Академический Документы

Профессиональный Документы

Культура Документы

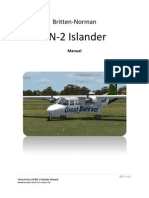

BN Islander Familiarisation Course

Загружено:

Ammar A. AlliИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BN Islander Familiarisation Course

Загружено:

Ammar A. AlliАвторское право:

Доступные форматы

Art Williams and Harry Wendt Aeronautical Engineering School 1

ISO 9001:2008

Certified QMS

BN-2 Islander Familiarisation Course

Introduction

The Islander is a conventional twin engine, High wing Aircraft of all Metal Construction.

The fuselage is of Semi Monocoque construction built up of fabricated frames and Span

wise stringers

Design and development

Design of the Islander started in 1963 and the first prototype BN-2 first flew on 13

June 1965, with the second prototype on 20 August 1966. Both of these had engines

that were less powerful than the production versions. The first production Islander

first flew on 24 April 1967.

General Characteristics

Crew: one or two pilots

Capacity: up to nine passengers

Length: 35 ft 8 in (10.86 m)

Wingspan: 49 ft (14.94 m)

Height: 13 ft 9 in (4.18 m)

Wing area: 325 ft (30.2 m)

Empty weight: 3,588 lb (1,627 kg)

Loaded weight: up to 6,600 lb BN2A-20 onwards (2,994 kg)

Max takeoff weight: 6,600 lb (2,994 kg)

Powerplant: 2 Lycoming O-540-E4C , 260 hp (195 kW) each

Issue: 1, Revision: 1 Aircraft Fam. Course (BN-2 Isl) January 3, 2011

Art Williams and Harry Wendt Aeronautical Engineering School 2

ISO 9001:2008

Certified QMS

Performance

Maximum speed: 170 mph (273 km/h)

Range: 874 miles (1,400 km)

Service ceiling 13,200 ft (4,024 m)

Rate of climb: 970 ft/min (295 m/min)

Wing loading: 2 lb/ft (9.78 kg/m

Variants

BN-2A Mk III-1 : First production version.

BN-2A Mk III-2 : Lengthened nose and higher operating weight

BN-2A Mk III-3 : Variant certified for operation in the United States

BN-2A Mk III-4 : III-2 fitted with rocket-assisted takeoff equipment

Trislander M : Proposed military version.

Lycoming O-540

The Lycoming O-540 is a family of six-cylinder, horizontally opposed aircraft engines

of 540 cubic inch (8.8 l) displacement, made by Lycoming Engines.

The fuselage

The fuselage is an aircraft's main body section that holds crew and passengers or

cargo.

The semi-monocoque fuselage is constructed from fabricated frames, longitudinal

stringers, longerons and stressed skin. The fuselage has seats for two pilots, operators

consoles and their seats. The cabin floor can have detachable tie-down rings installed.

Issue: 1, Revision: 1 Aircraft Fam. Course (BN-2 Isl) January 3, 2011

Art Williams and Harry Wendt Aeronautical Engineering School 3

ISO 9001:2008

Certified QMS

The avionics/electrical bays are installed forward of the windshield. Three main access

doors are installed in the center fuselage, two on the left and one on the right. An

access door for the rear avionics compartment is installed in the rear fuselage on the

left. Two large access panels are installed in the rear fuselage on the right. The front

panel gives access to the cabin heater, equipment racks and general access to flying

controls.

The rear panel gives access to the main battery. This panel has a small hinged access

panel to give quick access to connect/disconnect the battery.

The front left door gives access to the two flight compartment seats which have

inertia reel seat belts.

Most of the instruments are on the main instrument panel. Primary flight instruments

are grouped in front of the left pilots seat and repeated instruments in front of the

right seat. The engine instruments are grouped in the center of the panel. Controls

and indicators for aircraft systems are installed on two other panels. One is located

below the left side of the main instrument panel and the other in the roof.

The roof panel is installed above and forward of the seats. Manually-operated

elevator and elevator trim, rudder and rudder trim and aileron controls are installed in

the flight compartment. The aileron trim is electrically operated. The flap system

operates electrically through a flap selector switch on the center console.

