Академический Документы

Профессиональный Документы

Культура Документы

Pre-Commissioning and Commissioning Manual: Mellitah Oil & Gas BV

Загружено:

ThirukkumaranBalasubramanianОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pre-Commissioning and Commissioning Manual: Mellitah Oil & Gas BV

Загружено:

ThirukkumaranBalasubramanianАвторское право:

Доступные форматы

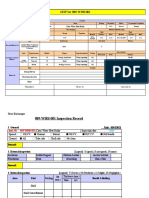

COM. JOB No. COMPANY DOC. No. REV.

Mellitah Oil & Gas BV

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON. JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

DATE 31 July 2010 SHEET 1 OF 13

WAFA GATHERING

PROCEDURE

DISTRIBUTION

COMPANY

MFO-TRIPOLI

MAN FIA

2

GEISENHEIM

MAN

FERROSTAAL

CLIENT 5

Pre-Commissioning and Commissioning Manual

INTERNAL

PM 1

PPM

PEM

PKM

PCM

PQM 1

PHM (Surface Facilities for 3 Infilling Wells at WAFA FIELD)

SM

PSM

ME

DCC 1

MFG

MFS

LE

PROPOSAL

PLANNING

CIVIL

INSTRUMENT

TION

ELECTRICAL

PIPING

PROCESS

CONTROL

SALES

ADMINISTRA

TION

SHIPPING

PLANT SITE 1

REV. DATE PAGE DESCRIPTION PREPD CHKD APPD CLIENT

P1 11.07.09 ALL For Approval E. Espiritu W.Melis Dr. Rodies

Clients Comments Incorporated

OTHERS P2 01.08.09 ALL E. Espiritu W.Melis Dr. Rodies

LT/ON/WIP/FP/109/09

F1 31.07.10 ALL As-Built E. Espiritu W.Melis W.Marschick

MAN FERROSTAAL OIL & GAS LTD.

Mellitah Oil & Gas BV COM. JOB No. COMPANY DOC. No. REV.

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

WAFA GATHERING SHEET 2 OF 13

PROCEDURE

Main Index

Pages

1. FOREWORD.. 3

1.1 Scope

1.2 Disclaimer

2. PURPOSE.. 3

3. DEFINITIONS AND ABBREEVIATION.... 4

3.1 Definitions

3.2 Abbreviations

4. PROCEDURES.... 5

5. SCOPE OF APPLICATION... 5

5.1 Pre-Commissioning Phase

5.2 Commissioning Phase

6. HSE POLICY. 9

7. HSE OBJECTIVES..10

8. REFERENCE DOCUMENTS.. 10

APPENDIX A PRE-COMMISSIONING FLOW DIAGRAM ... 11

APPENDIX B COMMISSIONING FLOW DIAGRAM . 12

MAN FERROSTAAL OIL & GAS LTD.

Mellitah Oil & Gas BV COM. JOB No. COMPANY DOC. No. REV.

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

WAFA GATHERING SHEET 3 OF 13

PROCEDURE

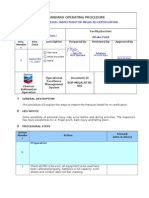

1. FOREWORD

1.1 Scope

This manual describes and contains the procedures, process and equipment for the project

phases required for carrying out mechanical pre-commissioning and commissioning process.

1.2 Disclaimer

This document has been developed to organize the compilation and presentation of QA

documentation for the entire project with a view to achieving mechanical completion.

Also to describe how pre-commissioning and commissioning of satellite station, well site and

equipment is planned and carried out in order to achieve:

Safe operation

No damage performance

Acceptance by the Client

2. PURPOSE

Pre-Commissioning/Commissioning is a comprehensive and systematic process to verify that

the systems perform as designed to meet the project requirements. Commissioning during the

construction and warranty phases is intended to achieve the following specific objectives:

1. Verify and document that equipment is installed and started per manufacturers

recommendations and the technical specification requirements.

2. Verify and document that equipment and systems receive complete operational

checkout by Contractor with the assistance of Companys representatives.

3. Verify and document equipment and system performance to detect trouble in advance

that may occur during normal operation.

4. Verify and mark that all related Documentation are approved without comments.

MAN FERROSTAAL OIL & GAS LTD.

Mellitah Oil & Gas BV COM. JOB No. COMPANY DOC. No. REV.

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

WAFA GATHERING SHEET 4 OF 13

PROCEDURE

3. DEFINITIONS AND ABBREVIATIONS

3.1 Definitions

Within the scope of this document the following definitions shall apply.

