Академический Документы

Профессиональный Документы

Культура Документы

Head Loss Calculation - Fire Hydrant Sys..Temporary Reiser

Загружено:

EngFaisal AlraiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Head Loss Calculation - Fire Hydrant Sys..Temporary Reiser

Загружено:

EngFaisal AlraiАвторское право:

Доступные форматы

PIPE FRICTION CALCULATION

The average velocity v in a pipe is calculated based on the formula [1] and the appropriate units

are indicated in parentheses. (see the last page for a table of all the symbols)

The Reynolds Re number is calculated based on formula [2].

If the Reynolds number is below 2000 than the flow is said to be in a laminar regime. If the

Reynolds number is above 4000 the regime is turbulent. The velocity is usually high enough in

industrial processes to make the flow regime turbulent. The viscosity of many fluids can be

found in the Cameron Hydraulic data book. The viscosity of water at 60F is 1.13 cSt.

If the flow is laminar then the friction parameter f is calculated with the laminar flow equation [3].

If the flow is turbulent then the friction parameter f is calculated based on the Swamee-Jain

equation [4].

In the turbulent flow regime the friction factor f depends on the absolute roughness of the pipe

inner wall. Table 1 provide some values for various materials.

STEEL 0.0018

ST.ST. 0.0018

CAST IRON 0.0102

PVC 0.00006

The friction factor DHFP/L is calculated with the Darcy-Weisback equation [5]

g =32.17 ft/s

The pipe friction loss DHFP is calculated with equation [6]

ENG. FAISAL ALRAI

FEB.22.2008

Calculation

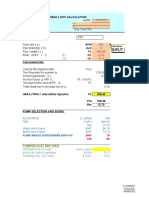

ESTIMATING PIPELINE HEAD LOSS AND PUMP SELECTION Project : TIARA UNITED TOWERS Date : 15/ 09 / 08

USING DARCY WEISBACH METHOD System : TEMP. FIRE FIGHTING RISER Prepared By : Eng. Faisal Alrai

INPUT Data

Liquid type : Water

q = flow rate Usgpm (GPM) m 113.55 500

D = pipe diameter in (inch) 6 6.165 UPVC CLASS E BS3505 500

L = pipe length ft (feet) m 110 360.89 1892.5

113.55

v velocity ft/s (feet/second)

The average velocity v in the pipe is:

V = 0.4085 Xq / D = 5.37 Ft / s

= viscosity CSt (centistokes) , WATER at 60 F 1.13

The Reynolds Re number is:

Re = 7745.8 x V *D / = 227099.84

Re^0.9 66159.945

= pipe roughness Ft (feet) 0.0018 steel STEEL 0.0018

f = friction parameter Non dimensional ST.ST. 0.0018

The friction parameter f is: CAST IRON 0.0102

f = 0.25 / {Log10 ( /3.7*D + 5.74 / Re^0.9)} 0.028046 PVC 0.00006

0.02805

HFP / L friction factor (feet of fluid/100 ft) of pipe

g = acceleration due to gravity (32.17 ft/s2) 32.17

The friction factor HFP / L is calculated with the Darcy-Weisback equation

HFP / L = 1200 f * V / D * 2g 2.45 Ft./100Ft of pipe

The pipe friction loss HFP is:

HFP = HFP / L * ( L/100) 8.84 Feet

ENG. FAISAL ALRAI

FEB.22.2008

Page 1 of 4

ESTIMATING PIPELINE HEAD LOSS AND PUMP SELECTION Project : TIARA UNITED TOWERS Date : 15/ 09 / 08

USING DARCY WEISBACH METHOD System : TEMP. FIRE FIGHTING RISER Prepared By ; Eng. Faisal Alrai

A- PIPE LOSS CALCULATION Table:1 CONVERSION FACTORS FOR HEAD LOSS FORMULA

hL = ( c1 X f X L X q ) / (d)^5 ( Ft. ) FLOW (q) c1 hL L d

hL = head loss Input data ft /min 6260 Ft of fluid Ft in

c1=conversion factor for head loss calculation (table1). 0.0311 gal /min 0.0311 Ft of fluid Ft in

f = darcy friction factor from moody curve 0.02804621 m /s 8.265x(10)10 Ft of fluid Ft mm

L = pipe length (feet) 110 m 360.89 q Lit. /min 22950 Ft of fluid Ft mm

q = flowrat gal/min 500.00 250000

d = pipe iside diameter ( inch) 150 mm upvc class E 6.165 .

