Академический Документы

Профессиональный Документы

Культура Документы

Outokumpu Product Range Wallchart

Загружено:

Kevin YewАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Outokumpu Product Range Wallchart

Загружено:

Kevin YewАвторское право:

Доступные форматы

Outokumpu

Classic family

Moda range Mildly corrosive environments

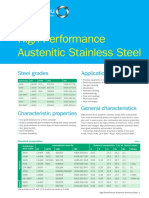

Steel designations Performance Typical chemical composition, % by mass

ASTM A80 Rp0.2 Grade

Outokumpu name EN Type UNS PRE % MPa family C Cr Ni Mo N Others

Moda 430/4016 1.4016 430 S43000 16 20 280 F 0.05 16.2

Alternatives

Moda 4510 1.4510 16 23 240 F 0.02 16.2 Ti

Moda 439/4510 1.4510 439 S43035 17 23 240 F 0.02 17.1 Ti

Moda 4511 1.4511 16 23 240 F 0.02 16.2 Nb

Moda 430Ti/4520 1.4520 430Ti 16 24 200 F 0.02 16.2 Ti

Moda 4589 1.4589 S42035 15 16 420 F 0.05 14.0 1.7 0.3 Ti

Low-Cr alternatives

Moda 410L/4003 1.4003 410L S40977 12 20 320 F 0.02 11.5 0.5

Moda 409/4512 1.4512 409 12 25 220 F 0.02 11.5 0.2 Ti

Moda 410S/4000 1.4000 410S S41008 13 19 250 F 0.03 12.5

Core range Corrosive environments

Steel designations Performance Typical chemical composition, % by mass

ASTM A80/A 50

1

Rp0.2 Grade

Outokumpu name EN Type UNS PRE % MPa family C Cr Ni Mo N Others

Core 304/4301 1.4301 304 S30400 18 45 230 A 0.04 18.1 8.1

Core 304L/4307 1.4307 304L S30403 18 45 220 A 0.02 18.1 8.1

Alternatives

Core 304LN/4311 1.4311 304LN S30453 21 40 290 A 0.02 18.5 9.2 0.14

Core 304L/4306 1.4306 304L S30403 18 45 220 A 0.02 18.2 10.1

Core 305/4303 1.4303 305 S30500 18 45 220 A 0.04 17.7 12.5

Core 321/4541 1.4541 321 S32100 17 40 220 A 0.04 17.3 9.1 Ti

Core 347/4550 1.4550 347 S34700 18 40 220 A 0.05 17.5 9.5 Nb

Core 301LN/4318 1.4318 301LN S30153 20 35 350 A 0.02 17.7 6.5 0.14

Core 301/4310 1.4310 301 S30100 17 40 250 A 0.10 17.0 7.0

Low-Ni alternatives

Core 201/4372 1.4372 201 S20100 17 45 350 A 0.05 16.1 3.6 0.08 Cu 6.6Mn

Core 201LN/4372 1.4372 201LN S20153 19 45 350 A 0.02 16.2 4.1 0.16 Cu 6.6Mn

Ni-free alternatives

Core 441/4509 1.4509 S43940 18 18 250 F 0.02 17.6 Ti Nb

Core 439M 439M S43932 18 221) 2051) F 0.02 17.6 Ti Nb

Core 4622 1.4622 S44330 21 221) 2051) F 0.02 21.0 Ti Nb Cu

Core 434/4113 1.4113 434 S43400 20 18 280 F 0.05 16.5 1.0

1)

Min. values acc. to ASTM A240, for strip t 5 mm.

Supra range Highly corrosive environments

Steel designations Performance Typical chemical composition, % by mass

ASTM A80/A501 Rp0.2 Grade

Outokumpu name EN Type UNS PRE % MPa family C Cr Ni Mo N Others

Supra 316/4401 1.4401 316 S31600 24 40 240 A 0.04 17.2 10.1 2.1

Supra 316L/4404 1.4404 316L S31603 24 40 240 A 0.02 17.2 10.1 2.1

Alternatives

Supra 316plus 1.4420 S31655 26 35 1) 310 1) A 0.02 20.3 8.6 0.7 0.19

Supra 316L/SANS4402 SANS4402 24 50 2) 290 2) A 0.02 17.2 10.1 2.1

Supra 316/4436 1.4436 316 S31600 25 40 240 A 0.04 16.9 10.7 2.6

Supra 316L/4432 1.4432 316L S31603 25 40 240 A 0.02 16.9 10.7 2.6

Supra 316L/4435 1.4435 316L S31603 26 40 240 A 0.02 17.3 12.6 2.6

Supra 316Ti/4571 1.4571 316Ti S31635 24 40 240 A 0.04 16.8 10.9 2.1 Ti

Ni-free alternative

Supra 444/4521 1.4521 444 S44400 25 20 320 F 0.02 18.0 2.0 Nb Ti

1) 2)

Min. values acc. to ASTM A240, for strip t 5 mm. Mechanical values acc. to SANS 50028-7.