Company Mellitah Oil & Gas BV, Libyan Branch

Contractor MAN Ferrostaal Oil & Gas Ltd., Libya

Pre-commissioning - Means all checks, cleaning and testing of satellite station and well

site and its implementation without introducing hydrocarbons or permanently energizing or

pressurizing satellite station and well site equipment and machinery. Pre commissioning

includes all activities implemented between Construction Completion and Ready for

Commissioning.

Commissioning - Means all activities associated with satellite station and well site

preparation or (overall or single sections) Operation prior to initial start-up.

Start-up - Means introduction of feedstock into process satellite station and well site with

the express intention to produce a product for the first time: it can be referred to also as

hydrocarbon in stage. Start-up includes all activities implemented between end of

commissioning and initial operation.

Initial Operation - Means the period after Start-up during which final adjustments to

optimize and troubleshoot the performance of satellite station and well site are made and

Performance test is conducted.

Performance tests - Means all tests carried out on the satellite station and well site (or

part thereof) to verify the capability of the satellite station and well site (or part thereof) to

meet performance guarantees.

3.2 Abbreviations

PM - Project Manager

SM - Site Manager

Constr. - Construction

Mech. - Mechanical

MAN FERROSTAAL OIL & GAS LTD.

Mellitah Oil & Gas BV COM. JOB No. COMPANY DOC. No. REV.

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

WAFA GATHERING SHEET 5 OF 13

PROCEDURE

Inst. - Inspection and Test Plan

QA - Quality Assurance

QM - Quality Management

SAT - Site Acceptance Test

DCC - Document Control Center

4. PROCEDURE

The activities and responsibilities of Pre-Commissioning and Commissioning are describe in

the flow diagrams in Appendix A and Appendix B

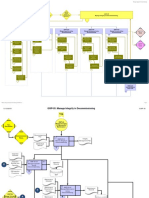

Appendix A Pre-Commissioning Flow Diagram

Appendix B Commissioning Flow Diagram

5. SCOPE OF APPLICATION

5.1 PRE-COMMISSIONING PHASE:

1. Re-tightening of bolts on the flanges and valves.

2. Checking of valves for close-open position:

a. Close the 4dia. Ball Valve on the blow down line (2D-150-100-BD-4-AA730-

Z) and marked with PLEASE DONT OPEN.

b. Close the 3dia. Ball Valve on line 2D-150-3446-CO-3-CA1130-Z and

marked with PLEASE DONT OPEN.

c. Close the 2dia. Ball Valve on line 2D-150-384-CO-2-CA1130-Z and marked

with PLEASE DONT OPEN.

d. Close the 8dia. Ball Valve on line 2D-150-381-CO-8-CA1130-Z and marked

with PLEASE DONT OPEN.

5.2 COMMISSIONING PHASE:

1. Preparation of Arnica 22 oil to be filled up at main tank of W.H.C.P

check for main level of oil at level gauge maximum.

2. Energization of W.H.C.P supply at 400V. Instrument cable signals at 24

VDC. Switch Oil Pump A & B to test to run.

MAN FERROSTAAL OIL & GAS LTD.

Mellitah Oil & Gas BV COM. JOB No. COMPANY DOC. No. REV.

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

WAFA GATHERING SHEET 6 OF 13

PROCEDURE

3. Pressurized V.H.P., H.P., L.P Accumulators at 360, 240, 10 bar

respectively. Adjusting V.H.P. at pressure switch-003 synchronized with

pressure transmitter at 360 bar inside W.H.C.P.

4. Pressurization of:

a. Wing Shutdown Valve

b. Flowline Valve

c. Master Valve SSV

d. Downwell Valve SSSV

e. Fusible Circuits A and Circuit B

Check for local/remote function.

5. Pressurization of Pilot Valves, checked for:

a. Reset Pressure for PSH

b. Reset Pressure for PSL

6. Checking of Emergency Shut Down(ESD)

a. Local Emergency Shutdown at W.H.C.P.

Associated with : SSSV Down Well Valve

SSV - Master Valve

Wing Valve SDV

Flowline Valve SDV

b. Remote Emergency Shutdown Control Room

Associated with : SSSV Downwell Valve

SSV - Master Valve

Wing Valve SDV

Flowline Valve SDV

7. Checking of Process Emergency Shutdown (PSD) at W.H.C.P.

a. Local Process Emergency Shutdown

Associated with : SSV Master Valve

Wing Valve SDV

Flowline Valve SDV

MAN FERROSTAAL OIL & GAS LTD.

