Академический Документы

Профессиональный Документы

Культура Документы

Veran Structural Model2

Загружено:

mr. oneАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Veran Structural Model2

Загружено:

mr. oneАвторское право:

Доступные форматы

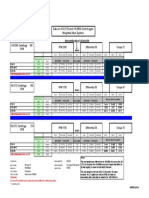

GENERAL STRUCTURAL NOTE & TABLES

CONT. TOP BARS

CONT. TOP BARS ADD'L. TOP BARS

ADD'L. TOP BARS

1.0 GENERAL

1.01 DRAWINGS SHALL NOT BE SCALED, UNLESS DIRECTED BY THE ENGINEER.

1.02 SUBMIT SHOP DRAWINGS FOR ALL STRUCTURAL STEEL AND REINFORCING STEEL

FOR APPROVAL BEFORE FABRICATION.

1.03 FOR STRUCTURAL ELEMENTS, STRUCTURAL DIMENSIONS PREVAIL OVER

ARCHITECTURAL DRAWINGS.

NOTE 3.7 ANCHORED

NOTE 3.7 ANCHORED BOTTOM BARS

BOTTOM BARS ANCHORED

2.0 DESIGN LOADS BOTTOM BARS

ADD'L. BOTTOM BARS NOTE 6.1

2.01 BASIC DESIGN LOADS ARE AS INDICATED ON TABLE 1. LIVE LOADS SHALL NOT BE

EXCEEDED AT ANY TIME. NOTE 6.1

2.02 PARTITIONS: REFER TO ARCHITECTURAL DRAWINGS FOR EXACT LAYOUT. DO NOT

ALTER PARTITION TYPES IF IT RESULTS

IN INCREASED WEIGHT. PROVIDE ALL NEEDED DOWELS AND ANCHORS BEFORE

POURING CONCRETE.

2.03 EQUIPMENT LOADS

COLUMN BEAM CONNECTION TRANSITION OF DIFF. BEAM TYP. DETAIL

- RECHECK EQUIPMENT LOADS SO THAT SLAB LOADS DO NOT EXCEED 1.9KPA,

INCLUDING MOUNTING PADS.

- IF LOAD EXCEEDS 1.9KPA, PROVIDE STEEL SPREADER BEAMS TO TRANSFER

LOADS TO BEAMS AND COLUMNS.

- SUBMIT CALCULATIONS AND SHOP DRAWINGS FOR SPREADER BEAMS.

- INSTALL HEAVY EQUIPMENT USING CRANES DIRECTLY TO FINAL POSITION

THRU WALL OPENINGS

- DO NOT BRING IN HEAVY EQUIPMENT THRU CORRIDORS, STAIRS OR ELEVATORS

UNLESS WITH PRIOR APPROVAL.

- LOCATIONS THAT CAN BE OVERLOADED BY PASSAGE OF HEAVY EQUIPMENT CONT. TOP BARS

BEAM CONT. TOP BARS

SHALL BE TEMPORARILY PROPPED DURING PASSAGE. ADD'L. TOP BARS

ADD'L. TOP BARS

3.0 STRUCTURAL DESIGN CRITERIA

3.01 APPLICABLE CODES: WORK SHALL BE GOVERNED BY ANY OR ALL OF THE FOLLOWING : NOTE 6.1

1. NATIONAL STRUCTURAL CODE OF THE PHILIPPINES (NSCP), 2001 EDITION BY ASEP

GIRDER

2. UNIFORM BUILDING CODE, 1997 EDITION, VOLUME 1-3, BY ICBO

3. ACI BUILDING CODE 318-05 ANCHORED

4. AISC 1997 EDITION CONT.BOTTOM BARS BOTTOM BARS

5. ACI-315, MANUAL OF STANDARD PRACTICE FOR DETAILING CONCRETE

3.02 SOIL BEARING CAPACITY ADD'L. BOTTOM BARS

ADD'L. BOTTOM BARS

SOIL BEARING CAPACITY USED FOR DESIGN ARE AS FOLLOWS:

