Академический Документы

Профессиональный Документы

Культура Документы

Tandem MIG

Загружено:

Weedman920 оценок0% нашли этот документ полезным (0 голосов)

60 просмотров1 страницаThe document discusses Tandem MIG welding, which uses two independently-controlled welding arcs through a single torch to improve productivity. The lead arc controls deposition rate and penetration, while the trailing arc controls weld bead appearance. This dual-wire process allows for exceptional welding speeds and high deposition rates compared to single-wire welding. The independent control of the arcs enhances weld pool dynamics to improve weld quality, penetration, and bead shape. Tandem MIG is well-suited for automotive and heavy equipment applications requiring high travel speeds or deposition rates.

Исходное описание:

Technical document

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe document discusses Tandem MIG welding, which uses two independently-controlled welding arcs through a single torch to improve productivity. The lead arc controls deposition rate and penetration, while the trailing arc controls weld bead appearance. This dual-wire process allows for exceptional welding speeds and high deposition rates compared to single-wire welding. The independent control of the arcs enhances weld pool dynamics to improve weld quality, penetration, and bead shape. Tandem MIG is well-suited for automotive and heavy equipment applications requiring high travel speeds or deposition rates.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

60 просмотров1 страницаTandem MIG

Загружено:

Weedman92The document discusses Tandem MIG welding, which uses two independently-controlled welding arcs through a single torch to improve productivity. The lead arc controls deposition rate and penetration, while the trailing arc controls weld bead appearance. This dual-wire process allows for exceptional welding speeds and high deposition rates compared to single-wire welding. The independent control of the arcs enhances weld pool dynamics to improve weld quality, penetration, and bead shape. Tandem MIG is well-suited for automotive and heavy equipment applications requiring high travel speeds or deposition rates.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

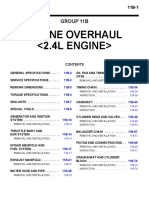

TANDEM MIG

PROCESS DEFINITION Pulsed/Standard mode:

Tandem MIG is a dual wire GMAW process that is Lead arc is synchronized

used in automated welding applications to improve pulsed while the Trailing

welding productivity. The process uses two welding arc is Constant Voltage for

power sources and two wire feeders acting in achieving maximum

tandem to deliver two wire electrodes through a welding speed and gap

bridging.

single welding torch.

The two welding g arcs that are g generated are Standard/Pulsed mode: Best for deep penetration

electrically isolated from one another and are th Lead

the L d arc is i in

i Constant

C t t Voltage

V lt moded which

hi h

maximizes penetration and travel speed while the

controlled independently. The welding arcs work

Trailing arc is in pulse mode to reduce heat input and

together, generally separated by less than 0.50

cool the weld puddle.

inches, in the same weld pool. The independent

Standard/Standard mode: Lead and Trailing arcs

control of the two welding arcs is used to control are both in Constant Voltage mode usually for welding

the thermal and fluid dynamics of the weld pool to with just one electrode and switching to the other

further enhance welding performance. The added when changing directions to reduce cycle time.

deposit rate achieved by the dual wire delivery and

the added weld pool control is used to overcome ADVANTAGES

single wire limitations to produce high travel speeds 9 Exceptional welding speeds

and electrode melt-off rates (weld metal 9 High weld metal deposition rate

deposition). 9 Superior weld quality:

Reduced heat input

Resists burn-through on thin materials

Maintains low spatter levels

Produces

P d goodd penetration

t ti on thi

thick

k

materials

Improves bead wetting at weld toes

Resists undercut

9 Bead profile control

9 Lowers production costs

9 Increases productivity

EQUIPMENT

Power Sources

It was vital that the two power sources

communicate with each other for the

synchronization of the two electric arcs.