PRE = %Cr + 3.3 x %Mo + 16 x %N Grade families:

Values for Rp0.2 yield strength and the A80 for elongation are according to A = Austenitic

EN 10088-2 min. values for cold rolled strip. F = Ferritic

D = Duplex

Chemical compositions and PRE calculations are based on Outokumpu M = Martensitic

typical values. PH = Precipitation hardening

Please see values for other product froms at steelfinder.outokumpu.com

Outokumpu

Pro family

Forta range Duplex and other high strength

(Yield strength RpO.2>400 MPa. PRE 16 to 43)

Steel designations Performance Typical chemical composition, % by mass

ASTM A80/A 50

4

Rp0.2 Grade

Outokumpu name EN Type UNS PRE % MPa family C Cr Ni Mo N Others

Duplex, high strength, high corrosion resistance and enhanced resistance to stress corrosion cracking

Forta DX 2205 1.4462 S32205 35 20 500 D 0.02 22.4 5.7 3.1 0.17

Forta LDX 2101 1.4162 S32101 26 20 530 D 0.03 21.5 1.5 0.3 0.22 5Mn Cu

Forta DX 2304 1.4362 S32304 26 20 450 D 0.02 23.0 4.8 0.3 0.10 Cu

Forta EDX 2304 1.4362 S32304 28 25 1) 500 1) D 0.02 23.8 4.3 0.5 0.18 Cu

Forta LDX 2404 1.4662 S82441 34 20 550 D 0.02 24.0 3.6 1.6 0.27 3Mn Cu

Forta SDX 100 1.4501 S32760 42 25 2) 530 2) D 0.02 25.4 6.9 3.8 0.27 W Cu

Forta SDX 2507 1.4410 S32750 43 20 550 D 0.02 25.0 7.0 4.0 0.27

Forta FDX 25 1.46353) S82012 25 35 4) 500 4) D 0.05 19.020.5 0.81.5 0.10.6 0.160.26 24Mn

Forta FDX 27 1.46373) S82031 27 35 4) 500 4) D 0.04 19.022.0 2.04.0 0.61.4 0.140.24 2.5Mn

High strength and high ductility

Forta H400 1.4376 40 400 5) A 0.04 17.5 4.0 0.20 6.8Mn

Forta H500 50 500 A

Forta H800 30 800 A

Forta H1000 13 1000 A

High strength and high hardness (temper rolled)

Forta 430/4016 1.4016 430 S43000 16 500700 F 0.05 16.2

Forta 301LN/4318 1.4318 301LN S30153 20 500900 A 0.02 17.7 6.5 0.14

Forta 301/4310 1.4310 301 S30100 17 5002000 A 0.10 17.0 7.0

Forta 304/4301 1.4301 304 S30400 18 500900 A 0.04 18.1 8.1

Forta 304L/4307 1.4307 304L S30403 18 500900 A 0.02 18.1 8.1

Forta 316/4401 1.4401 316 S31600 24 500700 A 0.04 17.2 10.1 2.1

Forta 316L/4404 1.4404 316L S31603 24 500700 A 0.02 17.2 10.1 2.1

Forta 316plus 1.4420 S31655 25 500700 A 0.02 20.3 8.6 0.7 0.19

Forta 316Ti/4571 1.4571 316Ti S32100 24 500700 A 0.04 16.8 10.9 2.1 Ti

1) 2) 3) 4) 5)

Outokumpu MDS-D35 for EDX 2304. Min values for plate acc. to EN 10088-2. Designation included in Stahl-Eisen-Liste. Min. values acc. to ASTM A240, for strip t 5 mm. Values acc.to EN 10088-2 and Stahl-Eisen-Liste.

