Академический Документы

Профессиональный Документы

Культура Документы

Stopaq Wrappingband Ez

Загружено:

Anisa RifqiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Stopaq Wrappingband Ez

Загружено:

Anisa RifqiАвторское право:

Доступные форматы

PRODUCT DATA SHEET

Version: June 2008

(concept)

STOPAQ Wrappingband EZ

Product Properties_STOPAQ CZH Paste

Product Information

Colour Greyish outerlayer

Generic type: STOPAQ Wrappingband EZ is a unique,

cost-effective product intended for a wide range of Specific el. resistivity >1012 ohm.cm

structural applications, where water ingress is a problem. Odor None

STOPAQ Wrappingband EZ is easy to install offering Shelf Life Unlimited

excellent sealing properties. This material is strengthened Max. Operating 70C

by a fiber mesh that is imbedded in the middle of the temp.

material and has a greyish polyester non-woven fiber top Min. Operating temp -45C

layer that allows for the immediate UV-resistant painting Adhesion to wet none

or coating after installation. STOPAQ Wrappingband EZ surfaces

adheres immediately to steel, PE, PP, epoxy, Water intake 0%

polyurethane, PVC, etc. without roughening the surface. Density 1,4 - 1,6g/cm (NEN 1833)

The material does not cure and can be cold-applied. Minimum application +5C

temperature

Product description: STOPAQ Wrappingband EZ is

engineered for use in many sealing applications against

the ingress of water, offering a long-term performance in

commercial, residential, telecommunications, utilities, General order information

transportation, electrical, water, wastewater, agricultural,

Product STOPAQ Wrappingband EZ is available in

and industrial as well as others. STOPAQ Wrappingband

different size ranging from 100mm,

EZ is also used in conjunction with other STOPAQ

200mm,300mm width x 10 meter length.

Products such as STOPAQ FN 4200 and STOPAQ CZH

Paste for sealing purposes of tankbottoms.

Packaging In boxes. 6 rolls per box of size

The STOPAQ Wrappingband EZ can be painted with a 2- 100mmx10m. 2 rolls per box of size

component polysiloxane coating such as Carboxane 2000 200mmx10m and 300mmx10m

or a 1-component such as Noxyde/Peganox. Handling Handle with care. Keep the boxes upright.

Features:

Controlled cold flow providing permanent inflow Storage Indoor, clean and dry. No shelf-life.

into the finest pores of the substrate

Temperature resistance up to +70C.

Conforms to any shape

Low surface tension; adheres on all dry substrates

at a molecular level

Surface tolerant: no grit-blasting, only wire

brushing or hand tool cleaning required

Constant film thickness

Non-crystalline

Chemically stable

Inert and amorphous

Benefits:

Harmless to environment and workers

Easy to apply and paint

Can be modelled onto all irregular shaped

objects

No osmosis or under creep possible

Guaranteed performance

Application examples

The primary applications are sealing around rooftop

vents, pipes, metal roof seams, flashings, residential and

commercial roofing, EPM roofing, and cable entries, holes

and voids, cracks, storage tanks roofs, industrial pools,

swimming pools, manholes, basements, floors, cable

joints and repairs, and etc.

PRODUCT DATA SHEET | STOPAQ WRAPPINGBAND EZ

Application instruction_Preparation Application instruction_Final steps

Application 1. Temperature probe, Dew point meter Visual The applied STOPAQ Wrappingband EZ must

equipment and 20 kV holiday tester.) inspection look smooth and tight.

2. Scissors, Putty knife.

3. Abrading pads and Wire brushes. Holiday Immediately after application of the Paste, a

4. Safety goggles, Hard hat & Gloves. detection for holiday testing should be carried out with a

steel surfaces High Voltage test unit (15 - 25 kV). Test with

High humidity STOPAQ Wrappingband EZ can be

minimum 15 kV. A brush probe is

applied in a humid atmosphere that does

recommended. No further testing is required.

not reach the dew point.

Application instruction_Mechanical protection

Work area and The work area and substrate should be Mechanical/UV The applied STOPAQ Wrappingband EZ

substrate protected against negative weather Protection starting should be protected against outside

influences. influences by a 2-component or 1-component

STOPAQ The Wrappingband EZ should be dry and liquid paint such Carboxane 2000 or

conditions have a temperature, (min. +5C) for the Noxyde/Peganox.

ease of shaping.

Application instruction_Surface Preparation Bringing into service

General The areas to be coated have to be clean, Handling Areas coated with STOPAQ should not be

dry, and free from grease and dust. All exposed to loads from supports or lifting

contamination has to be removed. equipment.