Empennage

Empennage is a term used to describe the tail portion of an aircraft. ("Empennage",

"tail", and "tail assembly" may be interchangeably used.) The empennage gives

stability to the aircraft and controls the flight dynamics: pitch and yaw.

Issue: 1, Revision: 1 Aircraft Fam. Course (BN-2 Isl) January 3, 2011

Art Williams and Harry Wendt Aeronautical Engineering School 4

ISO 9001:2008

Certified QMS

The landing gears

The main gears consists of an oleo pneumatic Struts (oil and Air operated). Its main

function is to support the aircraft on the ground during maneuvering and to absorb

the impact shock on landing.

Its a dual wheel assembly construction and has independent brake systems which are

operated by the Brake/rudder pedals in the cockpit

Nose gear

This assembly is use also to support the aircraft during maneuvering on the ground

and to absorb the shock of landing.

It is a single wheel assembly and is steerable by the use of cables which is also

connected to the rudder pedals.

Wings

The one-piece cantilever wing is made from pressed rib sections, fabricated spars,

span-wise stringers, machined plating and stressed skin plating.

The left and right engine recesses have stainless steel firewalls. There are two wing

fences installed. Each main landing gear tube is installed in a block in the wing and a

fitting in the nacelle structure.

Two integral fuel tanks in each wing form part of the wing between the front and rear

spars and outboard of each engine nacelle. The fuel tanks are sealed sections of the

wing structure. The inner fuel tank is the main tank and the outer fuel tank is the

transfer tank. Each tank has a fuel vent system.

The wing is attached to the fuselage by two main attachments on each side at the

front and rear spars, a drag-angle bracket and a shear attachment angle. Fairings are

installed at the leading and trailing edges to keep the aerodynamic profile at the wing-

to-fuselage intersection.

Issue: 1, Revision: 1 Aircraft Fam. Course (BN-2 Isl) January 3, 2011

Art Williams and Harry Wendt Aeronautical Engineering School 5

ISO 9001:2008

Certified QMS

These fairings wrap around the undersurface of the wing. The wing has under wing

hard points to attach under wing stores.

The Flight Controls

The flight controls consists of manually operated Ailerons, elevator, rudder and

electrically operated single slotted trailing edge flaps.

Aileron control is effected by manual movement of a conventional control wheel

attached through a sliding column to a Y shaped yoke

Movement is transferred from the cockpit via Pulleys, Cables, bell cranks and push

rods.

Flap Control

The wing flaps are movable panels on the inboard trailing edges of the wings. They are

hinged so that they may be extended downward into the flow of air beneath the

wings to increase lift and drag. Their purpose is to permit a slower airspeed and a

steeper angle of descent during a landing approach. In some cases they are also used

to shorten the takeoff distance.

The Flap control is electrically controlled by a motor and is actuated by a switch

located beneath the engine controls center pedestal

Rudder control

It is a movable surface hinged to the fixed surface that is located at the rear of the

aircraft called the vertical stabilizer, or fin. The rudder controls movement of the

airplane about its vertical axis and causes the airplane's nose to move to the right or

left and point in a different direction. This motion is called "yaw."

Issue: 1, Revision: 1 Aircraft Fam. Course (BN-2 Isl) January 3, 2011

Art Williams and Harry Wendt Aeronautical Engineering School 6

ISO 9001:2008

Certified QMS

Trims

Elevator Trim This a moveable tab attached to trailing edge of the elevator, It is

controlled by a wheel, chain and sprocket assembly located in the cockpit. Stbd of

the center console.

Rudder Trim This also a moveable tab of the same features as above. Located above

the pilots head in the cockpit.

Aileron trim This is a fixed tab cannot be adjusted from the cockpit may be located

on the Stbd Aileron adjust when on ground if a heavy wing condition exits.

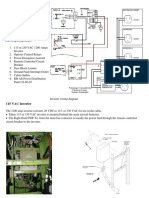

Electrical System

Attached to each engine is a Belt driven self rectifying alternator These are

controlled by individual circuitry and is independent of each other.

An aux source of power is provided by and internal 28 V DC Lead acid Battery, this is

located in the Avionics bay, the avionics bay is located in the Nose section of the

aircraft. The alternators are used to keep the battery fully charged.