Table:2 CONVERSION FACTORS FOR REYNOLDS NO. FORMULA

To find the friction factor ( f ) from curve , Re & Rr sould be calculated: FLOW (q) c2 F. density() absol.visc()

Reynolds no. Re = (c2 X q X ) / d X dX ft /sec 22700 lb/ft cp

Relative roughness of the pipe Rr = /d 6.782 gal /min 50.6 lb/ft cp

c2 = conversion factor for reynolds No. calculation 50.6 m /s 1273000 kg/m cp

= fluid weight density 62.34 Lit. /min 22950 kg/m cp

= fluid absolute viscosity 1.1

= Absolute reoughness values for clean pipe : 0.0018 Table:3 ()TYPICAL ABSOLUT ROUGHNESS VALUES FOR CLEAN PIPE

MATERIAL

Reynolds No. R. Roughness Inches Millimeters

Re Rr = /d STEEL 0.0018 0.046

232574.20924574 0.0000097 ST.ST. 0.0018 0.046

2.3257420925 CAST IRON 0.0102 0.259

Note: PVC 0.00006 0.0015

f =64/Re for laminar flow Re less than 2000

f - for turbulant flow Re greater than 2000 Table:4 DENSITIES AND VISCOOSITIES OF TYPICAL FLUIDS AT 60 F

FLUID Density Viscosity

f = 0.25 / {Log10 ( /3.7*D + 5.74 / Re^0.9)} f = 0.0280462 lb/ft

Table:5 CONVERSION FACTORS FOR VALVES AND FITTINGS FORMULA WATER 62.34 1.1

FLOW (q) C3 DIAMETER ETHAN 23 0.05

ft /sec 522 in PROPANE 31.2 0.12

gal /min 0.00259 in BUTANE 44.3 0.19

m /s 8265X(10)7 mm ETHYL ALCOHOL 49.9 1.3

Lit. /min 22.96 mm

ENG. FAISAL RAI

Feb.15.2008

Page 2 of 4

For flowrate (q) { gal/min} &water at 60F . Data and Factors will be: v = 0.4085*q/d

section flowrate factor factor density viscosity pip diam. friction pipe rough. pipe L hL V ( Ft/s )

q c1 c2 d f L(Ft) Ft

L1 500 0.0311 50.6 62.34 1.1 6.165 0.02805 0.0018 360.892388 8.84 5.37

L2 0 0.0311 50.6 62.34 1.1 1 0 0.0018 0 0 0.00

L3 0 0.0311 50.6 62.34 1.1 1 0 0.0018 0 0 0.00

L4 0 0.0311 50.6 62.34 1.1 1 0 0.0018 0 0 0.00

L5 0 0.0311 50.6 62.34 1.1 1 0 0.0018 0 0 0.00

L6 0 0.0311 50.6 62.34 1.1 1 0 0.0018 0 0 0.00

L7 0 0.0311 50.6 62.34 1.1 1 0 0.0018 0 0 0.00

Pipe Head Loss h L ( Ft ) 360.892388 8.84

B- VALVES AND FITTINGS HEAD LOSS

hLvf = c3 X K Xq/d^4 ( Ft. ) K FOR FITTINGS AND VALVES TYPE :

c3 = conversion factor for valve head loos calculation TYPE K

K = valve resistance coefficient Pipe entrance,inward proj. 0.78

K = f T X (L/d) Pipe entrance, Flush 0.5

f T = turbulant friction factors for a partucular pipe diam. Pipe Exit , all 1 OR

Ka 1.5 1.78

L/d for valves and fittings type : PIPE DIA.= 6 Ref. A&B

Type L/d from fT fitting Qty K1n K1n =[ f T X (L/d )] x No. of valve or fitting type

Gate valve 8 0.015 4 0.48 Table : 6 f T = turbulant friction factors for a partucular pipe diam.

Ball valve 6 0.015 0 0 Reference: A Reference: B

Butterfly valve 35 0.015 0 0 Fitting L/D pipe size fT

globe valve 340 0.015 0 0 Globe Valve 340 1 0.023

Check valve , lift 600 0.015 0 0 Gate Valve 8 1 1/4 0.022

Check valve , swing 50 0.015 2 1.5 Lift Check Valve 600 1 1/5 0.021

Check valve , tilting disc 20 0.015 0 0 Swing Check Valve 50 2 0.019

Ccheck valve , stop check 400 0.015 1 6 Ball Valve 6 2 1/2 - 3 0.018

Elbow -90 30 0.015 3 1.35 Butterfly Valve 35 4 0.017

Elbow-45 16 0.015 0 0 Pipe Entrance 0.5 6 0.015

Tee, flow through run 20 0.015 2 0.6 Pipe Exit 1 8 to 10 0.014

Tee, flow through branch 60 0.015 0 0 Tee Through 20 12 t0 16 0.013

Bend r/D=3 12 0.015 0 0 Tee- Branch flow 60 18 to 24 0.012

Bend r/D=6 17 0.015 0 0 Elbow-90 30

Bend r/D=12 34 0.015 0 0 Elbow -45 16

Bend r/D=20 50 0.015 0 0 Bend r/D=3 12

K b fittings 9.93 Bend r/D=6 17

Bend r/D=12 34

Bend r/D=20 50

ENG. FAISAL RAI

Feb.15.2008

kc for Equipment Page 3 of 4

Equipment kc

Equip. Qty. kc kc

CHIL. COIL 0 11 0

AHU COIL 0 0 Pipe Head Loss

H.Exch. 0 0 h L ( Ft. )

