/cm3).

spontaneous cell reaction, is therefore positive and

the cell voltage is negative. The results of rate of corrosion were listed in

When the measured value of (Ecorr) becomes the Table (3) which takes the following sequence:

less negative, the potential of the corresponding

Galvanic R(mpy) NaCl > tartrate > NaOH > oxalate >

cell becomes less positive, hence the (G) value CH3COOH >H3PO4 > Na2CO3

for the corrosion process becomes less negative,

and the process is thus less spontaneous.

The results of G shown in table (3) indicate 4. Conclusion

that the change in free energy takes the

following sequence: From the results of studing the corrosion of Ti-

6Al-4V alloy in different media by using

G (J/mol) Oxalate > Na2CO3> Tartarate electrochemical process at room temperature it

>NaOH> CH3COOH >H3PO4>NaCl can be concluded:

1. The corrosion of Ti-6Al-4V alloy in sodium

Table 3, oxalate solution has highest negative value of

Thermodynamic and Kinetic Function Values for corrosion potential which was thermodynamic

Corrosion of Ti-6Al-4V Alloy in Different Media. parameter.

Medium Free-energy Rate of 2. The corrosion of Ti-6Al-4V alloy in NaCl

values corrosion solution has highest value of corrosion current

-G(J/mol) R mpy density which was kinetic parameter.

NaCl 57228.36 938.9 3. The corrosion of Ti-6Al-4V alloy in NaCl

Sodium tartarate 508477.8 110.6 solution has lowest value of polarization

resistance.

NaOH 397271.2 79.4

4. The corrosion process of Ti-6Al-4V alloy in

Sodium Oxalate 511141.2 52.2

sodium oxalate solution more spontaneous than

Acetic acid 284404.8 44.227 other media accordance with G calculation

(thermodynamic function).

Phosphoric acid 247001.4 44.2

5. The corrosion rate of Ti-6Al-4V alloy in NaCl

Na2CO3 509211.2 42.48

solution is the highest among the other media

(kinetic function).

The negative sign of G value refer to

spontaneous of the corrosion reaction and the 5. References

corrosion in (Oxalate solution) in most

spontaneous compared with other media. [1] John F. McCab, Anderson`s, Applied dental

materials / Blackwell Scientific publications,

3.4. Rate of Corrosion (Rmpy) 1985.

[2] Smith BJ,Ducheyne P,Transitional Behavior

Any factor that enhances the value of (icorr) in Ti-6AL-4V fretting corrosion , pages 12

results in enhanced value of the corrosion rate on published : Jan 1996 ,Source ; STP1272-EB .

pure kinetic ground. The kinetic parameters were [3] Latifa kivnani and abdelilah, corrosion

obtained from the corrosion current densities and inhibition of Titanium in Artificial saliva

their dependencies on temperature using the containing fluoride, Equip Electrochimic et

following relationship [8, 9]: matriaux inorganiques Marco

chtainia@yahoo.fr, 2004.

Rate (mpy) = 0.13 icorr (e/p) (10) [4] M. Nakagawa, S. Matsuya, T. Shiraishi and

M. Ohta, Journal of Dental Research, Vol. 78,

Where: 1568-1572, 1999

Rmpy: is the rate of corrosion in (mil/year).

This page was created using Nitro PDF trial software.

82

To purchase, go to http://www.nitropdf.com/

Majid H. Abdulmageed Al-Khwarizmi Engineering Journal, Vol. 6, No. 3, PP 77 - 84 (2010)

[5] http:/ www. Astm, org/ [7] Shreir L.L. Corrosion, Metal/Environment

DIGITAL_LIBRARY/ STP/ SOURCE_ reactions, second edition Vol.1, 1976.

PAGES/STP 1272. Htm, p11, 2007. [8] Saleh J.M., Al-Shama L. M., and Hikmat

[6] Heitz E. and Schwenk W., Br.Corrosion J., N.A., Corrosion Sci., Vol.27,pp.22, 1987.

Vol.11, No.2, 1976. [9] Saleh J. M., Saleh K. A., and Hikmat N. A.,

Iraqi J. Sci., Vol.36, pp.803, 1995.

.

.

This page was created using Nitro PDF trial software.

83

To purchase, go to http://www.nitropdf.com/

6 3 (2010) 84 -77

Ti-6Al-4V

** *

* /

majed_hamed60@yahoo.com :

** /

)(Ti-6Al-4V

) ( ) ( . )

(. ) ( ) ( )

( .

.

Ti-6Al-4V :

Na2CO3 >Oxalate >H3PO4 >CH3COOH >NaOH >Tartrate >NaCl

) (

.

. NaCl>Tartrate>NaOH>Oxalate>CH3COOH>H3PO4 >Na2CO3 :

This page was created using Nitro PDF trial software.

84

To purchase, go to http://www.nitropdf.com/

Вам также может понравиться

- EspectometríaДокумент1 страницаEspectometríaJulioОценок пока нет

- Zinc Oxide-Eugenol and Calcium HydroxideДокумент5 страницZinc Oxide-Eugenol and Calcium HydroxideJulioОценок пока нет

- Dycal Tuigmrh en 1402 PDFДокумент2 страницыDycal Tuigmrh en 1402 PDFgisanuОценок пока нет

- University College Hospital: Cutaneous Larva MigransДокумент2 страницыUniversity College Hospital: Cutaneous Larva MigransJulioОценок пока нет

- P B Msds HydroxideДокумент5 страницP B Msds HydroxideJulioОценок пока нет

- T4 DNA Ligase: Escherichia ColiДокумент2 страницыT4 DNA Ligase: Escherichia ColiJulioОценок пока нет

