Академический Документы

Профессиональный Документы

Культура Документы

High Way - Railway Road Standard

Загружено:

Er Chandra Bose0 оценок0% нашли этот документ полезным (0 голосов)

8 просмотров7 страницHigh Way - Railway Road Standard

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документHigh Way - Railway Road Standard

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

8 просмотров7 страницHigh Way - Railway Road Standard

Загружено:

Er Chandra BoseHigh Way - Railway Road Standard

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

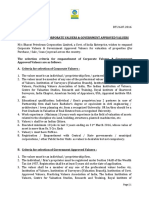

2.5 COMPARATIVE ANALYSIS OF HIGHWAY LOADING

STANDARDS

(a) Type of Loads

A critical comparative analysis of highway bridge loadings prescribed in

different countries has been presented by Thomas’. Many countries specify

the same uniformly distributed load for flexure and shear except Italy which

does not specify knife edge load with uniformly distributed load. Many

countries specify uniformly distributed loads for the full width of the traffic

lane while Sweden specifies it as a strip load in two strips of 0.6 m each

running for the entire loaded length. Alternatively Sweden allows the uniformly

distributed load to be applied uniformly over a width of 2.4 m. except the H.A

type group, all countries which have an equivalent uniformly distributed load

system, have at least an alternative truck loading which has to be considered

in the design. Designs based on H.A type loading should generally be checked

for H.B type loading.

In Italy separate Civil and Military loadings are specified and prominent

bridges are invariably designed for the heavier military loading. Many of the

countries do not explicitly specify military loadings, however IRC Class 70 R

of India, the caterpillar of Austria and the NK-80 loading of Russia are based

on the loading of military vehicles.

(b) Lane Width

The lane width in most countries is in the range of 2.5 to 4.0 m with

3 mas the most common value. However Japan prescribes a wider lane width

of 5.5 m. In countries like India, Pakistan and Russia, where there is no

standard lane loading; only the minimum widths of carriage way for different

tiumber of lanes are specified.

(c) Impact Allowance

In most of the countries, impact is related to the loaded length (span length)

although the exact relationship varies considerably from country to country.

Some of the countries like India and Austria specify different impact factors

for concrete and steel bridges. Higher impact factors specified for steel

bridges are due to the lighter structures being subjected to a larger dynamic

effect.

In countries like Italy and West Germany, impact is ignored for span

lengths exceeding 100 and 50 m respectively. In comparison, countries like

India and Australia specify certain minimum values of impact. Belgium and

France relate the impact factor to the dead load of the bridge. The impact

formula of Belgium is further complicated by the inclusion of speed of the

vehicle on the bridge deck.

(d) Magnitude of Loads, Bending Moment and Shear Forces

A comparative analysis of loadings specified in different countries has been

reported by Thomas’. British loading of Type HB is the most severe followed

by IRC loadings for both single and two lane simply supported spans. The

loadings of different countries vary considerably both qualitatively and

quantitatively.

Raina® has prescribed a critical comparison of bending moments and

shear forces developed in simply supported bridge decks due to the live loads

prescribed in various countries for spans ranging from 5 to 100 m. Tables 2.2

to 2.5 show the variation of maximum bending moment and shear force

(inclusive of impact) for salient values of simply supported predominant

spans of 5, 25, 50, 75 and 100 m.

Based on the comparative analysis, the following general observations are

noteworthy.

(1) The maximum bending moments for a single lane loading occurs due

to the British loadings of HB type for the span range of 5 to 100 m.

However the maximum shear force develops for HB type loading for

spans from 5 to 75 m and IRC loadings yicld the highest shear force

for 100 m span.

(2) Fortwo lanes, the West German Class 60 loading results in the maximum

bending moment and shear force for all the spans from 5 to 100 m.

(3) For both single and double lanes, the AASHTO loading gives the least

bending moment and shear force for all spans with magnitudes nearly

half that given by the German loading.

The British type HA and French loadings are almost similar in effect for

spans up to about 50 m and beyond that, the latter yields slightly higher

values of moments and shear forces for both single and double lanes.

The New Zealand loading is marginally heavier than that of AASHTO

loading for spans up to 50 m, beyond that, it gives the same values of

bending moment, but in the case of shear force, it results in higher

values for all spans.

(4

(5

The comparative analysis indicates the wide qualitative and quantitative

variation in the loadings of different countries. Analysis indicates that the

equivalent uniformly distributed load system appears to be the most acceptable

since it is simpler for application. Due to this factor many countries have

adopted the HA and AASHTO loadings for the design of bridge decks.