Ultra range Extremely corrosive environments (PRE>27)

Steel designations Performance Typical chemical composition, % by mass

ASTM A80 Rp0.2 Grade

Outokumpu name EN Type UNS PRE % MPa family C Cr Ni Mo N Others

Ultra 904L 1.4539 904L N08904 34 35 240 A 0.01 19.8 24.2 4.3 1.4Cu

Ultra 254 SMO 1.4547 S31254 43 35 320 A 0.01 20.0 18.0 6.1 0.20 Cu

Alternatives

Ultra 317L 1.4438 317L 1) S31703 28 35 240 A 0.02 18.2 13.7 3.1

Ultra 4439 1.4439 317LMN S31726 33 35 290 A 0.02 17.3 13.7 4.1 0.14

Ultra 725LN 1.4466 S31050 34 40 2) 250 2) A 0.01 25.0 22.3 2.1 0.12

Ultra 6XN 1.4529 N08926/ 45 40 2) 300 2) A 0.01 20.5 24.8 6.5 0.20 Cu

N08367

Ultra 4565 1.4565 S34565 46 30 420 A 0.02 24.0 17.0 4.5 0.45 5.5Mn

Ultra 654 SMO 1.4652 S32654 56 40 430 A 0.01 24.0 22.0 7.3 0.50 3.5Mn Cu

1) 2)

Also available as 317L with 11.7% Ni which is not consistent with 1.4438. Values for plate.

Dura range Heat treatable for greater hardness and strength

Steel designations Performance Typical chemical composition, % by mass

ASTM Rm 2)

Grade

Outokumpu name EN Type UNS HRC 1) MPa family C Cr Ni Mo N Others

Dura 410/4006 1.4006 410 S41000 540 M 0.12 12.0

Dura 4024 1.4024 550 M 0.16 13.2

Dura 420/4021 1.4021 420 S42000 4450* 580 M 0.20 13.0

Dura 420/4028 1.4028 420 S42000 4551* 620 M 0.30 12.5

Dura 420/4031 1.4031 420 S42000 4753* 640 M 0.38 13.5

Dura 420/4034 1.4034 420 S42000 4955* 700 M 0.45 13.7

Dura 4419 1.4419 4652* 660 M 0.38 13.3 0.9

Dura 4110 1.4110 5056* 680 M 0.50 14.8 0.6

Dura 4116 1.4116 680 M 0.50 14.4 0.6 V

Dura 4122 1.4122 4753* 650 M 0.41 16.1 1.0

Precipitation hardening

Dura 17-7PH 1.4568 631 S17700 3841** 820 PH 0.08 17.0 7.0 AI

Dura 17-4PH 1.4542 630 S17400 2440** 1100 PH 0.02 15.5 4.8 3.4Cu Nb

Dura 15-7PH 1.4574 632 S15700 4045** 860 PH 0.08 14.5 7.5 2.2 Al

1) 2) ) )

Achievable Rockwell hardness after final heat treatment of the fabricated part. Tensile strength in mill condition, Outokumpu typical values. * Hardness range according to EN 10088-2. ** Hardness range according to ASTM A564 (minimum values for

different heat treatment conditions).

Therma range High service temperatures (>550C)

Steel designations Performance Typical chemical composition, % by mass

ASTM Max service Grade

Outokumpu name EN Type UNS temp. (C) 1) family C Cr Ni Mo N Others

Therma 253 MA 1.4835 S30815 1150 A 0.09 21.0 11.0 0.17 Si Ce

Therma 310S/4845 1.4845 310S S31008 1050 A 0.05 25.5 19.1

Resistance to sulfur containing hot gases, lower thermal expansion

Therma 4713 1.4713 800 F 0.06 6.5 Al Si

Therma 4724 1.4724 850 F 0.07 12.5 Al Si

Therma 4742 1.4742 1000 F 0.07 17.5 Al Si

Resistance to carburizing and nitriding/low oxygen hot gas, higher creep strength

Therma 304H/4948 1.4948 304H S30409 750 A 0.05 18.1 8.3

Therma 321H/4878 1.4878 321H 850 A 0.05 17.3 9.1 Ti

Therma 347H 347H S34709 700 A 0.05 17.5 9.5 Nb

Therma 4828 1.4828 1000 A 0.05 19.3 11.2 Si

Therma 309S/4833 1.4833 309S S30908 1000 A 0.06 22.3 12.3

Therma 153 MA 1.4818 S30415 1050 A 0.05 18.5 9.1 0.15 Si Ce

Therma 314/4841 1.4841 314 S31400 1150 A 0.06 24.3 19.2 Si

1)

In dry air acc. EN 10095.

Prodec range Stainless steel grades optimized for improved machinability

with longer tool life and enhanced quality

Steel designations Performance Typical chemical composition, % by mass

ASTM HRB 1) CDB 2)

Rp0.2 Rp0.2 Grade

Outokumpu name EN Type UNS PRE A% MPa A% MPa family C Cr Ni Mo N Others

Prodec 304L/4307 1.4307 304L S30403 18 45 175 25/25/30 400/380/175 A 0.02 18.1 8.1

Prodec 316L/4404 1.4404 316L S31603 24 40 200 25/25/30 400/380/200 A 0.02 17.2 10.1 2.1

Prodec 303/4305 1.4305 303 S30300 17 35 190 15/15/20 400/400/190 A 0.05 17.2 8.1 0.3S

Prodec 17-4PH 3) 1.4542 630 S17400 10 520 10/10/12 600/600/520 PH 0.02 15.5 4.8 3.4Cu Nb

1) 2) 3)

HRB = Hot rolled bar. CDB = Cold drawn bar. Values are for diameter (d) 10 mm & 10 < d 16 mm & 16 < d 40 mm. Values for condition +P800.