- Reaction Conditions For BirA Biotin LigaseДокумент4 страницыReaction Conditions For BirA Biotin LigaseJulioОценок пока нет

- Marmur J. A Procedure For The Isolation of Deoxyribonucleic Acid For Micro-OrganismsДокумент2 страницыMarmur J. A Procedure For The Isolation of Deoxyribonucleic Acid For Micro-OrganismsJulioОценок пока нет

- Amylase A Sample EnzymeДокумент10 страницAmylase A Sample EnzymeJulioОценок пока нет

- Ligation-Free Cloning Kit Manual V3 FinalДокумент23 страницыLigation-Free Cloning Kit Manual V3 FinalJulioОценок пока нет

- Standard Operating Procedure: Hydrochloric AcidДокумент6 страницStandard Operating Procedure: Hydrochloric AcidJulio100% (1)

- Deoxyribonucleic Acid (DNA), Sodium Salt (D1626) - Product Information SheetДокумент2 страницыDeoxyribonucleic Acid (DNA), Sodium Salt (D1626) - Product Information SheetJulioОценок пока нет

- Solution Stoichiometry PDFДокумент6 страницSolution Stoichiometry PDFJulio100% (1)

- Material Safety Data Sheet: Hydrochloric Acid 32-38% SolutionДокумент8 страницMaterial Safety Data Sheet: Hydrochloric Acid 32-38% SolutionJulioОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Designing A DC MotorДокумент7 страницDesigning A DC MotorPravat SatpathyОценок пока нет

- Rivulis F3240 English Metric 20191223 WebДокумент10 страницRivulis F3240 English Metric 20191223 WebMehdi BassouОценок пока нет

- He3488lsw TdsДокумент2 страницыHe3488lsw TdsVi TrầnОценок пока нет

- TM 5-6115-20PДокумент193 страницыTM 5-6115-20PAdvocate100% (1)

- Comparison Used in IeltsДокумент3 страницыComparison Used in IeltsDuyen HongОценок пока нет

- 6CTA8.3-C240 FRO CLG862 40c0273en Parts CatalogueДокумент80 страниц6CTA8.3-C240 FRO CLG862 40c0273en Parts CataloguePurnama AbhieОценок пока нет

- Grade 7 LPДокумент5 страницGrade 7 LPMelfe John CerezoОценок пока нет

- MCQ For Midsem - Ind - Inst.Документ5 страницMCQ For Midsem - Ind - Inst.Nirav ChauhanОценок пока нет

- Cap 31Документ100 страницCap 31Gilmar FerrettiОценок пока нет

- Residential Construction Standards PDFДокумент93 страницыResidential Construction Standards PDFjamesbond1960100% (1)

- Workbook Answers: CCEA GCSE PhysicsДокумент40 страницWorkbook Answers: CCEA GCSE PhysicsCanioОценок пока нет

- Model Answer Lecture 02 PDFДокумент5 страницModel Answer Lecture 02 PDFAkol MajookОценок пока нет

- SS 1.4122Документ2 страницыSS 1.4122Bipin Sadasivan100% (2)

- Sirius Timer Relay ManualДокумент28 страницSirius Timer Relay ManualVinoth MahendranОценок пока нет

- FYP IntroДокумент19 страницFYP IntroPrincess NoohaОценок пока нет

- Basic Principal of Electrical CircuitryДокумент19 страницBasic Principal of Electrical CircuitryAreeba ParvezОценок пока нет

- EN 16407 HOIS PresentationДокумент26 страницEN 16407 HOIS PresentationEsin DenizОценок пока нет

- Crompton GrevesДокумент4 страницыCrompton Grevesabhinav4440Оценок пока нет

- Characterization of Surface Deposits On Human HairДокумент12 страницCharacterization of Surface Deposits On Human HairpigcognitoОценок пока нет

- Exam Style Answers 20 Asal Physics CBДокумент2 страницыExam Style Answers 20 Asal Physics CBAnshul ShahОценок пока нет

- Is 10028 3 1981 PDFДокумент27 страницIs 10028 3 1981 PDFManoj MishraОценок пока нет

- 6.5EFOZ InstallationДокумент92 страницы6.5EFOZ InstallationNick ArnouОценок пока нет

- Sector:: Automotive/Land Transport SectorДокумент20 страницSector:: Automotive/Land Transport SectorVedin Padilla Pedroso92% (12)

- Thermal Engineering Lectures1Документ120 страницThermal Engineering Lectures1romasokyОценок пока нет

- Disaster On The Horizon PresskitДокумент1 страницаDisaster On The Horizon PresskitChelsea Green PublishingОценок пока нет

- WRE - 412 - Lec01 - Introduction To Hydraulic StructuresДокумент40 страницWRE - 412 - Lec01 - Introduction To Hydraulic StructuresAzwad Abeer100% (1)

- Custo Screen 300 / 400 - Error Codes: Service ManualДокумент3 страницыCusto Screen 300 / 400 - Error Codes: Service ManualHari KarkiОценок пока нет

- Energy Efficient Roadway Lighting Opportunities and BenefitsДокумент15 страницEnergy Efficient Roadway Lighting Opportunities and BenefitsHesham AlzarooniОценок пока нет

- Heat ExchangerДокумент11 страницHeat ExchangerMangesh MandgeОценок пока нет

- ANSYS-Based Detailed Thermo-Mechanical Modeling of Complex Thermoelectric Power DesignsДокумент3 страницыANSYS-Based Detailed Thermo-Mechanical Modeling of Complex Thermoelectric Power DesignsablueleafОценок пока нет