Mellitah Oil & Gas BV COM. JOB No. COMPANY DOC. No. REV.

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

WAFA GATHERING SHEET 7 OF 13

PROCEDURE

8. Checking of Fusible Circuit A and Circuit B

a. Local At Well Head Control Panel

Associated with : SSSV Downwell Valve

SSV - Master Valve

Wing Valve SDV

Flowline Valve SDV

b. Remote at Control Building

Associated with : SSSV Downwell Valve

SSV - Master Valve

Wing Valve SDV

Flowline Valve SDV

9. Depressurizing Pilot Valves

a. Local At Well Head Control Panel

b. Remote at Control Building

10. Flowline and Process Instruments should be Loop Checked.

Simulating signals from field to DCS Interface at Control Room.

11. Motorized Valves should be supplied at proper voltage rating.

Functional test for local/remote signal for open/close. Manual hand

wheel for Open/Close should be checked.

12. Pneumatic Shutdown Valve should be checked for Open/Close

associated with Pneumatic Panel. Limit switches should be checked.

13. All hand switches should be function test for local and remote.

14. Energization of UPS shelter as per manufacturers instruction.

Check for:

a. Charging of battery.

b. Interior lighting.

c. Convenience outlet

d. HVAC energization

e. UPS main supply

f. 24VDC supply

MAN FERROSTAAL OIL & GAS LTD.

Mellitah Oil & Gas BV COM. JOB No. COMPANY DOC. No. REV.

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

WAFA GATHERING SHEET 8 OF 13

PROCEDURE

15. Functional Test of SCADA/RTU Panel

a. Internal lighting

b. Inside/Outside Temperature

c. Ventilation

16. Check the Graphical representation of the Wells / Facilities on the operators

Consoles (DCS workstation)

17. Communications link between RTU and Master Station in control building.

18. Illumination of Perimeter Lighting.

MAN FERROSTAAL OIL & GAS LTD.

Mellitah Oil & Gas BV COM. JOB No. COMPANY DOC. No. REV.

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

WAFA GATHERING SHEET 9 OF 13

PROCEDURE

6. QUALITY POLICY

MAN FERROSTAAL OIL & GAS LTD.

Mellitah Oil & Gas BV COM. JOB No. COMPANY DOC. No. REV.

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

WAFA GATHERING SHEET 10 OF 13

PROCEDURE

7. HSE POLICY

During Pre-Commissioning and Commission activities HSE policy should be implemented.

The purpose of HSE policy statement is to state and to communicate the Contractor

Commitment to HSE to all project personnel, Company, sub-contractors and Vendors.

The policy will be distributed to all project personnel, displayed on notice boards at each work

location and copies provided to Company and sub-contractors.

8. HSE OBJECTIVES

Contractor is fully aware that to implement the HSE policy and to realize the above objectives

it is essential to:

Educate and train the personnel in all pre-commissioning and commissioning

activities;

Motivate the personnel to ensure their constant awareness of the objectives;

Provide access to Process Safety Information;

Develop a Plan of Action for implementation of Employee Involvement;

Properly plan and execute the pre-commissioning and commissioning activities;

Consult with employees on the conduct of the Plan of Action.

10. REFERENCE DOCUMENTS

MN-052-P-Q-1023-00 Mechanical Completion and Pre-Commissioning Procedures

MN-052-P-Q-1026-00 Safety Manual

MN-052-P-Q-1003-00 Project Quality Management Plan (PQP)

MN-052-P-Q-1017-00 Punch Listing

MN-052-P-I-1000-00 Instrument Calibration and Loop/Logic Test Procedure

MN-052-P-I-1104-00 RTU SAT Procedure and Specification

MN-052-L-I-1109-00 RTU560 SW Configuration Program List(A34H)(SCADA

Package By ABB)

MN-052-L-I-1110-00 RTU560 SW Configuration Program List(A38)(SCADA

Package By ABB)

MN-052-L-I-1111-00 RTU560 SW Configuration Program List(A45H)(SCADA

Package By ABB)

MFI-M-VA-103 Commissioning

30262-M-VA-512 Engineering Queries

MAN FERROSTAAL OIL & GAS LTD.

Mellitah Oil & Gas BV COM. JOB No. COMPANY DOC. No. REV.

