Академический Документы

Профессиональный Документы

Культура Документы

Scrollsaw Woodworking & Crafts #49 (Holiday 2012)

Загружено:

bangbang63100%(1)100% нашли этот документ полезным (1 голос)

726 просмотров100 страницscroll shaw 2012

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документscroll shaw 2012

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

726 просмотров100 страницScrollsaw Woodworking & Crafts #49 (Holiday 2012)

Загружено:

bangbang63scroll shaw 2012

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 100

CRAFT

woodworking

Super Cool

Rubber Band

Crossbow

Cute Coin Bank ay

Lefer yg

wT

Dee Oen O.22

iW

]

THE WOODEN TEDDY BEAR, INC.

P.O. Box 33917

* Portland; OR 97292-3917

www.woodenteddybear.com

EXCALIBUR TILTING HEAD SCROLL SAWS scenes nresuro

“Absolutescrollsawing pleasure” mp

EX-30,

SDM-02 $79.95

‘Seyco's Magnifier Worklamp

SEYCO’S FANTASTIC NEW SCROLLERS DRILL

Scrollers can finally be free from the throat depth restrictions of a standard drill press and be

able to drill perfect 90 degree holes ! A simple adjustment screw provides precise angles

from 90 degrees to approximately 30 degrees -

This compact Scrollers Drill comes complete with a heavy duty DC power supply that plugs

directly into your standard AC wall plug. Built-in overload

protection - 1 year replacement warranty. Comes with a

rill index and 20 small bits size #61 through #80.

UNIQUE “WOOD SHAPING” ACCESSORIES

You wilted hese tools erect rears Carn Gusts Canes and alloter woe shaping jee!

‘SEYCO'S "SeeSander” Kit ‘SEYCO'S “FLEX DRUM” SANDER

” edegatad DUAL DRUM SANDER KIT.

Gomes completly previred Including the worklanp.

Sbae has ober pa eet anc hele for outing tour

Wortbench or stand.2 D501 Fex Oram kts we nced

{ore st abou opera acessories sich a he VF

hick wth saptr on te igh ee and ute the fx

Shalt option to Suppor tse STD sal 1 noe

ding eroms pliers crter

pace.

* 2

be yh Sool 5 On the web at... httpu/www.seyco.com

Toucan

Ken Ward of Cary, IIL, created this

wall hanging based on the logo of the

Palatine Hills Golf Course, where he

works as a starter/ranger. The logo

is made from -thick wood. Ken

used walnut, maple, bloodwood, and

yellowheart, and mounted the pieces on

a Baltic birch plywood backing board.

He made a custom frame from red oak.

“4. Fretwork Mantle Clock

Mark Russo of Laurel Springs, NJ, created this clock

using plans from the Berry Basket. The clock, called

American Pride Mantle Clock, is made from red oak,

Baltic birch, mahogany, and padauk. To show more

American pride, Mark added lapel pins representing the

US. armed forces, the U.S. Coast Guard, and an American

flag around the clock face. The project took Mark 31%

hours to complete.

Wildlife Silhouettes ¥

Louis Kraay of Zeeland, Mich., created

this piece using a basswood disc

with bark still attached. Louis made

patterns of 12 forest animals, arranged

them on the disc, and attached them

to the disc with spray adhesive. After

Louis cut the silhouettes, he applied

a spray varnish finish and attached

heavy black felt to the back to make

the silhouettes stand out.

Share Your Latest Work!

Senda slide, professional prin, or digital image

{G00 dp minimum) with 100 words about you

and your pice. Include your hometown, the

name ofthe pattern maker, and alist of woods

and materials used Send to Reader Galler,

ScallSaw Woodworking & Crafts, 1970 Broad

Street, East Petersburg Pa, 17520 ore-mal

KinseyfoxChapelPubishing.com,

10 Scroll Saw Woodworking & Crafts

Just FLOCK IT!

with Donjer Spray-on Fibers

Line Box and Gourd Interiors in just minutes.