A critical survey of the impact factors specified by the various countries

indicates the basic differences in their approach in assessing the dynamic

effect of live loads on the bridge deck: Raina® has indicated that the impact

formula prescribed by some countries is unnecessarily complicated since the

effect of live load on the bridge deck is comparatively less than that of dead

load for span lengths exceeding 25 m. However there is need for qualitative

research in this field to investigate the behavior of the bridge structure under

dynamic loads and the resulting data will be helpful in evolving rational design

procedures. From considerations of simplicity of loading and ease of its

application in design, type HA loading appears to be the most favorable among

the various load systems.

There is significant variation in the type of highway loads specified in the

standards of various countries. Raina® has made a critical analysis of the

bending moments and shear forces developed due to the standard loadings

specified by the various countries for single and double lane traffic, covering

spans in the range of 5 to 100 m as shown in Tables 2.2 to 2.5. For the range

of spans covered, the extreme variations in the bending moment and shear

forces developed due to AASHTO loadings is only half of that due to German

loadings. The loadings of the various other countries generally lie in between

the American and German loadings. In view of these wide variations, there

isa need for a systematic survey of vehicular loads on bridges for rationalization

of Highway Bridge loading standards.

Table 2.2 Maximum Bending Moments for One Lane Simply Supported

Spans of Bridge Decks due to Loads of Various Countries

Maximum Bending Moment Inclusive of Impact (kN-m)

Span] UK | UK | India | Germany | Japan | Sweden| France| North — | New

(m) | Type | Type | LRC | Class-60 | L-20 Ameri- | Zea-

H.A | H.B_ | Loads} Loads Loads land

Loads | Loads

s | 243 [756 | 687 | 672 551 | 450 | 390 231

25 | 3156 | 7862 | 5680 | 4952 | 4083 | 50S0 | 3290 2485

50 | 8656 | 19029 | 12496} 10830 11344} 11300 | 8870 5738

75 | 15117] 30251 | 19683 | 19877 21682) 17550 | 15848 9155

100 | 22875} 41487 | 33580| 31268 33494} 23800 | 24106 15184

Table 2.3 Maximum Shear Forces for One Lane Simply Supported

Spans of Bridge Decks due to Loads of Various Countries

Maximum Shear Force Inclusive of Impact (kN)

Span} U.K | U.K | India | Germany | Japan | Sweden | France | North New

(m) | Type | Type | LR.C | Class-60 | L-20 Ameri- | Zea-

HA | H.B_ | Loads| Loads — | Loads caA- | land

Loads | Loads ASHTO

HS:20-44

Loads

5 | 199 | 738 | 549 | 571 441 | 420 359 212 212

25 | 505 1451 | 978 | 807 653 | 820 569 369 447

50 | 693 | 1625 | 1090 | 872 908 910 | 710 | 410 501

75 | 806 | 1684 | 1477 | 1064 1156 | 940 | 845 | 529 606

100 | 915__| 1713 | 1776 | 1254 1340 | 955 | 964 | 647 758

Table 2.4 Maximum Bending Moments for Two Lane Simply Supported

Spans of Bridge Decks due to Loads of Various Countries

Maximum Bending Moment Inclusive of Impact (kN'm)

Span| UK | UK | India | Germany | Japan | Sweden | France | North | New

(m) | Type | Type | LR.C | Class-60 | L-20 Ameri- | Zea-

H.A | H.B | Loads | Loads Loads ca A- land

Loads | Loads ASHTO

HS:20-44

Loads

5 [488 | 838 | 687 |1224 | 827 |6so [780 | 462 462

25 | 6312 | 8914 | 5680 | 9904 6125 | 5819 | 6580 | 4044 4970

50 | 17132] 21914) 12496 | 21660 17016 | 15838 | 17740 | 9194 11476

75 | 30234] 35290] 23486] 39754 | 32523 | 26250 |31696 | 18310 | 18310

100 | 45750] 49112] 42880 | 62536 _| $0241 | 37300 _| 48212 | 30368 | 30368

Table 2.5 Maximum Shear Forces for Two Lane Simply Supported

Spans of Bridge Decks due to Loads of Various Countries

Maximum Shear Force Inclusive of Impact (kN)

Span] UK | UK | India | Germany| Japan | Sweden| France | North | New

(m) | Type | Type | LR.C | Class-60 | L-20 Amori- | Zeo-

H.A |H.B | Loads| Loads | Loads caA- | land

Loads | Loads ASHTO

HS:20-44

Loads

5 | 398 | 804 |594 | 1142 | 661 | 512 | 718 | 424 424

25 | 1010 | 1619 }978 | 1614 =| 980, 931 | 1138 | 738 394

50 | 1386 | 1856 | 1174 | 1744 | 1361 | 1267 | 1420 | 820 1002

75 |"1612 | 1952 | 1572 | 2128 . | 1735 | 1400 | 1690" | 1088 | 1212

100 | 1830 | 2018 | 1996 | 2508 | 2010 | 1492_| 1928 | 1294 | 1516

2.6 Indian Railway Bridge Loading Standards

Railway bridge loadings* should conform to the specifications of the Indian

Railway Standards (IRS) prescribed by tle Ministry of Railways, Government

of India. The various loads to be used are specified in the IRS Bridge rules.

