Академический Документы

Профессиональный Документы

Культура Документы

Piping Floating Procedure

Загружено:

Madhan RajИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Piping Floating Procedure

Загружено:

Madhan RajАвторское право:

Доступные форматы

Piping guidelines Part I No.

: PG W722/02/006

Piping design, Attachment IV Index: b

Piping Floating Procedure Page: 1 of 5

Attachment to Piping Guidelines

Piping Floating Procedure

Table of Contents

1 INTRODUCTION.....................................................................................................................................................2

2 DEFINITIONS...........................................................................................................................................................2

2.1 Floating of Pipes.................................................................................................................................................2

2.2 Stress Free Connection.......................................................................................................................................2

2.3 De-blocking of Spring Hangers..........................................................................................................................2

3 PROCEDURE............................................................................................................................................................2

4 CHECKS BEFORE FLOATING CAN BE DONE................................................................................................3

5 STEPS FOR FLOATING THE PIPING SYSTEM................................................................................................3

6 REQUIREMENTS....................................................................................................................................................3

6.1 Lateral Misalignment..........................................................................................................................................3

6.2 Axial Misalignment (root opening)....................................................................................................................3

6.3 Unbalanced Forces..............................................................................................................................................3

7 EXAMPLE ISOMETRIC SHOWING THE SIMULATION WEIGHT TO BE ATTACHED..........................4

8 Example format for Acceptable Misalignment and Unbalanced forces......................................................................5

Siemens AG . Power Generation The reproduction, transmission or use of this document or its

contents is not permitted without express written authority. Offenders

will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

H30-K5014 Anweisung/Richtlinie, engl. 2001-01 D97 /conversion/tmp/scratch/358106741.doc

Piping guidelines Part I No.: PG W722/02/006

Piping design, Attachment IV Index: b

Piping Floating Procedure Page: 2 of 5

1 Introduction

This document provides a general methodology on floating of the pipeline end before being

connected to any equipment to ensure stress free connection to the equipment nozzle. For

the list of nozzles that need to be floated refer to the stress guidelines.

2 Definitions

2.1 Floating of Pipes

Leaving the pipe weight and simulated insulation weight hanged from de-blocked springs

before connection to any equipment.

2.2 Stress Free Connection

Flanged or welded joints those are checked for proper alignment within the floating

condition (permitted connection loads) before connection to equipment.

2.3 De-blocking of Spring Hangers

Removing the locking arrangement from a variable/constant spring, so that the pipe is

suspended by means of spring coils.

3 Procedure

Before making the final connection to the equipment nozzle (for critical equipments like

Turbine, Boiler feed Pump etc. which do have rotating components and are sensitive to

the externally applied forces) it is desired to have a stress free connection in order to

achieve manufacturers requested clearances. This is achieved by de-blocking the springs

and then checking the alignment achieved at nozzles.

During floating all supports up to the first two rigid weight supports adjacent to each other

shall be de-blocked and adjusted until they carry the piping, insulation & medium weight

and a neutral weight position at the free end of the piping is achieved. Additional weight is

required to be hanged on pipeline by means of external sources (like sandbags on pipe)

to simulate the weight of insulation and medium. How much weight is to be applied is

found by the calculation and noted on the isometrics. De-Blocking is done from rigid

supports towards the equipment.

If horizontal misalignments at the nozzle are found beyond the acceptable limits, the pipe

is pulled using spring balance. This way the unbalanced force at the nozzle is measured.

Also the free end is forced back into welding position. If the measured force is accepted

by the equipment supplier, pipe could be connected to nozzle. If the loads are not

Siemens AG . Power Generation The reproduction, transmission or use of this document or its

contents is not permitted without express written authority. Offenders

will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

H30-K5014 Anweisung/Richtlinie, engl. 2001-01 D97 /conversion/tmp/scratch/358106741.doc

Piping guidelines Part I No.: PG W722/02/006

Piping design, Attachment IV Index: b

Piping Floating Procedure Page: 3 of 5

acceptable, springs hangers up to the first rigid support should be adjusted again to

reduce horizontal misalignment.