Create soft, fuzzy effects on your wood crafts such as:

Santas Clouds

Dolls Angels

Toy Furniture Flower Petals

Jewelry Model Car Seats

Decoys Tree Ornaments

Tool Handles Fretwork Backgrounds

eonsthe, sibilities endless! .

pelichibne Wee ! ‘The Swiss

Scroll

Sawblades

Call for brachure & color chart 800-336-6537

Late Sa een area he

Ee aE

Skip Tooth

Double Tooth

Are YOU a part of this group? Tone

Meeting scrollers from around the world |

"Double Tooth Reverse

~"Modiied Geomety

Spiral :

ails tiie ae

Visit us at: www.saw-online.com 2

a huge web site packed full of information ==

Benefits of Membership:

Annual Resource Directory

Quarterly Newsletter

Scholarship and |

Opportunity Grant programs

| Members only website full of helpful tools

Plus a lot more

Application available online

SAW, PO Box 340, Botkins, Oh. 45306

mention FoxT on yout dpplcation fora ree ft We met

wurwscrolisawercom ® HOLIDAY 2012.11

ae keeacs

Attaching

Patterns to

Blanks

Instead of using messy spray

adhesive or glue sticks that don't

always stick to wood, I use double-

sided dropcloth tape. I found

Painter's Mate Green dropcloth

tape in the paint section of my local

hardware store. Apply the tape

to the wood, remove the backing,

and place the pattern in position.

The tape holds the pattern tightly

but you can lift the pattern off and

reposition it as necessary. The tape

and pattern are easy to remove

after you finish cutting,

Keith Deck

Marseilles, Il.

Double-faced

Gropeloth tape

makes attaching

patterns clean

and easy.

Editor's Note: To find a local

supplier for Painter's Mate

Green dropeloth tape, visit

www.paintersmategreen.com.

Keeping Plywood Flat

To keep my plywood from warping, I buy an extra sheet of

fhick plywood and cut it to the nominal dimensions of my

plywood blanks. I place a '-thick piece on a stack of blanks,

making sure the sides are square, and then weight the top with

concrete stepping stones to prevent warping,

Bob Gatlin

Waco, Tex

ing Blades

TOP TIP in our Spring issue wins a dragon keep a box near my saw and save some of my old scroll saw

automaton kit with an electric motor unit from blades. I use them when I rough-cut a piece of wood to size. It

Timberkit, wwwtimberktscom. Send you tis or

techniques to Bob Duncan, Fox Chapel Publishing,

1970 Broad Street, East Petersburg PA 17520, or Howard Lampa

DuncanaFoxChapelPublishing.com Bonita Springs, Fla 7

saves my new blades for my project.

12 Scroll Saw Woodworking & Crafts

MAKERS OF

eee

<=J

Woodworking Tools er sve 360,000 rpm Shofu Lab Air-Z

: Air Driven Rotary Tool

Youtbe amazed how easy isto dovery

fine detal wok Nany woodcarversare

using ths rotaryteol. owefuand Step 6: Createa

sanding shim for the

partridge. The pieces

of the partridge willbe

shaped asa single unit.

Guta piece of thin plywood

‘ortempered hardboard

‘A Step 4: Sandthe to the rough shape of the

Toganterte:lioush eer ince anceacl partridge and use double-

oleae poet DEPTHS sided tape to attach the

Using aninflatable drum | Aftersanding a part, mark the pres Ouse

sanderandan 80-qritor | sides ofany adjoining pieces round the outside edges

100-grit drum. My goal | withapencilso you don't sand of the bied.

istogetitciosetothe | toomuch wood of them.

finished thicknesses;

later will fine-tune the

38 Scroll Saw Woodworking & Crafts

A Step 7: Refine the body. Use a thin putty knife ora

palette knife to carefully remove the wing from the sanding

shim. Reduce the thickness of the bird's body Ya (2mm) so

the wingis litte thicker than the body. Mark the thickness of

the body onto the wing,

‘A Step 8: Refine the wings. Sand and shape the wings,

staying ¥«" (2mm) above the pencilline indicating the

thickness of the bird's body. Then, sand the bird parts with a

220-grit sanding drum. Remove the pieces from the sanding

shim and reassemble them. Using progressively finer grits

cof sandpaper up to 220-grt, hand-sand the pieces in the

direction of the grain. Remove any across-the-grain scratches.