0 8.84

0

0 TOTAL VALVES & FITTINGS HEAD LOOS

Equip.kc = 0 c3 K q2 (d)^4

0.00259 11.43 250000 1444.54915

K = Ka+(K1 + K2 + K3 +Kn )+kc for valves + fittings & Equipment valves & fittings Head Loss

h L ( Ft. )

K = Ka + Kb + Kc 5.12 SEE NOTE

11.43

C TOTAL PRESSURE LOSS Bernoulli theorem

H = Z+[144 X P / ] + [ V / (2 X g)]

( pressure head and velocity head )

H = total head

Z = elevation above a reference level

p = pressure

v = mean velocity of the fluid in the pipeline

g = gravitional constat ( 32.2 ft/sec) US units.

Total head loss in the pipe line (h L)

PIPE LINE ,VALVES & FITTINGS

13.96 Ft.

Differintial pressure calculation

(p) = p1-p2 = /144 { Z2 - Z1 + (v2 - v1 ) / 2g + h L}

IF NO CHANGE IN PIPE SIZE , ,THE VELOSITY DROPS = 0

Pipe inlet Elivation (Z1) Pipe disch. Elev.(Z2)

0 360.89 Ft. 4.82 m 110 360.8

/144 hL Z2 - Z1 (v2 - v1 ) / 2g (p) PSI p Ft Mtr Bar

0.4329166667 13.96 360.89 0 162.2788 374.86 112.46 11.19

h Ft fluid = 2.31 p (psi) / SG

ENG. FAISAL RAI

Feb.15.2008

D PUMP SELECTION AND SIZING

HEAD ( TDH ) = Static head (Hs) + friction head (Hf) + pressure hesd ( Hp) + velocity head(Hv) Page 4 of 4

Static head ( Hs) = is measured from the surface of the liquid in the section vessel to the surface

of the liquid in the vessel where the liquid is being delivered. In closed-loop system , the total static head = 0 .

Fittings & valves Friction head Hf = K X V / 2g 5.12

Pipe Friction head ( From friction loss chart ) Hf = f X L /100 8.84

Velocity head Hv = V / 2g 0

f = friction ft/ 100 ft 0.02804621 Static Head 360.89

K = resistance coefficient 11.43 TOTAL DH ( Ft ) 374.85

V = Fluid velocity ft/sec. 5.37

g = acceleration due gravity = 32.2 ft./sec 32.2 Mtr 112.45

Result PSI 162.27

BAR 11.19

Design velocity = ( 4 - 6 ) ft / sec for section

= ( 6 - 8 ) ft / sec for discharge 500 GPM FIRE PUMP @ 15 BAR

1 PUMP Horsepower and efficiency:

water horsepower ( WHP ) = Outpot of the pump handlind a liquid

WHP = (Q X H X sg) / 3960

2 Brake horsepower ( BHP ) = Actual supplied power from motor

BHP = ( Q X H X sg ) / 3960 X = WHP /

= pump efficiency

3 Electric current for sizing starters and wire ( I ) [ Amp.]

I = 746 X BHP / 1.73 X E X PF X Eff for 3 ph

I = 746 X BHP / E X PF X Eff for 1 ph

E = Voltage ( volts) 380

PF = Power Factor 0.85

EFF. = Motor efficiency 0.75

1.73 242.25

419.09

Q ( GPM) H (Ft.) SG WHP BHP I ( AMP.)

500 374.85 1 47.33 63.11 112.33

PUMP BRAKE HORSPOWER BHP WILL BE +10% = 69.42 HP

75

ENG. FAISAL RAI

Feb.15.2008

OTHER METHOD

TOTAL PUMPING HEAD

Q (m3/s) H(m)

0.0315 114.28

ID = inch m

6.165 0.156591

f L(m) V ( m /s ) D(m) g

0.0280462089 110.03 1.638408 0.156591 9.81

hf = 4f X L x V / 2Dg = 4.26

hz hf hp H(m)

110.03 4.26 0.00 114.28

156.28

Q ( m /s ) 0.0315

W ( Kg/m3) 1000

H(m) 114.28

Eff. 0.75

WHP = Q X W X H / 75 = 48.06

HP / 0.75 = 64.08

HP kw

64.08 47.81

70.49

ENG. FAISAL RAI

Feb.15.2008

f = .005 ( 1 + 1 / 40 D ) ; D = Mtr.

