Академический Документы

Профессиональный Документы

Культура Документы

B Series Engine Training Course Pt.4

Загружено:

Tri KinartoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

B Series Engine Training Course Pt.4

Загружено:

Tri KinartoАвторское право:

Доступные форматы

Maintenance Procedures at 38,000 Kilometers [24,000 Miles], 1,000 Hours or 1 Yea

r

Check the tensioner arm, pulley, and stops for cracks. If any cracks are noticed

, the tensioner must be replaced.

With the belt on, verify that neither tensioner arm stops are in contact with th

e spring casing stop. If either stop is touching, the drive belt must be replace

d. After replacing the belt, if the tensioner arm stops are still in contact wit

h the spring casing stop, replace the tensioner.

142 Maintenance Procedures at 38,000 Kilometers [24,000 Miles], 1,000 Hours or

1 Year

check the torque of the tensioner capscrew.

With the belt removed, verify that the tensioner arm stop is in contact with the

spring case stop. If these two are not touching, the tensioner must be replaced

.

143 Maintenance Procedures at 77,000 Kilometers [48,000 Miles], 2,000 Hours or

2 Years

Air Compressor Inspect

Change the coolant

Check the damper

144 Troubleshooting

145 Troubleshooting Procedures and Techniques

A thorough analysis of the customer s complaint is the key to successful troublesh

ooting. The more information known about a complaint, the faster and easier the

problem can be solved.

The Troubleshooting Symptom Charts are organized so that a problem can be locate

d and corrected by doing the easiest and most logical things first. Complete all

steps in the sequence shown from top to bottom.

It is not possible to include all the solutions to problems that can occur; howe

ver, these charts are designed to stimulate a thought process that will lead to

the cause and correction of the problem.

146 Troubleshooting Procedures and Techniques

Follow these basic troubleshooting steps.

Get all the facts concerning the complaint.

Analyze the problem thoroughly.

Relate the symptoms to the basic engine systems and components.

Consider any recent maintenance or repair action that can relate to the complain

t.

Double-check before beginning any disassembly.

Solve the problem by using the symptom charts and doing the easiest things first

.

Determine the cause of the problem and make a thorough repair.

After repairs have been made, operate the engine to make sure the cause of the c

omplaint has been corrected.

147 Smoke, Black Excessive

Engine is being lugged down (Use lower gear ).

Load is excessive (Reduce the load. Check and clean the vessel bottom, or change

the propeller. Refer to manufacturer s instructions).

Plugged air filter (Inspect the air cleaner element. Replace as needed ).

AFC plunger not fully open (Inspect AFC air tube and fuel drain lines for restri

ction. Inspect the AFC operation ).

Intake air source is incorrect (If the vehicle is equipped with a valve to switc

h the intake source from under the hood to outside, position and set valve for t

he season )

Aftercooler restricted (if equipped) (Inspect for plugged passages in the afterc

ooler ).

Exhaust system restriction (Check the exhaust system for any restrictions ).

Charge air cooler is restricted or leaking (Inspect the charge air cooler for ai

r restrictions or leaks ).

148 Smoke, Black Excessive

Air leak between the turbocharger and the intake manifold (Check for leaks in th

e air crossover tube, charge air cooler connections, hoses, or through holes in

the manifold cover and repair or replace if necessary )

Exhaust leaks at the manifold or turbocharger (Check and correct any leaks in th

e exhaust manifold or turbocharger gaskets. Check for a cracked exhaust manifold

)

Turbocharger wastegate is malfunctioning (Check the wastegate for correct operat

ion )

Turbocharger is worn or malfunctioning (Check for the specified boost pressure.

Inspect the turbocharger. Replace if necessary )

Fuel contaminated (Verify by operating the engine with clean fuel from a tempora

ry tank ).

Injectors worn or malfunctioning (Remove and test the injectors. Replace as nece

ssary .

149 Smoke, Black Excessive

15?Injector sealing washer not correct (Check to see if an extra sealing washer

is installed under injector. Remove any additional sealing washer )

16?Injector sealing washer not correct (Remove injector and install the proper s

ealing washer )

17?Fuel injection pump timing is not correct (Put the engine at top dead center.

