Академический Документы

Профессиональный Документы

Культура Документы

Cy Hcs QDH RWH E215us

Загружено:

ezeizabarrenaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cy Hcs QDH RWH E215us

Загружено:

ezeizabarrenaАвторское право:

Доступные форматы

Hollow plunger cylinders Application & selection

Shown: HCS-20, RWH-121, RWH-202

For high force push and pull applications

product line

Collet-Lok

on and around the fixture

Load can be attached to either end of the cylinder,

providing a choice of push or pull actions - both realizing

full cylinder capacity

Very high cylinder capacities contained within

Swing clamps

small dimensions allow compact fixture designs

Spring return operation allows for easy unloading of

the workpiece

Threaded collars and base mounting holes allow mounting

flexibility, including table-top surfaces and T-slots

Nickel-plated plungers, plunger wipers and internal venting

Work supports

99_043

prevent corrosion and support longer operation life on all

HCS models

These cylinders are regularly used for The CY series hollow plunger cylinders can be manifold

upgrading mechanical clamping to faster mounted (except for CY-1254-25)

and easier hydraulic clamping. Other typical

Linear clamps

applications include production pressing,

punching and crimping operations.

Mechanical set-up

Hydraulic set-up

Product selection

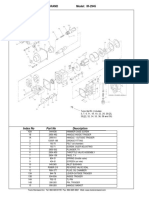

Cylinder Stroke Center Model Effective Oil Operating

capacity 1) hole number area capacity pressure

diameter

Traditional mechanical elements in a clamping fixture

are replaced by a hollow plunger hydraulic cylinder. lbs in in in2 in3 psi

2610 0.25 0.39 CY1254-25 0.87 0.22 3000

4000 0.33 0.53 MRH-20 1.33 0.41 3000

4000 0.33 0.53 RWH-20 1.33 0.41 3000

z Two Enerpac RWH-121 hollow cylinders mounted 4000 0.33 0.53 RWH-20T 1.33 0.41 3000

at the back side of a fixture. 4830 0.50 0.42 HCS-20* 0.96 0.38 5000

7410 0.31 0.77 CY2129-251) 2.47 0.77 3000

7410 0.63 0.77 CY2129-51) 2.47 1.56 3000

12,660 0.48 0.51 HCS-50* 2.52 1.19 5000

13,320 0.63 0.89 CY2754-5 4.44 2.80 3000

13,800 0.32 0.77 MRH-120 2.76 0.86 5000

13,800 0.32 0.77 QDH-120 2.76 0.86 5000

13,800 0.32 0.77 RWH-120 2.76 0.86 5000

13,800 1.02 0.77 RWH-121 2.76 2.76 5000

18,180 0.56 0.67 HCS-80* 3.63 1.99 5000

23,500 0.52 1.06 RWH-200 4.74 2.37 5000

23,500 2.02 1.06 RWH-202 4.74 9.48 5000

25,490 0.63 0.83 HCS-110* 5.06 3.19 5000

36,000 0.50 1.31 RWH-300 7.22 3.60 5000

36,000 1.00 1.31 RWH-301 7.22 7.22 5000

98_016

36,000 2.49 1.31 RWH-302 7.22 18.00 5000

1)

At maximum operating pressure. Note: Seal material Buna-N, Polyurethane, Teflon.

* This product is made to order. Please contact Enerpac for delivery information before

78

specifying in your design.

Dimensions & options CY, HCS, QDH, RWH series

Optional Heat Treated Hollow Saddles

Force: 2610-36,000 lbs

Saddle Cylinder Saddle Saddle Dimensions (in) A

type model number model No. A B C B Stroke: .25-2.49 inch

RWH-200, 202 HP-2015 2.11 1-8 .38 C

Threaded Pressure: 800-5000 psi

hollow RWH-300, 301, 302 HP-3015 2.49 1 - 7 .38

Smooth hollow saddles are standard on all RWH 20 and 30 ton models

(12 ton models are not equipped with saddles). E Cilindros de mbolo hueco

MRH-20, 120 RWH-20, 120, 121, QDH-20 F Vrins a piston creux

K K D Hohlkolbenzylinder

T T

F F

D D

A A

J J

W W

B B

Z H 5 Z H 5

D1 D1 Options

V V

MRH-20 1/8"-27NPT RWH-20 1/8"-27NPT Flange nuts

MRH-120 1/4"-18NPT RWH-120 1/4"-18NPT

Linear cylinders

U Y U Y RWH-121 1/4"-18NPT

QDH-120 1/4"-18NPT 86

other RWH model CY models HCS models

K K K Important

T T T

F F F Use Grade 8 (DIN12.9) bolt

D D D quality or better for pulling.