ENG. FAISAL RAI

Feb.15.2008

Relative roughness for some common materials can be found in the table below :

Roughness - k

Surface x 10 m

-3

feet

Copper, Lead, Brass, Aluminum (new) 0.001 - 0.002 3.33 - 6.7 10-6

PVC and Plastic Pipes 0.0015 - 0.007 0.5 - 2.33 10-5

Epoxy, Vinyl Ester and Isophthalic pipe 0.005 1.7 10-5

Stainless steel 0.015 5 10-5

Steel commercial pipe 0.045 - 0.09 1.5 - 3 10-4

Stretched steel 0.015 5 10-5

Weld steel 0.045 1.5 10-4

Galvanized steel 0.15 5 10-4

Rusted steel (corrosion) 0.15 - 4 5 - 133 10-4

New cast iron 0.25 - 0.8 8 - 27 10-4

Worn cast iron 0.8 - 1.5 2.7 - 5 10-3

Rusty cast iron 1.5 - 2.5 5 - 8.3 10-3

Sheet or asphalted cast iron 0.01 - 0.015 3.33 - 5 10-5

Smoothed cement 0.3 1 10-3

Ordinary concrete 0.3 - 1 1 - 3.33 10-3

Coarse concrete 0.3 - 5 1 - 16.7 10-3

Well planed wood 0.18 - 0.9 6 - 30 10-4

Ordinary wood 5 16.7 10-3

ENG. FAISAL RAI

Feb.15.2008

0

ENG. FAISAL RAI

Feb.15.2008

HEAD LOOS & PUMP SELECTION AND SIZING

HEAD ( H ) = Static head (Hs) + friction head (Hf) + pressure head ( Hp) + velocity head(Hv)

Static head ( Hs) = is measured from the surface of the liquid in the section

vessel to the surface of the liquid in the vessel where the liquid is being delivered.

In closed-loop system , the total static head = 0 .other equesions :

Fittings & valves Friction head Hf = K X V / 2g

Pipe Friction head ( From friction loss chart ) Hf = f X L /100

Velocity head Hv = V / 2g

f = friction ft/ 100 ft

K = resistance coefficient

V = Fluid velocity ft/sec.= V= 0.4085 * q / d 5.37

g = acceleration due gravity = 32.2 ft./sec

Design velocity = ( 4 - 6 ) ft / sec for section

= ( 6 - 8 ) ft / sec for discharge

SUMMERY HEAD LOOS

PRESSURE HEAD LOOS DUE TO PIPE FRICTION

SECTION FLOW DIAM. VELOSITY f ( Hfp/L ) L Hfp

GPM in ft/s ft/100 ft pipe ft ft fluid

L1 500 6.165 5.37 2.45 360.8924 8.843

0 #DIV/0! 0 0 0.000

#DIV/0! 0 0 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000 m

Hfp=L x f /100 SUBTOTAL 360.8924 8.843 2.70

Z1 = 0 Z2 = 360.89

Static head ELIV. Z2 - Z1 360.89

PRESSURE HEAD LOOS DUE TO FITTINGS

TYPE SECTION FLOW QTY DIA. VEL. v /2g k HfF

GPM in ft/s ft fluid ft fluid

ENTRANCE 500 1 16 5.37 0.45 1 0.45

BUTTERFLY 0 0 16 8.52 1.13 1 1.13

ELBOW 500 6 16 8.52 1.13 0.28 0.32

TEE 90 0 1 16 0.00 0.00 0.7 0.00

GATE VALVE 500 2 16 8.52 1.13 8 9.03

BALL VALVE 0 0 16 8.52 1.13 0.00

GLOB VALVE 0 0 16 0.00 0.00 0.00

1 5 8.52 1.13 1 1.13

1 5 0.00 0.00

1 5 0.00 0.00

1 5 0.00 0.00

HfF ( ft fluid )= k x V(ft/s) / 2 x 32.2 (ft/s) SUB TOTAL 12.05

PRESSURE LOOS DUE TO EQUIPMENT

SECTION FLOW TYPE QTY P SG P h equip

GPM in PSI Ft fluid ft fluid

250 filter 0 0.00 0.98 0.00 0.00

250 H. EXCH 0 0.00 0.98 0.00 0.00

250 Cont.valve 0 0.00 0.98 0.00 0.00

0.00

0.00

0.00

SUB TOTAL 0.00

h Ft fluid = 2.31 p (psi) / SG

SUMMERY

PIPE Hf = f X L /100 8.84

FITTINGS Hf = K X V / 2g 12.05

EQUIP.. h equip 0.00

VEL.HEAD Hv = V / 2g 1.47

Static Head Hs 360.89 m

TOTAL HEAD LOOS 383.25 116.845072

PSI 165.90989

HEAD LOOS & PUMP SELECTION AND SIZING

1 Horsepower and efficiency:

water horsepower ( WHP ) = Outpot of the pump handlind a liquid

WHP = (Q X H X sg) / 3960

2 Brake horsepower ( BHP ) = Actual supplied power from motor

BHP = ( Q X H X sg ) / 3960 X = WHP /

= pump efficiency

3 Electric current for sizing starters and wire ( I ) [ Amp.]

I = 746 X BHP / 1.73 X E X PF X Eff for 3 ph

I = 746 X BHP / E X PF X Eff for 1 ph

E = Voltage ( volts) 380

PF = Power Factor 0.85

EFF. = Motor efficienc 0.75

1.73 242.25

419.0925

Q ( GPM) H (Ft.) SG WHP BHP I ( AMP.)