FOOTINGS RESTING ON SOIL 3500 PSF (167.58 KPA)

NOTE 6.1

4.0 EARTHWORK CANTILEVER BEAM TYP. DETAIL BEAM TO GIRDER DETAIL

4.01 EXCAVATE FOOTINGS AS SHOWN. FOOTINGS SHALL REST DIRECTLY ON

UNDISTURBED "ADOBE." IF LOOSE, SOFT OR POOR SUBGRADE IS FOUND, NOTIFY

THE DESIGN ENGINEER FOR RE-EVALUATION OF SOIL BEARING.

4.02 COMPACT ALL BACKFILL IN LAYERS NOT MORE THAN 150MM TO 90% DENSITY.

4.03 BELOW SLAB ON GRADE PROVIDE 50MM GRANULAR BASE COMPACTED TO 90% DENSITY.

5.0 CONCRETE

5.01 REFER TO TABLE 2 FOR CONCRETE STRENGTH, SLUMP AND AGGREGATE SIZE.

5.02 COMPACT CONCRETE WITH VIBRATORS AND CURE FOR AT LEAST 7 DAYS USING

APPROVED METHODS

5.03 PROVIDE ALL DOWELS, ANCHORS, EMBEDDED CONDUITS, MOULDINGS, GROOVES,

ETC. BEFORE POURING.

6.0 FORMWORK

6.01 REFER TO TABLE 3 FOR FORMWORK STRIPPING DURATIONS.

6.02 PROVIDE CAMBER FOR ALL BEAMS WITH MORE THAN 6.0M SPANS, AT LEAST 2MM PER

0.15

METER SPAN AND/OR AS DIRECTED BY THE ENGINEER.

6.03 CHAMFER OR ROUND ALL EXPOSED EDGES OF COLUMNS AND BEAMS 20MM IF

REQUIRED BY ARCHITECT.

7.0 REINFORCEMENT

7.01 REFER TO TABLE 4 FOR TENSILE STRENGTH OF REINFORCING STEEL. WHERE NOT

SPECIFIED, USE ASTM GRADE 415.

7.02 REFER TO TABLE 5 FOR MINIMUM CONCRETE COVER.

7.03 REFER TO TABLE 6 FOR HOOKS AND BENDS. ALL STIRRUPS AND TIES FOR FRAMES

SHALL BE SEISMIC HOOPS.

7.04 SPLICES-GENERAL:

- SPLICES MAY BE LAPPED BARS, WELDED OR MECHANICAL.

- SPLICES ARE ALLOWED ONLY WHERE INDICATED ON SHOP DRAWINGS

APPROVED BY THE ENGINEER. 1A SPOT DETAIL 'A'

- LAP SPLICES SHALL NOT BE LOCATED WITHIN JOINTS OR 2 TIMES MEMBER SCALE:

-

DEPTH FROM FACE OF JOINTS

- STAGGER SPLICES AT LEAST 600MM

100mm THK D10@250 TOP BARS

7.05 LAP BAR SPLICES: 3-D12 TOP BARS

- USE CLASS B TENSION SPLICES FOR ALL COLUMNS, BEAMS, SUSPENDED LIGHTWEIGHT CHB D10@100 TOP BARS

SLABS, ELEVATOR WALLS

- USE CLASS A SPLICES ONLY WHERE ALLOWED BY THE ENGINEER. LANDING BEAM

- INDIVIDUAL BAR SPLICES WITHIN A BUNDLE SHALL NOT OVERLAP. ENTIRE

BUNDLES SHALL NOT BE LAP SPLICED.

0.15

- PROVIDE HOOP REINFORCEMENT OVER LAP LENGTHS SPACED NOT MORE

THAN D/4 OR 100MM

7.06 WELDED SPLICES: D10 TIES @ 200MM

100mm THK O.C. D10@250 BOT BARS

- CONFORM TO STRUCTURAL WELDING CODE. LOAD BEARING CHBBARS

4-D12 CONT. D10@130 CONT. D10 STIRRUPS @ 200 O.C

- ALL WELDED SPLICES MUST DEVELOP AT LEAST 125% FY.