Power sources

S

J W A Use Grade B7 (DIN10.9)

A A

W

threaded rod quality or better

B B B C for pulling applications.

W

H Z H

H Z Z

1/8"-27NPT D1

D1

D1 G1/4"

3/8"-18NPT U

Y RWH cylinders can be used

Valves

V V up to 10,000 psi maximum

working pressure (except

V RWH-20, RWH120, RWH121).

Y Y

U G1 U

Product dimensions in inches [ ]

Pallet components

Model A B C D D1 F H J K S T U V W Y Z

number

lbs

CY1254-25 2.25 2.00 - 1.75 1.75 0.56 0.29 - .375-16 unc - 0.62 1.25 .250-20 unc 0.97 0.39 0.38 1.0

MRH-20 2.39 2.06 - M48 X 1.5 1.77 1.00 0.28 0.12 .53 - 0.88 1.38 M6 X 1.0 1.50 0.50 0.25 1.3

RWH-20 2.39 2.06 - 1.875-16 un 1.79 1.00 0.28 0.12 .53 - 0.87 1.38 .250-20 unc 1.50 .500-20 unf 0.25 1.4

2.39 2.06 - 1.875-16 un 1.79 1.00 0.28 0.12 .500-20 unf - 0.49 1.38 .250-20 unc 1.50 0.53 0.25 1.4

System components

RWH-20T

HCS-20 3.43 2.93 2.60 M58 X 1.5 2.28 0.71 0.43 - M10 X 1.5 0.55 1.01 1.57 M6 X 1.0 1.57 0.42 0.39 2.4

CY2129-251) 2.31 2.00 - 2.63 2.50 1.13 0.31 - .750-10 unc - 1.13 1.75 .375-16 UNC 0.80 0.77 0.34 2.5

CY2129-51) 3.36 2.73 - 2.63 2.50 1.13 0.31 - .750-10 unc - 1.13 1.75 .375-16 UNC 1.54 0.77 0.44 3.0

HCS-50 3.80 3.32 2.95 M65 X 1.5 2.56 1.10 0.55 - M12 X 1.75 0.87 0.95 1.77 M8 X 1.25 1.77 0.51 0.47 3.3

CY2754-5 3.63 3.00 - 3.5 3.13 1.25 0.44 - .875-9 unc - 1.25 2.12 .375-16 UNC 1.61 0.89 0.44 6.0