Deco range Special surfaces

Available in Description

Polished/brushed

Wet Polished, Dry Polished, Brushed, Duplo Polishing a stainless steel surface with an abrasive belt of a certain grain size leads to a homogeneous, satin-like

(Polished and Brushed), Microlon and highly decorative surface finish. By optimizing the grain of the belt the surface finish can be fine-tuned to meet

specific application requirements. Polished surfaces have more or less clearly visible scoring, which also makes

scratches from daily wear and tear less visible. A polished surface is also easy to recreate, for example after repairs

or welding work, compared with a 2B or 2R surface.

Brushing (e.g. with Scotch Brite) provides a silky-matt finish with a pattern of very fine lines in brushing direction.

The fine polishing grit lines of Microlon lead to an elegant, dark gray surface appearance that gives interior and

exterior claddings a classy look.

Patterned

Linen, Linen Matt, Linen Star, Linen Supermatt, Square, Pattern rolling of stainless steel leads to an enhanced combination of design and function. Outokumpu offers a large

Diamonds, Microlinen, Leather Grain, Austenite, Haze, variety of patterned surface finishes each with different gloss and reflection effects. As standard we pattern roll on

Laser, Microchecker, Waterfall, Triangle, Top Pearl, 2R and by special request on 2B. The most popular designs are Linen, Haze, Laser, Microlinen, Diamonds, Square,

Ice Crystal, Beads, 1, 8, 9, 16, AN5 Microchecker and Leather Grain. Custom-made patterns can also be developed according to the customers needs.

After pattern rolling a recovery annealing is performed for improved formability. Extremely high flatness is achieved

by tension leveling.

Special surfaces

2R2, GritLine, Rolled-On, Matt, Supermatt High smoothness and reflectivity is achieved on the 2R2 finish almost equaling the gloss and smoothness of a

mirror polished (No. 8) surface finish. GritLine and Rolled-On are surface finishes with similar properties to polished

finishes but wtih improved corrosion resistance. The shot blasted surface finish called Supermatt is characterized by

a dull, extremely homogeneous and high quality appearance.

For more information and images on the Deco special surfaces go to outokumpu.com/deco

PRE = %Cr + 3.3 x %Mo + 16 x %N Grade families:

Values for Rp0.2 yield strength and the A80 for elongation are according to A = Austenitic

F = Ferritic

EN 10088-2 min. values for cold rolled strip. D = Duplex

Chemical compositions and PRE calculations are based on Outokumpu M = Martensitic

typical values. PH = Precipitation hardening

Please see values for other product forms at steelfinder.outokumpu.com

Performance

1000EN-GB:13. May 2016.

Strength vs. corrosion resistance

650

Yield strength Rp0.2 (MPa)

600

Forta LDX 2404

Forta

550 LDX 2101 Forta SDX 2507

Forta EDX 2304 Forta DX 2205

Forta Forta SDX 100

500 FDX 251

Forta

FDX 271

450

Moda 4589 Supra 316/4401 Ultra 4565

Forta DX 2304 Supra 316L/4404

Supra 316Ti/4571

Ultra 654 SMO

400

Core

201/4372

Core 301LN/4318

350 Moda

410L/4003 Core Supra Ultra 254 SMO

Core 304LN/ 444/

Moda 430/4016 434/ 4311 4521 Ultra 4439

300 Core 441/4509 4113 Supra Ultra 6XN

316plus1

Core

Core 304/4301 Ultra 725LN

301/4310 Supra 316L/4435

Moda

250 Moda

439/4510

410S/4000 Ultra 317L Ultra 904L

Core

Moda 409/4512 321/4541

Core 304L/4307

200 Supra 316L/4432

Moda 4510 Core Core Core 304L/4306

Moda Supra 316/4436

Moda 4511 429M1 46221 Core 305/4303

430Ti/4520 Core 347/4550

0

0 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60

Corrosion resistance (PRE)

Elongation vs. corrosion resistance

65

Elongation A80/A501 (%)

