Академический Документы

Профессиональный Документы

Культура Документы

Buehler Technotes - Indentation Testing Mapping

Загружено:

dev-nullАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Buehler Technotes - Indentation Testing Mapping

Загружено:

dev-nullАвторское право:

Доступные форматы

TECHNotes

Published by Buehler, a division of Illinois Tool Works Volume 7, Issue 1

HARDNESS TESTING TO MAP OR NOT TO MAP?

By: Dr. E. Mogire

EXECUTIVE SUMMARY The change in microstructure around the weld region (in the

Hardness of a material refers to the ability of a material to resist base material) near the fusion line presents challenges to the

penetration by a harder material. It is an empirical measure- integrity of the weld presenting a region prone to high resid-

ment of material properties indicating the ability of a material ual stresses (1-2). Development of high stresses coupled with

to withstand indentation under a static load or scratching. The undesired microstructure presents an area with a high poten-

resultant hardness value depends on the testing method. The tial for the welded joint to fail. This region is classified as a heat

main methods are; affected zone (HAZ) in a weld and is predominantly observed

1. Brinell; which uses a tungsten carbide ball indenter with in the base/parent material. The different components of a

hardness value calculated from the diametrical relation weld include the base metal showing the depth of penetration

between the ball and the impression made and the test of the weld, the heat affected zone, the fusion line and the weld

force used bead as shown in Figure 1 (a). For a multipass welded sample,

2. Rockwell; which uses a conical diamond or a tungsten the weld bead will have a corresponding HAZ, fusion lines and

carbide ball indenter with hardness values calculated from actual bead as the weld structure is built-up, as shown in Figure

the relation between the indentation depth under a large 1 (b), with 3 weld beads.

load compared to that made by a preload

3. Vickers and Knoop; which uses a diamond indenter with

the former having a pyramid shaped diamond and the

latter with a rhombohedral shaped diamond indenter, the

hardness value is calculated from the force used and the

length of the diagonals of the resultant indent

There are a wide variety of machines on the market that carry

out hardness testing based on the above testing methods.

Buehler is the leading supplier of indentation hardness testing

equipment, manufacturing machines to offer solutions for all of (A)

(B)

these methods individually or combined in one machine. The Figure 1 (a) is a schematic illustration of a weld, heat affected zone and base

following article highlights Vickers testing of welded compo- metal and (b) shows a fillet weld with three weld passes on a low alloy steel

substrate etched using 2% Nital to reveal the weld, heat affected zones and the

nents and how its also been applied to mapping of materials. three weld passes making up the weld

Indentation mapping relates to the ability to map out varia-

tions in hardness across a sample due to non-homogenous To observe the weld microstructures, components are micro-

nature of materials. Non-homogeneity, scopically investigated by doing metallographic testing involv-

manifested in variations in hard- ing a series of grinding/polishing stages and etching to reveal

ness across a test piece, is attrib- the microstructure, Figure 1 (b). The degree and/or extent of

utable to processing parameters. heat affected zone can then be metallographically analysed for

This will be illustrated for a weld- potential areas of extreme microstructural changes prone to

ed and an additive manufactured micro-crack formation.

metallic component. Mapping can For quantitative understanding of weld microstructures, inden-

also be applied to materials with tation hardness testing is normally carried out based on ISO

dual or multiphase components

9015/15614, which describes how testing is done; specifying

exhibiting localised variations in

loads, number of indents for parent/base material, heat affect-

hardness.

ed zones and welds, as well as the distances between indents

and the depth below the surface of the welded joint. To meet

Weld testing

the requirements stipulated in the standards can be quite chal-

Weld joints of metallic components show varying mechanical lenging, time consuming and subject to operator skill/experi-

properties starting from the weld itself, which might be of ence. We have simplified the process using our own in-house

the same material as the welded workpieces or might be of a software DiaMet as illustrated in Figures 2 and 3 for a fillet and

different material (alloy) compared to the components being a butt weld respectively.

welded together. Due to the high temperature nature of the

process, a fusion process occurs resulting in localised change

in microstructures from the weld, into the base materials.

Strong Partner, Reliable Solutions

(A)

Figure 2. Illustrates hardness testing of a fillet weld with differences observed from the

base metal, HAZ and weld regions

(B)

Figure 4 (a) illustrates weld mapping with chart showing actual Vickers values

and (b) showing map with weld passes (harder in red), heat affected area

(light blue) and base metal coloured blue.