Issue: 1, Revision: 1 Aircraft Fam. Course (BN-2 Isl) January 3, 2011

Вам также может понравиться

- LearJet-LJ31-31A PTM V2r2Документ364 страницыLearJet-LJ31-31A PTM V2r2Christiano Santos60% (5)

- PA31-350 POH For Operational Training OnlyДокумент238 страницPA31-350 POH For Operational Training OnlyPumba88100% (6)

- Challenger 601 ChecklistДокумент126 страницChallenger 601 Checklistgerezair100% (2)

- Century IservicemanualДокумент25 страницCentury IservicemanualJessica Stanton Aahcc0% (2)

- GTX335 - Ica - 190-00734-21 - 01Документ122 страницыGTX335 - Ica - 190-00734-21 - 01Cristhian342Оценок пока нет

- Training A320 StructureДокумент706 страницTraining A320 StructureMUHANDES UKRAINE100% (5)

- Britten Norman Islander Maintenance Manual Chapter 2.6 1/3Документ34 страницыBritten Norman Islander Maintenance Manual Chapter 2.6 1/3Keron George83% (6)

- Cessna Citation - X Ice - and - Rain Protect PDFДокумент10 страницCessna Citation - X Ice - and - Rain Protect PDFjuan100% (1)

- Cessna Citation X-ElectricalДокумент19 страницCessna Citation X-ElectricalTony NicholasОценок пока нет

- Bonanza 36 Parts 614Документ2 632 страницыBonanza 36 Parts 614José A. Montiel QuirósОценок пока нет

- Proline 21 h800 Cap 34Документ327 страницProline 21 h800 Cap 34danielОценок пока нет

- LEARJET 45 AC Electrical SystemДокумент4 страницыLEARJET 45 AC Electrical SystemRAFAEL MANZANILLAОценок пока нет

- 690a.b MMДокумент749 страниц690a.b MMJOSE ESCOBAR100% (1)

- Assignment 5Документ7 страницAssignment 5José A. Montiel Quirós0% (1)

- Manual BN2 enДокумент52 страницыManual BN2 enwalneysld33% (3)

- BN 2 Flight Manual PDFДокумент269 страницBN 2 Flight Manual PDFTongzkey Maraviles100% (1)

- Cessna 421 Updated Manual List As of June 2017Документ6 страницCessna 421 Updated Manual List As of June 2017Elmer VillegasОценок пока нет

- Aircraft Maintenance Manual BO 105-DikonversiДокумент4 страницыAircraft Maintenance Manual BO 105-DikonversiDwi Margono0% (1)

- General Aviation Antennas Catalog PDFДокумент254 страницыGeneral Aviation Antennas Catalog PDFrobbertmd100% (1)

- Quest Kodiak 100 - ChecklistДокумент3 страницыQuest Kodiak 100 - ChecklistJoão Santos100% (1)

- Pom Pa31-350Документ277 страницPom Pa31-350luiguias100% (1)

- PA31Документ9 страницPA31dagger21100% (3)

- LYCOMING O & LO-360 (76 Series) Parts Catalog PC-123 PDFДокумент29 страницLYCOMING O & LO-360 (76 Series) Parts Catalog PC-123 PDFBrunoОценок пока нет

- Pietenpol Sky ScoutДокумент11 страницPietenpol Sky Scoutconfused597100% (4)

- A-P-Technician-Airframe - PDF Edit PDFДокумент855 страницA-P-Technician-Airframe - PDF Edit PDFSahil Sharma100% (1)

- Cessna 210 Centurion 1970-1976 MM D2004-5-13Документ630 страницCessna 210 Centurion 1970-1976 MM D2004-5-13Anonymous qqRhxjYhssОценок пока нет

- Cessna 340: - Number 2 - February 2004Документ14 страницCessna 340: - Number 2 - February 2004Luis AndViОценок пока нет

- CRJ Poh 12 01 2008 PDFДокумент780 страницCRJ Poh 12 01 2008 PDFGeoffrey MontgomeryОценок пока нет

- Commander Package 2013Документ20 страницCommander Package 2013Carlos Marquez100% (1)

