Академический Документы

Профессиональный Документы

Культура Документы

VC-6000 Product Sheet BPT0002-En

Загружено:

Andy Kong KingИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

VC-6000 Product Sheet BPT0002-En

Загружено:

Andy Kong KingАвторское право:

Доступные форматы

Product Sheet

VIBROCONTROL 6000TM – Safety Monitoring System

Introduction & Benefits

Modern process industries employ expensive, complex, high-speed machinery. In an effort to maximise plant

efficiency and production throughput while maintaining long-term machine availability and reliability, it is vital

that the plant is protected against unexpected loss of production through unscheduled stoppages and the

machines are protected against expensive damage. VIBROCONTROL 6000 is the new benchmark safety

monitoring system that meets the criteria of reliability, sensitivity, accuracy and speed of reaction to sudden

changes in machine condition.

Compactness

VIBROCONTROL 6000 extreme

compactness is unsurpassed.

With just one 19” 3HE module

housing, up to 48 channels (with

an external power supply), or 36

channels (with a built-in power

supply) of continuous safety

monitoring are available!

Therefore three separate

machines, each with 16 or 12

channels, can be monitored using

one 3HE 19” module housing.

This allows utilisation of existing

cabinet space, or smaller new

cabinets, even for large, multi-rack

monitoring systems, thus saving

costs and space. Centralised

cabling and lower installation

costs save even further.

Versatility Speed Application-specific

VIBROCONTROL 6000 monitors With a minimum measurement, The application-specific module

almost any parameter with relay output and DC output concept simplifies the system

variations of just one module type, response time of 10 ms. as scalability, fits exactly the actual

which can be supplied as standard, VIBROCONTROL 6000 need or size of the monitoring

transmitters, i.e. with only DC provides a fast reaction to sudden system installation, reduces the

outputs, or with full alarm relays changes, guaranteeing maximum complexity of the hardware and

and DC outputs or with ModBus protection for vital machinery, firmware selection process and

communication through a CI- without requiring special modules provides a ready-to-use system

module change. that consume valuable rack requiring minimal on-site

space. configuration by the end-user.

Technical Information – VIBROCONTROL 6000 Safety Monitoring System

Application-specific are configured for a specific and data into the system for

Module Concept machine monitoring application. direct trending or calculating

new values for trending.

The standard safety monitoring A virtual data acquisition

TM

modules (SM) in VC 6000 module brings imported values

Symbol Measurement Description Explanation

smax peak, peak-peak Orbit radius or diameter

Relative shaft vibration Max. (x/y) Max. displacement in x/y directions

Vectors Magnitude & phase of harmonics

Velocity sensors With f0 = 8 or 15 Hz

Casing vibration Acceleration sensors Constant voltage or current type

No. of sensors/channels Rotor axial displacement

Axial position 2oo2 voting 2 out of 2 voting on axial position

2oo3 voting 2 out of 3 voting on axial position

Absolute speed Absolute or over-speed monitoring

Speed Speed change Speed variation in rpm/sec

Zero speed For activation of barring gear

Rod-drop No. of sensors/channels Monitoring of piston ring wear

Eccentricity No. of sensors/channels Monitoring of rotor bend

Monitoring of rotor expansion relative

Relative expansion No. of sensors/channels to stator expansion

Monitoring of temperature, pressure

Process value No. of process value inputs

and other process variables,

Controlled input signal for automatic

Binary No. of Trip-multiplier inputs activation of trip-multiplier during run-

up/coast-down

Alert & Danger alarm relay output

Alert & Danger relay Total no. of monitoring relay pairs

activation

Analogue DC voltage or current

DC output No. of DC-out channels output signals proportional to

measured value

Brüel & Kjær Vibro reserves the right to change specifications without notice.

