Академический Документы

Профессиональный Документы

Культура Документы

Mix Design Poster

Загружено:

Abhilash Kumar0 оценок0% нашли этот документ полезным (0 голосов)

227 просмотров1 страницаShort review of mix design through poster

Оригинальное название

Mix design poster

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документShort review of mix design through poster

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

227 просмотров1 страницаMix Design Poster

Загружено:

Abhilash KumarShort review of mix design through poster

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

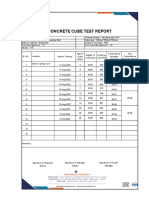

MIX DESIGN BY IS-10262-2009

DEPARTMENT OF CIVIL ENGINEERING , GBU APIRIL 2017

STEP:6. CALCULATION CEMENTIOUS MATERIAL

CONTENT

The process of selecting suitable

From the w/c ratio and the quantity of water per unit volume of

ingredients of concrete and de-

cement, calculate the amount of cementious material.

termining their relative amounts

with the objective of producing a After calculating the quantity of cement material, compare it with

concrete of the required, the values given in the table 5 of IS 456.

strength, durability and workabil-

ity as economically as possible The greater of the two values is then adopted.

is termed the concrete mix de-

sign.

STEP:7. FINDING OUT VOLUME PROPORTIONS FOR

COARSE AGGREGATE AND FINE AGGREGATE

PROCEDURE: Volume of coarse aggregate corresponding to unit volume of total

aggregate for different zones of fine aggregate is selected from

STEP:1. DESIGN SPECIFICATION REQUIRED table 3 of IS 10262.

Grade designation (whether Workability This table is only applicable for w/c ratio of 0.5.For w/c ratio other

M10, M15, M20 etc)

Exposure conditions (As per than 0.5 certain adjustment are made:

Type of cement to be used IS-456-Table-4) 1. For every +0.05 change in W/C ratio: -0.01 is done in propor-

Maximum nominal size of ag- Method of transporting and tion of coarse aggregate

gregates placing 2. For every -0.05 change in W/C ratio: +0.01is done in proportion

Minimum cement content Type of aggregate (angular, of coarse aggregate

sub angular, rounded etc)

Maximum water-cement ratio 3. For Pumpable Mix : -10 %

Type of admixture to be used

(if any)

STEP:8. MIX CALCULATION

STEP:2. TESTING OF MATERIAL

Concrete Tests to be Done VOLUME OF CON- 1m3

Ingredients CRETE(a)

Cement Specific - - - Volume of cement (b) (Mass of cement/specific gravity

Gravity of cement)*(1/1000)

Coarse Ag- Specific Water Ab- Free Sur- Sieve Analysis Volume of water (c) (Mass of water/specific gravity of

gregate Gravity sorption face water)*(1/1000)

Moisture Volume of admixture(d) (Mass of admixture/specific grav-

Fine Ag- Specific Water Ab- Free Sur- Sieve Analysis ity of admixture)*(1/1000)

gregate Gravity sorption face

Moisture Volume of total aggregate [a-(b+c+d)]

Admixture Specific - - - (C.A+F.A) (e)

(if any) Gravity Mass of coarse aggregate e*Volume of coarse aggre-

gate*specific gravity of coarse

STEP:3. TARGET STRENGTH CALCULATION aggregate*1000

Calculate the target compressive strength using the formula given Mass of fine aggregate e*Volume of fine aggre-

below. gate*specific gravity of fine ag-

gregate*1000

fck = fck + 1.65s

fck = Target compressive strength at 28 days in N/mm2.

STEP:9.TRIAL MIX

Conduct a trial mix as per the amount of material calculated above.

fck = Characteristic compressive strength at 28 days in N/mm2.

(same as grade of concrete, see table below)

s = Standard deviation (from Is 10262-2009,Table 1) STEP:10. MEASURMENT OF WORKABILITY(BY SLUMP

STEP:4. SELECTION OF WATER-CEMENT RATIO CONE TEST)

For preliminary calculation, water cement ratio as given is IS-456- The mix shall be carefully observed for freedom from segregation

Table 5 for different environmental exposure condition, may be and bleeding

used.