Figure 3. Illustrates hardness testing of a butt weld, the chart shows local variation around

the heat affected zone (HAZ) Figure 5 shows steel butt welded samples built up through a

sequence of multi-passes (a). These types of welds are general-

Depending on the weld and base metal type, the different ly taken through a post weld heat treatment (PWHT) to alleviate

regions of the weld will exhibit different microstructures. These the residual stresses generated during build-up. However,

microstructures have varying hardness levels as illustrated in residual stresses are not completely removed and examination

Figures 2 and 3 above. As you traverse towards the weld, you of the weld after PWHT will also reveal these regions as shown

will start with uninterrupted base metal, followed by a region in Figures 5(b) and (c). Its evident from the maps where high

with tempered and intercritical HAZ, a fine grained HAZ, a residual stresses exist (high hardness values), primarily around

coarse grained HAZ towards the weld fusion line and then the the HAZ, Cap and root areas.

weld. The HAZ region exhibits a varied microstructure and will

always be prone to localised variations in hardness as shown

on the chart, blue circles, Figure 3. Its clear that standard

techniques based on ISO9015 might capture local variations

in hardness around the HAZ since it involves doing a row of

indents. For a complete picture of the weld, weld mapping can

provide an exhaustive overview of this localised variations and

potential site of high stresses.

Mapping

With automated hardness testing, improved testing speeds

and development in hardness testing software, an alternative Figure 5 (a) shows a sequence of weld passes from the root to the weld cap, (b) &

method of qualitative and quantitative testing of welded com- (c) show two butt welded components after mapping. The weld maps show high

stress areas characterised by high hardness around the toes on the weld face,

ponents is now possible. This involves carrying out multiple down the heat affected zone near the fusion line and in the root areas of the weld.

indentations on a scanned area of a weld and then assigning

the differences in hardness values from the base material into Additive Manufactured Components

the weld a colour code, from which the software gives a visual Additive manufactured components are built up by adding

output of the variations in hardness. The main advantage of material layer by layer. These components can be manufac-

using the indentation mapping is the ease of identification of tured from steels, titanium, Inconel alloys among many others.

regions where high residual stresses exist. The maps can also Manufacturing processes include directed energy deposition

be used to qualitatively investigate the heat affected zone, the (DED) and Powder bed fusion (PBF) techniques. The DED

base material and the welded regions without the need to etch method generally has a higher build up rate compared to the

the sample. Figure 4, illustrates the weld sample in Figure 1 & PBF technique with both techniques resulting in residual stress

2, mapped with approximately 3000 indents. development due to repeated thermal cycles during layer

Comparing Figure 4(b) and Figure 1 above, there is a good addition. These residual stresses play a crucial role in perfor-

correlation between the etched and mapped out micrographs mance, integrity and lifetime of the components and thus the

with both methods showing the weld beads, the heat affected ability to evaluate them is critical (3-4). To map these compo-

zone and base/parent materials. nents out, they have to first be metallographically prepared

with the level of surface finish depending on the load being

used during Vickers indentation testing.

Visit our website at www.buehler.com for more information.

Figure 7 illustrates a hardened gear tooth mapped out to illustrate the case hardened

outer region and its uniformity across the gear tooth. High hardness regions in red have

Vickers values approaching 800Vickers whereas low hardness areas typical of core at

approximately 400Vickers

Summary

Weld measurements based on ISO standards can be

relatively quick and easy to carry out with the weld tool

on DiaMet software. Traditional techniques would take a

longer time and were also subject to operator skill/expe-

rience.

Weve also demonstrated there is good correlation

between etched weld samples and hardness mapped

Figure 6 illustrates an additive manufactured component mapped out illustrating regions that area. It is easy to identify the base/parent metal, heat

would be considered as having high residual stress (red). affected zones and the weld from mapped micrograph

akin to an etched weld sample. Its also clear from the

Case/Induction Hardened Surfaces micrographs that its relatively easy to identify weld passes

Certain mechanical components are normally surface hard- in a multipass weld and how each corresponding weld

ened to improve their mechanical performance by improving bead affects the adjoining one as the weld is built up.

surface wear characteristics with the advantage of low core Additive manufactured components can be mapped high-

strength characteristics to absorb stresses without cracking lighting local variations in hardness as a way of identifying

from repeated usage. Examples include gears (Figure 7), areas of high residual stresses

induction hardened cranks and cam shafts found for example Case hardened materials can be mapped thus providing a

in automotive sectors. How uniformly these surface treatments comprehensive pictorial view of uniformity of a hardening

are carried out, and their conformance to operational specified process.