Brüel & Kjær Vibro A/S Brüel & Kjær Vibro GmbH

2850 Nærum – Denmark 64293 Darmstadt – Germany

Tel.: +45 4580 0500 Tel.: +49 (0) 6151 428 1100

Fax: +45 4580 2937 Fax: +49 (0) 6151 428 1200

E-mail: info@bkvibro.com E-mail: info@bkvibro.de

www.bkvibro.com BPT0002-EN-11

Вам также может понравиться

- 7KT1681 Datasheet enДокумент5 страниц7KT1681 Datasheet enRodrigo VerniniОценок пока нет

- Instruction CV11016en MetrДокумент28 страницInstruction CV11016en MetrabdОценок пока нет

- Jaquet T400: Speed Measurement, Switching and Indicating InstrumentsДокумент4 страницыJaquet T400: Speed Measurement, Switching and Indicating InstrumentsPavel MelnikovОценок пока нет

- Produktkatalog 2017 enДокумент40 страницProduktkatalog 2017 enEectricals DepartmentОценок пока нет

- ARAD Octave Data Sheet Rel 4.02 2019Документ6 страницARAD Octave Data Sheet Rel 4.02 2019Sk RegОценок пока нет

- MA OPTISONIC6300-V2 en 220406 4006193903 R03Документ21 страницаMA OPTISONIC6300-V2 en 220406 4006193903 R03khanhptscОценок пока нет

- HAVBA4T0022GДокумент2 страницыHAVBA4T0022GzibrahimiОценок пока нет

- 7KM21120BA003AA0 Datasheet enДокумент6 страниц7KM21120BA003AA0 Datasheet enАндреи ПрокаОценок пока нет

- 7KT1670 Datasheet enДокумент4 страницы7KT1670 Datasheet enDaniel SchallerОценок пока нет

- HAVSP4T1600PДокумент2 страницыHAVSP4T1600PNISHANОценок пока нет

- DPM Series BrochureДокумент7 страницDPM Series BrochureGeeganage Thushan DhammikaОценок пока нет

- 7KM32201BA011EA0Документ6 страниц7KM32201BA011EA0Alejandro MagneОценок пока нет

- LXM28AU45M3X: Product Data SheetДокумент4 страницыLXM28AU45M3X: Product Data SheetKurdi Stan00Оценок пока нет

- HAVSP4T0040PДокумент2 страницыHAVSP4T0040PNOUASS NOUASSAОценок пока нет

- El Ofmld90 en PDFДокумент8 страницEl Ofmld90 en PDFمحمد المسعوديОценок пока нет

- Jenaer Ecostep-100 DatasheetДокумент6 страницJenaer Ecostep-100 DatasheetAdrien VAIDIEОценок пока нет

- Catalog SB200Документ19 страницCatalog SB200Song NguyễnОценок пока нет

- Brochure VC-6000 CM Engl.Документ8 страницBrochure VC-6000 CM Engl.Amith MenonОценок пока нет

- VMS500 HardwareДокумент2 страницыVMS500 HardwareJagan TnОценок пока нет

- 7KM32000CA011AA0 Datasheet enДокумент6 страниц7KM32000CA011AA0 Datasheet enŁukasz KrzesińskiОценок пока нет

- Siemens G120Документ26 страницSiemens G120ramprakashpatelОценок пока нет

- 7KM10200BA011DA0 Datasheet enДокумент6 страниц7KM10200BA011DA0 Datasheet enmarquesrafaelОценок пока нет

- Brochure Dew Point Sensors - ENДокумент12 страницBrochure Dew Point Sensors - ENosmanyildirim85Оценок пока нет

- Sentry AeДокумент4 страницыSentry AeVictor NoschangОценок пока нет

- HAVSO4T0022GДокумент2 страницыHAVSO4T0022GNISHANОценок пока нет

- 7KM54126BA001EA2 Datasheet enДокумент6 страниц7KM54126BA001EA2 Datasheet enPen TranОценок пока нет

- Coniq Condition Monitoring For Screens, Feeders and Their ExcitersДокумент4 страницыConiq Condition Monitoring For Screens, Feeders and Their ExcitersHpnoteОценок пока нет

- VC1500Документ4 страницыVC1500Antonius DickyОценок пока нет

- Handy Calibrator: Multi-Functional Hand-Held CalibratorДокумент4 страницыHandy Calibrator: Multi-Functional Hand-Held CalibratorAbdu RahmanОценок пока нет

- 7KM31201BA011EA0 Datasheet enДокумент6 страниц7KM31201BA011EA0 Datasheet enMuhammad Akmal RafiqueОценок пока нет