- Flight Simulation Emagazine: ReviewДокумент9 страницFlight Simulation Emagazine: Reviewprivateaerospace0% (1)

- 7GCBC PohДокумент75 страниц7GCBC PohEyal Nevo100% (1)

- PAT130A1 - Pratt Whitney Canada JT15D Archived SEPДокумент6 страницPAT130A1 - Pratt Whitney Canada JT15D Archived SEPDoor UR100% (1)

- Cessna Citation Jet-Landing Gear and BrakesДокумент11 страницCessna Citation Jet-Landing Gear and BrakesMamta KumariОценок пока нет

- Cessna 525 Citation JetДокумент53 страницыCessna 525 Citation JetStroie Alina100% (1)

- Gulfstream SV PFDДокумент3 страницыGulfstream SV PFDArslanKhan100% (1)

- Operation Manual For Cessna 120 140Документ52 страницыOperation Manual For Cessna 120 140Sidney Gianini JuniorОценок пока нет

- Class and Type Ratings Aeroplanes070605Документ10 страницClass and Type Ratings Aeroplanes070605Jasper KleinОценок пока нет

- Learjet A&E 35A-339Документ54 страницыLearjet A&E 35A-339Lucas AlvesОценок пока нет

- ATP IndexДокумент2 238 страницATP Indexernesto rodriguez100% (1)

- BD-700 MMEL Ver9Документ165 страницBD-700 MMEL Ver9ShinYamaОценок пока нет

- Metro 3 Operating Tips PDFДокумент18 страницMetro 3 Operating Tips PDFFatih Iscan100% (1)

- Installation Bulletin: Bulletin No: 385 APPLICABLE TO: KAP 150 and KFC 150 Flight Control Systems SubjectДокумент4 страницыInstallation Bulletin: Bulletin No: 385 APPLICABLE TO: KAP 150 and KFC 150 Flight Control Systems SubjectKumaraswamy RSОценок пока нет

- G1000 KingAirC90 G1000 GFC700PostInstallationCheckoutProcedureДокумент109 страницG1000 KingAirC90 G1000 GFC700PostInstallationCheckoutProcedureWilly GrОценок пока нет

- Section 7 - Figures: Air Tractor, Inc. Figures Page 7-I AT-802/802A June 21, 2018Документ129 страницSection 7 - Figures: Air Tractor, Inc. Figures Page 7-I AT-802/802A June 21, 2018Nal Almeida100% (1)

- MMEL LR60 Rev 5Документ102 страницыMMEL LR60 Rev 5Honorio Perez MОценок пока нет

- Suppl 120 EFIS EFI-890RДокумент12 страницSuppl 120 EFIS EFI-890Rsisko320100% (2)

- Shadin PDFДокумент35 страницShadin PDFAndrea VCorroОценок пока нет

- Hawker 800xp SpecsДокумент5 страницHawker 800xp SpecsCooper L100% (2)

- Turbo Commander MELДокумент53 страницыTurbo Commander MELAndre Peli100% (5)

- Big Airplane Safety A Cessna 340 340a Buyers GuideДокумент12 страницBig Airplane Safety A Cessna 340 340a Buyers Guidelolo laurent100% (1)

- Piper Parts Manual 761-589Документ471 страницаPiper Parts Manual 761-589Juan Manuel García100% (1)

- Vdocuments - MX - Pilatus Maintenance Organisation Capability List 2019 09 18 31 c13 AstrДокумент29 страницVdocuments - MX - Pilatus Maintenance Organisation Capability List 2019 09 18 31 c13 Astrbatteryshop100% (1)

- PRIMUS Digital Weather Radar System, Rev. 3 - 01.2006Документ168 страницPRIMUS Digital Weather Radar System, Rev. 3 - 01.2006Łukasz100% (1)

- Cessna 340 340AДокумент8 страницCessna 340 340Ajoserufoperezarias100% (2)

- Aerobask Phenom 300 - PerformancesДокумент83 страницыAerobask Phenom 300 - PerformancesInge AeronáuticoОценок пока нет

- Mooney M20E InspectionДокумент14 страницMooney M20E InspectionJavier100% (1)