Degreasing Degrease surfaces with isopropanol. Inspection Peel away from the sides to see if full

Salts and No need for additional cleaning adhesion has occurred (after 1 hour). If not

Bacteria full adhesion has occurred, press down with a

Condensation - Prior to - and during the application, the seam roller and/or heat the area with a hot

water substrate(s) must be at least 3C above air blower or heat gun

the dew point STOPAQ Information

Steel Surface preparation minimal St 2/3 Documentation Extensive information is available on our web-

according to ISO 8501-3. site. Detailed application instructions,

Other De-gloss and de-grease the surface by STOPAQ Technical Standard can be

substrates using an abrasive pad and isopropanol. acquired from our head office or local

distributor; info@stopaq.com

Certified staff The application of STOPAQ coating Systems

should always be carried out by certified

personnel.

STOPAQ Extensive laboratory tests and more than 10

Final control Substrates prepared for coating, should Performance years of service in extreme wet and chemical

be clean, dry and free of loose aggressive environments have proven that

rust/coating and dust according to dust Corrosion, Bacterial Growth or Stress

ISO 8502-3 grade 3. Corrosion Cracking cannot develop on

substrates, coated with STOPAQ.

Application instruction _ Application

Release foil Peel off the clear release foil from the roll

of the STOPAQ WRAPPINGBAND EZ and

align the product on the area you are

applying it to.

Seam roller Use a steel roller to apply, press the

product to the surface.

Cold weather Preheat the surface with for instance a

hot air gun. When not allowed, preheat

the rolls by carrying them inside the

cabin of the car.

STOPAQ Europe B.V.

Headquarter

Gasselterstraat 20

9503 JB Stadskanaal

The Netherlands

[T] +31 (0)599 696170

[F] +31 (0)599 696177

www.stopaq.com

DISCLAIMER: To the best of our knowledge, the technical data contained herein is true and accurate on the date of publication and is subject to

change without prior notice. User must contact STOPAQ Europe B.V. to verify correctness before specifying and ordering. No guarantee of accuracy

is given or implied. We assume no responsibility for coverage, performance or injuries resulting from use Liability, if any, is replacement of products.

No other warranty or guarantee of any kind is made by STOPAQ Europe, express or implied, statutory, by operation of law, or otherwise, including

merchantability and fitness for a particular purpose.

STOPAQ is a registered trademark of STOPAQ Europe B.V.

2/2

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- UditchhДокумент14 страницUditchhAnisa RifqiОценок пока нет

- Tank Lifting And: Seminar ManualДокумент69 страницTank Lifting And: Seminar Manualkirans60100% (5)

- Report LanYardДокумент9 страницReport LanYardAnisa RifqiОценок пока нет

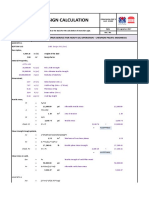

- Cal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Документ4 страницыCal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Anisa RifqiОценок пока нет

- Cal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Документ5 страницCal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Anisa Rifqi0% (1)

- Structural Simulation Erected Storage Tank With Jacking SystemДокумент6 страницStructural Simulation Erected Storage Tank With Jacking SystemAnisa RifqiОценок пока нет

- Storage Tank T - 303 - Duri HCT - Slo South (Bki-ti-17-Hct Duri-Hct-Ipm-T303-180)Документ177 страницStorage Tank T - 303 - Duri HCT - Slo South (Bki-ti-17-Hct Duri-Hct-Ipm-T303-180)Anisa Rifqi100% (3)

- Operating PracticesДокумент97 страницOperating PracticesAnisa RifqiОценок пока нет

- Support Jack Up (A)Документ1 страницаSupport Jack Up (A)Anisa RifqiОценок пока нет

- WireCoHandbook - Form 1001M-Low ResДокумент40 страницWireCoHandbook - Form 1001M-Low ResAnisa RifqiОценок пока нет

- Staad 4Документ37 страницStaad 4saisssms9116100% (2)

- Bunding of Storage Tanks and Transfer FacilitiesДокумент4 страницыBunding of Storage Tanks and Transfer FacilitiesAjiri IvoviОценок пока нет

- Process Industry PracticesДокумент1 страницаProcess Industry PracticesAnisa RifqiОценок пока нет

- P-313-R-001-001-C Tower Test Programme 500kV 4AA+0 REV C PDFДокумент102 страницыP-313-R-001-001-C Tower Test Programme 500kV 4AA+0 REV C PDFAnisa Rifqi0% (1)

- Engrowth Expansion Calculation PagesДокумент224 страницыEngrowth Expansion Calculation Pagesali96161Оценок пока нет