500 383.25 1 48.390383 64.52051 114.8489

71

The Friction Coefficient - The flow is

The Friction Coefficient for Laminar Flow laminar when Re < 2300

= 64 / Re (7) transient when 2300 < Re < 4000

The Friction Coefficient for Turbulent Flow turbulent when Re > 4000

= f( Re, k / dh )

k = relative roughness of tube or duct wall (m, ft)

k / dh = the roughness ratio

Relative roughness for materials are determined by experiments.

Relative roughness for some common materials can be found in the table below :

Roughness - k

Surface x 10-3 m feet

Copper, Lead, Brass, Aluminum (new) 0.001 - 0.002 3.33 - 6.7 10-6

PVC and Plastic Pipes 0.0015 - 0.007 0.5 - 2.33 10-5

Epoxy, Vinyl Ester and Isophthalic pipe 0.005 1.7 10-5

Stainless steel 0.015 5 10-5

Steel commercial pipe 0.045 - 0.09 1.5 - 3 10-4

Stretched steel 0.015 5 10-5

Weld steel 0.045 1.5 10-4

Galvanized steel 0.15 5 10-4

Rusted steel (corrosion) 0.15 - 4 5 - 133 10-4

New cast iron 0.25 - 0.8 8 - 27 10-4

Worn cast iron 0.8 - 1.5 2.7 - 5 10-3

Rusty cast iron 1.5 - 2.5 5 - 8.3 10-3

Sheet or asphalted cast iron 0.01 - 0.015 3.33 - 5 10-5

Smoothed cement 0.3 1 10-3

Ordinary concrete 0.3 - 1 1 - 3.33 10-3

Coarse concrete 0.3 - 5 1 - 16.7 10-3

Well planed wood 0.18 - 0.9 6 - 30 10-4

Ordinary wood 5 16.7 10-3

The friction coefficient - - can be calculated by the Colebrooke Equation:

1 / 1/2 = -2,0 log10 [ (2,51 / (Re 1/2)) + (k / dh) / 3,72 ] (9)

Roughness Ratio - k / dh.

Вам также может понравиться

- Total Head, N.P.S.H. and Other Calculation Examples: Jacques Chaurette P. Eng., June 2003Документ41 страницаTotal Head, N.P.S.H. and Other Calculation Examples: Jacques Chaurette P. Eng., June 2003Anonymous 1fyKr9XSeGОценок пока нет

- Hazen Williams EquationДокумент1 страницаHazen Williams EquationNur IzzaidahОценок пока нет

- Tri P10Документ10 страницTri P10Dvd Davide La CruzОценок пока нет

- Frictional Head Loss Calculation in Pumping SystemsДокумент1 страницаFrictional Head Loss Calculation in Pumping Systemsaman vermaОценок пока нет

- Sizing Duct Work SheetДокумент4 страницыSizing Duct Work SheetMaulana MaftuhiОценок пока нет

- Pump CalcДокумент1 страницаPump CalcMoch WildanОценок пока нет

- Air Blower Pipe Sizing Calculation Common Main HeaderДокумент7 страницAir Blower Pipe Sizing Calculation Common Main HeaderEngFaisal AlraiОценок пока нет

- Water Spray Hydraulic CalculationsДокумент5 страницWater Spray Hydraulic CalculationsVigneshwaran Santharam100% (1)

- Fire Calculation1Документ7 страницFire Calculation1Jesús Yarleque RamosОценок пока нет

- Hydraulic Calculation ProcedureДокумент2 страницыHydraulic Calculation ProcedureAmodu Usman AdeyinkaОценок пока нет

- Design Calculation Sheet: Chilled Water Secondary PumpsДокумент2 страницыDesign Calculation Sheet: Chilled Water Secondary PumpsgerrydimayugaОценок пока нет

- NFPA 13 hydraulic calculation for ordinary hazard group 1Документ2 страницыNFPA 13 hydraulic calculation for ordinary hazard group 1towiwaОценок пока нет

- Pump HeadДокумент12 страницPump HeadJunaid MateenОценок пока нет

- Sizing Calculation of General Service PumpsДокумент193 страницыSizing Calculation of General Service Pumpsmkha87Оценок пока нет

- JP5 Pump CalculationДокумент1 страницаJP5 Pump CalculationalvinchuanОценок пока нет