Specific recommendations are available for the design of steel. R.C.C, P.S.C,

masonry and plain concrete arch bridges in the relevant bridge codes.

The railway tracks are classified according to the importance of traffic

as main and branch lines. The three types of gauges used in the Indian

Railways are.

(1) Broad gauge (BG): 1676 mm (5’-6”)

(2) Metre gauge (MG): 1000 mm (3’-3.375”)

(3) Narrow gauge (NG): 762 mm (2'-6”)

At present, the Indian Railways have adopted the unigauge policy with the

broad gauge as the standard gauge throughout the country. Consequently

many important old lines are being converted into broad gauge.

The various loads and forces to be considered in the design of bridge

members are:

(1) Dead and live loads:

(2) Dynamic effects

(3) Cetrifugal force due to curvature of track

(4) Temperature and frictional effects

(5) Racking force

(6) Wind and earthquake forces

IRS Bridge Rules recommends the use of equivaenk uniformly distributed

loads (EUDL) on each track and also the coefficient of dynamic augment

(CDA) for spans varying from | to 130 m for both BG and MG as shown

in Tables 2.6 and 2.7.

The equivalent loads specified for the computation of bending moment and

shear forces can directly be used in place of the various wheel loads of the rolling,

stock. Hence except in the case of special bridges like the Rigid Frame, balanced

cantilever and Suspension bridges, the designer can directly use the equivalent

loads in place of the basic wheel loads. The Impact Factors (CDA) listed in the

Tables are for single track spans of BG and MG based on the relation:

CDA =0.15 + <1.0 where L=span

(6+L) .

For main girders of double track spans, the value specified above is

multiplied by a reduction factor of 0.72.

Bridges located in the seismic zones have to be designed to resist the

stresses produced due to seismic effects conforming to the recommendations

in the Indian Standard Code IS: 1893-1975'°.

Table 2.6 E.U.D.L., C.D.A and Longitudinal Loads for

Modified B.G. Loading

Span Total UD.L Total UDL CDA ‘Tractive Braking

for B.M for SF (LF) Effort Force

(m) (kN) (KN) (KN) CKN)

1 490 490 1,000 81 62

2 490 519 1.000 164 123

3 490 662 1,000 245 184

4 596 178 0.950 245. 184

5 7A 888 0.877 245 184

6 838 985 0817 245 185

7 oI 1068 0,765 327 221

8 981 1154 0.721 409 276

9 1040 1265 0.683 409 216

10 1101 1377 0.650 490 331

2 1377 1589 0.594 490 331

1s 1631 1801 0.531 490 368

20 1964 2168 0.458 735 496

235 2356 2586 0.408 735 565

30 2127 2997 0372 981 662

40 3498 3815 0324 981 816

50 4253 4630, 0.293 981 978

60 5051 5442 0271 981 1140

72 5831 6254 0.255 981 1301

80 6603 7065 0.243 981 1463

90 7391 7876 0.233 981 1625

100 8201 8686 0.225 981 1787

110 9011 9496 0219 981 1949

120 9820 10306 0.213 981 2110

130 10630 1s 0.209 981 2272

Bridges planned in the coastal areas have to be designed to withstand the

effect of wind pressure. The basic wind pressure is to be obtained from the

meteorological records or from the Indian Standard Code IS: 875-1987".

Table 2.7 E.U.D.L., C.D.A and Longitudinal Loads for

Modified -M.G. Loading

Span TotalE.U.D.L Total E.U.D.L CDA Tractive Braking

for BM forS.F (LF) Effort Force

(m) (KN) (KN ) (KN) (KN)

1 314 314 1.000 89 7

2 314 365 1.000 18 B

3 326 452 1,000 118 us

4 429 536 0.950 157 18

5 501 616 0.877 157 124

6 581 685 0817 157 124

7 644 755 0.765 176 135

8 714 819 0.721 209 157

9 774 871 0.683 262 169

to 828 934 0.650 262 198

12 953 1061 0594 314 235

15 1138 1252 0.531 353 253

20 1421 1532 0.458 an 353

25 1677 1833 0.408 523 401

30 1991 2144 0.372 628 486

40 2589 2748 0.324 628 594

50 3099 3269 0.293 628 702

60 3625 3819 0271 08 810

70 4178 an 0.255 8 918

80 4721 4922 0243 28 1026

90 5274 5470 0233 8 1134

100 5822 6017 0.225 8 1242

110 6365 6562 0219 8 1349

120 6908 7106 0213 os 1487

8 1565

130 7451 1649 0.209

Вам также может понравиться

- Is Unit-5 Part 1Документ27 страницIs Unit-5 Part 1Er Chandra BoseОценок пока нет