4 Checks before Floating can be done

Tag no. of all the spring blocks matching with isometrics.

All guides and axial stops (between the component nozzles up to the first two rigid weight

supports adjacent to each other) are installed and functional.

Load set points of springs is matching with manufacturers drawing.

5 Steps for Floating the Piping system

For missing weights (insulation, medium etc.) spare weight should be attached at the spring

hangers.

De-blocking of spring hangers from the first two rigid weight supports adjacent to each

other to the component nozzle.

Adjusting of spring hangers up to the first rigid weight support to achieve a neutral weight

position.

By spring balance, forcing the free end back to welding position and making a note of effort

required.

6 Requirements

To achieve the stress free condition requirements stipulated in ASME B31.1, chapter 127.3,

relevant WPS, STIM 04.001 and those provided by equipment manufacturer should be met. The

same can be summarised as:-

6.1 Lateral Misalignment

The maximum lateral misalignment should not exceed the specified values in ASME B31.1

Chapter 127.4C or equipment supplier provided values.

6.2 Axial Misalignment (root opening)

The maximum axial misalignment should be within the WPS specified range.

6.3 Unbalanced Forces

It is generally permitted that the maximum unbalanced component forces and moments at

the turbine connection should not exceed 20% of the permitted hot load values. The actual

Siemens AG . Power Generation The reproduction, transmission or use of this document or its

contents is not permitted without express written authority. Offenders

will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

H30-K5014 Anweisung/Richtlinie, engl. 2001-01 D97 /conversion/tmp/scratch/358106741.doc

Piping guidelines Part I No.: PG W722/02/006

Piping design, Attachment IV Index: b

Piping Floating Procedure Page: 4 of 5

unbalanced force in the cold condition has to be approved by the component supplier

before making the final connection to equipment.

7 Example Isometric showing the simulation weight to be attached

Siemens AG . Power Generation The reproduction, transmission or use of this document or its

contents is not permitted without express written authority. Offenders

will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

H30-K5014 Anweisung/Richtlinie, engl. 2001-01 D97 /conversion/tmp/scratch/358106741.doc

Piping guidelines Part I No.: PG W722/02/006

Piping design, Attachment IV Index: b

Piping Floating Procedure Page: 5 of 5

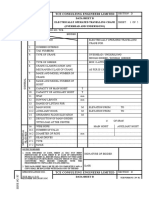

8 Example format for Acceptable Misalignment and Unbalanced forces

Siemens AG . Power Generation The reproduction, transmission or use of this document or its

contents is not permitted without express written authority. Offenders

will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

H30-K5014 Anweisung/Richtlinie, engl. 2001-01 D97 /conversion/tmp/scratch/358106741.doc

Вам также может понравиться

- Nissan Frontier Service Manual Engine MechanicalДокумент205 страницNissan Frontier Service Manual Engine MechanicalDaniel Aguirre100% (1)

- Recommended Testing Procedures For HDPE PipeДокумент1 страницаRecommended Testing Procedures For HDPE Pipeosto72Оценок пока нет

- Hdpe Pipe Design PDFДокумент27 страницHdpe Pipe Design PDFAshley Dillon TothОценок пока нет

- Wiik & Hoeglund Pipe FittingsДокумент60 страницWiik & Hoeglund Pipe Fittingsliang jasonОценок пока нет

- Wet Well Pumping Station Design GuideДокумент61 страницаWet Well Pumping Station Design Guideawhk2006100% (3)

- Introduction To Piping EngineeringДокумент33 страницыIntroduction To Piping EngineeringkysucoОценок пока нет

- Swimming Pool DesignДокумент49 страницSwimming Pool Designcashlover100% (1)