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

WAFA GATHERING SHEET 11 OF 13

PROCEDURE

APPENDIX A

PRE-COMMISSIONING FLOW DIAGRAM

01 Plan is drawn up for pre-commissioning

Activities in all applicable discipline and

Start expediting. This includes schedules for all

Pre-commissioning vendor assisted activities.

02 / 03 / 04

Pre-commissioning starts when a

individual system have been signed

SM 01 off as mechanically complete.

Planning Remaining punch list items are

worked off during this phase unless it

is specifically agreed that they can be

completed later. All ITP items which

are part of the pre-commissioning

phase completed QM dossiers are

signed off by DFE and Company.

DFE Inst. 02 Each system is reported Ready for

Commissioning on receiving the

Loop checks for Company Endorsement on the

Instrumentation completed QM dossier.

05 When all systems have been signed off

with any remaining punch items agreed.

The plant is ready for commissioning.

Vendor Rep. 03

SAT for Vendor

Supplied Systems

DFE Mech.

04

Vendor-assisted

Pre-commissioning

activities

CM

05

Pre-commissioning

Activities are

coordinated to

ensure timely

completion of all

CM

06

The completed

dossiers for all

systems are collated

and added to the

mechanical

catalogue

END

Pre-commissioning

MAN FERROSTAAL OIL & GAS LTD.

Mellitah Oil & Gas BV COM. JOB No. COMPANY DOC. No. REV.

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

WAFA GATHERING SHEET 12 OF 13

PROCEDURE

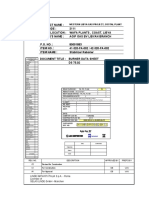

APPENDIX B

COMMISSIONING FLOW DIAGRAM

Start

Commissioning

PM 01 PEM

Allocation of Operating Manual

resources

01 Operating manual includes:

- commissioning procedures

- detailed level 3 planning schedule and

SM 02 personnel resources requirements which have

Start of site activities been integrated by PCM into overall project

safety and HSE schedules and approved by PM and Client as

training of operating appropriate

personnel Plant is ready for commissioning; Mechanical

Completion certificate has been signed. Status

of the plant is contractually defined

SM 03 02 When the plant is ready for commissioning the

Check deliveries of Site Material SM will also be responsible for site

chemicals and other Receiving management.

consumables

03 Chemicals and other consumables will have

been ordered according to the requirements

specified in the operating manual

SM

04

04 Contacts with the Client

Establish measures for

Co-ordinate client supplies and services

co-operation with

Meeting and reports schedule

06 Agreement of commissioning team with punch

SM 05 list produced when plant is ready for

Check pipes, vessels, commissioning

machinery, electrical

equipment &

instrumentation

yes

Significant Engineering Query

deviation

no

LSE

06

Update documentation

to include any minor

differences between

07 Gradual start-up of plant to rated capacity.

SM Tightness inspection

07

Start-up of systems

per operating manual

08 Check list for the commissioning phase will be

project specific according to contract

requirement

SM

08 Input from

Start trial and carry out Engineering Query

activities which could

not be done during

pre-commissioning

Continued on

page 11, step 09

MAN FERROSTAAL OIL & GAS LTD.

Mellitah Oil & Gas BV COM. JOB No. COMPANY DOC. No. REV.

Libyan Branch C/0579/WA/08 MN-052-P-Q-1028-00 F1

CON JOB No. CONTRACTOR DOC. No. REV.

520 08 30375 QM-4-PR-MFO-2028 F1

WAFA GATHERING SHEET 13 OF 13

PROCEDURE

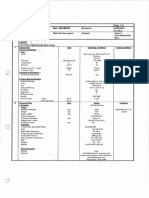

Continued from

page 10, step 08

09 Set optimum process parameters

Record plant parameters

SM 09 Set optimum process parameters

Optimise plant in

preparation for

guarantee runs

PEM

yes

Modifications Input from technical

required query/eng. change

procedure

no

10 Record and confirm data

SM 10 PEM Balancing consumption figures

Carry out performance Output from technical Determine emission date

guarantee runs query/eng. change Compare actual plant data to contractual

procedure requirement

Discuss results with Client

11 Punch list is agreed with Client

SM Solve or clarify with Client

11 Handbook for

Clear punch list performance

Guarantee Test

12 Apply for provisional completion certificate

SM

12

Hand over plant to

Client

End

Commissioning

MAN FERROSTAAL OIL & GAS LTD.