MRH-120 2.54 2.20 - M70 X 1.5 2.76 1.38 0.39 0.19 M18 X 1.5 - 0.60 2.00 M6 X 1.0 1.19 0.77 0.25 3.1

QDH-120 2.54 2.22 - 2.750-16 UN 2.75 1.38 0.39 0.19 .750-10 UNC - 0.62 2.00 .312-18 UNC 1.19 0.77 0.25 3.0

Yellow pages

RWH-120 2.54 2.22 - 2.750-16 UN 2.75 1.38 0.39 0.19 .750-16 UNF - 0.61 2.00 .312-18 UNC 1.19 0.77 0.25 3.1

RWH-121 4.24 3.22 - 2.750-16 UN 2.75 1.38 0.53 0.19 .750-16 UNF - 0.73 2.00 .312-18 UNC 1.19 0.77 0.25 4.8

HCS-80 4.31 3.75 3.35 M75 X 1.5 2.95 1.26 0.67 - M16 X 2.0 0.94 1.27 2.17 M8 X 1.25 1.97 0.67 0.47 5.1

RWH-200 5.39 4.88 - 3.875-12 UN 3.88 2.12 0.75 0.19 1.06 - 0.88 3.25 .375-16 UNC 1.50 1.06 0.38 13.6

RWH-202 8.39 6.37 - 3.875-12 UN 3.88 2.12 0.75 0.19 1.06 - 0.88 3.25 .375-16 UNC 1.50 1.06 0.38 17.0

HCS-110 4.74 4.11 3.66 M90 X 2.0 3.54 1.57 0.75 - M20 X 2.5 1.26 1.44 2.56 M10 X 1.5 2.36 0.83 0.59 7.9

RWH-300 5.52 5.02 - 4.500-12 UN 4.49 2.54 0.85 0.19 1.31 - 0.88 3.62 .375-16 UNC 1.66 1.31 0.62 19.0

RWH-301 6.52 5.52 - 4.500-12 UN 4.49 2.54 0.85 0.19 1.31 - 0.88 3.62 .375-16 UNC 1.66 1.31 0.62 21.5

RWH-302 9.52 7.03 - 4.500-12 UN 4.49 2.54 0.85 0.19 1.31 - 0.88 3.62 .375-16 UNC 1.66 1.31 0.62 24.0

1)

For these models G1 = manifold and .125-27 NPTF

www.enerpacwh.com 79

Вам также может понравиться

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!От EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Рейтинг: 5 из 5 звезд5/5 (2)

- Introduction To Coiled Tubing Equipment and ApplicationДокумент43 страницыIntroduction To Coiled Tubing Equipment and ApplicationAhmed ElkashifОценок пока нет

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheОт EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheРейтинг: 4.5 из 5 звезд4.5/5 (2)

- 500 650 HCI 750 Top Drive PDFДокумент2 страницы500 650 HCI 750 Top Drive PDFdraghiceanu100% (1)

- TD 340 HCДокумент4 страницыTD 340 HCDaniel Ángel PenaОценок пока нет

- Enerpac RR Series CatalogДокумент4 страницыEnerpac RR Series CatalogTitanplyОценок пока нет

- John Deere 46 Backhoe BrochureДокумент2 страницыJohn Deere 46 Backhoe Brochurevovoboss0% (1)

- Helac Basket Rotator L20 ManualДокумент24 страницыHelac Basket Rotator L20 ManualStuart Sainsbury100% (1)

- Powerchokes: Standard Choke SCB All-Purpose Severe ServiceДокумент2 страницыPowerchokes: Standard Choke SCB All-Purpose Severe ServiceZeeshan KhanОценок пока нет

- 4.0 Shaft, Axle & BearingДокумент75 страниц4.0 Shaft, Axle & BearingphyrdowsОценок пока нет

- Enerpac RCH Series CatalogДокумент2 страницыEnerpac RCH Series CatalogTitanplyОценок пока нет

- M02 T05 03 Hydracrowd Final PDFДокумент30 страницM02 T05 03 Hydracrowd Final PDFWaldir Jhon GonzalezОценок пока нет

- RCH-Series, Hollow Plunger Cylinders: Shown From Left To Right: RCH-306, RCH-120, RCH-1003Документ2 страницыRCH-Series, Hollow Plunger Cylinders: Shown From Left To Right: RCH-306, RCH-120, RCH-1003AwanОценок пока нет

- Series QCT and QCB Cylinders With Integrated Guide: Double-Acting, Magnetic Piston, Guided Ø 20, 25, 32, 40, 50, 63 MMДокумент5 страницSeries QCT and QCB Cylinders With Integrated Guide: Double-Acting, Magnetic Piston, Guided Ø 20, 25, 32, 40, 50, 63 MMVanesaОценок пока нет

- Hydra Rig HR 660 Coiled Tubing Injector Data SheetДокумент2 страницыHydra Rig HR 660 Coiled Tubing Injector Data SheetЭльмирОценок пока нет

- Linear CylindersДокумент36 страницLinear CylindersNHI_DKОценок пока нет

- TC Product SpecificationДокумент8 страницTC Product SpecificationNitin AmbarОценок пока нет

- Workholding Cylinders EN-USДокумент36 страницWorkholding Cylinders EN-USRoberto RodriguezОценок пока нет

