Академический Документы

Профессиональный Документы

Культура Документы

Pump Featurer

Загружено:

Sergio Roberto Cabrera BurgosАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pump Featurer

Загружено:

Sergio Roberto Cabrera BurgosАвторское право:

Доступные форматы

WUXI HONGYUAN PUMP

High Pressure Reciprocating Plunger Pump

Designed in accordance with API674 Standard to satisfy different process requirements

Various technologies and unique features to achieve product reliability and advantage

Modular design could provide customized solutions

Wuxi Hong Yuan pump manufacturing co., ltd

Address: No.63, Xida Road,Fang Qian Town, Wuxi New District, Jiangsu

Province, China

Mobile phone: 86-13861810779 Email:hy@chinawxhypump.com

Tel: 86-510-83219970 / 83219971 Fax: 86-510-83210909

WWW.CHINAWXHYPUMP.COM (English) WWW.WXHYBY.COM (Chinese)

The right to technical changes is reserved

WEARPROOF

Unique forced Lubrication System

Driven by crank shaft, the internal

forced lubrication oil pump could

produce sufficient pressurized

lubricating oil lubricate all movable

parts.

Step type crosshead act as a piston,

pumping oil through the hole of rod to

crank bearing during the rearward stroke.

Released oil inject to the bearing of gear

shaft, and splash on the back of cooler plate.

Low lubrication oil level not only saving

the oil consuming, but also reduced oil heat.

THRUSTPROOF

Integrated Dual Helical Gear Reducer

Integrated double helical reduction

gears provide compact design

accurate transmission, no wear parts

inside.

Floating crankshaft and pinion are free of

axial loads

Elimination of the thrust to extend bearing

lift

Improvement of the reliability due to reduce

stress concentration at the crankshaft and

gear.

Double rows of rollers spherical roller crank

bearing could self-aligning and suit for

heavy loads.

CRACKPROOF

Unique Design Liquid End

Special internal structure combined

with advanced fabrication process to

optimize the pump head free from

crack destroy.

Middle and low Pressure Liquid End

Optimized design of internal structure of

pump lead with detailed FEA fatigue

analysis to eliminate stress concentration.

Advanced spark machining for rounded

intersection reduce the stress level.

High Pressure Liquid End

Incorporate coaxial valve combine suction

and discharge valve in one piece, and the

valve divide pump head into high pressure

area and low pressure area, eliminate

alternating stress in the two areas, the

arrangement prevent pump head from

fatigue failure.

LEAKPROOF

Special Designed Seal and Sealing Structure

Spring loaded self-adjusting Y Ring

with internal leakage return design

reduce maintenance work load

Y Spring standard design

Stuffing box Packing spring actuated

needn't adjust gland outside

Self-tightening Y Seal ring make low

friction and reliable seal

Double seal with internal leakage return

design reduce leakage to atmosphere

THE WHY ADVANTAGE ON ULTRA HIGH FLUID END

Through nearly ten years of service, the Wuxi Hongyuan

Pump 20,000 psi&36,000Psi Fluid End has remained the most

efficient, easy-to-use, and simple maintenance.

WHY Fluid End Features

Serviceability

*Five minute packing change

*Fifteen minute pop-out valve cartridge change

*No special tools or equipment required

*Plungers clamped, NOT threaded, for easy maintenance

Simplicity Versatility

*Fast in Fast in-the-field pressure range

*Fewer parts than other Ultra HP fluid ends

conversion with simple bolt-on WHY Fluid

*One-piece cartridges include suction & Ends

Discharge valves, seats, springs, and seals *Convertibility of the WHY design allows

one unit to do the work that another

*Swing-down manifold for easy access to

manufacturer would require multiple units or

components several hours of downtime to perform

20,000 psi WHY Fluid End Features

*Water lubricated packing set

*Carbide coated plungers

*Specially designed manifold connections are superior to industry standard connections and feature

easily replaceable seals

*High volumetric efficiency

*All pressure-bearing components precision machined from high quality stainless steel

Five Minute Packing

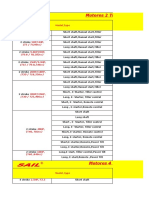

WHY30032

After years of development, Wuxi Hongyuan WHY25028 106L/m

WHY20026

Pump could manufacture a variety models of 81L/m

WHY16026

70L/m

pump to achieve 20,000 Psi. WHY9018

55L/m

26L/m

Power 75kw 160kw 200kw 250kw 300kw

Ensuring our customers get the satisfying products, strict test is necessary.

