Академический Документы

Профессиональный Документы

Культура Документы

Seleccion Chaveteros Norma JIS PDF

Загружено:

alanv8Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Seleccion Chaveteros Norma JIS PDF

Загружено:

alanv8Авторское право:

Доступные форматы

[Technical Data]

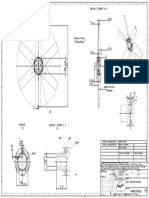

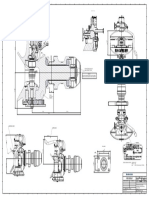

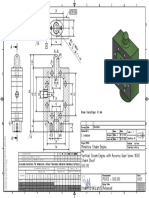

Machine Keys and Key Grooves Excerpts from JIS B 1301(1996)

1. Parallel Keys and Key Grooves 2. Slope Key, Gib Head Key and Key Groove

Gib Head Key Section of Key(A-A)

S1 1.6 Section of Key Section of Key Groove S1

Slope Key 6.3

b

b

b

(Code T)

b

1

1.6 S1=Tolerance of b r2

2

c

S1

25

25

6.3 6.3

h

c

h

A

b

6.3 b2 C c

S2 1.6 6.3 30 f

25

25

1 c 6.3

S2=Tolerance of h 1.6 S2 3.2 Slope 1

h

1

2 3.2 100 1000

h1

b1 1

6.3 6.3 S1=Tolerance of b

h

h

2 A

h2

t2

1.6

r1 1.6 h2=h, f=h, eb S2 Section of Key Groove

1

h

S2=Tolerance of h h2=h, fh, e=b

2 r2

t1

d

t2

b2 1.6

6.3

1.6

t 12

d b1

6.3

r1

Unit:mm

Dimension of Key Groove Reference Unit:mm

Key Nominal (Sliding Type) Standard Precision Class Dimension of Key Groove Dimension of Key Groove Reference

Reference Reference Reference Reference Applicable Key Nominal

Dimension b1 b2 b1 b2 b1 and b2 b h b1 and b2

Dimension r1 and r2 Dimension Dimension Dimension Shaft Dia.(1) Dimension Reference Reference Reference Applicable

bh

of b1, b2 Tolerance Tolerance Tolerance Tolerance Tolerance (1) 2

of t1 of t2 of t2, t1 d Reference Tolerance Reference h1 c Reference Tolerance r1 and r2 Dimension Dimension Dimension Shaft Dia.( )

bh Tolerance of t1 of t2 of t2, t1 d

(H9) (D10) (N9) (Js9) (P9) Dimension (h9) Dimension Dimension (D10)

22 2 + 0.025 +0.060 0.004 0.006 1.2 1.0 6~8 22 2 0 2 0 6~30 2 +0.060 1.2 0.5 + 0.05 6~8

0.0125 0.16 0.08

33 3 0 +0.020 0.029 0.031 0.08~0.16 1.8 1.4 8~10 33 3 0.025 3 0.025 6~36 3 +0.020 1.8 0.9 0 8~10

+ 0.1 ~0.25 ~0.16

44 4 2.5 1.8 10~12 44 4 4 7 8~45 4 2.5 1.2 10~12

+ 0.030 +0.078 0 0.012 0 h9

55 5 0.0150 3.0 2.3 12~17 0 0 +0.078

0 +0.030 0.030 0.042 55 5 5 8 10~56 5 3.0 1.7 + 0.1 12~17

0.030 0.030 +0.030

66 6 3.5 2.8 17~22 66 6 6 10 0.25 14~70 6 0.16 3.5 2.2 0 17~22

0.16~0.25

(77) 7 4.0 3.0 20~25 (77) 7 7.2 0 10 ~0.40 16~80 7 ~0.25 4.0 3.0 20~25

+ 0.036 +0.098 0 0.015 0.036

87 8 0.0180 4.0 3.3 22~30 0 +0.098

0 +0.040 0.036 0.051 87 8 7 11 18~90 8 4.0 2.4 22~30

0.036 +0.040

108 10 5.0 3.3 30~38 108 10 8 0 12 22~110 10 5.0 2.4 + 0.2 30~38

h11

128 12 5.0 3.3 38~44 128 12 8 0.090 12 28~140 12 5.0 2.4 0 38~44

149 14 5.5 3.8 44~50 149 14 9 14 0.40 36~160 14 0.25 5.5 2.9 44~50

+ 0.043 +0.120 0 0.018 0.25~0.40 0 +0.120

(1510) 15 0.0215 5.0 5.0 50~55 (1510) 15 10.2 0 h10 15 ~0.60 40~180 15 ~0.40 5.0 5.0 + 0.1 50~55