- Cilindro Hidraulico EnerpacДокумент4 страницыCilindro Hidraulico EnerpacrrОценок пока нет

- Holte Reverse Circulation Brochure 2019Документ24 страницыHolte Reverse Circulation Brochure 2019Milad RahimiОценок пока нет

- Exploiting of Coiled TubingДокумент298 страницExploiting of Coiled Tubingbelahmeurs86% (7)

- Open Circuit Piston Motors: Reverse Displacement Motor (RDM)Документ4 страницыOpen Circuit Piston Motors: Reverse Displacement Motor (RDM)CaioОценок пока нет

- Open Circuit Piston Motors: Reverse Displacement Motor (RDM)Документ4 страницыOpen Circuit Piston Motors: Reverse Displacement Motor (RDM)CaioОценок пока нет

- Ir Turbo-Air-6000 A4Документ6 страницIr Turbo-Air-6000 A4Aris Fitama ZeinauraОценок пока нет

- SLB Coil Tubing Services Manual PDFДокумент33 страницыSLB Coil Tubing Services Manual PDFDeepak RanaОценок пока нет

- Dimensions & StrengthsДокумент34 страницыDimensions & StrengthsMiguel RodriguezОценок пока нет

- RCH-Series, Hollow Plunger Cylinders Versatility in Testing, Maintenance and Tensioning ApplicationsДокумент2 страницыRCH-Series, Hollow Plunger Cylinders Versatility in Testing, Maintenance and Tensioning ApplicationsPedro Vieira PedrobecoОценок пока нет

- High Tonnage Cylinders Brochure 9389 En-GbДокумент20 страницHigh Tonnage Cylinders Brochure 9389 En-GbEnus BenjaminОценок пока нет

- Metal Membrane Coupling L Series: Product Description Design FeaturesДокумент8 страницMetal Membrane Coupling L Series: Product Description Design FeaturesAl jabr Al khwarizmiОценок пока нет

- X3675 - enAU - 3675 Wash Box SS - 1114Документ2 страницыX3675 - enAU - 3675 Wash Box SS - 1114Edson MirandaОценок пока нет

- A33 Manual Acople WoochangДокумент16 страницA33 Manual Acople WoochangEduardoОценок пока нет

- Enerpac SC Series CatalogДокумент2 страницыEnerpac SC Series CatalogTitanplyОценок пока нет

- Hydraulic Side Acting GripsДокумент4 страницыHydraulic Side Acting Gripsmohamed ahmedОценок пока нет

- Well InterventionДокумент21 страницаWell InterventionCito Ali100% (1)

- Ctu - 800injector - Hydraulic Circuit PDFДокумент56 страницCtu - 800injector - Hydraulic Circuit PDFDhruba Jyoti Buragohain100% (1)

- Modern LinearДокумент16 страницModern LinearAl BorkiОценок пока нет

- ENERPAC RAR - 325eUS - 2Документ4 страницыENERPAC RAR - 325eUS - 2RegisIHCОценок пока нет

- Breaker Owners Manual 2001 PDFДокумент56 страницBreaker Owners Manual 2001 PDFAtanu DubeОценок пока нет

- Basic Drilling EngineeringДокумент26 страницBasic Drilling EngineeringbhuvanchaudhariОценок пока нет

- A Mefi MC001 E1Документ16 страницA Mefi MC001 E1aptureincОценок пока нет

- Linear Motion Devices: Screw JacksДокумент15 страницLinear Motion Devices: Screw JacksDaniel ClitОценок пока нет

- Coiled Tubing Down Hole ToolsДокумент9 страницCoiled Tubing Down Hole Toolsanthony lakpahОценок пока нет

- Spec Jack Enerpac RRДокумент4 страницыSpec Jack Enerpac RRdennis rio perdanaОценок пока нет

- Basic Drilling EngineeringДокумент26 страницBasic Drilling Engineeringgfaux03Оценок пока нет

- 9851 2962 01b - Robbins 34RH C - Technical Specification - EnglishДокумент8 страниц9851 2962 01b - Robbins 34RH C - Technical Specification - EnglishJulio Acevedo MartinezОценок пока нет