A Step 9: Add the texture details. Draw the leaf

grooves using the pattem as a quide. Carve a groove along

those lines. use a Wonder Wheel to carve and bumnish the

detail lines. You can also use a rotary tool with a carving bit.

D> Step 10: Add the

eye, Cut ale" (mm)-

diameter maple dowel to

114" 38mm) long. Round

one end of the dowel, and

then bum and bumnish the

end of the dowel. luse a

Wonder Wheel, butyou

could use a woodburner j

ora propane torch. Cut

the extra length off the

bottom of the dowel and

alue itn place. Blow the (

dust off the pieces using r

compressed air. Check to \

make sure everything is

sanded smooth,

earth en ues

Step 11: Apply a heavy coat of clear satin gel

polyurethane. Let the wood soak up what it needs to fillin

‘any open grain. Coat the top and sides of each part, but avoid

zs

:

2

3

Puzzle pieces

detail patterns

Squished Santa puzzle patterns

wwwscrolisawerscom ® HOLIDAY 2012 59.

Squished Santa puzzle patterns

Puzzle pieces {

detail patterns

(©2012 ScollSaw Woodworking & Crafts

vine tinny ie:

doorsand back,2¢ach «Round tothpieks

6°x7"(152mmx7BMM) pric paint, suchas

Pine, 98"t034" (16mm aid FolkArt: gold.

to 19mm)-thickframe/——(buckes)

pieces, 6° x7 (1s2mm

xTTenm) ae

“eoneorgaphite Blades: 47 eves-oah

Fresh ase copy of —

the pattems = Pena

ere + Woodoumerand stew

Detail

“Meta weaken

an + Beltsander with

-Brashinges seach “tena

306 (mma) OT

sBaashasgeia' “pac aterm

en =Drilan bit:

“pgs 20each—Gmm-dameter

1x3 im) ng Tet

-Minwaxstin: special

walnut Hammer

+ Sandpaper: 120 grit, Seal eae,

“Tope:eordoublesied “Pte

-Aayflepans suchas (gm shader brush,

DeltaCeramcoat:tompte jn

red Santasuit; white —_ 1% (3mm) shader brush

(uittrim, beard, hai); *E¥etopper

black (gloves, boots, Knife

ees); Cistmas green

(bags, doorhol); bam naw onseemrpmee

red (door exterior) eee

SPECIAL SOURCES:

Brass hinges and hasps ar available from Cherry

Thee Toys, 800-848-4363, wwrw.cherytreetoys.com.

Small wood screws ae available from Meise

Hardware Specialties, 800-441-9870,

www meiselwoodhobby.com.

Corolea and Ken Hower ve on a farm

A ‘outside Arkansas City, Kan For more ofher

‘work ist her website ot puzzlesinabox

om. Taeirson Kevin ives in loro,

ran, where he worksin production and

ddstibution for their local newspaper.

Making a Maze-Lid Box

Adding a game to the

lid makes this box fun

as well as functional

By Carole Rothman

Te storvatins box is like a maze itself, with many

Paths and a few dead ends before I reached the

finish. It started with a search for interesting new box

lids. A friend remarked that one of my designs looked

like a maze and suggested that an actual maze would

make a really neat box lid. Challenged, found

a website that showed how to construct mazes.

Armed with this knowledge and some i" graph

Paper, I got to work. Several versions later, [had

my design. To find the right size of ball bearings,

test-drove small sugar balls (dragées, from my cake.

@ days) through the paths

decora

All that remained was the clear acrylic plastic

cover, a material I hadn't used before. After one or

two meltdowns, I found the blade (a Flying Dutchman

Polar blade) and technique (slow speed) to use, Four

small screws later, the maze lid was good to go.

Start by cutting

listed. Attach the patterns to the blanks using

epositionable spray adhesive, and drill the holes

marked on the patterns. When drilling the blade-entry

holes for the maze area, make sure you center the drill

bit between the cutting lines.

g the blanks to the rough sizes

Marts te a cat

ut the maze. Insert a#3 blade ito one ofthe blade-entry

holes and cut the maze. Be careful not to break off any ofthe arms

(of the maze. Do not cut the outer profile ofthe lid yet.