- 7KM31200BA011DA0 Datasheet enДокумент7 страниц7KM31200BA011DA0 Datasheet enMNSanthoshKumarRajuОценок пока нет

- Rosemount 144-PCДокумент8 страницRosemount 144-PCAnonymous YSA8CZ0Tz5Оценок пока нет

- Convertidor CoriolisДокумент20 страницConvertidor CoriolisAlan MedОценок пока нет

- 7KM21120BA003AA0Документ8 страниц7KM21120BA003AA0jaydeeppanchalОценок пока нет

- PT PID+Fuzzy Temperature Controller - B0Документ17 страницPT PID+Fuzzy Temperature Controller - B0Johnny Liu JohnnyОценок пока нет

- Bently 3300 - 55 ManualДокумент6 страницBently 3300 - 55 Manualwagner machado de moraesОценок пока нет

- 6300 SP OverviewSpecsДокумент8 страниц6300 SP OverviewSpecsRicardas KragnysОценок пока нет

- 7KM211 SheetДокумент7 страниц7KM211 SheetsuadОценок пока нет

- Brochure VPFlowScope In-Line - ENДокумент8 страницBrochure VPFlowScope In-Line - ENCARLOS CHAVEZОценок пока нет

- Solid State SensorsДокумент39 страницSolid State SensorsRona Mae Raza RecaldeОценок пока нет

- 7KM31200BA011DA0 Datasheet en PDFДокумент8 страниц7KM31200BA011DA0 Datasheet en PDFPeter UhuleОценок пока нет

- 7KM21120BA003AA0 Datasheet enДокумент8 страниц7KM21120BA003AA0 Datasheet enDavidMarianОценок пока нет

- WNTC Manual CompletoДокумент114 страницWNTC Manual CompletoDanilo ReisОценок пока нет

- HAVSO4T0040GДокумент2 страницыHAVSO4T0040GNISHANОценок пока нет

- TEKTRONIX THS3024 DatasheetДокумент13 страницTEKTRONIX THS3024 Datasheetarness22Оценок пока нет

- Data Sheet 7KM2112-0BA00-3AA0: ModelДокумент8 страницData Sheet 7KM2112-0BA00-3AA0: ModelClaudiu VlasceanuОценок пока нет

- Protective Relays Guide SCHNEIDER-1Документ56 страницProtective Relays Guide SCHNEIDER-1WONDIMUОценок пока нет

- Torsional Vibration Measurement: With OROS Teamwork AnalyzersДокумент4 страницыTorsional Vibration Measurement: With OROS Teamwork AnalyzersОлег ЗахарийОценок пока нет

- HAVSO4T0015GДокумент2 страницыHAVSO4T0015GNISHANОценок пока нет

- 7KG96611FA301AA0 Datasheet enДокумент2 страницы7KG96611FA301AA0 Datasheet enccuevasarenasОценок пока нет

- Ref 542 LeafletДокумент4 страницыRef 542 Leafletmukesh_kht1Оценок пока нет

- Specification MPU600-Series-B ssks003Документ6 страницSpecification MPU600-Series-B ssks003montanovillarroelfabiolalourdeОценок пока нет

- Bosch Ic cg902 903 904Документ8 страницBosch Ic cg902 903 904SaadОценок пока нет

- Vipam 3000Документ24 страницыVipam 3000edgarcoo100% (1)

- 7KM32201BA011EA0 Datasheet enДокумент6 страниц7KM32201BA011EA0 Datasheet enVinicius NadalОценок пока нет

- KISTLER 4502a - EnglishДокумент8 страницKISTLER 4502a - EnglishDexter PoliОценок пока нет

- HAVSO4T0007GДокумент2 страницыHAVSO4T0007GNISHANОценок пока нет

- Psr-Pc51-1no-1nc-24dc-Sc - 2702522Документ6 страницPsr-Pc51-1no-1nc-24dc-Sc - 2702522Andy Kong KingОценок пока нет

- Quint4 5VDCДокумент12 страницQuint4 5VDCAndy Kong KingОценок пока нет

- Emhub Kota Damansara Sharing 23.02.23Документ14 страницEmhub Kota Damansara Sharing 23.02.23Andy Kong KingОценок пока нет