- OPen Circuit Hyd PumpДокумент26 страницOPen Circuit Hyd PumpTyprix IseeОценок пока нет

- Renk Water Power Pbr170sbДокумент6 страницRenk Water Power Pbr170sbhumayun121Оценок пока нет

- Hydra Rig HR 680 Coiled Tubing Injector Data SheetДокумент2 страницыHydra Rig HR 680 Coiled Tubing Injector Data SheetDowell Josp RalhОценок пока нет

- CLP en PDFДокумент2 страницыCLP en PDFAnthony FuОценок пока нет

- Flygt A-C Series: WCXH Axial Flow PumpsДокумент4 страницыFlygt A-C Series: WCXH Axial Flow PumpsKrrishОценок пока нет

- Rotary Actuator Catalogue-Reduced PDFДокумент34 страницыRotary Actuator Catalogue-Reduced PDFMazhar HussainОценок пока нет

- Hydralics Aeroquip - Swivle - JointsДокумент20 страницHydralics Aeroquip - Swivle - JointssunnyartboyОценок пока нет

- Steering Rudders CruiseДокумент8 страницSteering Rudders CruiseSRAR100% (1)

- RCH-Series Hollow Plunger Cylinders EN-USДокумент2 страницыRCH-Series Hollow Plunger Cylinders EN-USsara madrigalОценок пока нет

- KC Series Single Cylinder Cone CrusherДокумент14 страницKC Series Single Cylinder Cone CrusherRodrigo RodriguesОценок пока нет

- Bomba de Vacio 12Документ16 страницBomba de Vacio 12Jairzhino EspinozaОценок пока нет

- Boltec MC - 9851 2202 01fДокумент4 страницыBoltec MC - 9851 2202 01fPablo Luis Pérez PostigoОценок пока нет

- 03 IADCpresentation APIДокумент5 страниц03 IADCpresentation APISivaОценок пока нет

- Ventpro: Dimensional and Electrical DataДокумент15 страницVentpro: Dimensional and Electrical DataManuelОценок пока нет

- Hydra Series: Choke ValveДокумент8 страницHydra Series: Choke ValveJorge EduardoОценок пока нет

- Proportional Pressure-Reducing Valve For Hydraulics: V1300.4982 FunctionДокумент6 страницProportional Pressure-Reducing Valve For Hydraulics: V1300.4982 FunctionezeizabarrenaОценок пока нет

- Parts Manual Mitsubishi MG730 98160 93910Документ306 страницParts Manual Mitsubishi MG730 98160 93910ezeizabarrenaОценок пока нет

- Ficha Técnica ER-SPRДокумент3 страницыFicha Técnica ER-SPRezeizabarrenaОценок пока нет

- Exclusive Offer Pressure Sensors 07.2015 DE ENДокумент2 страницыExclusive Offer Pressure Sensors 07.2015 DE ENezeizabarrenaОценок пока нет

- Terex-Ta35sh Ce Uid 30978721001507128915Документ3 страницыTerex-Ta35sh Ce Uid 30978721001507128915ezeizabarrenaОценок пока нет

- 5ad0ac6a-f015-43a3-964c-1b266028419eДокумент8 страниц5ad0ac6a-f015-43a3-964c-1b266028419eezeizabarrenaОценок пока нет

- Return To Index: Spare Parts List Regulated Pump HPR 210-02Документ37 страницReturn To Index: Spare Parts List Regulated Pump HPR 210-02ezeizabarrenaОценок пока нет

- IR 2945 PartsListДокумент2 страницыIR 2945 PartsListezeizabarrenaОценок пока нет

- Cartridge Solenoid Valve Type VR 032Документ4 страницыCartridge Solenoid Valve Type VR 032ezeizabarrenaОценок пока нет

- G6A PCB Relay: Ordering InformationДокумент9 страницG6A PCB Relay: Ordering InformationezeizabarrenaОценок пока нет

- P7067 4Документ24 страницыP7067 4ezeizabarrenaОценок пока нет

- DTV315S DD-C2X010501GBДокумент16 страницDTV315S DD-C2X010501GBezeizabarrena100% (1)