Firstly: The row material will be put in storage after inspect. About casting parts, it must

be do UT detection in case defects inside.

Second: During machining period, dimension must be measured after each craft. When

finished, the parts are put in storage after finally inspection.

Thirdly: Before delivery the pump unit will test under continue working condition last 8

hours

Delivery Test Terms: Power end oil temperature 75

Max pressure 110% working pressure

Pump unit noise 80A

Vibration test 0.02mm

Вам также может понравиться

- Robinair Vacuum Pumps: Cooltech™ and Vacumaster™ FeaturesДокумент3 страницыRobinair Vacuum Pumps: Cooltech™ and Vacumaster™ FeaturesAero MidiОценок пока нет

- Thosiba TurbinesДокумент16 страницThosiba Turbinesilusee100% (1)

- WSP Series Self Priming PumpsДокумент1 страницаWSP Series Self Priming PumpsabmopalhvacОценок пока нет

- Equipment:: Figure 1: Vertical Turbine PumpДокумент8 страницEquipment:: Figure 1: Vertical Turbine PumphamizanОценок пока нет

- Hidrostal Submersible Immersible PDFДокумент8 страницHidrostal Submersible Immersible PDFariyamanjulaОценок пока нет

- 3698 Pit ViperДокумент6 страниц3698 Pit ViperDaniel Quiroz100% (1)

- Midstream SolutionsДокумент12 страницMidstream SolutionsEdmund LimОценок пока нет

- Stationary Concrete Pump: SP 1600 / SP 1800 / SP 2000 / SP 2800Документ4 страницыStationary Concrete Pump: SP 1600 / SP 1800 / SP 2000 / SP 2800ghjtyuОценок пока нет

- AHLSTAREndSuctionSingleStage E10083Документ28 страницAHLSTAREndSuctionSingleStage E10083katlego01Оценок пока нет

- Process CryostarДокумент8 страницProcess CryostarNarayan MarndiОценок пока нет

- Ahlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentДокумент28 страницAhlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentARYAN_FATHONI_AMRIОценок пока нет

- Top Drive 750 Product SheetДокумент2 страницыTop Drive 750 Product SheetMehdi SoltaniОценок пока нет

- Technical Data Portable Concrete Pump: SP 2800 SP 2800 SP 2800Документ2 страницыTechnical Data Portable Concrete Pump: SP 2800 SP 2800 SP 2800AmrishОценок пока нет

- 02 02 Wirbelrad EnglischДокумент4 страницы02 02 Wirbelrad EnglischOsama TahaОценок пока нет

- Brochure BEGEMANN PA Pumps-Low ResolutionДокумент6 страницBrochure BEGEMANN PA Pumps-Low ResolutionIsaac RubioОценок пока нет

- Ekipirovka Za SmazvaneДокумент105 страницEkipirovka Za SmazvaneBobby BobbyОценок пока нет

- Process PumpsДокумент10 страницProcess PumpsJohn WatsonОценок пока нет

- Evodos Type 25 CentrifugeДокумент8 страницEvodos Type 25 CentrifugeFilippo FerrariОценок пока нет

- Rotare Vane PumpsДокумент10 страницRotare Vane PumpsZoran DjurdjevicОценок пока нет

- Fb199-CA Flygt Sub Brochure Sm2Документ36 страницFb199-CA Flygt Sub Brochure Sm2MarcsLeungОценок пока нет

- Jaypee Cement Plant Grinding Uniit-3Документ27 страницJaypee Cement Plant Grinding Uniit-3sunil kumar patelОценок пока нет

- Ejector BrochureДокумент8 страницEjector Brochurebabis1980Оценок пока нет

- Wemco Product OverviewДокумент24 страницыWemco Product OverviewAkilesh AravindakshanОценок пока нет

- 3022 B4ce78acДокумент12 страниц3022 B4ce78acmmkattaОценок пока нет

- Subsea Gate Valve: Suzhou Douson Drilling & Production Equipment Co., LTDДокумент2 страницыSubsea Gate Valve: Suzhou Douson Drilling & Production Equipment Co., LTDindraОценок пока нет

- SANY SR250 Rotary Drilling RigДокумент8 страницSANY SR250 Rotary Drilling RigSandeep Kumar DangdaОценок пока нет