hardness limits, provides a degree of confidence on the final

mechanical performance. Traditional methods involve carrying References

out effective case depth or case hardness depth studies on a 1. Francis JA, Bhadeshia HKDH and Withers PJ. Welding

single row of hardness indents starting from the surface into residual stress in ferritic power plants steels. Materials

the core of the material and noting where the hardness values Science and Technology. 2007; 23(9):1009-1020.

go below 550 Vickers point. This is a snapshot view of how 2. Ma R, Fang K, Yang JG, Liu XS, Fang HY Grain refine-

hardening has been carried out (see Figure 7). ment of HAZ in multi-pass welding, Journal of Materials

The alternative and a more comprehensive way of validating Processing Technology, Volume 214, Issue 5, May 2014,

the case/induction hardening process is to map out an area Pages 1131-1135

of interest as shown in Figure 7 above, which highlights unifor- 3. Kumar S, Kundu A, Venkata KA, Evans A, Truman CE, Francis

mity in hardness as a function of the core hardness using JA, et al. Residual stresses in laser welded ASTM A387

mapping tools in DiaMet software. Grade 91 steel plate. Materials Science and Engineering

A. 2013; 575:160-168.

4. Gibson I, Rosen DW, Stucker B. Additive manufacturing

technologies. Vol. 238. New York: Springer, 2010.

5. Bernd B, Omer B, Rosemary G, Additive manufacturing

of Ti6Al4V components by shaped metal deposition:

Microstructure and mechanical properties, Materials &

Design, Volume 31, Supplement 1, June 2010, S106-S111

6. metal deposition: Microstructure and mechanical proper-

ties, Materials & Design, Volume 31, Supplement 1, June

2010, S106-S111

BUEHLER Worldwide Headquarters European Headquarters BUEHLER China

North America-South America Offices BUEHLER Germany info.cn@buehler.com

41 Waukegan Road info.eu@buehler.com

Lake Bluff, Illinois 60044-1699 USA BUEHLER Japan

BUEHLER France info.japan@buehler.com

P: 800 BUEHLER (800-283-4537)

info.eu@buehler.com

P: (847) 295-6500 BUEHLER Asia-Pacific

www.buehler.com | info@buehler.com BUEHLER United Kingdom info.asia@buehler.com

2017 BUEHLER, a division of Illinois Tool Works Inc. Printed in U.S.A. info.eu@buehler.com

Вам также может понравиться

- Arc Welding 2 by Steve BleileДокумент72 страницыArc Welding 2 by Steve Bleiledev-nullОценок пока нет

- Book 1 Bloat WareДокумент22 страницыBook 1 Bloat Waredev-nullОценок пока нет

- SUS Katalog enДокумент19 страницSUS Katalog endev-nullОценок пока нет

- Book 1 Bloat WareДокумент22 страницыBook 1 Bloat Waredev-nullОценок пока нет

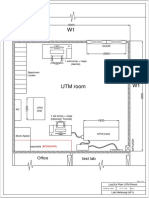

- Office Test Lab: (Bongkar)Документ1 страницаOffice Test Lab: (Bongkar)dev-nullОценок пока нет

- SujaidrДокумент1 страницаSujaidrdev-nullОценок пока нет

- Friends.S01E01.1080p.bluray - Reenc DeeJayAhmedДокумент29 страницFriends.S01E01.1080p.bluray - Reenc DeeJayAhmedokayguyОценок пока нет

- 9 Practical Cswip 3 0 Practical Visual Inspection PDFДокумент13 страниц9 Practical Cswip 3 0 Practical Visual Inspection PDFdev-nullОценок пока нет

- Electrical Engineering BA (B), Analog Electronics, ET065G 6 Credits ET064G 7.5 CreditsДокумент43 страницыElectrical Engineering BA (B), Analog Electronics, ET065G 6 Credits ET064G 7.5 Creditsdev-nullОценок пока нет

- Ajmse 1 2 3 PDFДокумент5 страницAjmse 1 2 3 PDFdev-nullОценок пока нет

- UnivДокумент6 страницUnivdev-nullОценок пока нет

- Rip x264 YifyДокумент105 страницRip x264 Yifydev-nullОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Business PlanДокумент22 страницыBusiness PlanRanjitha Kalaiselvan100% (2)