- 001793984Документ5 страниц001793984Oussama FerjaniОценок пока нет

- Text Technical Information - MOSFET Relays: Omron A5 Catalogue 2007 283-418 11/9/06 10:56 Am Page 316Документ4 страницыText Technical Information - MOSFET Relays: Omron A5 Catalogue 2007 283-418 11/9/06 10:56 Am Page 316ezeizabarrenaОценок пока нет

- jGUN DSP3Документ1 страницаjGUN DSP3ezeizabarrenaОценок пока нет

- Return To Index: Spare Parts List Regulated Pump HPR 210-02Документ37 страницReturn To Index: Spare Parts List Regulated Pump HPR 210-02ezeizabarrenaОценок пока нет

- Technical Information Series C: Slip-In Cartridge Valve CoversДокумент11 страницTechnical Information Series C: Slip-In Cartridge Valve CoversezeizabarrenaОценок пока нет

- Ingersoll RandДокумент22 страницыIngersoll RandezeizabarrenaОценок пока нет

- 308.8158.3.1-2 Laser 100-170 enДокумент2 страницы308.8158.3.1-2 Laser 100-170 enezeizabarrenaОценок пока нет

- RH6.5 Prospekt PDFДокумент14 страницRH6.5 Prospekt PDFДрагиша Небитни Трифуновић100% (1)

- System 20Документ5 страницSystem 20ezeizabarrenaОценок пока нет

- Llave de Impacto 3/4": Modelo 220PДокумент1 страницаLlave de Impacto 3/4": Modelo 220PezeizabarrenaОценок пока нет

- Manual SiemensДокумент8 страницManual SiemensJavier ModeОценок пока нет

- Perma Crimp Hydraulic Crimp ChartДокумент12 страницPerma Crimp Hydraulic Crimp ChartezeizabarrenaОценок пока нет

- Ingersoll RandДокумент22 страницыIngersoll RandezeizabarrenaОценок пока нет

- DC18SE PB Rev 0Документ3 страницыDC18SE PB Rev 0ezeizabarrenaОценок пока нет

- Bedia Assembly ClsДокумент1 страницаBedia Assembly ClsezeizabarrenaОценок пока нет

- Pa Technical Bulletin: ModelДокумент7 страницPa Technical Bulletin: ModelezeizabarrenaОценок пока нет

- CleanfixДокумент136 страницCleanfixezeizabarrenaОценок пока нет

- DS-160 Service Data PDFДокумент9 страницDS-160 Service Data PDFsaadОценок пока нет

- Midterm Exam StatconДокумент4 страницыMidterm Exam Statconlhemnaval100% (4)

- Cencon Atm Security Lock Installation InstructionsДокумент24 страницыCencon Atm Security Lock Installation InstructionsbiggusxОценок пока нет

- Opel GT Wiring DiagramДокумент30 страницOpel GT Wiring DiagramMassimiliano MarchiОценок пока нет

- DFUN Battery Monitoring Solution Project Reference 2022 V5.0Документ50 страницDFUN Battery Monitoring Solution Project Reference 2022 V5.0A Leon RОценок пока нет

- T R I P T I C K E T: CTRL No: Date: Vehicle/s EquipmentДокумент1 страницаT R I P T I C K E T: CTRL No: Date: Vehicle/s EquipmentJapCon HRОценок пока нет

- Ril Competitive AdvantageДокумент7 страницRil Competitive AdvantageMohitОценок пока нет

- Hyundai Himap BcsДокумент22 страницыHyundai Himap BcsLim Fung ChienОценок пока нет

- MOL Breaker 20 TonДокумент1 страницаMOL Breaker 20 Tonaprel jakОценок пока нет

- Software Hackathon Problem StatementsДокумент2 страницыSoftware Hackathon Problem StatementsLinusNelson100% (2)

- Flyer Manuale - CON WATERMARK PAGINE SINGOLEДокумент6 страницFlyer Manuale - CON WATERMARK PAGINE SINGOLEjscmtОценок пока нет

- 01 RFI Technical Form BiodataДокумент8 страниц01 RFI Technical Form BiodataRafiq RizkiОценок пока нет