0 +0.050 0.043 0.061 0.043 0.070 +0.050 0

1610 16 6.0 4.3 + 0.2 50~58 1610 16 10 0 16 45~180 16 6.0 3.4 50~58

0.090

1811 18 7.0 4.4 0 58~65 1811 18 11 18 50~200 18 7.0 3.4 58~65

+ 0.2

0 h11

2012 20 7.5 4.9 65~75 2012 20 12 20 56~220 20 7.5 3.9 0 65~75

0.110

2214 22 9.0 5.4 75~85 2214 22 14 22 63~250 22 9.0 4.4 75~85

+ 0.052 +0.149 0 0.022 0 0 +0.149 + 0.1

(2416) 24 0.0260 8.0 8.0 80~90 (2416) 24 16.2 0.070 h10 24 0.60 70~280 24 0.40 8.0 8.0 0 80~90

0 +0.065 0.052 0.074 0.40~0.60 0.052 +0.065

2514 25 9.0 5.4 85~95 2514 25 14 22 ~0.80 70~280 25 ~0.60 9.0 4.4 85~95

2816 28 10.0 6.4 95~110 0 + 0.2

2816 28 16 h11 25 80~320 28 10.0 5.4 95~110

0.110 0

3218 32 11.0 7.4 110~130 3218 32 18 28 90~360 32 11.0 6.4 110~130

(3522) 35 11.0 11.0 125~140 (3522) 35 22.3 0 h10 100~400 35 11.0 11.0 + 0.15 125~140

0.084 0

0 32 + 0.3

3620 36 12.0 8.4 130~150 3620 36 20 0.130 h11 36 12.0 7.1 0 130~150

(3824) 38 + 0.062 +0.180 0 0.026 12.0 12.0 140~160 (3824) 38 24.3 0 h10 36 38 12.0 12.0 + 0.15 140~160

0.0310 0 0.084 +0.180 0

4022 40 0 +0.080 0.062 0.088 0.70~1.00 13.0 9.4 150~170 0.062 0 1.00 +0.080 0.70 + 0.3

4022 40 22 0.130 h11 36 40 13.0 8.1 0 150~170

~1.20 ~1.00

(4226) 42 13.0 13.0 160~180 (4226) 42 26.3 0 h10 40 42 13.0 13.0 + 0.15 160~180

0.084 0

4525 45 15.0 10.4 170~200 4525 45 25 0 40 45 15.0 9.1 170~200

+ 0.3

5028 50 17.0 11.4 200~230 5028 50 28 0.130 45 50 17.0 10.1 200~230

0

5632 56 20.0 12.4 230~260 5632 56 32 50 56 20.0 11.1 230~260

6332 63 + 0.074 +0.220 0 0.032 1.20~1.60 20.0 12.4 260~290 1.60 1.20

6332 63 0 32 50 63 +0.220 20.0 11.1 + 0.3 260~290

0.0370 h11 ~2.00 ~1.60

7036 70 0 +0.100 0.074 0.106 22.0 14.4 290~330 7036 70 0.074 36 56 70 +0.100 22.0 13.1 0 290~330

0

8040 80 25.0 15.4 330~380 8040 80 40 0.160 63 80 25.0 14.1 330~380

9045 90 + 0.087 +0.260 0 0.037 2.00~2.50 28.0 17.4 380~440 2.50 2.00

9045 90 0 45 70 90 +0.260 28.0 16.1 380~440

0.0435 ~3.00 ~2.50

10050 100 0 +0.120 0.087 0.124 31.0 19.5 440~500 10050 100 0.087 50 80 100 +0.120 31.0 18.1 440~500

Note(1) The applicable shaft diameter is calculated from the torque corresponding to the strength of the key, for presentation as 1

Note( ) From the values for given below, which are in the appropriate range in the table, one should be selected.

referential data for general-purpose use. When the key is of an appropriate size relative to the torque to be transmitted, a

The tolerance for l should be h12 under JIS B0401(dimension tolerance and fitting), in principle.

shaft thicker than the applicable shaft diameter may be used. In some cases, t1 and t2 should be adjusted so that a side

6,8,10,12,14,16,18,20,22,25,28,32,36,40,45,50,56,63,70,80,90,100,110,125,140,160,180,200,220,250,280,320,360,400

of the key will come into uniform contact with the shaft and the hub. A shaft narrower than the applicable shaft diameter

Note(2) The appropriate shaft diameter should be matched with the torque corresponding to the strength of the key.

should not be used.

Reference The nominal sizes given in( )should not be used unless they are absolutely necessary.

Reference The nominal sizes given in( )do not conform to the relevant international standard and must not be used in new design.