Check and adjust the fuel timing )

18?Fuel injection pump is malfunctioning (Remove the fuel injection pump. Check

the calibration of the fuel injection pump )

19?Piston rings not sealing (blue smoke) (Check for excessive blowby)

150 Smoke, White Excessive

Starting procedure is not correct (Verify the correct starting procedure )

Coolant temperature is below specification or the intake manifold air temperatur

e is below specification (Refer to the Coolant Temperature Below Normal symptom

tree )

Intake manifold heater wiring harness malfunctioning (Check the wiring harness )

Poor fuel quality or wrong fuel grade (Verify by operating the engine from a tem

porary supply of number 2 diesel fuel. Check fuel specifications for proper fuel

grade )

Fuel injection pump timing is not correct (Put the engine at top dead center. Ch

eck and adjust the fuel timing )

Injector sealing washer not correct (Remove injector and install the proper seal

ing washer )

Вам также может понравиться

- CreditsДокумент4 страницыCreditsTri KinartoОценок пока нет

- Nissan PK215 IndonesiaДокумент1 страницаNissan PK215 IndonesiaTri KinartoОценок пока нет

- Ncis (PS 3)Документ15 страницNcis (PS 3)Tri KinartoОценок пока нет

- Miku Hatsune - Project Diva F Trophy Guide & RoadmapДокумент15 страницMiku Hatsune - Project Diva F Trophy Guide & RoadmapTri Kinarto100% (1)

- Nissan CWM330 IndonesiaДокумент1 страницаNissan CWM330 IndonesiaTri Kinarto50% (2)

- Last Resort Guide to Winning a Difficult GameДокумент16 страницLast Resort Guide to Winning a Difficult GameTri Kinarto50% (4)

- Summer SagaДокумент3 страницыSummer SagaasdasdОценок пока нет

- Walkthrough Summertime Saga 0.12.7Документ13 страницWalkthrough Summertime Saga 0.12.7Tri Kinarto100% (2)

- Mia and Helen WalkthroughДокумент1 страницаMia and Helen WalkthroughTri KinartoОценок пока нет

- Electronic Management SystemsДокумент12 страницElectronic Management SystemsTri KinartoОценок пока нет

- Play the Dungeon of Lulu Farea Kill Screw Marry gameДокумент1 страницаPlay the Dungeon of Lulu Farea Kill Screw Marry gameTri KinartoОценок пока нет

- Nissan CDA260 IndonesiaДокумент2 страницыNissan CDA260 IndonesiaTri KinartoОценок пока нет

- Auga WalkthroughДокумент1 страницаAuga WalkthroughTri KinartoОценок пока нет

- Dungeon of Lulu TL NoteДокумент1 страницаDungeon of Lulu TL NoteTri KinartoОценок пока нет

- Direct and General Support Maintenance MДокумент693 страницыDirect and General Support Maintenance MTri KinartoОценок пока нет

- How To Maintenance Landcruiser Pt.3Документ8 страницHow To Maintenance Landcruiser Pt.3Tri KinartoОценок пока нет

- TSI Vs CRDi Part 8Документ1 страницаTSI Vs CRDi Part 8Tri KinartoОценок пока нет

- How To Maintenance Landcruiser Pt.3Документ8 страницHow To Maintenance Landcruiser Pt.3Tri KinartoОценок пока нет

- TSI Vs CRDi Part 6Документ1 страницаTSI Vs CRDi Part 6Tri KinartoОценок пока нет

- TSI Vs CRDi Part 7Документ1 страницаTSI Vs CRDi Part 7Tri KinartoОценок пока нет

- CWA260 Spec SheetДокумент1 страницаCWA260 Spec SheetTri KinartoОценок пока нет

- UD Trucks CWA 260 specifications and pricesДокумент2 страницыUD Trucks CWA 260 specifications and pricesTri KinartoОценок пока нет

- HINO GENUINE TRUCK PARTS AND ACCESSORIES CATALOGUEДокумент12 страницHINO GENUINE TRUCK PARTS AND ACCESSORIES CATALOGUETri Kinarto100% (1)

- TSI Vs CRDi Part 5Документ1 страницаTSI Vs CRDi Part 5Tri KinartoОценок пока нет

- TSI Vs CRDi Part 3Документ1 страницаTSI Vs CRDi Part 3Tri KinartoОценок пока нет

- TSI Vs CRDi Part 4Документ1 страницаTSI Vs CRDi Part 4Tri KinartoОценок пока нет

- TSI Vs CRDi Part 2Документ1 страницаTSI Vs CRDi Part 2Tri KinartoОценок пока нет

- Installation GuideДокумент1 страницаInstallation GuideTri KinartoОценок пока нет

- TSI Vs CRDi Part 1Документ1 страницаTSI Vs CRDi Part 1Tri KinartoОценок пока нет