- Flygt Öğütücülü PompalarДокумент8 страницFlygt Öğütücülü PompalarAndrey GyrychОценок пока нет

- PumpsДокумент5 страницPumpsEloi Magpantay HernandezОценок пока нет

- Kumar Pumps BroucherДокумент18 страницKumar Pumps BroucherSrikanth Kesanakurthi50% (2)

- Rotex Pneumatic Cylinder CatalogueДокумент4 страницыRotex Pneumatic Cylinder Cataloguekumar ambujОценок пока нет

- Product Manual: Date: June 2006 Supersedes: 806B 04/11 CДокумент36 страницProduct Manual: Date: June 2006 Supersedes: 806B 04/11 CAlejandro RSОценок пока нет

- Ps 40 9 eДокумент8 страницPs 40 9 eManuel De LeonОценок пока нет

- Swisspump Sewage 50hzДокумент92 страницыSwisspump Sewage 50hzdaviko313Оценок пока нет

- 2 Bridge PlugsДокумент9 страниц2 Bridge PlugsaaaОценок пока нет

- Pivot MasterДокумент2 страницыPivot MasterAleck VieyraОценок пока нет

- Goulds API 3600 i-FRAME: API BB3 Between-Bearing, Axially Split, Multistage PumpДокумент12 страницGoulds API 3600 i-FRAME: API BB3 Between-Bearing, Axially Split, Multistage PumpJean Peak100% (1)

- BGDegassingCentrifugalPumpEN E10114Документ2 страницыBGDegassingCentrifugalPumpEN E10114Abdalla FarisОценок пока нет

- Rotating Mandrel Casing HangerДокумент1 страницаRotating Mandrel Casing HangerClOudyo VirgílioОценок пока нет

- 576047-191 Bomba Red Yacket 3 PDFДокумент2 страницы576047-191 Bomba Red Yacket 3 PDFEstacion AvenidaОценок пока нет

- Char Lynn 2kДокумент34 страницыChar Lynn 2kJas Sum100% (1)

- National Boom Trucks Spec Ef6a51Документ8 страницNational Boom Trucks Spec Ef6a51Juan Carlos Torres MartinezОценок пока нет

- Sturdy Bearing Assembly and Axial Heat Expansion: PumpsДокумент8 страницSturdy Bearing Assembly and Axial Heat Expansion: PumpsTejas MahadikОценок пока нет

- Profesionalni Klipni Kompresori KatalogДокумент8 страницProfesionalni Klipni Kompresori KatalogDamir HodžićОценок пока нет

- Bredel SPX Slangenpomp - BrochureДокумент24 страницыBredel SPX Slangenpomp - BrochurejoseluisbeitoОценок пока нет

- Drilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2Документ40 страницDrilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2MEREUEULEUОценок пока нет

- CV Yuwana Bakti - 2023Документ16 страницCV Yuwana Bakti - 2023aditya pamungkasОценок пока нет

- Oil SkimmerДокумент4 страницыOil SkimmerManish KhakhraОценок пока нет

- Pump Sales WebДокумент7 страницPump Sales WebGermán Soledad MolinaОценок пока нет

- Hiteam Fluid Control Company ProfileДокумент13 страницHiteam Fluid Control Company ProfileSen VanОценок пока нет

- 2535-S Industriaseko GlassДокумент17 страниц2535-S Industriaseko GlassFreddy De la BarraОценок пока нет

- JSC Hammer Attachment CATALOGДокумент24 страницыJSC Hammer Attachment CATALOGAdeelОценок пока нет

- 370lc en KatalogДокумент16 страниц370lc en KatalogI am a Celtic100% (1)

- Floating RoofДокумент12 страницFloating Roofnaveenbaskaran1989Оценок пока нет

- Can KДокумент12 страницCan KSergio RinconОценок пока нет

- Παρουσίαση της νέας Flygt BIBOДокумент8 страницΠαρουσίαση της νέας Flygt BIBOidator_blogОценок пока нет

- Series E: Product GuideДокумент8 страницSeries E: Product GuideFrank Felipe Cruz ChavezОценок пока нет

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!От EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Рейтинг: 5 из 5 звезд5/5 (2)

- Machines, Tools and Methods of Automobile ManufactureОт EverandMachines, Tools and Methods of Automobile ManufactureРейтинг: 4 из 5 звезд4/5 (1)