- Calibration of A Bourdon ManometerДокумент5 страницCalibration of A Bourdon ManometerMyat Thu HtetОценок пока нет

- Safety Code for Public Swimming PoolsДокумент18 страницSafety Code for Public Swimming PoolsAditi Bansal100% (5)

- ANSYS TutorialДокумент44 страницыANSYS Tutorialsauravc88Оценок пока нет

- ANSYS TutorialДокумент44 страницыANSYS Tutorialsauravc88Оценок пока нет

- Pressure VesselДокумент32 страницыPressure VesselYonjon SubhaОценок пока нет

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsОт EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsОценок пока нет

- Specification For HDPE MANHOLES PDFДокумент4 страницыSpecification For HDPE MANHOLES PDFPipeline EngineerОценок пока нет

- Bell and Gossett Sump DesignДокумент8 страницBell and Gossett Sump DesignVelpandian ManiОценок пока нет

- 2010 AWWA Life Cycle HDPE in PW Apps Camille RubeizДокумент37 страниц2010 AWWA Life Cycle HDPE in PW Apps Camille RubeizmbobterateraОценок пока нет

- HDPE Pipeline Installation and DesignДокумент19 страницHDPE Pipeline Installation and Designcrys suryo prayogo100% (1)

- SH290 Service TextДокумент204 страницыSH290 Service TextDu TrầnОценок пока нет

- Pump Suction Piping PDFДокумент12 страницPump Suction Piping PDFChanchal GuptaОценок пока нет

- Design Aspects of Steam GeneratorsДокумент12 страницDesign Aspects of Steam GeneratorsMadhan Raj100% (1)

- RINA Rules For The Classification 2015 Part B CH 5 To 8Документ190 страницRINA Rules For The Classification 2015 Part B CH 5 To 8Jorge Isaac Mendoza MarchanОценок пока нет

- Standard Piping Design Basis DocumentДокумент25 страницStandard Piping Design Basis DocumentMadhan RajОценок пока нет

- Tension Compression and ShearДокумент27 страницTension Compression and ShearRizal Muhammad FaradayОценок пока нет

- Tender For Centrifugal Pumps HPДокумент96 страницTender For Centrifugal Pumps HPAnne Sharon100% (1)

- Initial Dilution SpreadsheetДокумент8 страницInitial Dilution Spreadsheetgeonova5Оценок пока нет

- Comparing Properties of Pipes Made from Ductile Iron, Steel, Concrete, HDPE & GRPДокумент3 страницыComparing Properties of Pipes Made from Ductile Iron, Steel, Concrete, HDPE & GRPDBasak_1974Оценок пока нет

- Spring Hanger Support Design-StepsДокумент19 страницSpring Hanger Support Design-StepsrgopalanОценок пока нет

- Pipe Mech Design AWWA M45 AДокумент5 страницPipe Mech Design AWWA M45 AalvinchuanОценок пока нет

- CPHEEO Manual PDFДокумент777 страницCPHEEO Manual PDFJaved HasanОценок пока нет

- Document: Technical Specification: PBSIM & BFS Consulting EngineeringДокумент15 страницDocument: Technical Specification: PBSIM & BFS Consulting EngineeringAmar RajawatОценок пока нет

- PMS Sheet GRE PipeДокумент3 страницыPMS Sheet GRE PipeSOPANОценок пока нет

- Tutorial 2-Equilibrium 1Документ2 страницыTutorial 2-Equilibrium 1Sai KrishnaОценок пока нет

- Lump MassДокумент10 страницLump Masspkshrawal1976Оценок пока нет

- Well ServicingHR ManualДокумент149 страницWell ServicingHR ManualMohammed teggar100% (3)

- Attachment-6 TBE ANSI Pump BCUДокумент31 страницаAttachment-6 TBE ANSI Pump BCURanu Januar100% (1)

- Appendix A Open Seawater Intake and Brine Outfall Assessment PDFДокумент56 страницAppendix A Open Seawater Intake and Brine Outfall Assessment PDFFaisal KasanofaОценок пока нет