- B Series Engine Training Course Pt.6Документ1 страницаB Series Engine Training Course Pt.6Tri KinartoОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Electric Vehicle TechnologyДокумент13 страницElectric Vehicle TechnologySarvesh RamaniОценок пока нет

- List of Vendor ManualsДокумент8 страницList of Vendor ManualsAlexОценок пока нет

- Bobcat E45 SpecificationsДокумент1 страницаBobcat E45 SpecificationsGoran MatovicОценок пока нет

- Tesla Model X Hitch InstallationДокумент24 страницыTesla Model X Hitch InstallationSergey021Оценок пока нет

- Tuning Your CarДокумент17 страницTuning Your CarAndré Luís Della VolpeОценок пока нет

- TCDS E4ea PT6 PDFДокумент22 страницыTCDS E4ea PT6 PDFGabriielLoopez100% (2)

- Himalayan Specifications EnglishДокумент2 страницыHimalayan Specifications EnglishEliseo BayquinОценок пока нет

- Cec 85128 C 1Документ19 страницCec 85128 C 1Fodil ZouОценок пока нет

- Man Tga Flashcodes For EcasДокумент6 страницMan Tga Flashcodes For Ecasrichard100% (55)

- Schema Fonctionnel PDFДокумент2 страницыSchema Fonctionnel PDFTiago RomeroОценок пока нет

- Honda BF 30 User Manual PDFДокумент4 страницыHonda BF 30 User Manual PDFMisho Misho0% (1)

- Vietnam Airlines B787 Training CourseДокумент2 страницыVietnam Airlines B787 Training CoursePhạm Hà TiếnОценок пока нет

- Pps 951703 Audi 09d Transmission EngДокумент79 страницPps 951703 Audi 09d Transmission EngQuattro-Sports Auto-Transmission EAОценок пока нет

- DFA1101GZ5AD6J 907 Operational Manual 200606 - EnglishДокумент0 страницDFA1101GZ5AD6J 907 Operational Manual 200606 - EnglishSelmirije2Оценок пока нет

- BSBM3-1 Group3Документ5 страницBSBM3-1 Group3Lyka FerrerОценок пока нет

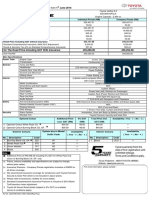

- Vellfire PM Ipte PDFДокумент1 страницаVellfire PM Ipte PDFTrader Teknik SqdОценок пока нет

- Crane Sany STC250HДокумент9 страницCrane Sany STC250HAlfin ListioОценок пока нет

- Report - Electric VehiclesДокумент32 страницыReport - Electric VehiclesTechSci Research100% (2)

- Outline Dimensions: XCMG Construction Machinery Co., LTDДокумент4 страницыOutline Dimensions: XCMG Construction Machinery Co., LTD余Оценок пока нет

- Characteristic Curves for Bhatia Coke MotorДокумент1 страницаCharacteristic Curves for Bhatia Coke MotorsyamprasadОценок пока нет

- Specialized Lookup Examples (Excell)Документ19 страницSpecialized Lookup Examples (Excell)FrozenОценок пока нет

- 4.2. Efficycle - Design Report - Specification Sheet FormatДокумент6 страниц4.2. Efficycle - Design Report - Specification Sheet FormatTyhghjОценок пока нет

- 2003 Ford F-150 Service & Repair ManualДокумент8 681 страница2003 Ford F-150 Service & Repair ManualVernon Parker100% (2)

- Audi Rs3 Ttrs - Daza DnwaДокумент242 страницыAudi Rs3 Ttrs - Daza DnwaRoland Hendriks100% (2)

- TE 250 USA 2012: Spare Parts Manual: ChassisДокумент32 страницыTE 250 USA 2012: Spare Parts Manual: ChassisAna CiocanОценок пока нет

- Side Impact Sensor 8212 C Pillar Removal and InstallationДокумент2 страницыSide Impact Sensor 8212 C Pillar Removal and InstallationMichael HernandezОценок пока нет

- Class C licence knowledge test questionsДокумент52 страницыClass C licence knowledge test questionsbhoraji123Оценок пока нет

- ListДокумент2 страницыListRahul KumarОценок пока нет

- San Diego Imperial ValleyДокумент2 страницыSan Diego Imperial ValleyspalomosОценок пока нет

- Mercury Repair ManualДокумент638 страницMercury Repair ManualJames HicksОценок пока нет