2857 The groove for the boss should be slanted to 1/100, in principle. 2858

Вам также может понравиться

- Metco 16C 10-040Документ8 страницMetco 16C 10-040JSH100Оценок пока нет

- Blind Flange 1,2, Hinge, Handlen & Plug PDFДокумент1 страницаBlind Flange 1,2, Hinge, Handlen & Plug PDFArief MaulanaОценок пока нет

- Pages From Toyota Hilux Wiring DiagramsДокумент6 страницPages From Toyota Hilux Wiring DiagramsPoon Electronic Training CentreОценок пока нет

- DP1100Документ3 страницыDP1100tunradotОценок пока нет

- PSC Girder MethodologyДокумент12 страницPSC Girder MethodologySaurabh KumarОценок пока нет

- Procedure For Field Joint CoatingДокумент10 страницProcedure For Field Joint CoatingM Waqas HabibОценок пока нет

- 17 Free Data Science Projects To Boost Your Knowledge & SkillsДокумент18 страниц17 Free Data Science Projects To Boost Your Knowledge & SkillshamedfazelmОценок пока нет

- JIS B 1301-1996 - Chavetero PDFДокумент1 страницаJIS B 1301-1996 - Chavetero PDFPablo PasqualiniОценок пока нет

- Chaveta Norma JISДокумент1 страницаChaveta Norma JISADP RovalОценок пока нет

- 010 - Key and Their Corresponding Keyways PDFДокумент1 страница010 - Key and Their Corresponding Keyways PDFBaguz SaputraОценок пока нет

- WFBR22F00382-0 - 860 - 6-6 - P5ZL - 35 - Pa - 38 - 10 - AДокумент1 страницаWFBR22F00382-0 - 860 - 6-6 - P5ZL - 35 - Pa - 38 - 10 - AAlan Miguel PuffОценок пока нет

- Tapcon 230 Expert 6655746 ENДокумент2 страницыTapcon 230 Expert 6655746 ENParthiban.PОценок пока нет

- Tapcon 230 Basic 6655745 ENДокумент1 страницаTapcon 230 Basic 6655745 ENPalash DahakeОценок пока нет

- Blind Flange 1,2, Hinge, Handlen & PlugДокумент1 страницаBlind Flange 1,2, Hinge, Handlen & PlugArief MaulanaОценок пока нет

- Prestressed Girder Elevation: Bar Bending DiagramДокумент1 страницаPrestressed Girder Elevation: Bar Bending DiagramMelrose LaforgaОценок пока нет

- Braced Cuts: Q Q CN G H1q2 CH B9 CN g1 Q H C B9 HДокумент1 страницаBraced Cuts: Q Q CN G H1q2 CH B9 CN g1 Q H C B9 HjcvalenciaОценок пока нет

- Ball Rollers (For Upward Facing) : Milled Stainless SteelДокумент1 страницаBall Rollers (For Upward Facing) : Milled Stainless SteelLộcLộcОценок пока нет

- 0BZ Bosa Britalia 10Документ1 страница0BZ Bosa Britalia 10genesisbarrockОценок пока нет

- Crankshaft NutДокумент1 страницаCrankshaft Nutmavas88069Оценок пока нет

- Razvan 4 AcoperisДокумент1 страницаRazvan 4 AcoperisMaria MateiОценок пока нет

- Ficha Tecnica Valvula Prueba y DrenajeДокумент1 страницаFicha Tecnica Valvula Prueba y DrenajeGabino CRОценок пока нет

- Drawing 5 112120141754838Документ1 страницаDrawing 5 112120141754838k koradiaОценок пока нет

- Pedoman Obat EmergencyДокумент10 страницPedoman Obat EmergencyPOKJA PKPOОценок пока нет

- Estructuras Cimientacion: Aula Aprestamiento S.H.V. S.H.MДокумент1 страницаEstructuras Cimientacion: Aula Aprestamiento S.H.V. S.H.MCarlos MezaОценок пока нет

- Schematic - Regen Radio Experimenal - 2022-07-30Документ1 страницаSchematic - Regen Radio Experimenal - 2022-07-30nestor.escala7666Оценок пока нет

- Parallel Keys Parallel Keys: Selectable Dimensions Configurable DimensionsДокумент1 страницаParallel Keys Parallel Keys: Selectable Dimensions Configurable DimensionsFrandika PrimayogaОценок пока нет

- Kusen Pintu Kayu Type 51 & 61Документ3 страницыKusen Pintu Kayu Type 51 & 61Glen SangariОценок пока нет