- KT EVS Data Sheet EДокумент1 страницаKT EVS Data Sheet EAndy Kong KingОценок пока нет

- HOERBIGER Explosion Relief Valves: Reliable Protection Against The Effects of Dust ExplosionsДокумент4 страницыHOERBIGER Explosion Relief Valves: Reliable Protection Against The Effects of Dust ExplosionsAndy Kong KingОценок пока нет

- Phoenix Contact Termination CarrierДокумент8 страницPhoenix Contact Termination CarrierAndy Kong KingОценок пока нет

- 8265 EmptyEnclosures EK00 III enДокумент7 страниц8265 EmptyEnclosures EK00 III enAndy Kong KingОценок пока нет

- Module Carrier - TC-XC96-DI32-EX2-PR-HIMAX01 - 2908750: Key Commercial DataДокумент2 страницыModule Carrier - TC-XC96-DI32-EX2-PR-HIMAX01 - 2908750: Key Commercial DataAndy Kong KingОценок пока нет

- Data Declaration: Safety-Related Systems. The Hardware Has Been Subjected To A Failure Modes and Effects AnalysisДокумент2 страницыData Declaration: Safety-Related Systems. The Hardware Has Been Subjected To A Failure Modes and Effects AnalysisAndy Kong KingОценок пока нет

- MTL4521 L 5521Документ1 страницаMTL4521 L 5521Andy Kong KingОценок пока нет

- Temperature Converter: Voltage MV/TC Type B Cold Junction Compensation CJC +Документ3 страницыTemperature Converter: Voltage MV/TC Type B Cold Junction Compensation CJC +Andy Kong KingОценок пока нет

- Data Declaration: Safety Systems. The Hardware Has Been Subjected To A Failure Modes and Effects Analysis (FMEA)Документ2 страницыData Declaration: Safety Systems. The Hardware Has Been Subjected To A Failure Modes and Effects Analysis (FMEA)Andy Kong KingОценок пока нет

- Module Carrier - TC-XC96-AI32-EX2-PRS-HIMAX01 - 2908732: Key Commercial DataДокумент7 страницModule Carrier - TC-XC96-AI32-EX2-PRS-HIMAX01 - 2908732: Key Commercial DataAndy Kong KingОценок пока нет

- SMART Transmitter Power Supply: Input Ch.1 Eex Ia Iic Input Ch.2 Eex Ia IicДокумент4 страницыSMART Transmitter Power Supply: Input Ch.1 Eex Ia Iic Input Ch.2 Eex Ia IicAndy Kong KingОценок пока нет

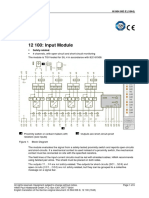

- 12 100: Input ModuleДокумент6 страниц12 100: Input ModuleAndy Kong KingОценок пока нет

- 2-Fold Input Module 13 110 (Ex) I, Safety-RelatedДокумент8 страниц2-Fold Input Module 13 110 (Ex) I, Safety-RelatedAndy Kong KingОценок пока нет

- System 1: Optimization and Diagnostics SoftwareДокумент14 страницSystem 1: Optimization and Diagnostics SoftwareAndy Kong KingОценок пока нет

- Quint 10a ExДокумент15 страницQuint 10a ExAndy Kong KingОценок пока нет

- Nibococ PDFДокумент16 страницNibococ PDFAndy Kong KingОценок пока нет

- CRR 02428Документ74 страницыCRR 02428kglorstadОценок пока нет

- Operating and Installation Manual Flow Transmitter SE56 Basic VersionДокумент96 страницOperating and Installation Manual Flow Transmitter SE56 Basic VersionCampos LucasОценок пока нет

- 8-Zone Telephone Alarm System: User's ManualДокумент30 страниц8-Zone Telephone Alarm System: User's ManualNgoc TuanОценок пока нет

- Multical MC 66C Technical Description 5511-634 GB Rev C1Документ62 страницыMultical MC 66C Technical Description 5511-634 GB Rev C1StefanОценок пока нет