- 1312P00039 Bne1Документ1 страница1312P00039 Bne1Sergio Roberto Cabrera BurgosОценок пока нет

- Quotation of Block 211005Документ1 страницаQuotation of Block 211005Sergio Roberto Cabrera BurgosОценок пока нет

- DV PR 807034701Документ1 страницаDV PR 807034701Sergio Roberto Cabrera BurgosОценок пока нет

- BL LSZ-LFZSNT215102Документ1 страницаBL LSZ-LFZSNT215102Sergio Roberto Cabrera BurgosОценок пока нет

- DV PR 807034701Документ1 страницаDV PR 807034701Sergio Roberto Cabrera BurgosОценок пока нет

- LXVAP210811A5Документ1 страницаLXVAP210811A5Sergio Roberto Cabrera BurgosОценок пока нет

- Bank ModifyДокумент1 страницаBank ModifySergio Roberto Cabrera BurgosОценок пока нет

- SEAFIRST - NHP Helm Pump - User ManualДокумент2 страницыSEAFIRST - NHP Helm Pump - User ManualSergio Roberto Cabrera BurgosОценок пока нет

- EATON Vickers Vane Motor PDFДокумент17 страницEATON Vickers Vane Motor PDFAndri HermantoОценок пока нет

- Precios Motores Fuera BordaДокумент8 страницPrecios Motores Fuera BordaSergio Roberto Cabrera BurgosОценок пока нет

- LXVAP210811A5Документ1 страницаLXVAP210811A5Sergio Roberto Cabrera BurgosОценок пока нет

- SAIL 2 Stroke and 4 Stroke Outboard Motor 2.5hp To 60hp, 2021Документ6 страницSAIL 2 Stroke and 4 Stroke Outboard Motor 2.5hp To 60hp, 2021Sergio Roberto Cabrera BurgosОценок пока нет

- Hf260D-100 Diesel Engine Hydraulic Drilling RigДокумент1 страницаHf260D-100 Diesel Engine Hydraulic Drilling RigSergio Roberto Cabrera BurgosОценок пока нет

- EATON Vickers Vane Motor PDFДокумент17 страницEATON Vickers Vane Motor PDFAndri HermantoОценок пока нет

- Bomba Alta PresiónДокумент18 страницBomba Alta PresiónSergio Roberto Cabrera BurgosОценок пока нет

- SAIL 2 Stroke and 4 Stroke Outboard Motor 2.5hp To 60hp, 2021Документ6 страницSAIL 2 Stroke and 4 Stroke Outboard Motor 2.5hp To 60hp, 2021Sergio Roberto Cabrera BurgosОценок пока нет

- RFQ N°245Документ2 страницыRFQ N°245Sergio Roberto Cabrera BurgosОценок пока нет

- Blince Update PI About Hydraulic MotorДокумент1 страницаBlince Update PI About Hydraulic MotorSergio Roberto Cabrera BurgosОценок пока нет

- Bomba Alta PresiónДокумент18 страницBomba Alta PresiónSergio Roberto Cabrera BurgosОценок пока нет

- PVS 0349 C CD 251 00Документ1 страницаPVS 0349 C CD 251 00Sergio Roberto Cabrera BurgosОценок пока нет

- Espacios - Confinados - Modo de Compatibilidad - ReparadoДокумент2 страницыEspacios - Confinados - Modo de Compatibilidad - ReparadoSergio Roberto Cabrera BurgosОценок пока нет

- Plataforma Móviles.Документ32 страницыPlataforma Móviles.Sergio Roberto Cabrera BurgosОценок пока нет

- Instruct Ivo Contrat I StasДокумент1 страницаInstruct Ivo Contrat I StasSergio Roberto Cabrera BurgosОценок пока нет

- Seafirst Catalogue 1Документ28 страницSeafirst Catalogue 1Sergio Roberto Cabrera BurgosОценок пока нет

- Eyes WashДокумент2 страницыEyes WashSergio Roberto Cabrera BurgosОценок пока нет

- Bomba Alta PresiónДокумент18 страницBomba Alta PresiónSergio Roberto Cabrera BurgosОценок пока нет

- Bomba Alta PresiónДокумент18 страницBomba Alta PresiónSergio Roberto Cabrera BurgosОценок пока нет

- Plataforma Móviles.Документ32 страницыPlataforma Móviles.Sergio Roberto Cabrera BurgosОценок пока нет