- MG206 Chapter 3 Slides On Marketing Principles and StrategiesДокумент33 страницыMG206 Chapter 3 Slides On Marketing Principles and StrategiesIsfundiyerTaungaОценок пока нет

- 1 075 Syn4e PDFДокумент2 страницы1 075 Syn4e PDFSalvador FayssalОценок пока нет

- S 101-01 - PDF - User Interface - Computer MonitorДокумент130 страницS 101-01 - PDF - User Interface - Computer Monitormborghesi1Оценок пока нет

- Modal Case Data Form: GeneralДокумент4 страницыModal Case Data Form: GeneralsovannchhoemОценок пока нет

- M70-700 4th or 5th Axis Install ProcedureДокумент5 страницM70-700 4th or 5th Axis Install ProcedureNickОценок пока нет

- NCR Minimum WageДокумент2 страницыNCR Minimum WageJohnBataraОценок пока нет

- CORDLESS PLUNGE SAW PTS 20-Li A1 PDFДокумент68 страницCORDLESS PLUNGE SAW PTS 20-Li A1 PDFΑλεξης ΝεοφυτουОценок пока нет

- Effective Communication LeaderДокумент4 страницыEffective Communication LeaderAnggun PraditaОценок пока нет

- Ap06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónДокумент9 страницAp06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónJenny Lozano Charry50% (2)

- VB 850Документ333 страницыVB 850Laura ValentinaОценок пока нет

- Invoice Acs # 18 TDH Dan Rof - Maret - 2021Документ101 страницаInvoice Acs # 18 TDH Dan Rof - Maret - 2021Rafi RaziqОценок пока нет

- Part A Plan: Simple Calculater Using Switch CaseДокумент7 страницPart A Plan: Simple Calculater Using Switch CaseRahul B. FereОценок пока нет

- Colibri - DEMSU P01 PDFДокумент15 страницColibri - DEMSU P01 PDFRahul Solanki100% (4)

- Computer System Sevicing NC Ii: SectorДокумент44 страницыComputer System Sevicing NC Ii: SectorJess QuizzaganОценок пока нет

- U2 - Week1 PDFДокумент7 страницU2 - Week1 PDFJUANITO MARINOОценок пока нет

- Black BookДокумент28 страницBlack Bookshubham50% (2)

- Chapter 123 RevisedДокумент23 страницыChapter 123 RevisedCristy Ann BallanОценок пока нет

- TokyoДокумент6 страницTokyoMarcio BonziniОценок пока нет

- A Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentДокумент7 страницA Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentNadiah AUlia SalihiОценок пока нет

- Workbook to Accompany Maintenance & Reliability Best PracticesОт EverandWorkbook to Accompany Maintenance & Reliability Best PracticesРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsОт EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsРейтинг: 4 из 5 звезд4/5 (11)

- A Complete Guide to Safety Officer Interview Questions and AnswersОт EverandA Complete Guide to Safety Officer Interview Questions and AnswersРейтинг: 4 из 5 звезд4/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchОт EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchРейтинг: 4 из 5 звезд4/5 (10)

- Guidelines for Auditing Process Safety Management SystemsОт EverandGuidelines for Auditing Process Safety Management SystemsОценок пока нет

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОт EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОценок пока нет

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsОт EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsРейтинг: 5 из 5 звезд5/5 (1)

- SketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyОт EverandSketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyРейтинг: 1.5 из 5 звезд1.5/5 (2)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisОт EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)От EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Рейтинг: 5 из 5 звезд5/5 (2)

- Autodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersОт EverandAutodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersОценок пока нет

- Certified Solidworks Professional Advanced Weldments Exam PreparationОт EverandCertified Solidworks Professional Advanced Weldments Exam PreparationРейтинг: 5 из 5 звезд5/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersОт EverandRules of Thumb for Maintenance and Reliability EngineersРейтинг: 4.5 из 5 звезд4.5/5 (12)

- The Invisible Rainbow: A History of Electricity and LifeОт EverandThe Invisible Rainbow: A History of Electricity and LifeРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Chemical Process Safety: Learning from Case HistoriesОт EverandChemical Process Safety: Learning from Case HistoriesРейтинг: 4 из 5 звезд4/5 (14)