- Integrated Research Assingment - Dna Helicase-Dna (Dnab)Документ3 страницыIntegrated Research Assingment - Dna Helicase-Dna (Dnab)Trey GuestОценок пока нет

- Chapter 15 Local AnestheticsДокумент27 страницChapter 15 Local AnestheticskmcalleОценок пока нет

- Fabrication of Polyaniline Nanofiber Via Electrospinning For The Development of Carbon Monoxide SensorДокумент37 страницFabrication of Polyaniline Nanofiber Via Electrospinning For The Development of Carbon Monoxide SensorUPLB Office of the Vice Chancellor for Research and ExtensionОценок пока нет

- Crystallization and EvaporationДокумент15 страницCrystallization and EvaporationYawn D Artist100% (1)

- Allowable DP CalculationДокумент22 страницыAllowable DP CalculationAJAY1381Оценок пока нет

- Global Pharma StrategyДокумент15 страницGlobal Pharma StrategyDr Amit RangnekarОценок пока нет

- Eor Course 2012 Lecture#1 IntroductionДокумент28 страницEor Course 2012 Lecture#1 Introductioncrown212Оценок пока нет

- Accuracy, Precision, and Percent ErrorДокумент16 страницAccuracy, Precision, and Percent ErrorEve YapОценок пока нет

- P - 21 Estimation of Percentage of Glucose (Benedict's Method)Документ1 страницаP - 21 Estimation of Percentage of Glucose (Benedict's Method)Dr. Tapan Kr. DuttaОценок пока нет

- Category 2-Bonus PacketДокумент9 страницCategory 2-Bonus Packetapi-312542882Оценок пока нет

- Race 2019Документ418 страницRace 2019Sadia KhanОценок пока нет

- Weld Metal Selector GuideДокумент28 страницWeld Metal Selector GuideBassam AbdelazeemОценок пока нет

- 3 Way Control Valve STEVI 450-451Документ22 страницы3 Way Control Valve STEVI 450-451Ricky 83Оценок пока нет

- Geomet 321Документ2 страницыGeomet 321Satnam Rachna FastenersОценок пока нет

- Micro-And Nano-Encapsulation TechnologiesДокумент43 страницыMicro-And Nano-Encapsulation TechnologiesMauricio FemeníaОценок пока нет

- A Comprehensive Approach To Formation Damage Diagnosis and Corresponding Stimulation Type and Fluid SelectionДокумент10 страницA Comprehensive Approach To Formation Damage Diagnosis and Corresponding Stimulation Type and Fluid SelectionLeopold Roj DomОценок пока нет

- As 4289-1995 Oxygen and Acetylene Gas Reticulation SystemsДокумент8 страницAs 4289-1995 Oxygen and Acetylene Gas Reticulation SystemsSAI Global - APACОценок пока нет

- Cassava Flour Processing StagesДокумент8 страницCassava Flour Processing StagesAhmed BinОценок пока нет

- Novo GO ALKYD GlossyДокумент1 страницаNovo GO ALKYD Glossysarah magdyОценок пока нет

- Directional Spool Valves, Direct Operated, With Solenoid Actuation Type WE XH and WE XMДокумент12 страницDirectional Spool Valves, Direct Operated, With Solenoid Actuation Type WE XH and WE XMpedro 1Оценок пока нет

- Manual C17 - EN - Site PDFДокумент27 страницManual C17 - EN - Site PDFCristu CristianОценок пока нет

- General Us Lite PDFДокумент179 страницGeneral Us Lite PDF2791957Оценок пока нет

- Lab Report 1Документ9 страницLab Report 1Nailton MafraОценок пока нет

- Astmf 2307-03Документ5 страницAstmf 2307-03Pegfan85Оценок пока нет

- Strength and of Pond Ash ConcreteДокумент29 страницStrength and of Pond Ash ConcreteNaveed BОценок пока нет

- Hydrocortisone FormulationДокумент2 страницыHydrocortisone FormulationSafrin Puji RahayuОценок пока нет

- Algae Air FilterДокумент20 страницAlgae Air Filterapi-626221766Оценок пока нет

- Ansul Line ProportionersДокумент4 страницыAnsul Line ProportionerskambiadoОценок пока нет

- Roles of Double Salt FormationДокумент8 страницRoles of Double Salt FormationAmer AlkalaifhОценок пока нет