- MHC JSW Amnat2013Документ12 страницMHC JSW Amnat2013Er Chandra BoseОценок пока нет

- Estimation SheetДокумент1 страницаEstimation SheetEr Chandra BoseОценок пока нет

- Bose Construction - Desktop PC Build with Intel i5, ASUS B660M, 16GB RAM, 500GB NVME, 27Документ1 страницаBose Construction - Desktop PC Build with Intel i5, ASUS B660M, 16GB RAM, 500GB NVME, 27Er Chandra BoseОценок пока нет

- Feasibility Study For Cotton Spinning MillДокумент122 страницыFeasibility Study For Cotton Spinning MillNoman Ansari100% (2)

- Me ST 3 ST7014 Dec 2016Документ2 страницыMe ST 3 ST7014 Dec 2016Er Chandra BoseОценок пока нет

- Design of Tower FoundationsДокумент7 страницDesign of Tower FoundationsGuillermo LockhartОценок пока нет

- Is Unit-5 Part 2Документ30 страницIs Unit-5 Part 2Er Chandra BoseОценок пока нет

- Industrial Structures NotesДокумент86 страницIndustrial Structures NotesEr Chandra BoseОценок пока нет

- IS 4995 (Part 1) 1974Документ20 страницIS 4995 (Part 1) 1974Sumit Narayan0% (1)

- A Project Report On Analysis and DesignДокумент14 страницA Project Report On Analysis and Designyoyo 9585873163100% (1)

- PROJECT PROFILE ON SPINNING MILL (14400 SPINDLESДокумент6 страницPROJECT PROFILE ON SPINNING MILL (14400 SPINDLESAnand Arumugam0% (1)

- SELVAM-Plumbing QuationДокумент1 страницаSELVAM-Plumbing QuationEr Chandra BoseОценок пока нет

- A Project Report On Analysis and Design of Multi Storey (G+6) Residential Building Using Staad ProДокумент131 страницаA Project Report On Analysis and Design of Multi Storey (G+6) Residential Building Using Staad ProEr Chandra BoseОценок пока нет

- Toilet DetailsДокумент1 страницаToilet DetailsEr Chandra BoseОценок пока нет

- Eti 5Документ10 страницEti 5Er Chandra BoseОценок пока нет

- Annexure-II (Application For Empanelment of Government Approved Valuers)Документ4 страницыAnnexure-II (Application For Empanelment of Government Approved Valuers)Er Chandra BoseОценок пока нет

- Structural Glass Design SummaryДокумент1 страницаStructural Glass Design SummaryEr Chandra BoseОценок пока нет

- Screen Shot 2016-07-27 at 3.50.29Документ1 страницаScreen Shot 2016-07-27 at 3.50.29Er Chandra BoseОценок пока нет

- Notice For Empanelment of CV & GAVДокумент2 страницыNotice For Empanelment of CV & GAVEr Chandra BoseОценок пока нет

- Guru MSC Project ReportДокумент62 страницыGuru MSC Project ReportEr Chandra BoseОценок пока нет

- St7016 Prefabricated StructuresДокумент128 страницSt7016 Prefabricated StructuresSelva Raj77% (13)

- Annexure-I (Application For Empanelment of Coporate Valuers)Документ4 страницыAnnexure-I (Application For Empanelment of Coporate Valuers)Er Chandra BoseОценок пока нет

- Basic Principle of ValuvationДокумент20 страницBasic Principle of ValuvationEr Chandra BoseОценок пока нет

- Segregation of Fresh ConcreteДокумент1 страницаSegregation of Fresh ConcreteEr Chandra BoseОценок пока нет

- Mineral and chemical admixtures improve concrete propertiesДокумент2 страницыMineral and chemical admixtures improve concrete propertiesEr Chandra BoseОценок пока нет

- Model MaterialsДокумент2 страницыModel MaterialsEr Chandra BoseОценок пока нет

- Ce2404 Pcs NotesДокумент49 страницCe2404 Pcs NotesChockalingamОценок пока нет

- Concrete Beam 10m - 100mm - 300mmДокумент1 страницаConcrete Beam 10m - 100mm - 300mmEr Chandra BoseОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)