- Conect orДокумент1 страницаConect orSergio Roberto Cabrera BurgosОценок пока нет

- Bomba Alta PresiónДокумент18 страницBomba Alta PresiónSergio Roberto Cabrera BurgosОценок пока нет

- Donna Hay Magazine 2014-10-11 PDFДокумент172 страницыDonna Hay Magazine 2014-10-11 PDFlekovic_tanjaОценок пока нет

- Academic Reading: All Answers Must Be Written On The Answer SheetДокумент21 страницаAcademic Reading: All Answers Must Be Written On The Answer SheetLemon MahamudОценок пока нет

- Class 12 Maths Project On Prime NumbersДокумент13 страницClass 12 Maths Project On Prime Numbersanon_3835245630% (1)

- Relationsh Between EM and Young S ModuliДокумент7 страницRelationsh Between EM and Young S ModuliDwight AndersonОценок пока нет

- ChipmunkДокумент19 страницChipmunkema.nemec13Оценок пока нет

- Five Star Hotel and ResortДокумент9 страницFive Star Hotel and ResortAISHОценок пока нет

- Zincanode 304 pc142Документ3 страницыZincanode 304 pc142kushar_geoОценок пока нет

- Material Requirement Planning (MRP)Документ55 страницMaterial Requirement Planning (MRP)Lisa CarlsonОценок пока нет

- PTP S3Документ8 страницPTP S3Yongyin SHENGОценок пока нет

- Manufacuring EngineeringДокумент3 страницыManufacuring Engineeringapi-79207659Оценок пока нет

- Biologically Active Compounds From Hops and Prospects For Their Use - Karabín 2016Документ26 страницBiologically Active Compounds From Hops and Prospects For Their Use - Karabín 2016Micheli Legemann MonteОценок пока нет

- (G. Lakshmi Narasaiah) Finite Element Analysis PDFДокумент349 страниц(G. Lakshmi Narasaiah) Finite Element Analysis PDFmoljaime1326Оценок пока нет

- Efficient Rice Based Cropping SystemДокумент24 страницыEfficient Rice Based Cropping Systemsenthilnathan100% (1)

- Tsel Manual ThermoselДокумент25 страницTsel Manual ThermoselPedro AlvelaisОценок пока нет

- Viscous Fluid Flow Frank M White Third Edition - Compress PDFДокумент4 страницыViscous Fluid Flow Frank M White Third Edition - Compress PDFDenielОценок пока нет

- Contact Inform 2002 PDFДокумент24 страницыContact Inform 2002 PDFFrank AlmeidaОценок пока нет

- Biomediacal Waste Project FinalДокумент43 страницыBiomediacal Waste Project Finalashoknr100% (1)

- DS Ltch00601daa0 R05Документ4 страницыDS Ltch00601daa0 R05rajareddy235Оценок пока нет

- The Joy Luck Club Book 1Документ12 страницThe Joy Luck Club Book 1loronalicelОценок пока нет

- SR6 Core Rulebook Errata Feb 2020Документ6 страницSR6 Core Rulebook Errata Feb 2020yrtalienОценок пока нет

- Bhagwati School Strap Report AnalysisДокумент60 страницBhagwati School Strap Report AnalysisReverse Minded100% (1)

- Trawl Master Present A TieДокумент19 страницTrawl Master Present A Tieapi-3719203Оценок пока нет

- Eating With Chloe Lets EatДокумент150 страницEating With Chloe Lets Eatemily.jarrodОценок пока нет

- Updated SAP Cards Requirement JalchdДокумент51 страницаUpdated SAP Cards Requirement Jalchdapi-3804296Оценок пока нет

- Iron Ore ProcessДокумент52 страницыIron Ore Processjafary448067% (3)

- Digital Signal Processing: B.E Ece (5Th Semester)Документ17 страницDigital Signal Processing: B.E Ece (5Th Semester)Saatwat CoolОценок пока нет

- Earth Science (Metamorphic Rocks)Документ8 страницEarth Science (Metamorphic Rocks)MA. ALEXIS LAURENОценок пока нет

- Trends in FoodДокумент3 страницыTrends in FoodAliОценок пока нет

- Greater Occipital Nerve Block: Pain ManagementДокумент3 страницыGreater Occipital Nerve Block: Pain Managementkillingeyes177Оценок пока нет