Вам также может понравиться

- ELEFW328 (LE-32GT7-B3) Service Manual For ELEMENT PDFДокумент69 страницELEFW328 (LE-32GT7-B3) Service Manual For ELEMENT PDFdeng jianyu100% (1)

- Learn Machinery Diagnosis with Versatile Fault SimulatorДокумент16 страницLearn Machinery Diagnosis with Versatile Fault SimulatorDrAnkuran Saha0% (1)

- Allbright Industries (M) SDN BHD: Doc No.: RevДокумент10 страницAllbright Industries (M) SDN BHD: Doc No.: RevMaint100% (1)

- Physics XII Concept Maps PDFДокумент15 страницPhysics XII Concept Maps PDFcbsegirlsaipmt100% (1)

- Catalogo PDF TeriosДокумент404 страницыCatalogo PDF TeriosAlvaro Necochea Muñoz71% (7)

- API 580 RBI-Training-Course-SlidesДокумент291 страницаAPI 580 RBI-Training-Course-Slidespotebrayan20Оценок пока нет

- Saep 306Документ15 страницSaep 306nadeem shaikh100% (1)

- MOG-HSEQ-P-005 Rev A3 Corporate HSE Training Awarness and Competence ProcedureДокумент29 страницMOG-HSEQ-P-005 Rev A3 Corporate HSE Training Awarness and Competence ProcedureSamerОценок пока нет

- HOIS (12) R8 RP For Statistical Analysis - FCДокумент244 страницыHOIS (12) R8 RP For Statistical Analysis - FCDevin HardyОценок пока нет

- CP1 B9 Lecture No. 4 - Short Circuit Analysis PDFДокумент195 страницCP1 B9 Lecture No. 4 - Short Circuit Analysis PDFHillОценок пока нет

- Manpower List - Aims HCMLДокумент5 страницManpower List - Aims HCMLJuliyanto STОценок пока нет

- Sandvik QJ330 Electrical Spare PartsДокумент12 страницSandvik QJ330 Electrical Spare PartsEnry Hm100% (2)

- 0 EM Plan A01 1Документ19 страниц0 EM Plan A01 1bilo1984Оценок пока нет

- Visual Inspection WeldДокумент53 страницыVisual Inspection Weldshifa100% (1)

- 88 D 340 nh3 Storage Tank Sept 10 2014 2Документ9 страниц88 D 340 nh3 Storage Tank Sept 10 2014 2mohamed abd eldayemОценок пока нет

- SEIP for Claus Waste Heat Boiler InspectionДокумент6 страницSEIP for Claus Waste Heat Boiler InspectionThinh NguyenОценок пока нет

- Function Test Procedure1Документ6 страницFunction Test Procedure1armin heidari100% (1)

- Inspection OF Fired Heaters: For Restricted CirulationДокумент59 страницInspection OF Fired Heaters: For Restricted Cirulationasif rahim100% (1)

- Mellitah Oil & Gas BV: Libyan BranchДокумент8 страницMellitah Oil & Gas BV: Libyan BranchSamerОценок пока нет

- Guide to Failure Analysis in Oil and Gas IndustryДокумент6 страницGuide to Failure Analysis in Oil and Gas IndustryThirukkumaranBalasubramanian100% (1)

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureДокумент19 страницMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanianОценок пока нет

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureДокумент19 страницMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanianОценок пока нет

- Fitness-for-Service Program Schedule: Thinning and Crack AssessmentsДокумент1 страницаFitness-for-Service Program Schedule: Thinning and Crack Assessmentspeach5Оценок пока нет

- Sop-miqa-Attk-001 - Pressure Vessel Inspection For Migas Re-Certification (2007)Документ10 страницSop-miqa-Attk-001 - Pressure Vessel Inspection For Migas Re-Certification (2007)Iksan Adityo MulyoОценок пока нет

- Profile Engr. Owais Manzoor (Lead Metallurgist) : International AffiliationДокумент6 страницProfile Engr. Owais Manzoor (Lead Metallurgist) : International AffiliationOwais Manzoor MalikОценок пока нет

- GasketsДокумент20 страницGasketsParthiban NagarajanОценок пока нет

- Sample RBI ReportДокумент4 страницыSample RBI ReportSyed Mahmud Habibur RahmanОценок пока нет

- Risk-Based Inspection Analysis WorkbookДокумент11 страницRisk-Based Inspection Analysis Workbookcoolguy12345Оценок пока нет

- HAZOP Study Checklist (26092011) - 6 PDFДокумент1 страницаHAZOP Study Checklist (26092011) - 6 PDFHina ImranОценок пока нет