BOT BARS 3-D12 BOTTOM BARS

- WELDING OF STIRRUPS AND TIES TO MAIN BARS NOT ALLOWED.

8.0 MASONRY

8.01 REFER TO ARCHITECTURAL DRAWINGS FOR EXACT TYPE, LOCATION. IF NOT

SPECIFIED, REFER TO TABLE 9.

1B SPOT DETAIL 'B'

8.02 IF NOT SHOWN ON THE DRAWINGS, PROVIDE 2-12MM REBAR AT ALL CORNERS, - SCALE:

WALL INTERSECTIONS AND PERIMETERS OF ALL OPENINGS.

8.03 GROUT ALL CELLS CONTAINING REBAR.

8.04 SEAL AND GUARANTEE ALL EXTERIOR MASONRY WALL JOINTS WITH COLUMNS

AND BEAMS FROM WATER PENETRATION BY USING GROUTED TUBE WATERSTOP

SYSTEMS.

HEHERSON B. JUAN AS-BUILT (2) TWO-STOREY

RESIDENCE S - 02

Вам также может понравиться

- Calculation of Foundation Design Excel SheetДокумент11 страницCalculation of Foundation Design Excel SheetRODRIGO, RHYZA100% (1)

- Mitchella Partridge Berry Materia Medica HerbsДокумент3 страницыMitchella Partridge Berry Materia Medica HerbsAlejandra GuerreroОценок пока нет

- Analysis Report Tensile Canopy - HOCKEY STADIUM - R0 - AДокумент23 страницыAnalysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ANeeraj KumarОценок пока нет

- Detailed Design: General Notes TABLE '1' Structural SteelworkДокумент1 страницаDetailed Design: General Notes TABLE '1' Structural Steelworkmsiddiq1Оценок пока нет

- QAHD Office Building 30 M Structural Plans-S100.0Документ1 страницаQAHD Office Building 30 M Structural Plans-S100.0Adrian PachecoОценок пока нет

- N12192.1a-C-0-000-1-01-0 Civil Design Basis Rev-0Документ18 страницN12192.1a-C-0-000-1-01-0 Civil Design Basis Rev-0Anonymous 3kDy7eОценок пока нет

- ReportДокумент52 страницыReportFeroz Khan PatthanОценок пока нет

- Cast in Place Pipe Anchor Pole FoundationДокумент2 страницыCast in Place Pipe Anchor Pole FoundationBAWA ALEXОценок пока нет

- Spreadsheets To BS 8110Документ11 страницSpreadsheets To BS 8110NitinShepurОценок пока нет

- Bracing - DetДокумент48 страницBracing - DetAUNGPSОценок пока нет

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreДокумент1 страницаLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenОценок пока нет

- Russian Code STAADДокумент34 страницыRussian Code STAADsriganesh07Оценок пока нет

- Peb BuildingДокумент4 страницыPeb BuildingHiren DesaiОценок пока нет

- Crack Width Check (CoP Concrete 2013) CPRДокумент4 страницыCrack Width Check (CoP Concrete 2013) CPRAndrew WtchengОценок пока нет

- Technical Specifications CanopyДокумент5 страницTechnical Specifications CanopyNaman SharmaОценок пока нет

- Standard Joist Load TablesДокумент120 страницStandard Joist Load TablesIvanBaezОценок пока нет

- Symbols For Signalling Circuit DiagramsДокумент27 страницSymbols For Signalling Circuit DiagramsrobievОценок пока нет

- Noise Barriers Supply and Installation For Burfiwala Lane & Gokhale Road Junction FlyoverДокумент20 страницNoise Barriers Supply and Installation For Burfiwala Lane & Gokhale Road Junction FlyoverAvinash JagtapОценок пока нет