- Compressed Air GuidelinesДокумент7 страницCompressed Air Guidelinesj_moellersОценок пока нет

- Pump Head Calculation for DIC R&D Condenser Water SystemДокумент1 страницаPump Head Calculation for DIC R&D Condenser Water SystemMFaiz RHamiraОценок пока нет

- Centrifugal Pump Calculation For Safety Shower-Rev.03Документ22 страницыCentrifugal Pump Calculation For Safety Shower-Rev.03Ashish PawarОценок пока нет

- Hydraulic CalculationsДокумент6 страницHydraulic CalculationsmehranОценок пока нет

- Hydro Calc WebДокумент8 страницHydro Calc WebgrabettyОценок пока нет

- Sizing and Specifying Pumps R2Документ27 страницSizing and Specifying Pumps R2royОценок пока нет

- Pressure Drop in PipelineДокумент13 страницPressure Drop in PipelineNilambar BarihaОценок пока нет

- PUMP SIZING FORMULAEДокумент1 страницаPUMP SIZING FORMULAEvofaithОценок пока нет

- Fire Hydrant CalculatorДокумент4 страницыFire Hydrant CalculatorTri SubaktiОценок пока нет

- Pump Design - 2Документ1 страницаPump Design - 2kapsarcОценок пока нет

- Pump CurveДокумент3 страницыPump CurveLINIEL DE JESUSОценок пока нет

- Sample Calculation 50% Pump Speed 1. Pump SpeedДокумент2 страницыSample Calculation 50% Pump Speed 1. Pump SpeedMAXUELОценок пока нет

- Simulation of Distillation For ACETONE-BENZENE-CHLOROFORMДокумент8 страницSimulation of Distillation For ACETONE-BENZENE-CHLOROFORMfjcgОценок пока нет

- ZM KV Idag eДокумент6 страницZM KV Idag elutfi awnОценок пока нет

- Friction Loss in Pipe LineДокумент3 страницыFriction Loss in Pipe LineAvinash VasudeoОценок пока нет

- Hazen WilliamsДокумент2 страницыHazen WilliamssushilkumarОценок пока нет

- Pneumatic Conveying Spreadsheet-ContentДокумент27 страницPneumatic Conveying Spreadsheet-Contentaladdin4dОценок пока нет

- Pump SizingДокумент3 страницыPump Sizingtimayaa1000Оценок пока нет

- Line Sizing GuidelinesДокумент2 страницыLine Sizing GuidelinesHarryBouterОценок пока нет

- Is 13039 External Fire HydrantДокумент10 страницIs 13039 External Fire HydrantNanu PatelОценок пока нет

- Tank sizing for 150% pump capacity and sprinkler demandДокумент3 страницыTank sizing for 150% pump capacity and sprinkler demandEngFaisal AlraiОценок пока нет

- Sizing For Two PhaseДокумент6 страницSizing For Two PhaseKong LingweiОценок пока нет

- PUMP CALCULATION SHEETДокумент4 страницыPUMP CALCULATION SHEETMuhammad BilalОценок пока нет

- 5.3 Design of Waste Heat Boiler: (13) : DataДокумент7 страниц5.3 Design of Waste Heat Boiler: (13) : Datamoni beeОценок пока нет

- Calculating total system head in USCS unitsДокумент9 страницCalculating total system head in USCS unitsIrfanshah2013Оценок пока нет

- Cooling Tower ComparisonДокумент4 страницыCooling Tower ComparisonKiran DasОценок пока нет

- VSD Calculator for Fan Energy SavingsДокумент10 страницVSD Calculator for Fan Energy SavingsCésar Christian JankoОценок пока нет

- Pump Sizing Calculation SheetДокумент7 страницPump Sizing Calculation SheetManik Kandan100% (1)

- Calculation of PumpДокумент19 страницCalculation of Pumparifin rizal100% (1)

- Piping Pressure Drop and Pump Design Calculation Sheet: Operating Conditions Discharge ConditionsДокумент17 страницPiping Pressure Drop and Pump Design Calculation Sheet: Operating Conditions Discharge ConditionsDhanny Miharja100% (1)

- Yazd-System Description For Clean Drain System PDFДокумент7 страницYazd-System Description For Clean Drain System PDFace-winnieОценок пока нет

- Pump Sizing CalculationДокумент18 страницPump Sizing CalculationChaitanya BhattОценок пока нет

- CPCДокумент2 страницыCPCUok RitchieОценок пока нет

- Pump sizing calculationДокумент6 страницPump sizing calculationAtty Atty100% (1)

- 6DSUPP Desuperheater Supplement BrochureДокумент4 страницы6DSUPP Desuperheater Supplement BrochureПавел ЛукьяновОценок пока нет