- Example Surge AnalysisДокумент68 страницExample Surge AnalysisJeEJyZa100% (4)

- Pipe SupportДокумент10 страницPipe Supportmohammed kadhimОценок пока нет

- Compressor Torque Manual GES089Документ93 страницыCompressor Torque Manual GES089Jeff LОценок пока нет

- Sea Water Intake & Outfall System For Coastal Power ProjectsДокумент3 страницыSea Water Intake & Outfall System For Coastal Power ProjectsAldy NovaldyОценок пока нет

- Types of Boilers PDFДокумент5 страницTypes of Boilers PDFJosé RubioОценок пока нет

- Ut Referance NotesДокумент164 страницыUt Referance NotesRaja BoopathyОценок пока нет

- Lime-Dosing Wam Inc Brochure 0114 EDIT PDFДокумент4 страницыLime-Dosing Wam Inc Brochure 0114 EDIT PDFWidiyanto WidiyantiОценок пока нет

- Pfaudler Din Be Reactors 1Документ42 страницыPfaudler Din Be Reactors 1Nancy GarciaОценок пока нет

- AutoPIPE QuickStart - Model Modification - WorkbookДокумент63 страницыAutoPIPE QuickStart - Model Modification - WorkbookJames100% (1)

- Shell and Tube Heat Exchanger DesignДокумент41 страницаShell and Tube Heat Exchanger DesignAhmad Budiman100% (2)

- Technical Specification - Patratu-3LPE CoatingДокумент24 страницыTechnical Specification - Patratu-3LPE CoatingAJAY PatilОценок пока нет

- Variable Spring SupportsДокумент12 страницVariable Spring SupportsMadhan RajОценок пока нет

- Astm f1155 1998Документ25 страницAstm f1155 1998nerissaloveОценок пока нет

- Intake and outfall structure design optimizationДокумент4 страницыIntake and outfall structure design optimizationMurali KrishnaОценок пока нет

- Water Quality Management of Swimming Pool PDFДокумент11 страницWater Quality Management of Swimming Pool PDFMadhan Raj100% (1)

- Guidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) AnalysisДокумент8 страницGuidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) Analysisgpskumar22Оценок пока нет

- Info Gas StationsДокумент70 страницInfo Gas StationsGuillermo CorderoОценок пока нет

- Article Regulation Esna 1997Документ12 страницArticle Regulation Esna 1997lebrixОценок пока нет

- Container OfficeДокумент1 страницаContainer OfficeBANGGAОценок пока нет

- Vol IIДокумент74 страницыVol IIBhaskar ReddyОценок пока нет

- Acid Cleaning ProcedureДокумент6 страницAcid Cleaning ProcedureMadhan RajОценок пока нет

- SleeveДокумент16 страницSleeveengsamerhozinОценок пока нет

- Guidelines For Sewage Works Design: January 2008Документ28 страницGuidelines For Sewage Works Design: January 2008Ishan RanganathОценок пока нет

- Water HammerДокумент12 страницWater Hammerkanbouch100% (1)

- 10 Drying of PulpsДокумент8 страниц10 Drying of PulpsMadhan RajОценок пока нет

- Assessment of Effective Stiffness Formulation of Concrete Coated Rigid Pipeline (ASME Paper)Документ6 страницAssessment of Effective Stiffness Formulation of Concrete Coated Rigid Pipeline (ASME Paper)bubbly_blu2Оценок пока нет

- Wind Load NSCP 2010 SampleДокумент5 страницWind Load NSCP 2010 SampleRichard Tagle100% (1)

- Book 2: Chapter 4 - Fluid Flow: Application LimitationsДокумент20 страницBook 2: Chapter 4 - Fluid Flow: Application LimitationsVaniya GoelОценок пока нет

- Eot Crane Datasheet-BДокумент5 страницEot Crane Datasheet-Bbashok20Оценок пока нет