Prepare the bottom of the maze. Align the grain

tlirections ofthe id middle and lid bottom. Then, glue and clamp

the lid middle tothe ld bottom. | used ashop-made bow press to

clamp the small pieces together. Allow the glue to dry, and sand.

the surface of the lid middle smooth,

Glue the maze elements together. lign the gain direction

ofthe maze with that ofthe assembled middle and bottom. Carefully

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Ackermann SteeringДокумент6 страницAckermann Steeringbangbang63100% (1)

- ScreenPrint Ultimate GuideДокумент56 страницScreenPrint Ultimate Guidevishwaupula100% (13)

- Wood Magazine Issue #191Документ67 страницWood Magazine Issue #191bangbang63100% (2)

- Wood Magazine Issue #189Документ96 страницWood Magazine Issue #189bangbang63100% (1)

- Presentation Document - AquilonДокумент6 страницPresentation Document - Aquilonbangbang63Оценок пока нет

- DOJ - Law Enforcement Intelligence - Guide For State, Local, & Tribal Law Enforcement Agences (2d Ed. May 2009)Документ496 страницDOJ - Law Enforcement Intelligence - Guide For State, Local, & Tribal Law Enforcement Agences (2d Ed. May 2009)J Cox100% (1)

- Asean Travel TourismДокумент40 страницAsean Travel Tourismbangbang63Оценок пока нет

- Online VideoДокумент19 страницOnline Videobangbang63Оценок пока нет

- Ntos 45 Annex 10 Amvs Audit March 2016Документ131 страницаNtos 45 Annex 10 Amvs Audit March 2016bangbang63Оценок пока нет

- 08 Rigging WheelsДокумент3 страницы08 Rigging Wheelsbangbang63Оценок пока нет

- Volunteer For ToursmДокумент11 страницVolunteer For Toursmbangbang63Оценок пока нет

- Homestay in MalaysiaДокумент18 страницHomestay in Malaysiabangbang63Оценок пока нет

- Homestay DevelopmentДокумент5 страницHomestay Developmentbangbang63Оценок пока нет

- TElenor GroupДокумент168 страницTElenor Groupbangbang63100% (1)

- Magmax ManualДокумент26 страницMagmax Manualbangbang63Оценок пока нет

- ASEAN Homestay StandardДокумент80 страницASEAN Homestay StandardHidayat Al BanjariОценок пока нет

- Digital PhotographyДокумент57 страницDigital PhotographyS Praveen KumarОценок пока нет

- Travel Mugs - Screen PrintedДокумент6 страницTravel Mugs - Screen PrintedjdrmyersОценок пока нет

- Dolls House and Miniature Scene Feb 2015 (Kat) - SuperunitedkingdomДокумент76 страницDolls House and Miniature Scene Feb 2015 (Kat) - Superunitedkingdombangbang63100% (4)

- Two Part Silicone CastingДокумент14 страницTwo Part Silicone Castingbangbang63100% (1)

- Ecoss 4Документ9 страницEcoss 4bangbang63Оценок пока нет

- Unesco Annual ReportДокумент178 страницUnesco Annual Reportbangbang63Оценок пока нет

- Scrool Saw Woodworking and Crafts Magazine 01Документ92 страницыScrool Saw Woodworking and Crafts Magazine 01Patricia Arias GОценок пока нет

- Fun & Easy Scroll Saw ProjectsДокумент196 страницFun & Easy Scroll Saw Projectsbangbang63100% (3)

- Scrollsaw Woodworking & Crafts #32 (Fall 2008) PDFДокумент100 страницScrollsaw Woodworking & Crafts #32 (Fall 2008) PDFbangbang63100% (3)

- Scrollsaw Woodworking & Crafts #50 (Spring 2013)Документ100 страницScrollsaw Woodworking & Crafts #50 (Spring 2013)bangbang63100% (2)

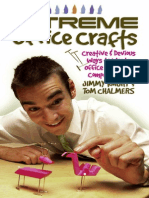

- Extreme Office CraftsДокумент112 страницExtreme Office CraftssovrlicОценок пока нет

- 2009-09 Wood Magazine PDFДокумент92 страницы2009-09 Wood Magazine PDFbangbang63Оценок пока нет