Refer the table 3 (As per IS-456) to choose right type of environ- STEP:11.REPEATING TRIAL MIXES

ment depending upon different exposure conditions to con-

crete. If the required workability or compressive strength is not obtained

from trail mix 1, then various trail mixes are produced by vary-

STEP:5. SELECTION OF WATER CONTENT ing w/c ratio, quantity of admixture used to get required value.

From table 2 of IS 10262 w/c ratio can be calculated according to RESULTS:

maximum size of aggregate used.

The values given in the table 2 is applicable only for angular CONCRETE CEMENT :F.A :C.A

coarse aggregate and for a slump value in between 25 to GRADE

50mm. M15 1 : 2 : 4

Acc. To IS code certain adjustments are made to compute water

M20 1 : 1.5 : 3

content for slump value other than 25-50mm and for other type M25 1 : 1 : 2

of aggregate used.

Вам также может понравиться

- Concrete Mix Design Calculation For M20, M25, M30 Concrete With Procedure & ExampleДокумент9 страницConcrete Mix Design Calculation For M20, M25, M30 Concrete With Procedure & ExampleRAMPALLI GATTAIAHОценок пока нет

- Concrete Mix Design For - M5: (As Per IS 10262-2019)Документ8 страницConcrete Mix Design For - M5: (As Per IS 10262-2019)mahesh naikОценок пока нет

- Bitumen Test FormetДокумент12 страницBitumen Test FormetBilal Ahmed BarbhuiyaОценок пока нет

- Cement Concrtet Mix Design of M-20 Grade For RCC WorkДокумент7 страницCement Concrtet Mix Design of M-20 Grade For RCC WorkSandip Roy100% (1)

- FT004 - FLAKINESS & ELONGATION INDICESdДокумент23 страницыFT004 - FLAKINESS & ELONGATION INDICESdjjksite voyantsОценок пока нет

- Combine Flakiness & Elongation TestДокумент1 страницаCombine Flakiness & Elongation TestFariha AzadОценок пока нет

- Sand Replacement TestДокумент8 страницSand Replacement Testkrishna buildconОценок пока нет

- Client Caterpillar Signs PMC Compaction Test by Sand ReplacementДокумент1 страницаClient Caterpillar Signs PMC Compaction Test by Sand ReplacementBrahammanand BairwaОценок пока нет

- Trial Mix Two (420,430)Документ14 страницTrial Mix Two (420,430)Tewodros TadesseОценок пока нет

- Test Report: M/S Pcil & MBPCL Joint VentureДокумент7 страницTest Report: M/S Pcil & MBPCL Joint VentureImran KhanОценок пока нет

- SCC m55 Birla Sakthi (Scc-081)Документ6 страницSCC m55 Birla Sakthi (Scc-081)sooricivilОценок пока нет

- ICBP Paving Provides Durability and Flexibility at Low CostДокумент24 страницыICBP Paving Provides Durability and Flexibility at Low CostAbhishek RanaОценок пока нет

- M 40 PQC With GGBS 340-60Документ6 страницM 40 PQC With GGBS 340-60Er Dnyaneshwar PatilОценок пока нет

- Date: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreДокумент2 страницыDate: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreVithun PoojaryОценок пока нет

- Concrete Mix Design of M-15 (PCC)Документ141 страницаConcrete Mix Design of M-15 (PCC)Abhishek SinghОценок пока нет

- Automatic-M25 Concrete Mix Design As Per Is Code - Excel SheetДокумент50 страницAutomatic-M25 Concrete Mix Design As Per Is Code - Excel Sheetshaik saifulla lОценок пока нет

- FREQUENCY OF TEST & ACCEP. LIMITS Ajit Pratap SinghДокумент10 страницFREQUENCY OF TEST & ACCEP. LIMITS Ajit Pratap SinghAjit P. SinghОценок пока нет

- FT003 - Aggregate Impact Value TestДокумент15 страницFT003 - Aggregate Impact Value Testjjksite voyantsОценок пока нет

- Rigid PavementsДокумент36 страницRigid PavementsSubodh BardeОценок пока нет

- Bitumen Extraction Test Observation SheetДокумент2 страницыBitumen Extraction Test Observation SheetramОценок пока нет