- Design of Pedestal Mkd. On Grid A (Braced Bay)Документ10 страницDesign of Pedestal Mkd. On Grid A (Braced Bay)Kaustubh JadhavОценок пока нет

- Understanding Roof Live Load ReductionsДокумент1 страницаUnderstanding Roof Live Load ReductionsrarewishboneОценок пока нет

- State of The Art Penelitian - Chat GPT 2023Документ137 страницState of The Art Penelitian - Chat GPT 2023restyОценок пока нет

- Strategic Management Plan analyzing Unilever's macro and micro environmentsДокумент17 страницStrategic Management Plan analyzing Unilever's macro and micro environmentsMd Moshiul HaqueОценок пока нет

- Pennar - Decking Profile-REPLYДокумент3 страницыPennar - Decking Profile-REPLYkushaljp8989Оценок пока нет

- Trust 1 Ramos vs. RamosДокумент3 страницыTrust 1 Ramos vs. Ramosmr. oneОценок пока нет

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 21Документ1 страницаASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 21Anonymous 0x2pwMCWgjОценок пока нет

- SSX Diaphragm: Truextent® Replacement Diaphragms For JBL and RADIANДокумент2 страницыSSX Diaphragm: Truextent® Replacement Diaphragms For JBL and RADIANIvica IndjinОценок пока нет

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectДокумент22 страницыOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectToy GamesОценок пока нет

- BH-8 00Документ2 страницыBH-8 00Naveen ChodagiriОценок пока нет

- Technical Info on Fine Thread Drywall ScrewsДокумент2 страницыTechnical Info on Fine Thread Drywall ScrewsNajeeb AhmedОценок пока нет

- General Construction NotesДокумент1 страницаGeneral Construction NotesjanelleОценок пока нет

- IS 14817 (Part 2) 2004 - MECHANICAL VIBRATION - EVALUATION OF MACHINE VIBRATION - PART 2 LARGE LAДокумент11 страницIS 14817 (Part 2) 2004 - MECHANICAL VIBRATION - EVALUATION OF MACHINE VIBRATION - PART 2 LARGE LAAbinashBeheraОценок пока нет

- Design Aids of Flexural Members and Beam Columns Based On Limit State Method PDFДокумент16 страницDesign Aids of Flexural Members and Beam Columns Based On Limit State Method PDFscshekarОценок пока нет

- Fabrication Tolerances for Cold-Formed and Built-Up Structural MembersДокумент4 страницыFabrication Tolerances for Cold-Formed and Built-Up Structural MembersSyed Tauseef ShahОценок пока нет

- Section A-A: Wall Cheq'D PlateДокумент1 страницаSection A-A: Wall Cheq'D PlateAL BASTAKI CONTRACTING L.L.C.50% (2)

- Compilation 2010-t-2Документ1 страницаCompilation 2010-t-2api-271252079Оценок пока нет

- Sheet Size and Sewage Rising Main DetailsДокумент1 страницаSheet Size and Sewage Rising Main DetailsmohdnazirОценок пока нет

- POS CAL TP No10 Vb2 C200x80x7 - 5 CVR Bolt R0 20180731Документ26 страницPOS CAL TP No10 Vb2 C200x80x7 - 5 CVR Bolt R0 20180731Nguyễn Duy QuangОценок пока нет

- Timber dome structures for salt storageДокумент6 страницTimber dome structures for salt storageLidhia Fairuz HarlyОценок пока нет

- AsrsДокумент58 страницAsrsaman_88_vermaОценок пока нет

- Bs5950 Calculation Decking SheetДокумент6 страницBs5950 Calculation Decking SheetKho C Ahl100% (1)

- Concrete Mix Design As Per IS CodeДокумент11 страницConcrete Mix Design As Per IS CodeRavikant YadavОценок пока нет