Wire Feeders APPLICATIONS

High Travel Speed Welding: High Deposition Welding:

Welding Torch Automotive components Heavy equipment

Wheels, large and small ASME tanks

MODES OF TRANSFER Cylinders Structural

Tanks Railroad industry

Two wire electrodes are positioned in line, in the Gussets and Stiffeners Pipe and tubular

direction of travel. The first electrode, the lead, Many thin gauge lap and components

controls deposition rate and penetration. The filler welds

second electrode, the trail, controls weld bead REFERENCES

appearance. www.lincolnelectric.com

www.wolfrobotics.com/products/images/TwinWireMIGbro.pdf

Вам также может понравиться

- DS Limitor P Back Up Fuse Links Without Controlled Power Dissipation ENДокумент12 страницDS Limitor P Back Up Fuse Links Without Controlled Power Dissipation ENGilberto MejiaОценок пока нет

- Practical Transformer Handbook: for Electronics, Radio and Communications EngineersОт EverandPractical Transformer Handbook: for Electronics, Radio and Communications EngineersРейтинг: 4 из 5 звезд4/5 (16)

- Tandem MigДокумент4 страницыTandem MigMiguel AndradeОценок пока нет

- Interconnects: P. Vaishnavi - 208221020Документ39 страницInterconnects: P. Vaishnavi - 208221020Palawar VaishnaviОценок пока нет

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionОт EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionОценок пока нет

- Complete Short Circuit CycleДокумент8 страницComplete Short Circuit CycleWilly UioОценок пока нет

- Plasma Arc Machining - Lect 2Документ17 страницPlasma Arc Machining - Lect 2sachhpОценок пока нет

- Cast Resin Transformer Catalog PDFДокумент21 страницаCast Resin Transformer Catalog PDFOggie Kent Castillo100% (1)

- Gas Metal Arc Welding: (Gmaw / Mig)Документ16 страницGas Metal Arc Welding: (Gmaw / Mig)Anonymous cgcKzFtXОценок пока нет

- Elektronapon Celpack KatДокумент2 страницыElektronapon Celpack KatCsaba VargaОценок пока нет

- The Manual Metal Arc ProcessДокумент2 страницыThe Manual Metal Arc Processdinar tunjungОценок пока нет

- MBRF2045CT Datasheet PDFДокумент3 страницыMBRF2045CT Datasheet PDFPablo AllosiaОценок пока нет

- Vs 3c10ev07t m3Документ6 страницVs 3c10ev07t m3matheuzalexsanderОценок пока нет

- 17A17BДокумент10 страниц17A17BburaqbarakahsbОценок пока нет

- Fusion Welding Processes2011Документ33 страницыFusion Welding Processes2011Anish Chakrabarti100% (1)

- 1DB 38062 enДокумент2 страницы1DB 38062 enIkhuosho AbodeОценок пока нет

- Surface Tension Transfer (STT) : ApplicationДокумент6 страницSurface Tension Transfer (STT) : ApplicationAnonymous dvrhf5Оценок пока нет

- New Product "Expanded ESD Rated MLCC Portfolio"Документ5 страницNew Product "Expanded ESD Rated MLCC Portfolio"julianaОценок пока нет

- Paar-Tronic-Cy: Flexible, Screened, Colour Coded To DIN 47100, Meter Marking, EMC-preferred TypeДокумент2 страницыPaar-Tronic-Cy: Flexible, Screened, Colour Coded To DIN 47100, Meter Marking, EMC-preferred TypeKelvin NgumbauОценок пока нет

- Littelfuse Power Semiconductor Schottky Diode MBRF-783717Документ4 страницыLittelfuse Power Semiconductor Schottky Diode MBRF-783717Franchesco PocasangreОценок пока нет

- StainTrode DДокумент2 страницыStainTrode DGyanaranjan2011Оценок пока нет

- Cable N2xyДокумент1 страницаCable N2xyAlicia AltamiranoОценок пока нет

- Arco SumergidoДокумент16 страницArco SumergidoottopardoОценок пока нет

- Welding - Quality Concerns & In-Service Welding: October 7, 2015Документ37 страницWelding - Quality Concerns & In-Service Welding: October 7, 2015江宸宸Оценок пока нет

- Helukabel 1DB 33054 enДокумент2 страницыHelukabel 1DB 33054 enLaurentiu CatalinОценок пока нет

- JST B4B EH A (LF) (SN) DatasheetДокумент4 страницыJST B4B EH A (LF) (SN) DatasheetDeep SharmaОценок пока нет

- 11 SmawДокумент19 страниц11 SmawLương Hồ Vũ100% (2)

- 3na HRC Din FuseДокумент20 страниц3na HRC Din Fusesuresh kanchanaОценок пока нет

- Manual Metal Arc Welding or Shielded Metal Arc WeldingДокумент19 страницManual Metal Arc Welding or Shielded Metal Arc WeldingLâm ThanhОценок пока нет