- M25 Mix Design 100 Recycled AggregateДокумент9 страницM25 Mix Design 100 Recycled AggregateRakesh ReddyОценок пока нет

- Aggregate Crushing Value and Ten Percent Fines ValueДокумент3 страницыAggregate Crushing Value and Ten Percent Fines ValueShuvro ChakravortyОценок пока нет

- Class'C' Concrete-2Документ9 страницClass'C' Concrete-2Tewodros TadesseОценок пока нет

- RMM CalibrationДокумент18 страницRMM CalibrationPrasanna S KulkarniОценок пока нет

- Annexure 2 Form 72 (Scope) Annexure IДокумент4 страницыAnnexure 2 Form 72 (Scope) Annexure IVaghasiyaBipinОценок пока нет

- Mix Design M60 PDFДокумент3 страницыMix Design M60 PDFGreeshma KajolОценок пока нет

- Cube Test ReportДокумент1 страницаCube Test ReportShubham MareОценок пока нет

- CTSB Presentation-FinalДокумент19 страницCTSB Presentation-FinalBidur JhaОценок пока нет

- Shree Balaji Test House Pvt. Ltd. Geotechnical ReportДокумент64 страницыShree Balaji Test House Pvt. Ltd. Geotechnical ReportPhani Krishna BadipatiОценок пока нет

- Six Lanning of Delhi Agra Section Wet Mix Macadam CalibrationДокумент12 страницSix Lanning of Delhi Agra Section Wet Mix Macadam CalibrationRSBIPL NH17 LABОценок пока нет

- Calculations For Safe Bearing CapacityДокумент3 страницыCalculations For Safe Bearing Capacityimran khanОценок пока нет

- Mix Design and Pie Chart RepresentationДокумент40 страницMix Design and Pie Chart RepresentationKuldeep ChakerwartiОценок пока нет

- Revised Design Mix of M60 Grade As Per MK SootaДокумент2 страницыRevised Design Mix of M60 Grade As Per MK SootaMukesh SharmaОценок пока нет

- DBM Job MixДокумент3 страницыDBM Job MixSOIGNE ENGINEERING CONSULTANTSОценок пока нет

- TDS - Polyalk CP 293+Документ1 страницаTDS - Polyalk CP 293+Anonymous ouZFaSBRОценок пока нет

- Summary of Quality Control Tests Required For BridgesДокумент4 страницыSummary of Quality Control Tests Required For BridgesJakka LakshmikanthОценок пока нет

- Compressive Strength of AAC BlockДокумент11 страницCompressive Strength of AAC BlockImran KhanОценок пока нет

- 1.summary of Concrete Mix DesignsДокумент2 страницы1.summary of Concrete Mix DesignsGanesh Kumar TulabandulaОценок пока нет

- Pour Card: Correction For Moisture Content For DLCДокумент1 страницаPour Card: Correction For Moisture Content For DLCQuality JamОценок пока нет

- Summary of Revised Codes For Concrete in 2018Документ4 страницыSummary of Revised Codes For Concrete in 2018Vijayakrishna SingamsettiОценок пока нет

- Mix Design For PQCДокумент34 страницыMix Design For PQCSAMRADDHI PRAJAPATIОценок пока нет

- Concrete dispatch slip quality planДокумент1 страницаConcrete dispatch slip quality planShesha ShayanОценок пока нет

- Pavement Crust ThicknessДокумент10 страницPavement Crust ThicknessHarsh DeepОценок пока нет

- SR No Description of Material & Test Specifications Charges M.E Testing PNC Existing Rates CementДокумент3 страницыSR No Description of Material & Test Specifications Charges M.E Testing PNC Existing Rates CementAtulОценок пока нет

- Core Cutting FormatДокумент1 страницаCore Cutting FormatDeven PatleОценок пока нет

- Atterberg's LimitДокумент1 страницаAtterberg's LimitShesha ShayanОценок пока нет

- AIMIL Fully Automatic Compression Tester FACTДокумент3 страницыAIMIL Fully Automatic Compression Tester FACTvasudeva yasasОценок пока нет