- BoqДокумент24 страницыBoqDilshad AhemadОценок пока нет

- GratingДокумент8 страницGratingGhanshyam PandeyОценок пока нет

- Can Csa S806-02 (115-119)Документ5 страницCan Csa S806-02 (115-119)JEISON CALIXTO VARGASОценок пока нет

- EMCO Electro Drum BrakesДокумент7 страницEMCO Electro Drum Brakeshardik033Оценок пока нет

- Stranges Table rainfall runoff parametersДокумент4 страницыStranges Table rainfall runoff parametersVishnuteja AОценок пока нет

- Structure Design of Foundation of Light Pole IS 875Документ8 страницStructure Design of Foundation of Light Pole IS 875YashwantRajVermaОценок пока нет

- 1m X 1m Single Cell Box CulvДокумент6 страниц1m X 1m Single Cell Box CulvKush Deka100% (1)

- Technical Data Sheet For Hilti HIT HY 200 Injectable Mortar in Concrete Technical Information ASSET DOC 8258686 PDFДокумент41 страницаTechnical Data Sheet For Hilti HIT HY 200 Injectable Mortar in Concrete Technical Information ASSET DOC 8258686 PDFiabdillahОценок пока нет

- Rhomboidal Steel Wire Rope Net Panels SpecificationДокумент5 страницRhomboidal Steel Wire Rope Net Panels SpecificationSOMNATH JANAОценок пока нет

- 2.analysis and Design of Inclined Columns - CompressДокумент77 страниц2.analysis and Design of Inclined Columns - Compressyigit erkoc100% (1)

- CFSD - Paper - 2013 AISI CFS Design Manual - 11-05-2014 PDFДокумент13 страницCFSD - Paper - 2013 AISI CFS Design Manual - 11-05-2014 PDFBONDHON-2 APARTMENTОценок пока нет

- Culvert End Section PlansДокумент19 страницCulvert End Section PlansHemanthОценок пока нет

- Corrugated Sheets Design GuideДокумент12 страницCorrugated Sheets Design GuideRama KrishnaОценок пока нет

- ACI 347-04 Guide To Formwork For ConcreteДокумент3 страницыACI 347-04 Guide To Formwork For ConcreteAlpin MaulidinОценок пока нет

- Class A Loads Govt. of West Pakistan - Code of Practice Highway BridgesДокумент1 страницаClass A Loads Govt. of West Pakistan - Code of Practice Highway BridgesBunkun150% (1)

- 8 Truss Connection SystemДокумент27 страниц8 Truss Connection SystemyoooОценок пока нет

- How To Retrofit RCC StructureДокумент25 страницHow To Retrofit RCC StructureAmit GargОценок пока нет

- Keshmen Consult SDN BHD: Design of Slab On Grade To TR34Документ2 страницыKeshmen Consult SDN BHD: Design of Slab On Grade To TR34Kevin LowОценок пока нет

- Laboratory Test Frequency LGEDДокумент6 страницLaboratory Test Frequency LGEDmohammed nusrot hossanОценок пока нет

- Castellated Beam PropertiesДокумент2 страницыCastellated Beam Propertieshemantkle2uОценок пока нет

- Design of Base Plate and Anchor BoltsДокумент7 страницDesign of Base Plate and Anchor BoltsShaikh Muhammad AteeqОценок пока нет

- Technical - Reference - 2007 STAAD PRO CFE 1993Документ3 страницыTechnical - Reference - 2007 STAAD PRO CFE 1993Jamv JamvОценок пока нет

- 006 STRCT1Документ1 страница006 STRCT1kingjam dimacaling2019Оценок пока нет

- Construction Notes: ElevationДокумент1 страницаConstruction Notes: ElevationJohn PaderangaОценок пока нет

- Abutment A & BДокумент1 страницаAbutment A & Bmr. oneОценок пока нет

- AsdfdsfgfДокумент1 страницаAsdfdsfgfmr. oneОценок пока нет

- Top of Deck SlabДокумент1 страницаTop of Deck Slabmr. oneОценок пока нет

- Incident Report Starbucks Wall NewДокумент4 страницыIncident Report Starbucks Wall Newmr. oneОценок пока нет