- Purpose: The Purpose of This Document Is To Carry Out Hydraulic CalculationДокумент14 страницPurpose: The Purpose of This Document Is To Carry Out Hydraulic CalculationEkundayo John100% (1)

- 01 - Head Loss Calculation - 01Документ15 страниц01 - Head Loss Calculation - 01pangit catcatОценок пока нет

- Relationships for Smoke Control CalculationsДокумент148 страницRelationships for Smoke Control CalculationsArgile-assholeОценок пока нет

- All System Pump Head LoosДокумент33 страницыAll System Pump Head LoosEngFaisal Alrai100% (1)

- Cooling Tower Package Engineering in Halliburton - Multi Chem Batch PlantДокумент3 страницыCooling Tower Package Engineering in Halliburton - Multi Chem Batch PlantragulОценок пока нет

- CW Pipe Thickness Calculation - 80% Vacuum - With RCCДокумент39 страницCW Pipe Thickness Calculation - 80% Vacuum - With RCCAshitava Sen0% (1)

- Water DemandДокумент3 страницыWater DemandRaxKitОценок пока нет

- Friction Loss FlowДокумент3 страницыFriction Loss FlowCapri AkvotechОценок пока нет

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BДокумент37 страницDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTOROОценок пока нет

- Duct Size Calculator (Si) Duct Size Calculator (Ip) : W H Galvanised 0.15Документ4 страницыDuct Size Calculator (Si) Duct Size Calculator (Ip) : W H Galvanised 0.15Mohd Izham Idris100% (1)

- Gamp5 Categories & Validation DeliverablesДокумент20 страницGamp5 Categories & Validation DeliverablesEngFaisal AlraiОценок пока нет

- Vendor Management Across The Product Life Cycle: Key To Colour CodesДокумент1 страницаVendor Management Across The Product Life Cycle: Key To Colour CodesEngFaisal AlraiОценок пока нет

- Spreadsheet ValidationДокумент63 страницыSpreadsheet ValidationLeyvert De JesusОценок пока нет

- 2018 International Swimming Pool and Spa CodeДокумент104 страницы2018 International Swimming Pool and Spa CodeEngFaisal Alrai100% (2)

- DMAIC Method in Six Sigma - 5 Phases Complete OverviewДокумент16 страницDMAIC Method in Six Sigma - 5 Phases Complete OverviewEngFaisal AlraiОценок пока нет

- Fire Sprinklers Hydraulic CalculationsДокумент38 страницFire Sprinklers Hydraulic CalculationsVerlin Ann LacastesantosОценок пока нет

- Pharmastate: User Requirements Specification (Urs) ForДокумент9 страницPharmastate: User Requirements Specification (Urs) ForEngFaisal AlraiОценок пока нет

- 8D Report FormatДокумент1 страница8D Report FormatDeepak ShrivastavОценок пока нет

- 2 - Hvac Duck WorkДокумент41 страница2 - Hvac Duck WorkEngFaisal AlraiОценок пока нет

- Healthcare Data Information SpreadsheetДокумент10 страницHealthcare Data Information SpreadsheetEngFaisal AlraiОценок пока нет

- All NFPA Tables Fire Sprinklers & Fire Pump: Classification of OccupanciesДокумент5 страницAll NFPA Tables Fire Sprinklers & Fire Pump: Classification of OccupanciesEngFaisal AlraiОценок пока нет

- Chilled Water LabelДокумент3 страницыChilled Water LabelEngFaisal AlraiОценок пока нет

- Const Estimate Made EasyДокумент27 страницConst Estimate Made EasyJohnMiguelMolina100% (2)

- User Requirement Specification (URS) of EquipmentsДокумент2 страницыUser Requirement Specification (URS) of EquipmentsEngFaisal AlraiОценок пока нет

- Differenance Btween ROEDI WaterДокумент1 страницаDifferenance Btween ROEDI WaterEngFaisal AlraiОценок пока нет

- Chilled Water Pump Head Calculation SHEETДокумент15 страницChilled Water Pump Head Calculation SHEETraifaisalОценок пока нет

- Sound Attenuator InstallationДокумент9 страницSound Attenuator InstallationLuis UrzoОценок пока нет

- Dehumidification CalculationДокумент3 страницыDehumidification CalculationReda KadryОценок пока нет

- Acoustic Calculation of Ventilation Systems Noise LevelsДокумент4 страницыAcoustic Calculation of Ventilation Systems Noise LevelsEngFaisal AlraiОценок пока нет

- تفريد تسليحДокумент4 страницыتفريد تسليحMerleauОценок пока нет

- 00 HVAC CalcДокумент52 страницы00 HVAC Calcibson045001256Оценок пока нет

- Software ImplementationДокумент1 страницаSoftware ImplementationEngFaisal AlraiОценок пока нет

- AC Duct Cal. REV. 2Документ6 страницAC Duct Cal. REV. 2EngFaisal AlraiОценок пока нет