- M-25 Design MixДокумент7 страницM-25 Design MixAbhishek GoundОценок пока нет

- Compaction Test by Core Cutter (Is: 2720, Part 29)Документ2 страницыCompaction Test by Core Cutter (Is: 2720, Part 29)Francis Aw Soon LeeОценок пока нет

- Results of Compressive Strength of Concrete / Grout CubesДокумент1 страницаResults of Compressive Strength of Concrete / Grout CubesSABEASNОценок пока нет

- CMRL P2C401 Final Report 1-319-338Документ20 страницCMRL P2C401 Final Report 1-319-338Kishore KumarОценок пока нет

- Effect of Test Conditions on Subgrade StrengthДокумент46 страницEffect of Test Conditions on Subgrade StrengthChau Suktana EnlingОценок пока нет

- Test Certificate: Chettinad Cement Corporation PVT LTDДокумент1 страницаTest Certificate: Chettinad Cement Corporation PVT LTDChander BauraОценок пока нет

- Developing rural roads agency in BiharДокумент2 страницыDeveloping rural roads agency in Biharvijay kumarОценок пока нет

- WMM Design DataДокумент42 страницыWMM Design DatapreranaОценок пока нет

- Tm-22 m35 RCCДокумент19 страницTm-22 m35 RCCVeera ManiОценок пока нет

- BBS For Test Pile-03 at OMG - 1000mm DiaДокумент5 страницBBS For Test Pile-03 at OMG - 1000mm DiaAjay MalikОценок пока нет

- Bituminous Mix DesignДокумент62 страницыBituminous Mix DesignShaim RehanОценок пока нет

- Mix Design M25 Grade Designed As Per Is 10262 - 2009 & Is 456 - 2000Документ4 страницыMix Design M25 Grade Designed As Per Is 10262 - 2009 & Is 456 - 2000narasimha salihundamОценок пока нет

- Concrete Mix Design, Is StandardДокумент12 страницConcrete Mix Design, Is StandardKumaresvaranОценок пока нет

- EvsДокумент52 страницыEvsSumit VermaОценок пока нет

- Dumb AssДокумент2 страницыDumb AssAbhilash KumarОценок пока нет

- DumbassДокумент2 страницыDumbassAbhilash KumarОценок пока нет

- Australian Sizes: D - Deformed Bar - Grade 300 300 Mpa N - Normal 10Документ2 страницыAustralian Sizes: D - Deformed Bar - Grade 300 300 Mpa N - Normal 10mrinmoyОценок пока нет

- Dumb DumbДокумент1 страницаDumb DumbAbhilash KumarОценок пока нет

- Industrial ShedДокумент7 страницIndustrial ShedAbhilash KumarОценок пока нет

- Fucking DumbДокумент1 страницаFucking DumbAbhilash KumarОценок пока нет

- New Doc 2018-01-06Документ1 страницаNew Doc 2018-01-06Abhilash KumarОценок пока нет

- Ccat Booklet Cv1Документ37 страницCcat Booklet Cv1Abhilash KumarОценок пока нет

- Csmrs Training ReportДокумент73 страницыCsmrs Training ReportAbhilash KumarОценок пока нет

- Steel CombinationДокумент14 страницSteel CombinationAbhilash KumarОценок пока нет

- No. of StationДокумент6 страницNo. of StationAbhilash KumarОценок пока нет

- Seek Suspense Within ConceptДокумент1 страницаSeek Suspense Within ConceptAbhilash KumarОценок пока нет

- Self-Healing ConcreteДокумент17 страницSelf-Healing ConcreteAbhilash KumarОценок пока нет

- Mix ConcreteДокумент47 страницMix ConcreteAbhilash KumarОценок пока нет

- Nansulate For Energy Efficient WindowsДокумент5 страницNansulate For Energy Efficient WindowsbulentbulutОценок пока нет

- Reality Lighting 2022 灯饰目录Документ277 страницReality Lighting 2022 灯饰目录qq1691492197Оценок пока нет

- SFD N004 2013 PDFДокумент21 страницаSFD N004 2013 PDFMohamed Abo-ZaidОценок пока нет