60

Supra 316/4401

Core 304/4301

Supra 316L/4404

55 Core 304L/4307 Supra 316Ti/4571

Core 304L/4306

Core 305/4303

50

Supra 316L/4432

Core 201/4372 Supra 316/4436

45

Core 321/4541 Core

Core

Core 301/4310 304LN/4311 Ultra 725LN Ultra 6XN

347/4550 Supra 316L/4435

40

Supra 316plus1 Forta Ultra 654 SMO

FDX 271 Ultra 4439 Ultra 254 SMO

35 Moda 4510 Ultra 904L

Moda 4511 Core Forta Ultra 317L

301LN/4318 FDX 251 Ultra 4565

30 Forta

EDX

Moda 410S/4000 Moda 409/4512 2304 Forta SDX 100

25 Moda 4511

Supra

Moda 439/4510

444/

Core Core Forta DX 2205

4521

439M1 46221

20 Forta SDX 2507

Moda Moda Forta LDX 2404

410L/ 430/4016 Core Core

4003 441/ 434/ Forta LDX 2101

15 Moda 4509 4113 Forta DX 2304

4589

0

0 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60

Corrosion resistance (PRE)

Moda Mildly corrosive environments Values for Rp0.2 yield strength and the A80 for elongation are

according to EN 10088-2 min. values for cold rolled strip.

Core Corrosive environments

Chemical compositions and PRE calculations are based on

Supra Highly corrosive environments Outokumpu typical values. MODA, CORE, SUPRA, FORTA, ULTRA, DURA, THERMA, DECO,

1) 316PLUS and 153 MA are trademarks of Outokumpu Oyj.

Forta Duplex and other high strength (PRE 16 to 43) According to ASTM A240.

PRODEC, EDX, FDX, FDX 25, FDX 27, LDX, 253 MA, 254 SMO, 654 SMO,

Ultra Extremely corrosive environments (PRE > 27) Please see values for other product forms at LDX 2101, LDX 2404 are registered trademarks of Outokumpu Oyj.

steelfinder.outokumpu.com

17-4 PH and 17-7 PH are registered trademarks AK Steel Corporation.

Вам также может понравиться

- Outokumpu - Wallchart Product RangesДокумент5 страницOutokumpu - Wallchart Product RangesXavierОценок пока нет

- Steel Grades 2 PDFДокумент2 страницыSteel Grades 2 PDFcanakyuz0% (1)

- Outokumpu Stainless Steel Wall Chart PDFДокумент1 страницаOutokumpu Stainless Steel Wall Chart PDFcnaren67Оценок пока нет

- Outokumpu Core Range DatasheetДокумент16 страницOutokumpu Core Range DatasheetsachedalОценок пока нет

- Stainless Steel Data PDFДокумент4 страницыStainless Steel Data PDFRobert SumińskiОценок пока нет

- Pressure Vessel ITP Rev 0Документ3 страницыPressure Vessel ITP Rev 0Enaam AtaallahОценок пока нет

- Aço China - Cross Reference SteelДокумент12 страницAço China - Cross Reference SteelPaulo BaltorОценок пока нет

- SPECIFICATIONS OF PIPES & TUBESДокумент3 страницыSPECIFICATIONS OF PIPES & TUBESanescobar0001Оценок пока нет

- Chemical Composition of Stainless Steel (P-2)Документ1 страницаChemical Composition of Stainless Steel (P-2)candraОценок пока нет

- FFFДокумент20 страницFFFAhmed AlsabaaОценок пока нет

- Outokumpu Steel Grades Properties Global StandardsДокумент20 страницOutokumpu Steel Grades Properties Global StandardsLance BlackstarОценок пока нет

- Bab IiДокумент8 страницBab Iibeni firiyaОценок пока нет

- Atlas Steels Product Manual Section 9Документ12 страницAtlas Steels Product Manual Section 9Alexis A. Illarramendi G.Оценок пока нет

- PR-Request FormДокумент2 страницыPR-Request FormVajid MadathilОценок пока нет

- Sss Sttttaaaaiiiinnnnlllleeeessssssss Sssstttteeeeeeeellllssss Typical Composition % Uns WNR Ss / C CR Ni Mo NB CuДокумент4 страницыSss Sttttaaaaiiiinnnnlllleeeessssssss Sssstttteeeeeeeellllssss Typical Composition % Uns WNR Ss / C CR Ni Mo NB CuAdriano Dorneles de OliveiraОценок пока нет

- Ferritic and martensitic stainless steel cross reference listДокумент1 страницаFerritic and martensitic stainless steel cross reference listPlant Head PrasadОценок пока нет

- Amg RTJ Data PDFДокумент8 страницAmg RTJ Data PDFsiswoutОценок пока нет

- Stainless Steel Grade Composition ChartДокумент6 страницStainless Steel Grade Composition Charteusufiqbal100% (1)