- Heat Exchangers: Submitted To: Mr. AtifДокумент12 страницHeat Exchangers: Submitted To: Mr. Atifmak412Оценок пока нет

- Manage integrity for decommissioning plansДокумент32 страницыManage integrity for decommissioning plansWekesa CalebОценок пока нет

- Industrial Plant Inspection GuideДокумент5 страницIndustrial Plant Inspection GuideMohamedОценок пока нет

- CUI Risk Factors on Insulated PipingДокумент21 страницаCUI Risk Factors on Insulated PipingRenan Soares KieferОценок пока нет

- Digital Media TextДокумент17 страницDigital Media TextGhemiel Bobiles100% (1)

- MMMZ MZT PDFДокумент14 страницMMMZ MZT PDFMartin MeiОценок пока нет

- Blanking and Blinding PracticeДокумент8 страницBlanking and Blinding PracticeBabyface888100% (1)

- JERES-D-001 Design Criteria For Pressure VesselsДокумент37 страницJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianОценок пока нет

- JERES-D-001 Design Criteria For Pressure VesselsДокумент37 страницJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianОценок пока нет

- Installation PlanДокумент28 страницInstallation PlanThirukkumaranBalasubramanianОценок пока нет

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveОт EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveОценок пока нет

- Foam Hose Reel Testing ProcedureДокумент26 страницFoam Hose Reel Testing ProcedureVijil JohnrajОценок пока нет

- MOG-HSEQ-P-005 Rev A3 Corporate HSE Training Awarness and Competence ProcedureДокумент18 страницMOG-HSEQ-P-005 Rev A3 Corporate HSE Training Awarness and Competence ProcedureSamerОценок пока нет

- Nebosh IGC3 FormatДокумент11 страницNebosh IGC3 FormatAnish Fermin83% (6)

- Methodology Tapping Methodology of WaterlineДокумент15 страницMethodology Tapping Methodology of WaterlineBryОценок пока нет

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldДокумент3 страницыSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadОценок пока нет

- HSE Safety Permit to Work ProcedureДокумент32 страницыHSE Safety Permit to Work Proceduregobi100% (1)

- Written Schemes of Examinations Example Template - Course DownloadДокумент9 страницWritten Schemes of Examinations Example Template - Course Downloadgamil2Оценок пока нет

- ES.0.08.0002 Rev.B - Engineering Data Request Form PDFДокумент1 страницаES.0.08.0002 Rev.B - Engineering Data Request Form PDFSaravanan VaradarajanОценок пока нет

- Wfp291338 For Quality and Quantity Inspection of FoodsДокумент14 страницWfp291338 For Quality and Quantity Inspection of FoodsOzlem MepОценок пока нет

- Example Problem RBI PSV - Rev1Документ17 страницExample Problem RBI PSV - Rev1RizkiОценок пока нет

- RSP - ALL - WI0573 - CC Permit To Work Management - Appendix 01Документ1 страницаRSP - ALL - WI0573 - CC Permit To Work Management - Appendix 01sani priadi100% (1)

- Esab, Ok 309L (29.12.16)Документ1 страницаEsab, Ok 309L (29.12.16)RodrigoОценок пока нет

- Problems Reliability PDFДокумент2 страницыProblems Reliability PDFmanasaavvaruОценок пока нет

- Datasheet Briosil Primer 6-7360P - Eng - 25-08-11Документ3 страницыDatasheet Briosil Primer 6-7360P - Eng - 25-08-11SUBODHОценок пока нет

- Inspection Plan NDTДокумент7 страницInspection Plan NDTEdison WalitОценок пока нет

- Saep 325Документ43 страницыSaep 325AbdullahОценок пока нет

- Shrikant B. Moje CVДокумент6 страницShrikant B. Moje CVPaul PhiliphsОценок пока нет

- Offshore Hydrocarbon Releases Statistics 2002Документ74 страницыOffshore Hydrocarbon Releases Statistics 2002vwagh50% (2)

- Sa 6717Документ1 страницаSa 6717biplabpal2009Оценок пока нет

- PSBR 1 TemplateДокумент2 страницыPSBR 1 TemplatesathishОценок пока нет

- Hydrostatic Test ProcedureДокумент7 страницHydrostatic Test Procedurelaleye_olumideОценок пока нет

- ASME Standards Benefits Case StudyДокумент33 страницыASME Standards Benefits Case StudyssОценок пока нет