- Structural Steel ErectionДокумент8 страницStructural Steel Erectionbratishkaity100% (1)

- Staad Pro V8i Manual 2016Документ775 страницStaad Pro V8i Manual 2016Larry89% (9)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Limitations and Quality Upgrading Techniques For Utilization of MSW Incineration Bottom Ash in Engineering Applications - A ReviewДокумент12 страницLimitations and Quality Upgrading Techniques For Utilization of MSW Incineration Bottom Ash in Engineering Applications - A Reviewvitor_alberto_7Оценок пока нет

- Prism Cryogenic Oxygen Generators: Reliable On-Site SupplyДокумент4 страницыPrism Cryogenic Oxygen Generators: Reliable On-Site SupplyEdwin RosasОценок пока нет

- Kouga MaintainanceДокумент28 страницKouga MaintainancematshonaОценок пока нет

- SE45 46 Surge Arr DigitalДокумент6 страницSE45 46 Surge Arr DigitalSpecForceОценок пока нет

- Optimal Bracing System For Steel TowersДокумент4 страницыOptimal Bracing System For Steel TowersSaravanan Silamban100% (1)

- TDS - 4S Service ManualДокумент271 страницаTDS - 4S Service ManualLeonardo Alvarez100% (4)

- Shaping Processes For PlasticsДокумент92 страницыShaping Processes For PlasticsmindmaczaОценок пока нет

- Ador BookletДокумент22 страницыAdor Bookletgssrraju0% (1)

- Datasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFДокумент4 страницыDatasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFYogesh GawadeОценок пока нет

- 10 Important Questions and Answers About Temperature Sensing Using Thermocouple SensorsДокумент3 страницы10 Important Questions and Answers About Temperature Sensing Using Thermocouple SensorsVignesh RajanОценок пока нет

- Aade 10 DF Ho 26Документ9 страницAade 10 DF Ho 26Trần Anh ĐứcОценок пока нет

- MasterSeal Traffic 1330Документ3 страницыMasterSeal Traffic 1330Jonathan Wardrop100% (1)

- Ente 201800628Документ36 страницEnte 201800628ragulaceОценок пока нет

- Ign-4-32-18c - HDPE Pipes - SDR PNДокумент17 страницIgn-4-32-18c - HDPE Pipes - SDR PNgeofoun100% (2)

- GPA Sampling Method (Scope, Definition, Principles, Safety)Документ27 страницGPA Sampling Method (Scope, Definition, Principles, Safety)Candra Aditya Wiguna100% (2)

- GAS - by BASF - 1 PDFДокумент12 страницGAS - by BASF - 1 PDFD K SОценок пока нет

- CALOR EMAG Bag.1 PDFДокумент10 страницCALOR EMAG Bag.1 PDFAditya AgasiОценок пока нет

- Notes On Sprockets and ChainsДокумент6 страницNotes On Sprockets and Chainsjjoohhnn90Оценок пока нет

- Esab 6013 PDFДокумент1 страницаEsab 6013 PDFBijaya RaulaОценок пока нет

- Aws - The Practical Welding Engineer PDFДокумент154 страницыAws - The Practical Welding Engineer PDFSEGO4EVER100% (5)

- DB'S Calculation: Energy Conservation-Special Notes GeneralДокумент1 страницаDB'S Calculation: Energy Conservation-Special Notes GeneralAbid AyubОценок пока нет

- Dahu 1 PDFДокумент2 страницыDahu 1 PDFdwi wahyu sugiartoОценок пока нет

- A New Model in The Medical Waste ManagementДокумент23 страницыA New Model in The Medical Waste ManagementKâmil VARINCAОценок пока нет

- Manual RM648-848 Enatelv1.2Документ13 страницManual RM648-848 Enatelv1.2TRỊNH VĂN THIỆN100% (1)

- Robertson #3 Liq 2021 LiqДокумент27 страницRobertson #3 Liq 2021 LiqRenathielly Fernanda da SilvaОценок пока нет

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelДокумент20 страницUniversity of Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456Оценок пока нет

- CentraCore PDFДокумент2 страницыCentraCore PDFsathya2040Оценок пока нет

- Easypure Ii Reservoir Feed Water Purification System: Operating Manual and Parts List Lt1305X1 Rev. 0Документ42 страницыEasypure Ii Reservoir Feed Water Purification System: Operating Manual and Parts List Lt1305X1 Rev. 0Anonymous 7qn4qmОценок пока нет

- Hydro Test ProcedureДокумент17 страницHydro Test Procedureyaser elgoharyОценок пока нет

- 05892E02Документ39 страниц05892E02adelОценок пока нет