- Power Plant: Better Life Created by SteelДокумент4 страницыPower Plant: Better Life Created by SteelAlejandro Jose Garcia FernandezОценок пока нет

- Stainless Steel Bar Types and Chemical CompositionsДокумент1 страницаStainless Steel Bar Types and Chemical CompositionsNikola KrajcevskiОценок пока нет

- Equivalência Aços 4Документ1 страницаEquivalência Aços 4izzygodswanОценок пока нет

- Uv 421 TT (Sa FB 1 65 DC h5)Документ4 страницыUv 421 TT (Sa FB 1 65 DC h5)brunizzaОценок пока нет

- Uv 420 TTR / Uv 420 TTR-W Uv 420 TTR / Uv 420 TTR-W: Classifications EN 760Документ1 страницаUv 420 TTR / Uv 420 TTR-W Uv 420 TTR / Uv 420 TTR-W: Classifications EN 760Bala BiniОценок пока нет

- Article - Stainless Steel Fasteners and Their Chemical CompositionДокумент3 страницыArticle - Stainless Steel Fasteners and Their Chemical Compositiongaju_scribdОценок пока нет

- Equivalences - Stainless Steel, 303, 304, 316, 316L, 410, 416, 431, F51, F55, 174PH, Standard Grade, IMCO, Special Grades, Sheffield UKДокумент3 страницыEquivalences - Stainless Steel, 303, 304, 316, 316L, 410, 416, 431, F51, F55, 174PH, Standard Grade, IMCO, Special Grades, Sheffield UKIsaac IglesiasОценок пока нет

- Astm A493 16Документ2 страницыAstm A493 16wongОценок пока нет

- Welding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsДокумент1 страницаWelding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsLLОценок пока нет

- Uk Intnl Equiv GradesДокумент1 страницаUk Intnl Equiv GradesLLОценок пока нет

- Equivalent SpecificationsДокумент3 страницыEquivalent SpecificationsYudha Andrie Sasi ZenОценок пока нет

- High Performance Austenitic Stainless SteelДокумент12 страницHigh Performance Austenitic Stainless SteelNitin VermaОценок пока нет

- Material Specifications Tradename Astm Specification UNS Werkstoff DIN Barstock Forging Casting Diversity Rpa Key Pipe Fittings Number NumberДокумент3 страницыMaterial Specifications Tradename Astm Specification UNS Werkstoff DIN Barstock Forging Casting Diversity Rpa Key Pipe Fittings Number NumberErcan YilmazОценок пока нет

- Grades: Grade EN / DIN Aisi/Astm Uns Ss Afnor OverigДокумент2 страницыGrades: Grade EN / DIN Aisi/Astm Uns Ss Afnor OverigIvan AlexievОценок пока нет

- SMAW FCAW GTAW SAW welding processes material types costsДокумент1 страницаSMAW FCAW GTAW SAW welding processes material types costsRajkumar AОценок пока нет

- Technical Data Sheet: Survey of GradesДокумент12 страницTechnical Data Sheet: Survey of GradesOmkarОценок пока нет

- SAW Fluxes Stainless and Heat Resistant Steels: Basicity To BoniszewskiДокумент3 страницыSAW Fluxes Stainless and Heat Resistant Steels: Basicity To BoniszewskiSungJun ParkОценок пока нет

- Stainless Steel International StandardsДокумент3 страницыStainless Steel International StandardsAmir MusaibОценок пока нет

- Gear Grades EquivalenttablesДокумент1 страницаGear Grades Equivalenttablesamir_fortunateОценок пока нет

- Astm A358 PDFДокумент3 страницыAstm A358 PDFgaminОценок пока нет

- Material y ToleranciasДокумент1 страницаMaterial y ToleranciasvictoryanezОценок пока нет

- Kevinsteel SA 1210Документ4 страницыKevinsteel SA 1210meisamОценок пока нет

- Steel - Equivalent Grades PDFДокумент23 страницыSteel - Equivalent Grades PDFSowmen Chakroborty100% (1)

- Standard steel and alloy types and their designationsДокумент1 страницаStandard steel and alloy types and their designationsmpptanksОценок пока нет

- Bavaria Flux BF 5.1Документ3 страницыBavaria Flux BF 5.1Filipe CordeiroОценок пока нет

- Tabel Persamaan bahan dasar dan presisi roda gigiДокумент1 страницаTabel Persamaan bahan dasar dan presisi roda gigiboschОценок пока нет

- ISO 15510:2010 lists stainless steel grades with comparative designationsДокумент3 страницыISO 15510:2010 lists stainless steel grades with comparative designationstugulea72 GabiОценок пока нет