- SADPmini2 Portable Dewpoint Meter DatasheetДокумент3 страницыSADPmini2 Portable Dewpoint Meter Datasheetsreenivas1234Оценок пока нет

- FSC Fassi Stability Con+ PDFДокумент3 страницыFSC Fassi Stability Con+ PDFHong-Nam KimОценок пока нет

- Design, Development and Performance Study of A Polymer Coated Capacitive Sensor For Measuring Moisture Content of SoilДокумент5 страницDesign, Development and Performance Study of A Polymer Coated Capacitive Sensor For Measuring Moisture Content of SoilMeghanaGLОценок пока нет

- Sensor For RobotДокумент4 страницыSensor For RobotMegha OmshreeОценок пока нет

- Trace Dissolved Oxygen Sensor: Model 499A TrdoДокумент4 страницыTrace Dissolved Oxygen Sensor: Model 499A TrdoNIRINTSOA Samoelinica Nanah SidonieОценок пока нет

- Sensors For Handling and Processing TechnologyДокумент180 страницSensors For Handling and Processing TechnologyrezaОценок пока нет

- 17 - Industry 4.0 An Amanofacturing EcosysДокумент28 страниц17 - Industry 4.0 An Amanofacturing Ecosysorlando moraОценок пока нет

- SP-220 Manual TypeFДокумент60 страницSP-220 Manual TypeFpcatruongОценок пока нет

- KNX Home and Building ControlДокумент92 страницыKNX Home and Building ControlMarius37Оценок пока нет

- Sensidyne Sensair-Cmb DatasheetДокумент2 страницыSensidyne Sensair-Cmb DatasheetEmrah MertyürekОценок пока нет

- Temposonics: Magnetostrictive Linear Position SensorsДокумент13 страницTemposonics: Magnetostrictive Linear Position SensorsPreeda SuksathidОценок пока нет

- Motion Detection Using Passive Infrared Sensor - 24 Pages PDFДокумент24 страницыMotion Detection Using Passive Infrared Sensor - 24 Pages PDFStephanie May DancesОценок пока нет

- Arduino Sensor ModulesДокумент7 страницArduino Sensor ModulesterraveracruzОценок пока нет

- C-9104 Conventional Ultraviolet Flame Detector Issue 2.05Документ2 страницыC-9104 Conventional Ultraviolet Flame Detector Issue 2.05Seagull MarineОценок пока нет

- Electronic Heat Cost Allocators WHE46..Документ8 страницElectronic Heat Cost Allocators WHE46..Crni202Оценок пока нет

- Instrumentation FundamentalsДокумент40 страницInstrumentation Fundamentalsarsenic_94Оценок пока нет

- Measurement-Technology-Catalogue ENG WebДокумент44 страницыMeasurement-Technology-Catalogue ENG WebbzivkovicОценок пока нет

- Wearable Biosensors 1222865689459971 8Документ20 страницWearable Biosensors 1222865689459971 8kedarbestОценок пока нет

- City Multi CodesДокумент23 страницыCity Multi CodesNdega Ya ChumaОценок пока нет

- Fan Regulator Using 8051 MicrocontrollerДокумент2 страницыFan Regulator Using 8051 MicrocontrollerSatyam LalaОценок пока нет

- Mitutoyo Rockwell Hardness TesterДокумент16 страницMitutoyo Rockwell Hardness TesterArdian ArdianОценок пока нет

- CondutivimetroДокумент108 страницCondutivimetroTalles CursoОценок пока нет

- Voltage Output Programmable Sensor Conditioner: Features DescriptionДокумент25 страницVoltage Output Programmable Sensor Conditioner: Features DescriptionMilan ĐorđevicОценок пока нет

- SR868C6 Controller Manual PDFДокумент16 страницSR868C6 Controller Manual PDFUltisolar0% (1)

- PVED-CL Controller For Electro-Hydraulic SteeringДокумент128 страницPVED-CL Controller For Electro-Hydraulic SteeringcjalanisОценок пока нет

- Thermator II Multifunktions TemperaturkalibratorДокумент8 страницThermator II Multifunktions TemperaturkalibratorAgus KurniawanОценок пока нет