- Chef Monica's ContractДокумент12 страницChef Monica's Contractmr. oneОценок пока нет

- FGHFДокумент1 страницаFGHFmr. oneОценок пока нет

- SdadfdsfaДокумент1 страницаSdadfdsfamr. oneОценок пока нет

- Combined Footing Design: ASDIP Foundation 4.4.2Документ4 страницыCombined Footing Design: ASDIP Foundation 4.4.2mr. oneОценок пока нет

- Circular Column Axial Load Enhancement: Code: NCHRP/ Aashto LRFD 2012Документ1 страницаCircular Column Axial Load Enhancement: Code: NCHRP/ Aashto LRFD 2012mr. oneОценок пока нет

- SDFDFGDFGДокумент2 страницыSDFDFGDFGmr. oneОценок пока нет

- SdasaДокумент1 страницаSdasamr. oneОценок пока нет

- Base Plate / Anchorage Design: ASDIP Steel 5.0.5Документ3 страницыBase Plate / Anchorage Design: ASDIP Steel 5.0.5mr. oneОценок пока нет

- Circular Column Axial Load Enhancement: Code: NCHRP/ Aashto LRFD 2012Документ1 страницаCircular Column Axial Load Enhancement: Code: NCHRP/ Aashto LRFD 2012mr. oneОценок пока нет

- SdasfdfaДокумент1 страницаSdasfdfamr. oneОценок пока нет

- Circular Column Axial Load Enhancement: Code: NCHRP/ Aashto LRFD 2012Документ1 страницаCircular Column Axial Load Enhancement: Code: NCHRP/ Aashto LRFD 2012mr. oneОценок пока нет

- PS No. 18Документ1 страницаPS No. 18mr. oneОценок пока нет

- Rep Strike Revilla - E-Sports BillДокумент4 страницыRep Strike Revilla - E-Sports Billmr. oneОценок пока нет

- Circular Column Axial Load Enhancement: Code: NCHRP/ Aashto LRFD 2012Документ1 страницаCircular Column Axial Load Enhancement: Code: NCHRP/ Aashto LRFD 2012mr. oneОценок пока нет

- 2nd Quarter ScienceДокумент1 страница2nd Quarter Sciencemr. oneОценок пока нет

- Spread Footing Design: ASDIP Foundation 4.4.2Документ4 страницыSpread Footing Design: ASDIP Foundation 4.4.2heherson juanОценок пока нет

- SdasdasdДокумент1 страницаSdasdasdmr. oneОценок пока нет

- Rep Strike Revilla - E-Sports Bill - FinalДокумент5 страницRep Strike Revilla - E-Sports Bill - Finalmr. oneОценок пока нет

- Committee On Local Government: Prepared by LUJДокумент6 страницCommittee On Local Government: Prepared by LUJmr. oneОценок пока нет

- Office of Congressman Strike B. RevillaДокумент1 страницаOffice of Congressman Strike B. Revillamr. oneОценок пока нет

- Rep Strike Revilla - Roll-Over Internet Bill - With EsigДокумент5 страницRep Strike Revilla - Roll-Over Internet Bill - With Esigmr. oneОценок пока нет

- Rep Strike Revilla - Roll-Over Internet Bill - With EsigДокумент5 страницRep Strike Revilla - Roll-Over Internet Bill - With Esigmr. oneОценок пока нет

- Briefer - 17 March 2021 - HealthДокумент5 страницBriefer - 17 March 2021 - Healthmr. oneОценок пока нет

- Briefer - 15 March 2021 - Subcommittee On Police AdminДокумент7 страницBriefer - 15 March 2021 - Subcommittee On Police Adminmr. oneОценок пока нет

- Briefer - 15 Sept 2020 - CHTEДокумент6 страницBriefer - 15 Sept 2020 - CHTEmr. oneОценок пока нет