- Stainless Steel, 303, 304, 316, 316L, 410, 416, 431, F51, F55, 174PH, Standard Grade, IMCO, Special Grades, Sheffield UKДокумент3 страницыStainless Steel, 303, 304, 316, 316L, 410, 416, 431, F51, F55, 174PH, Standard Grade, IMCO, Special Grades, Sheffield UKSumit SharmaОценок пока нет

- Swagelok TubingДокумент1 страницаSwagelok TubingMmstevens00Оценок пока нет

- Stainless Steel Solutions For The Aerospace Industry: UgitechДокумент4 страницыStainless Steel Solutions For The Aerospace Industry: UgitechMarkОценок пока нет

- TABELA - DUPLEX - Outokumpu Forta Range DatasheetДокумент18 страницTABELA - DUPLEX - Outokumpu Forta Range DatasheetRogerio VagoОценок пока нет

- Stainless Steel Grades DatasheetsДокумент7 страницStainless Steel Grades DatasheetsYeda ZОценок пока нет

- AISI 4130 Steel - 25CrMo4 - 1.7218 - 708A25 - SCM430 - Special SteelДокумент3 страницыAISI 4130 Steel - 25CrMo4 - 1.7218 - 708A25 - SCM430 - Special SteelGeorge LawrenceОценок пока нет

- Lnm309h-Eng Stainless Steel Solid WireДокумент1 страницаLnm309h-Eng Stainless Steel Solid WiredantegimenezОценок пока нет

- International Starch Institute: Wrought Stainless SteelsДокумент14 страницInternational Starch Institute: Wrought Stainless SteelsSilmina AdzhaniОценок пока нет

- Duplex Stainless Steel CompareДокумент1 страницаDuplex Stainless Steel CompareichrakОценок пока нет

- FCAW - Flux Coredpowder Cored WiredДокумент40 страницFCAW - Flux Coredpowder Cored WiredGabor VatoОценок пока нет

- Steel Grades Equivalence Table1 PDFДокумент13 страницSteel Grades Equivalence Table1 PDFVictor ParvanОценок пока нет

- Welding ProcessesДокумент28 страницWelding ProcessesAnaswarpsОценок пока нет

- 005-Interlloy Grade 4340 Hardened and Tempered BarДокумент3 страницы005-Interlloy Grade 4340 Hardened and Tempered BarDhruv MehtaОценок пока нет

- Techinfo WorkpieceДокумент1 страницаTechinfo Workpiecesototo90Оценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Mechanical Properties of Stainless SteelДокумент1 страницаMechanical Properties of Stainless SteelKevin YewОценок пока нет

- Liquid Loads on a Tank Wall using PCA TablesДокумент1 страницаLiquid Loads on a Tank Wall using PCA TablesKevin YewОценок пока нет

- External Thread Dimensions For Metric Coarse Pitch Screw ThreadsДокумент1 страницаExternal Thread Dimensions For Metric Coarse Pitch Screw ThreadstnchsgОценок пока нет

- Alloy CharacteristicsДокумент2 страницыAlloy CharacteristicsKevin YewОценок пока нет

- Oil StorFage Tank Foundations BobergДокумент3 страницыOil StorFage Tank Foundations BobergNabil Al-KhirdajiОценок пока нет

- Bolts Tensile Strength ComparisonДокумент1 страницаBolts Tensile Strength ComparisonKevin YewОценок пока нет

- Bolts Tensile Strength ComparisonДокумент1 страницаBolts Tensile Strength ComparisonKevin YewОценок пока нет

- Phone: 1300 365 110 Stocking Locations included:Trade Centres (pick up or deliveryДокумент41 страницаPhone: 1300 365 110 Stocking Locations included:Trade Centres (pick up or deliveryKevin YewОценок пока нет

- Truemax HG38M Placing BoomДокумент1 страницаTruemax HG38M Placing BoomKevin YewОценок пока нет

- Development of Australian Reinforcing Bar StandardsДокумент9 страницDevelopment of Australian Reinforcing Bar StandardskevinyewОценок пока нет

- Truemax HG32DДокумент1 страницаTruemax HG32DKevin YewОценок пока нет

- PCA Table For SF More Than 16Документ1 страницаPCA Table For SF More Than 16kevinyewОценок пока нет

- Humour in EngineeringДокумент8 страницHumour in EngineeringKevin YewОценок пока нет

- Astm-D 5402-93 PDFДокумент3 страницыAstm-D 5402-93 PDFTeymur RegenmaisterОценок пока нет

- Bahasa Inggris Kelas 1Документ2 страницыBahasa Inggris Kelas 1Diyah LailaОценок пока нет