- TE 1 Notes PDFДокумент196 страницTE 1 Notes PDFfatigue puttaОценок пока нет

- MODULE 3 - Pertinent Building Laws and RegulationsДокумент45 страницMODULE 3 - Pertinent Building Laws and RegulationsCammyОценок пока нет

- Domestic Timber Deck Design: Technical Design Guide Issued by Forest and Wood Products AustraliaДокумент24 страницыDomestic Timber Deck Design: Technical Design Guide Issued by Forest and Wood Products AustraliaHaibo LVОценок пока нет

- Pawling - Entrance MatsДокумент12 страницPawling - Entrance Matsmk779900mkОценок пока нет

- Seismic Analysis of Reinforced Concrete Shear WallsДокумент6 страницSeismic Analysis of Reinforced Concrete Shear WallsShrishail SambanniОценок пока нет

- ACI 350 CalculationДокумент3 страницыACI 350 CalculationBoris GalindoОценок пока нет

- Revised Malaysian Code of Timber StructuresДокумент6 страницRevised Malaysian Code of Timber Structuresmcwong_98Оценок пока нет

- Ccip Ec2 BridgesДокумент140 страницCcip Ec2 BridgesnuОценок пока нет

- CVE4002 Lecture 05 Timber FramingДокумент67 страницCVE4002 Lecture 05 Timber FramingKeith YangОценок пока нет

- Vahterus Plate and Ring Prhe-EnДокумент4 страницыVahterus Plate and Ring Prhe-EnMartin CorkeryОценок пока нет

- Acson Catalogue Air Handling Unit 1201 PDFДокумент12 страницAcson Catalogue Air Handling Unit 1201 PDFfaiz budiОценок пока нет

- Astm A560Документ5 страницAstm A560MAX ALBERTO JUAREZ AVALOSОценок пока нет

- New Ansi 118.15Документ2 страницыNew Ansi 118.15Tensile TestingОценок пока нет

- 15 Church Street - BC IssueДокумент67 страниц15 Church Street - BC Issuemarlonmasudog.jrОценок пока нет

- Mechanical Properties of SteelДокумент1 страницаMechanical Properties of SteelrianrureОценок пока нет

- Tabla 310.15 (B) (16) - Ampacidades PDFДокумент1 страницаTabla 310.15 (B) (16) - Ampacidades PDFDettagli GuateОценок пока нет

- Astm A319.370238-1Документ2 страницыAstm A319.370238-1Fabio Augusto Hincapie Henao100% (1)

- KS3 TestДокумент6 страницKS3 TestVytheeshwaran Vedagiri80% (5)

- Concrete Kerb Specification SheetДокумент1 страницаConcrete Kerb Specification Sheetyamanta_rajОценок пока нет

- Joints in Steel Construction - Simple Connections - Part 22 PDFДокумент1 страницаJoints in Steel Construction - Simple Connections - Part 22 PDFkakem61Оценок пока нет

- Thermodynamics Problems PDFДокумент21 страницаThermodynamics Problems PDFSubhash KorumilliОценок пока нет

- Condenser: Lesson 3 Lesson Title: Learning Outcomes: at The End of The Lesson, Students of BTLE Will Be Able ToДокумент37 страницCondenser: Lesson 3 Lesson Title: Learning Outcomes: at The End of The Lesson, Students of BTLE Will Be Able ToAliceОценок пока нет

- Cable truss structures overviewДокумент30 страницCable truss structures overviewlarisa_bucatariuОценок пока нет

- Low Cost Housing Report 3 GateДокумент71 страницаLow Cost Housing Report 3 GateS.K. Recruiting100% (1)

- FogbugzДокумент15 страницFogbugzLim Wee BengОценок пока нет

- ASTM STP538 - Cleaning Stainless SteelДокумент11 страницASTM STP538 - Cleaning Stainless SteelPeter FowlesОценок пока нет

- Computational Fluid Dynamics Simulation of The Progress of Fire Smoke in Large Space, Building AtriaДокумент7 страницComputational Fluid Dynamics Simulation of The Progress of Fire Smoke in Large Space, Building AtriaAravind KumarОценок пока нет