- Pontoon Bridge StabilityДокумент2 страницыPontoon Bridge Stabilityপ্রিয়দীপ প্রিয়মОценок пока нет

- Piping Stress Analysis and Design Training CoursesДокумент1 страницаPiping Stress Analysis and Design Training CoursesMeena RezkallahОценок пока нет

- Sedimentation Tank DesignДокумент6 страницSedimentation Tank DesignManish KumarОценок пока нет

- Oil Cooler - Pre Design Data SheetДокумент3 страницыOil Cooler - Pre Design Data SheetSakthi VelОценок пока нет

- Static Mixers Waste & WaterДокумент3 страницыStatic Mixers Waste & WaterIsmael KhalilОценок пока нет

- Presentation FRP 06Документ10 страницPresentation FRP 06Mohamed BouchouatОценок пока нет

- Special Support in PipingДокумент6 страницSpecial Support in PipingAKHIL JOSEPHОценок пока нет

- Oil & Gas Pump Selection GuideДокумент79 страницOil & Gas Pump Selection GuideArunkumarОценок пока нет

- 4.3 Basic Design Awwa D100 & Api 650Документ7 страниц4.3 Basic Design Awwa D100 & Api 650Miguel Martinez Guerrero100% (1)

- R5000 IomДокумент26 страницR5000 Iomfuminori0% (1)

- HydraulicsДокумент42 страницыHydraulicsAslam ChohanОценок пока нет

- Air Stripping: The Removal of Volatile Contaminants From Water and Contaminated SoilsДокумент39 страницAir Stripping: The Removal of Volatile Contaminants From Water and Contaminated SoilsMohammed Al-DahlanОценок пока нет

- Reviewed Design Input for QIPP Slop Tank FabricationДокумент2 страницыReviewed Design Input for QIPP Slop Tank FabricationMathivanan AnbazhaganОценок пока нет

- Pipeline Hydraulic Design Proposal PDFДокумент62 страницыPipeline Hydraulic Design Proposal PDFDhia SlamaОценок пока нет

- Water Treatment Plant SpecsДокумент131 страницаWater Treatment Plant SpecsDhaval ParmarОценок пока нет

- SKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1Документ31 страницаSKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1kebarongan12Оценок пока нет

- Pipe Stress Analysis Training Complete CourseДокумент24 страницыPipe Stress Analysis Training Complete CourseFábio GamaОценок пока нет

- Pump Types Guide - Find the right pump for the jobДокумент6 страницPump Types Guide - Find the right pump for the jobEnvergyProjectsОценок пока нет

- DR014 LAB Feedwater-Suctionline Pipe Routing RequirementsДокумент4 страницыDR014 LAB Feedwater-Suctionline Pipe Routing RequirementsMadhan RajОценок пока нет

- Siemens piping slope requirementsДокумент4 страницыSiemens piping slope requirementsMadhan RajОценок пока нет

- List of Standards: Si - No Description Drawing NoДокумент2 страницыList of Standards: Si - No Description Drawing NoMadhan RajОценок пока нет

- DR008 - Earthing of PipingДокумент3 страницыDR008 - Earthing of PipingMadhan RajОценок пока нет

- DR008 - Earthing of PipingДокумент3 страницыDR008 - Earthing of PipingMadhan RajОценок пока нет

- Steel PhaseДокумент174 страницыSteel PhasechopkarОценок пока нет

- BoilerДокумент29 страницBoilerMadhan RajОценок пока нет

- Trunnion Calculation 0193 - 001Документ9 страницTrunnion Calculation 0193 - 001Madhan RajОценок пока нет

- Outokumpu Duplex Stainless Steel Data SheetДокумент12 страницOutokumpu Duplex Stainless Steel Data SheetbayumahardikaОценок пока нет

- Black Liquor Recovery - How Does It WorkДокумент7 страницBlack Liquor Recovery - How Does It Workmancini10Оценок пока нет