- Viscosity Grade Bitumen, Bitumen VG 20, VG 30, VG 40 SpecificationДокумент3 страницыViscosity Grade Bitumen, Bitumen VG 20, VG 30, VG 40 SpecificationParthiban GuruОценок пока нет

- PolymerisationДокумент59 страницPolymerisationkid unique100% (2)

- Elring Sealing Compound Dirko Black: Technical DatasheetДокумент7 страницElring Sealing Compound Dirko Black: Technical Datasheetperico_Оценок пока нет

- Welding Specification for Austenitic, Duplex and Superduplex PipeworkДокумент45 страницWelding Specification for Austenitic, Duplex and Superduplex Pipeworkmurugesan0% (1)

- Modal Rayon Lyocell Rayon: Cuproamonium Rayon Acetate RayonДокумент18 страницModal Rayon Lyocell Rayon: Cuproamonium Rayon Acetate RayonHrs Shihab100% (1)

- Classification of Matter Textbook PDFДокумент26 страницClassification of Matter Textbook PDFファルファン ラウルОценок пока нет

- G52-00 (Reapproved 2016) E1 PDFДокумент4 страницыG52-00 (Reapproved 2016) E1 PDFHadi Howaida100% (1)

- Over FibersДокумент2 страницыOver FibersMohamed Abo-ZaidОценок пока нет

- ChemtoolДокумент9 страницChemtoolgusfabi1Оценок пока нет

- Energy From ChemicalsДокумент20 страницEnergy From Chemicalshafizhapni100% (7)

- SB - SB70 Rev2Документ12 страницSB - SB70 Rev2riversgardenОценок пока нет

- PTC Audit Checksheet 20220909Документ2 страницыPTC Audit Checksheet 20220909yeucongnghemoiОценок пока нет

- Lecture On Photocromic and Thermochromic ColorantДокумент19 страницLecture On Photocromic and Thermochromic ColorantWaky Mahmudul HasanОценок пока нет

- S10-Specification For Gabion Reinforced Earth SystemДокумент9 страницS10-Specification For Gabion Reinforced Earth SystemwongtianhuiОценок пока нет

- MGN628 - Part - 6 - GRP - Construction - R07.20 - PAG 29Документ40 страницMGN628 - Part - 6 - GRP - Construction - R07.20 - PAG 29Steven Salazar ArangoОценок пока нет

- Instruction Manual For SLICE Exothermic Cutting EquipmentДокумент20 страницInstruction Manual For SLICE Exothermic Cutting EquipmentSGI HORIZONОценок пока нет

- Durable Actuator Solutions: Centrifugal Casting Electropolishing ProcessДокумент2 страницыDurable Actuator Solutions: Centrifugal Casting Electropolishing ProcessJignesh TamkeОценок пока нет

- Rigaku Journal 33-1-24-29Документ6 страницRigaku Journal 33-1-24-29Sarmiento HerminioОценок пока нет

- UNIT-3 (Lecture-4) Expansion JointsДокумент38 страницUNIT-3 (Lecture-4) Expansion JointsSabbir hossainОценок пока нет

- PT SULFINDO ADIUSAHA PROJECT DEPARTEMENT WO/WR: PR : BOQ Pekerjaan Piping & Stell Strucure Portable Steel Cooling Tower CA plaДокумент8 страницPT SULFINDO ADIUSAHA PROJECT DEPARTEMENT WO/WR: PR : BOQ Pekerjaan Piping & Stell Strucure Portable Steel Cooling Tower CA plaaris munandarОценок пока нет

- Design, Dimensioning and Execution of Precast SFRC Arch SegmentsДокумент18 страницDesign, Dimensioning and Execution of Precast SFRC Arch Segmentshfdfghj jggfghОценок пока нет

- Operation Manual Muffle Furnace SeriesДокумент9 страницOperation Manual Muffle Furnace SeriesZafar IqbalОценок пока нет

- Fabrication and Analysis of Excavator Bucket TeethДокумент30 страницFabrication and Analysis of Excavator Bucket Teethsai deepthiОценок пока нет

- Salts PDFДокумент7 страницSalts PDFpiyushОценок пока нет

- 331 Flux-Cored Wire Data SheetДокумент2 страницы331 Flux-Cored Wire Data Sheetanon_985163484Оценок пока нет

- Isonem Anti Sound PaintДокумент1 страницаIsonem Anti Sound Paintdante67Оценок пока нет

- Quality For Road and Engineer Hand BookДокумент255 страницQuality For Road and Engineer Hand BookvenkyОценок пока нет

- Chap07 PDFДокумент15 страницChap07 PDFABОценок пока нет