- MOG-HSEQ-In-G-051 Rev A3 Corporate HSE Requirements During Yearly Schedualed SHT Dwn.Документ27 страницMOG-HSEQ-In-G-051 Rev A3 Corporate HSE Requirements During Yearly Schedualed SHT Dwn.SamerОценок пока нет

- Topside Inspection Procedure for Pressure VesselДокумент54 страницыTopside Inspection Procedure for Pressure VesselIksan Adityo Mulyo100% (1)

- Astm / Api TablesДокумент126 страницAstm / Api TablesсвакОценок пока нет

- Heat Exchanger Concepts (Att. VIII)Документ28 страницHeat Exchanger Concepts (Att. VIII)Syed M. Imran Ali100% (1)

- Relief Valve Inspection GuideДокумент1 страницаRelief Valve Inspection Guide@@ngОценок пока нет

- Safe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallДокумент1 страницаSafe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallHarun AkkayaОценок пока нет

- Safety Analysis Function Evaluation Chart: TBBM Tanjung Uban ProjectДокумент3 страницыSafety Analysis Function Evaluation Chart: TBBM Tanjung Uban ProjectAriz Joelee ArthaОценок пока нет

- DBBVДокумент29 страницDBBVsanchay2503Оценок пока нет

- Chemical Compatibility Chart Updated 9.23.16Документ1 страницаChemical Compatibility Chart Updated 9.23.16cnotebookОценок пока нет

- Dayang Enterprise Inspection and Test PlanДокумент3 страницыDayang Enterprise Inspection and Test PlanAmyОценок пока нет

- Remaining Life Assessment - PJB Services PDFДокумент1 страницаRemaining Life Assessment - PJB Services PDFbobyОценок пока нет

- Mellitah Oil & Gas BVДокумент12 страницMellitah Oil & Gas BVThirukkumaranBalasubramanianОценок пока нет

- CEIL Engineering FinHR Advt 202324 02Документ6 страницCEIL Engineering FinHR Advt 202324 02ThirukkumaranBalasubramanianОценок пока нет

- Job Description-Mechanical EngineerДокумент1 страницаJob Description-Mechanical EngineerThirukkumaranBalasubramanianОценок пока нет

- Job Description-Process EngineerДокумент1 страницаJob Description-Process EngineerThirukkumaranBalasubramanianОценок пока нет

- Summarized Technical - Information Data'sДокумент1 страницаSummarized Technical - Information Data'sThirukkumaranBalasubramanianОценок пока нет

- D2-001-AM Part 1Документ118 страницD2-001-AM Part 1ThirukkumaranBalasubramanianОценок пока нет

- Job Description-Piping EngineerДокумент1 страницаJob Description-Piping EngineerThirukkumaranBalasubramanianОценок пока нет

- DS 7502Документ4 страницыDS 7502ThirukkumaranBalasubramanianОценок пока нет

- Final Report TOTAL EP MYANMARДокумент24 страницыFinal Report TOTAL EP MYANMARThirukkumaranBalasubramanianОценок пока нет

- Execution of Tie-Ins Without A Plant ShutdownДокумент3 страницыExecution of Tie-Ins Without A Plant ShutdownThirukkumaranBalasubramanianОценок пока нет

- PALL FILTER - Process Data SheetДокумент2 страницыPALL FILTER - Process Data SheetThirukkumaranBalasubramanianОценок пока нет

- INITIAL RISK REVIEW - WAFA Cold CutДокумент6 страницINITIAL RISK REVIEW - WAFA Cold CutThirukkumaranBalasubramanianОценок пока нет

- Mellitah Oil & Gas BV: Welding Procedure Specification For Stainless Steel PipingДокумент9 страницMellitah Oil & Gas BV: Welding Procedure Specification For Stainless Steel PipingThirukkumaranBalasubramanianОценок пока нет

- Non Oily Wastewater To The SeaДокумент1 страницаNon Oily Wastewater To The SeaThirukkumaranBalasubramanianОценок пока нет

- Mellitah Oil & Gas BV: Field Bending OF LinepipeДокумент4 страницыMellitah Oil & Gas BV: Field Bending OF LinepipeThirukkumaranBalasubramanianОценок пока нет

- Cold CuttingДокумент2 страницыCold CuttingThirukkumaranBalasubramanianОценок пока нет

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureДокумент583 страницыMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanian0% (1)

- Reference ListДокумент28 страницReference ListThirukkumaranBalasubramanianОценок пока нет