- Enviroclean 25 LTRДокумент1 страницаEnviroclean 25 LTRMaziyarОценок пока нет

- Hexagon MI GLOBAL S DataSheet Letter EN NAFTA Rel5Документ22 страницыHexagon MI GLOBAL S DataSheet Letter EN NAFTA Rel5dudecastro1542Оценок пока нет

- Edexcel A-Level Biology Experimental Design Marks Scheme (1) (Full Permission)Документ16 страницEdexcel A-Level Biology Experimental Design Marks Scheme (1) (Full Permission)FardeenKhanОценок пока нет

- Digestion Unit 1 QДокумент15 страницDigestion Unit 1 QKajana Sivarasa ShenthanОценок пока нет

- AS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesДокумент31 страницаAS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDuy PhướcОценок пока нет

- Forecasting ExercisesДокумент2 страницыForecasting ExercisesAsh VinaОценок пока нет

- Ebrosur Silk Town PDFДокумент28 страницEbrosur Silk Town PDFDausОценок пока нет

- Belden CatalogДокумент24 страницыBelden CatalogMani MaranОценок пока нет

- 2 Profile OMORIS - Presentation 2020-2Документ20 страниц2 Profile OMORIS - Presentation 2020-2lemuel bacsaОценок пока нет

- NASA Technical Mem Randum: E-Flutter N78Документ17 страницNASA Technical Mem Randum: E-Flutter N78gfsdg dfgОценок пока нет

- Advanced Composite Materials Design EngineeringДокумент19 страницAdvanced Composite Materials Design EngineeringpanyamnrОценок пока нет

- LogiquidsДокумент2 страницыLogiquidsAloma FonsecaОценок пока нет

- EVOLUTION Class Notes PPT-1-10Документ10 страницEVOLUTION Class Notes PPT-1-10ballb1ritikasharmaОценок пока нет

- HS-2172 Vs HS-5500 Test ComparisonДокумент1 страницаHS-2172 Vs HS-5500 Test ComparisonRicardo VillarОценок пока нет

- Cricothyroidotomy and Needle CricothyrotomyДокумент10 страницCricothyroidotomy and Needle CricothyrotomykityamuwesiОценок пока нет

- Chapter 7 (Additional Notes) Thermodynamics Review (Power Plant Technology by M Wakil)Документ29 страницChapter 7 (Additional Notes) Thermodynamics Review (Power Plant Technology by M Wakil)Aries SattiОценок пока нет

- Pemanfaatan Limbah Spanduk Plastik (Flexy Banner) Menjadi Produk Dekorasi RuanganДокумент6 страницPemanfaatan Limbah Spanduk Plastik (Flexy Banner) Menjadi Produk Dekorasi RuanganErvan Maulana IlyasОценок пока нет

- Mycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Документ10 страницMycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Abdul MuqsitОценок пока нет

- Applying Value Engineering to Improve Quality and Reduce Costs of Ready-Mixed ConcreteДокумент15 страницApplying Value Engineering to Improve Quality and Reduce Costs of Ready-Mixed ConcreteayyishОценок пока нет

- Sanchez 07 Poles and Zeros of Transfer FunctionsДокумент20 страницSanchez 07 Poles and Zeros of Transfer FunctionsYasmin KayeОценок пока нет

- 2 - Alaska - WorksheetsДокумент7 страниц2 - Alaska - WorksheetsTamni MajmuniОценок пока нет

- Masturbation It Might Feel Good But ItsДокумент7 страницMasturbation It Might Feel Good But ItsKshivam KhandelwalОценок пока нет

- MPC-006 DДокумент14 страницMPC-006 DRIYA SINGHОценок пока нет

- II Unit - End EffectorsДокумент49 страницII Unit - End EffectorsGnanasekarОценок пока нет

- Navmesh Plus: How ToДокумент7 страницNavmesh Plus: How TobladimirОценок пока нет