- Production Plant BoQ in EgyptДокумент15 страницProduction Plant BoQ in Egyptxchannel28Оценок пока нет

- AC Size Calculation (28!5!11)Документ4 страницыAC Size Calculation (28!5!11)jiguparmar1516Оценок пока нет

- Architectural engineering calculations spreadsheetДокумент18 страницArchitectural engineering calculations spreadsheetEngFaisal AlraiОценок пока нет

- @S V All FansДокумент23 страницы@S V All Fansamo3330Оценок пока нет

- Web DesignДокумент1 страницаWeb DesignEngFaisal AlraiОценок пока нет

- 300 Lit Water Tanks Stem Heating CalculationДокумент8 страниц300 Lit Water Tanks Stem Heating CalculationEngFaisal AlraiОценок пока нет

- TelecomДокумент1 страницаTelecomEngFaisal AlraiОценок пока нет

- Piezoelectric Effect GuideДокумент9 страницPiezoelectric Effect GuideFasihah Arshad100% (1)

- E 0211Документ23 страницыE 0211Thinh ViproОценок пока нет

- Lab Report 2 (Thermo) - UTSДокумент8 страницLab Report 2 (Thermo) - UTSsiddhant dhimanОценок пока нет

- Corrosion Resistant OCTG and Bar For Sour Gas Service PDFДокумент14 страницCorrosion Resistant OCTG and Bar For Sour Gas Service PDFallouche_abdОценок пока нет

- Moving Wall UDf ExampleДокумент6 страницMoving Wall UDf Exampleqasim zaheerОценок пока нет

- Structural Design of Steel StructuresДокумент43 страницыStructural Design of Steel Structureskiran sreekumarОценок пока нет

- Loss of Field or Excitation Protection of Alternator or GeneratorДокумент4 страницыLoss of Field or Excitation Protection of Alternator or Generatorsiddhant103Оценок пока нет

- Chapter 6 Exercises Problems AnswersДокумент9 страницChapter 6 Exercises Problems AnswersA Sibiescu100% (1)

- 03 - Metal CastingДокумент66 страниц03 - Metal Castinghh100% (1)

- MPWP Complete NotesДокумент71 страницаMPWP Complete Noteskent kamauОценок пока нет

- Investigation of Self-Similarity Solution For Wake Flow of A CylinderДокумент5 страницInvestigation of Self-Similarity Solution For Wake Flow of A CylinderpundoОценок пока нет

- Cambridge University PressДокумент32 страницыCambridge University Pressswapnil mhaskeОценок пока нет

- Microscope Parts and FunctionsДокумент2 страницыMicroscope Parts and FunctionsMhais Angelika DyОценок пока нет

- Assignment 1Документ17 страницAssignment 1gripppo24Оценок пока нет

- Thermodynamic Analysis of Internal Combustion EnginesДокумент26 страницThermodynamic Analysis of Internal Combustion Engineschethan rОценок пока нет

- Composite Stress MethodsДокумент47 страницComposite Stress Methodsluuvandong48xf396Оценок пока нет

- Thesis PDFДокумент102 страницыThesis PDFEmayavaramban ManiОценок пока нет

- Moocs Lecture On Experimental Stress Analysis by Prof.K.Ramesh, Iit Madras 27-1Документ29 страницMoocs Lecture On Experimental Stress Analysis by Prof.K.Ramesh, Iit Madras 27-1muhammad hamzaОценок пока нет

- Finite Element Analysis of Aircraft Wing Using Composite StructureДокумент22 страницыFinite Element Analysis of Aircraft Wing Using Composite StructureAumair MalikОценок пока нет

- Lost Foam Casting Process ExplainedДокумент7 страницLost Foam Casting Process ExplainedMohd AzriОценок пока нет

- Double Pipe Heat ExchangersДокумент36 страницDouble Pipe Heat Exchangersshreyasnil50% (2)

- Quiz 1 - Transport PhenomenaДокумент3 страницыQuiz 1 - Transport PhenomenaDaffa IbrahimОценок пока нет

- DG401 451Документ2 страницыDG401 451Mauricio SaulОценок пока нет

- Edm English PDFДокумент13 страницEdm English PDFEstherОценок пока нет

- FePO4 Raman SpectraДокумент14 страницFePO4 Raman SpectraPaola FarfanОценок пока нет

- VW 44045 enДокумент16 страницVW 44045 enIsabel SierraОценок пока нет

- Seminar 2Документ20 страницSeminar 2Kishor PatilОценок пока нет

- Axial and Flexural Performance of Adhesive Connection On Cold-Formed Steel StructuresДокумент10 страницAxial and Flexural Performance of Adhesive Connection On Cold-Formed Steel Structurespiscesas45Оценок пока нет

- Surface Tension CoeffДокумент12 страницSurface Tension CoeffRattanarak DolОценок пока нет