- PSG 15 Repairs or Modifications Dated 13th Nov 2013 PDFДокумент13 страницPSG 15 Repairs or Modifications Dated 13th Nov 2013 PDFThirukkumaranBalasubramanianОценок пока нет

- Mellitah Oil & Gas BVДокумент12 страницMellitah Oil & Gas BVThirukkumaranBalasubramanianОценок пока нет

- Atlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFДокумент57 страницAtlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFMikku KattaОценок пока нет

- Aspee Hi-Tech: Knapsack SprayerДокумент2 страницыAspee Hi-Tech: Knapsack SprayerThirukkumaranBalasubramanianОценок пока нет

- DataSheet 105723Документ2 страницыDataSheet 105723ThirukkumaranBalasubramanianОценок пока нет

- DataSheet 105723Документ2 страницыDataSheet 105723ThirukkumaranBalasubramanianОценок пока нет

- EDA-31054FFJRA Series Datasheet20120221Документ12 страницEDA-31054FFJRA Series Datasheet20120221M8R-xf9b1g214Оценок пока нет

- Self Dehydrating Manual Type SDBДокумент39 страницSelf Dehydrating Manual Type SDBneoph138Оценок пока нет

- MICROCONTROLLERДокумент26 страницMICROCONTROLLEREnrique “khosrau” AlgunoОценок пока нет

- Improving transient stability using AVR, governor and PSSДокумент8 страницImproving transient stability using AVR, governor and PSSAnas MahmoodОценок пока нет

- PL Hu SL CS SKДокумент137 страницPL Hu SL CS SKNegrutaMiauОценок пока нет

- Embedded Systems LabДокумент60 страницEmbedded Systems LabKishore Cherala100% (2)

- Syscal Junior Standard ResistivitymeterДокумент2 страницыSyscal Junior Standard ResistivitymeterMauricio Santisteban Campos RoblesОценок пока нет

- IRLR3705Z IRLU3705Z: Automotive MosfetДокумент12 страницIRLR3705Z IRLU3705Z: Automotive MosfetFer NandoОценок пока нет

- Last Saved:: Date Description Last Modif Name Index-LabДокумент3 страницыLast Saved:: Date Description Last Modif Name Index-Labluiz carlos de souzaОценок пока нет

- Post-Processing Your OVM/UVM Simulation ResultsДокумент7 страницPost-Processing Your OVM/UVM Simulation ResultsGudipalii Ravi KumarОценок пока нет

- AKNM - 3049 - AKNMGptcДокумент53 страницыAKNM - 3049 - AKNMGptchod eceОценок пока нет

- Cisco 640-721: Practice Exam: Question No: 1Документ66 страницCisco 640-721: Practice Exam: Question No: 1mario1349Оценок пока нет

- Flt93 Iom Flujo SwitchДокумент96 страницFlt93 Iom Flujo SwitchQ Llanos HenryОценок пока нет

- TGS 6x2 Midlift Lite TractorДокумент4 страницыTGS 6x2 Midlift Lite TractorAbrar HussainОценок пока нет

- Talbot Effect Reinterpreted: Paul Latimer and Randy F. CrouseДокумент10 страницTalbot Effect Reinterpreted: Paul Latimer and Randy F. CrousePierre ChausseОценок пока нет

- Evermotion Archinteriors PDFДокумент2 страницыEvermotion Archinteriors PDFAllisonОценок пока нет

- Profibus Foundation Fieldbus As-Interface Interbus Modbus-1 Can/Open Devicenet EthernetДокумент6 страницProfibus Foundation Fieldbus As-Interface Interbus Modbus-1 Can/Open Devicenet EthernetSellappan MuthusamyОценок пока нет

- S 24 Cs 08Документ34 страницыS 24 Cs 08mj15015100% (1)

- 2.95-V To 6-V Input, 3-A Output, 2-Mhz, Synchronous Step-Down Switcher With Integrated Fets (Swift™)Документ38 страниц2.95-V To 6-V Input, 3-A Output, 2-Mhz, Synchronous Step-Down Switcher With Integrated Fets (Swift™)Jorge MateusОценок пока нет

- Network Planning and DesignДокумент17 страницNetwork Planning and DesignaviОценок пока нет

- High Sensitivity, 1 MHZ, Gmr-Based Current Sensor Ic in Space-Saving, Low Resistance QFN and Soic-8 PackagesДокумент26 страницHigh Sensitivity, 1 MHZ, Gmr-Based Current Sensor Ic in Space-Saving, Low Resistance QFN and Soic-8 PackagesRahul P KrishnanОценок пока нет