- L05 Transmissionlines v4.ppsДокумент16 страницL05 Transmissionlines v4.ppsM Kumar MarimuthuОценок пока нет

- Leb 1Документ3 страницыLeb 1neden olmasınОценок пока нет

- 1.1 Diode, SCR, TriacДокумент67 страниц1.1 Diode, SCR, Triac727721eumt082Оценок пока нет

- Welding Process: Mma (Manual Metal Arc)Документ1 страницаWelding Process: Mma (Manual Metal Arc)Fauzan RusmayadiОценок пока нет

- 09hermetically Sealed OilДокумент2 страницы09hermetically Sealed OiljuliancansenОценок пока нет

- 11 SmawДокумент19 страниц11 SmawfinhayОценок пока нет

- Commonly Used Welding Process Techniques-OverviewДокумент51 страницаCommonly Used Welding Process Techniques-OverviewaadmaadmОценок пока нет

- 21001en 17012Документ2 страницы21001en 17012Mahesh KumbharОценок пока нет

- 12 TIG WeldingДокумент27 страниц12 TIG WeldingPraviBeetlesОценок пока нет

- FCAW-GS Flux Cored Arc Welding-Gas ShieldedДокумент20 страницFCAW-GS Flux Cored Arc Welding-Gas ShieldedasrafiОценок пока нет

- Resistance WeldingДокумент22 страницыResistance WeldingGarden005Оценок пока нет

- SAW BasicДокумент24 страницыSAW BasicHakan MuralОценок пока нет

- M08 - Gmaw & FcawДокумент30 страницM08 - Gmaw & Fcawசுரேஷ் பாலமுருகன்Оценок пока нет

- Welding ProcessesДокумент20 страницWelding Processesvikasbhadoria9894Оценок пока нет

- RK CableДокумент1 страницаRK CableKristaОценок пока нет

- Esab Buddy Tig 160 PDFДокумент2 страницыEsab Buddy Tig 160 PDFErick SavrinaldoОценок пока нет

- 7TKK000014 - JH VBT Furnace Switch BR - DGTДокумент8 страниц7TKK000014 - JH VBT Furnace Switch BR - DGTHamid SamavatiОценок пока нет

- 10 Methods To Reduce Cost in Your Cable AssemblyДокумент26 страниц10 Methods To Reduce Cost in Your Cable AssemblyCao CuongОценок пока нет

- 11 TIG WeldingДокумент29 страниц11 TIG WeldingudomОценок пока нет

- Topflex Emv Uv 3 Plus 2yslcyk JДокумент2 страницыTopflex Emv Uv 3 Plus 2yslcyk JagusОценок пока нет

- Industrial Electronics: I. Welding SystemsДокумент26 страницIndustrial Electronics: I. Welding SystemsAnthony SosaОценок пока нет

- Class 11 GMAWДокумент39 страницClass 11 GMAWSaurabh TripathiОценок пока нет

- Module-I Power Semiconductor Devices: Prepared by Jeena John Asst. Prof. in Eee Soe, CusatДокумент50 страницModule-I Power Semiconductor Devices: Prepared by Jeena John Asst. Prof. in Eee Soe, CusatJEENA JOHNОценок пока нет

- STT Lassen Surface Tenstion Transfer Welding Process Rev4Документ31 страницаSTT Lassen Surface Tenstion Transfer Welding Process Rev4Queiroz NeyОценок пока нет

- Twin Wire Mig BroДокумент8 страницTwin Wire Mig Broraghavender1Оценок пока нет

- Welding Week 1Документ27 страницWelding Week 1Chriv SokundavannОценок пока нет

- Somenath GhoshДокумент52 страницыSomenath Ghoshravi00098Оценок пока нет

- RC Cable Lugs May2020Документ140 страницRC Cable Lugs May2020Whisnu BhuntoroОценок пока нет

- DS Limitor P Back Up Fuse Links Without Controlled Power Dissipation enДокумент14 страницDS Limitor P Back Up Fuse Links Without Controlled Power Dissipation enAnonymous cNyCZ75Оценок пока нет

- Certification of eVTOL AircraftДокумент19 страницCertification of eVTOL AircraftrlwersalОценок пока нет