- Kusen Pintu Kayu Type 51 & 61Документ3 страницыKusen Pintu Kayu Type 51 & 61Glen SangariОценок пока нет

- En AX22u-4Документ2 страницыEn AX22u-4YakupovОценок пока нет

- Detail Drawing Pipe Vise AzriДокумент1 страницаDetail Drawing Pipe Vise AzriAdam FitriОценок пока нет

- Tapcon 230 Basic 6787368 ESДокумент1 страницаTapcon 230 Basic 6787368 ESMaximiliano SanchezОценок пока нет

- Tapcon 230 Pro 6787371 ESДокумент2 страницыTapcon 230 Pro 6787371 ESHoward LamonОценок пока нет

- Tapcon 230 Expert 6787385 ESДокумент2 страницыTapcon 230 Expert 6787385 ESCristhian SaízОценок пока нет

- This Drawing Is The Property of MIKANO International Limited. and Must Not Be Re Issued, Copied or Reproduced Without Their Consent in WritingДокумент2 страницыThis Drawing Is The Property of MIKANO International Limited. and Must Not Be Re Issued, Copied or Reproduced Without Their Consent in WritingXamiPati50% (2)

- Ej Plate A 0420Документ1 страницаEj Plate A 0420Stefan MilojevicОценок пока нет

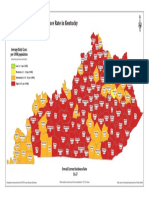

- Incidence Map 1111Документ1 страницаIncidence Map 1111WBKOОценок пока нет

- Dimension Tables: Speed Reducer CHH - 613 DA To 618 DAДокумент1 страницаDimension Tables: Speed Reducer CHH - 613 DA To 618 DAsalpa nugrahaОценок пока нет

- Ringfeder Coupling 303 Aus - Info Drawing - 15990007Документ1 страницаRingfeder Coupling 303 Aus - Info Drawing - 15990007fahrul amirОценок пока нет

- Mas Que Tu Amigo Trombone IДокумент2 страницыMas Que Tu Amigo Trombone IEdgardo Mendez GuzmanОценок пока нет

- Đế Vương 1Документ4 страницыĐế Vương 1Duy Tính TrầnОценок пока нет

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterДокумент1 страницаYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterVictor Ingol LozanoОценок пока нет

- Key Plan:: Symbols & AbbreviationsДокумент1 страницаKey Plan:: Symbols & Abbreviationsmahmudulalam konokОценок пока нет

- Sigra Sirkuit DiagramДокумент147 страницSigra Sirkuit DiagramKhilmi Ainur RifqiОценок пока нет

- Tangent Amp-50-Service-ManualДокумент4 страницыTangent Amp-50-Service-ManualRaika ZamboniniОценок пока нет

- Steel Structure Connection DrawingsДокумент1 страницаSteel Structure Connection DrawingsKavi ArasanОценок пока нет

- DZX-1051 AДокумент2 страницыDZX-1051 AZain UddinОценок пока нет

- Give Thanks FingerstyleДокумент1 страницаGive Thanks FingerstyleAli SuryaОценок пока нет

- Inventorwizard: Miniature Steam Engine Vertical Steam Engine With Reverse Gear (Anno 1830) Steam Chest 000.010Документ1 страницаInventorwizard: Miniature Steam Engine Vertical Steam Engine With Reverse Gear (Anno 1830) Steam Chest 000.010Lucas MaccagnanОценок пока нет

- Colibri-Alto SaxДокумент1 страницаColibri-Alto SaxStephen RiceОценок пока нет

- Connecting RodДокумент1 страницаConnecting RodCốGắngNàoОценок пока нет

- Post-Classical Review Crossword 2017Документ4 страницыPost-Classical Review Crossword 2017api-439999505Оценок пока нет

- Incidence Map 10182021Документ1 страницаIncidence Map 10182021Debbie HarbsmeierОценок пока нет

- BM1-664-M-2013-01 General LayoutДокумент1 страницаBM1-664-M-2013-01 General LayoutMulia R'n RОценок пока нет

- Teras Elemen: Ervi Dn8HdДокумент3 страницыTeras Elemen: Ervi Dn8HdjoegempakОценок пока нет

- Ba - 100 SeriesДокумент21 страницаBa - 100 SeriesArtamei WestriОценок пока нет

- Dilermando Reis Noite de Lua1Документ7 страницDilermando Reis Noite de Lua1daniel nogaraОценок пока нет

- CylinderHead RightДокумент1 страницаCylinderHead RightAlbert AshokОценок пока нет

- Profil Make New Gland Cylinder Boom PC1250SP-8Документ1 страницаProfil Make New Gland Cylinder Boom PC1250SP-8Ahmad RhamdaniОценок пока нет