- M 120Документ40 страницM 120ilkinОценок пока нет

- Vibration Control of A Traveling Suspended SystemДокумент8 страницVibration Control of A Traveling Suspended SystemMadhan RajОценок пока нет

- Design Calc Saud It SampleДокумент25 страницDesign Calc Saud It SampleglazetmОценок пока нет

- Black Liquor Recovery - How Does It WorkДокумент7 страницBlack Liquor Recovery - How Does It Workmancini10Оценок пока нет

- 9ni 4coДокумент102 страницы9ni 4cosunsirОценок пока нет

- PPV PresentationДокумент66 страницPPV PresentationIvan BogdanОценок пока нет

- EGR Valve Emulator EML810/24 Installation Guide: BrownДокумент1 страницаEGR Valve Emulator EML810/24 Installation Guide: BrownРадослав БошковОценок пока нет

- Sweeper (Brushes With Convoluted Sections) (One Piece End Caps) (72 - ) - (S - N 435400101 & Above, 783700101 & Above) - SweeperДокумент3 страницыSweeper (Brushes With Convoluted Sections) (One Piece End Caps) (72 - ) - (S - N 435400101 & Above, 783700101 & Above) - SweeperCristian SchildОценок пока нет

- Weg 10018xp3e405tДокумент5 страницWeg 10018xp3e405tcorsini999Оценок пока нет

- Locitte 577 Fast Cure Pipe LEM BESI KACA LASДокумент384 страницыLocitte 577 Fast Cure Pipe LEM BESI KACA LASnoviОценок пока нет

- 9702 s10 Ms 23Документ4 страницы9702 s10 Ms 23Hubbak KhanОценок пока нет

- Pros and Cons of Engineering BranchesДокумент6 страницPros and Cons of Engineering BranchesAnuj KansalОценок пока нет

- 0 - Geotechnical Site Classification and Croatian National Annex For Eurocode 8 - P.kvasnicka, Leo Matesic and K.ivandic - 2011 - 8182Документ10 страниц0 - Geotechnical Site Classification and Croatian National Annex For Eurocode 8 - P.kvasnicka, Leo Matesic and K.ivandic - 2011 - 8182nebojsadj6411Оценок пока нет

- ID2CNC MachineExplode AllДокумент22 страницыID2CNC MachineExplode AllNixonGarcia100% (1)

- Rao 1961Документ10 страницRao 1961Sãröj ShâhОценок пока нет

- Manual Termostato Digitall t6812 FancoilДокумент4 страницыManual Termostato Digitall t6812 FancoilaarroyofОценок пока нет

- 8FG D CE049!20!0608 Multi Function DisplayДокумент73 страницы8FG D CE049!20!0608 Multi Function DisplayDuong Van HoanОценок пока нет

- Annex XДокумент3 страницыAnnex XHardikОценок пока нет

- PDC Lab ReportДокумент13 страницPDC Lab Reportarslan_uetanОценок пока нет

- Tabela TROUBLESHOOTING FT 2010Документ14 страницTabela TROUBLESHOOTING FT 2010Lucas TavaresОценок пока нет

- Thermal Management of Electronics Using Phase ChangeДокумент9 страницThermal Management of Electronics Using Phase ChangeRaj kumarОценок пока нет

- พอฤทัย วิริยะภาค26 3.5Документ2 страницыพอฤทัย วิริยะภาค26 3.55.6 25 [พิงค์แพรว]นางสาวพอฤทัย วิริยะภาคОценок пока нет

- Case StudiesДокумент104 страницыCase StudiesIshanОценок пока нет

- The Linea - Heavy Duty Cafe Espresso MachineДокумент112 страницThe Linea - Heavy Duty Cafe Espresso Machinevicky wicaksanaОценок пока нет

- Machine Design Data BookДокумент19 страницMachine Design Data BookSunnyChoudharyОценок пока нет