- Velocity Analysis-Instantaneous Center MДокумент7 страницVelocity Analysis-Instantaneous Center MSuman_SamadderОценок пока нет

- Low Delay Based QSD MultiplierДокумент6 страницLow Delay Based QSD MultiplierInternational Journal of Innovative Science and Research Technology100% (2)

- Oracle Ebs InstallationДокумент22 страницыOracle Ebs InstallationMr. JalilОценок пока нет

- Windy Hill Middle School - Trumpet Warm Up BookДокумент61 страницаWindy Hill Middle School - Trumpet Warm Up BookGleyce VieiraОценок пока нет

- B.S. in Electronics Engineering - BSECE 2008 - 2009Документ2 страницыB.S. in Electronics Engineering - BSECE 2008 - 2009Vallar RussОценок пока нет

- Using Synonyms As Context CluesДокумент11 страницUsing Synonyms As Context Cluesapi-405390959Оценок пока нет

- Cytomat Software InformationДокумент34 страницыCytomat Software InformationCarlosReisОценок пока нет

- Certification Authorities Software Team (CAST) Position Paper CAST-30Документ12 страницCertification Authorities Software Team (CAST) Position Paper CAST-30Adeen KhanОценок пока нет

- B.pharmacy Project SD of GlimepirideДокумент12 страницB.pharmacy Project SD of Glimepiridemanvitha varmaОценок пока нет

- Stability and Stable Production Limit of An Oil WellДокумент15 страницStability and Stable Production Limit of An Oil WellNwakile ChukwuebukaОценок пока нет

- DTP German Volume Training StyleДокумент37 страницDTP German Volume Training StyleRyan Pan100% (1)

- CAT 2020 QUANT Previous Year QuestionsДокумент49 страницCAT 2020 QUANT Previous Year QuestionsApoorva SharmaОценок пока нет

- Eddy AxialДокумент20 страницEddy Axialandrea19711971Оценок пока нет

- Boiler Efficiency PresentationДокумент13 страницBoiler Efficiency PresentationAhmad Sabree Abdul BasitОценок пока нет

- 9011 VW Rebar Strainmeter (E)Документ2 страницы9011 VW Rebar Strainmeter (E)JasonОценок пока нет

- Transition Elements Final 1Документ44 страницыTransition Elements Final 1Venkatesh MishraОценок пока нет

- Fatique Lecture NotesДокумент41 страницаFatique Lecture NotesMarcel SilvaОценок пока нет

- UNIT - 3: Fast-Fourier-Transform (FFT) Algorithms: Dr. Manjunatha. PДокумент100 страницUNIT - 3: Fast-Fourier-Transform (FFT) Algorithms: Dr. Manjunatha. PMVRajeshMaliyeckalОценок пока нет

- Bombardier Global 7500 Pilots AcronymsДокумент18 страницBombardier Global 7500 Pilots AcronymsGourav DasОценок пока нет

- BDU Konfrans 2022 Tezis JurnaliДокумент395 страницBDU Konfrans 2022 Tezis JurnalinarminpashabayliОценок пока нет

- C Programming Board Solve PDFДокумент12 страницC Programming Board Solve PDFEstiak Hossain ShaikatОценок пока нет

- Flight Inspection of GAST D Approach and Taxi Guidance Systems - v1Документ10 страницFlight Inspection of GAST D Approach and Taxi Guidance Systems - v1Olivier LaylyОценок пока нет

- Pokropivny 2007Документ4 страницыPokropivny 2007vasanthanilОценок пока нет

- Engine Overhaul : Group 11BДокумент80 страницEngine Overhaul : Group 11BДмитрий100% (1)

- What Is Host Program? How To Create Host Program? and What Is .Prog File?Документ5 страницWhat Is Host Program? How To Create Host Program? and What Is .Prog File?redroОценок пока нет

- Cad and Dog 2Документ5 страницCad and Dog 2Muhammad RifaiОценок пока нет

- Working With Files and Directories: Chapter 11Документ62 страницыWorking With Files and Directories: Chapter 11Abdelahad SatourОценок пока нет

- TUNAY Manuscript PrefinalДокумент94 страницыTUNAY Manuscript PrefinalC100% (1)

- Excel FunctionsДокумент13 страницExcel Functionsfhlim2069Оценок пока нет