- 18M Span Superstructure Drawings - MCW - 07.05.2019Документ7 страниц18M Span Superstructure Drawings - MCW - 07.05.2019Tanveer IqbalОценок пока нет

- Catalog de Prezentare Jante de Aliaj IrmscherДокумент16 страницCatalog de Prezentare Jante de Aliaj IrmscherApopii CatalinОценок пока нет

- Inventorwizard: Tooling Manual Clamp: Range 0 - 75Mm 000.007 Clamp FootДокумент1 страницаInventorwizard: Tooling Manual Clamp: Range 0 - 75Mm 000.007 Clamp Footmishael romanОценок пока нет

- 8DJH36-23865 SwgGra 20200228130231Документ3 страницы8DJH36-23865 SwgGra 20200228130231NedyHortetlОценок пока нет

- Toshiba 42pw33q - S Ch. Pw33 SchematicsДокумент18 страницToshiba 42pw33q - S Ch. Pw33 SchematicstodorloncarskiОценок пока нет

- HHW 35 m6 GBДокумент6 страницHHW 35 m6 GBSuper WhippedОценок пока нет

- A Research Paper On Design and Analysis of Shaftless Steam TurbineДокумент5 страницA Research Paper On Design and Analysis of Shaftless Steam TurbineEditor IJTSRDОценок пока нет

- Dataproducts - LZR 1260 Laser Printer (1989)Документ6 страницDataproducts - LZR 1260 Laser Printer (1989)Bobby ChippingОценок пока нет

- 006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapДокумент20 страниц006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapEko Budi HartantoОценок пока нет

- CENG6206 Soil Dynamics ExerciseProblemДокумент4 страницыCENG6206 Soil Dynamics ExerciseProblemFekadu Wub100% (1)

- 02 - Student Lesson 2 Pile Driving SystemДокумент91 страница02 - Student Lesson 2 Pile Driving SystemdannyzuanОценок пока нет

- Operational Definition of TermsДокумент2 страницыOperational Definition of TermsHazel Grace Tugado Torrecampo67% (3)

- EOT CRANE - Rev 2Документ6 страницEOT CRANE - Rev 2Koushik BhaumikОценок пока нет

- How To Build Pyramids and Other Orgone GeneratorsДокумент6 страницHow To Build Pyramids and Other Orgone GeneratorsGuy Jones100% (2)

- Códigos de Falhas Hyundai R3607AДокумент13 страницCódigos de Falhas Hyundai R3607AGuemep GuemepОценок пока нет

- Persuasive Speech Outline Spring 2016Документ2 страницыPersuasive Speech Outline Spring 2016api-311467409Оценок пока нет

- Unit 5 GeosyntheticsДокумент315 страницUnit 5 Geosyntheticskowshik1737551Оценок пока нет

- Deaton FE Slab DesignДокумент57 страницDeaton FE Slab DesignMohamed AliОценок пока нет

- Assignment 1Документ4 страницыAssignment 1MikeyОценок пока нет

- Clutch ListДокумент42 страницыClutch ListAnkan MitraОценок пока нет

- Extended End-Plate Stiffener PDFДокумент2 страницыExtended End-Plate Stiffener PDFaams_sОценок пока нет

- Thermofisher U01316-R2-Gp-Precision-Baths PDFДокумент73 страницыThermofisher U01316-R2-Gp-Precision-Baths PDFelduОценок пока нет

- Aurora: AE MC-120 SeriesДокумент2 страницыAurora: AE MC-120 SeriestasoОценок пока нет

- Computer Netwroks 15CS52: Venugopala Rao A S Assistant Professor (Senior) Dept of CSE, SMVITM BantakalДокумент12 страницComputer Netwroks 15CS52: Venugopala Rao A S Assistant Professor (Senior) Dept of CSE, SMVITM BantakalVenugopal RaoОценок пока нет

- US Hex Bolt SizesДокумент2 страницыUS Hex Bolt SizesYana Jarang OlОценок пока нет

- 545 ELP-ES-2011 - Catálogo de DisipadoresДокумент24 страницы545 ELP-ES-2011 - Catálogo de DisipadoresrichkidОценок пока нет

- Calculation Rail Beam (Hoist Capacity 3 Ton)Документ4 страницыCalculation Rail Beam (Hoist Capacity 3 Ton)Edo Faizal2Оценок пока нет

- 02-Engine Mechanical System PDFДокумент129 страниц02-Engine Mechanical System PDFSigit Indrawan100% (1)

- Breakdown Price by DivisionsДокумент6 страницBreakdown Price by DivisionsFoisulAlamОценок пока нет