- Bombardier Challenger Global 00-Powerplant PDFДокумент30 страницBombardier Challenger Global 00-Powerplant PDFJesus GonzalezОценок пока нет

- CE500 Note Taking Guide v1.12Документ16 страницCE500 Note Taking Guide v1.12MiguelОценок пока нет

- Pa-44 1995 Poh PDFДокумент377 страницPa-44 1995 Poh PDFMaximiliano Obach Schwemmer100% (1)

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsОт EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsОценок пока нет

- AETДокумент267 страницAETAmmar A. AlliОценок пока нет

- Cessna 208 Fam CourseДокумент7 страницCessna 208 Fam CourseAmmar A. Alli100% (1)

- Cessna 206 Familiarisation CourseДокумент4 страницыCessna 206 Familiarisation CourseAmmar A. AlliОценок пока нет

- Cessna 172 Familiarisation CourseДокумент4 страницыCessna 172 Familiarisation CourseAmmar A. AlliОценок пока нет

- Cessna 185 Familiarisation CourseДокумент5 страницCessna 185 Familiarisation CourseAmmar A. AlliОценок пока нет

- 11Документ5 страниц11ccoyureОценок пока нет

- Document No. T51-08-DOC-0002-A Date: 12/9/2009 Page 1 of 1Документ4 страницыDocument No. T51-08-DOC-0002-A Date: 12/9/2009 Page 1 of 1Steven PentonОценок пока нет

- Tecnam P2002 Sierra Deluxe - Flight ManualДокумент70 страницTecnam P2002 Sierra Deluxe - Flight Manuallegoulu0% (1)

- 412 MM CH53 PDFДокумент24 страницы412 MM CH53 PDFpancaОценок пока нет

- Ata 56 - Windows CorДокумент15 страницAta 56 - Windows CorIdrisОценок пока нет

- Basicaircraftstructure 110325070203 Phpapp02Документ36 страницBasicaircraftstructure 110325070203 Phpapp02Kv PavanОценок пока нет

- Bruhn 73 C4Документ28 страницBruhn 73 C4brhОценок пока нет

- Composite Materials in The Airbus A380 - From History To FutureДокумент10 страницComposite Materials in The Airbus A380 - From History To FutureAhmet SönmezОценок пока нет

- Aircraft Structures NotesДокумент31 страницаAircraft Structures NotesSenthil KumarОценок пока нет

- Fieseler Storch EngДокумент14 страницFieseler Storch EngMiguel GómezОценок пока нет

- SRM 51-00-00 226 7 R20Документ4 страницыSRM 51-00-00 226 7 R20leibnitz garciaОценок пока нет

- 05 10 10 inДокумент34 страницы05 10 10 inÜmit KazanОценок пока нет

- Vijay BS - ResumeДокумент2 страницыVijay BS - ResumeJoel AndrewsОценок пока нет

- Dgca Module 11 Part 02 PDFДокумент21 страницаDgca Module 11 Part 02 PDFBhaskerNegiОценок пока нет

- Aircraft Painting Centre Painting Process Document: Publication No QA/DOC/094Документ32 страницыAircraft Painting Centre Painting Process Document: Publication No QA/DOC/094Jimmy HaddadОценок пока нет

- 282 Group PaperДокумент15 страниц282 Group Paperapi-538048965Оценок пока нет

- Principles of AviationДокумент15 страницPrinciples of AviationDzharl RingkaОценок пока нет

- 1961 08 10Документ8 страниц1961 08 10Uroš RoštanОценок пока нет

- Oscar Ho F18Документ116 страницOscar Ho F18MirkoОценок пока нет

- Dassault Falcon 000dx Ex StructureДокумент30 страницDassault Falcon 000dx Ex StructureAB1984Оценок пока нет

- Design and Construction of A Composite Airframe For UAV ResearchДокумент87 страницDesign and Construction of A Composite Airframe For UAV ResearchItgeltbayarОценок пока нет

- StructureДокумент352 страницыStructurebeyramiОценок пока нет

- Pietenpol Air CamperДокумент16 страницPietenpol Air CamperricardoОценок пока нет

- Taylorcraft Service Manual BB12Документ48 страницTaylorcraft Service Manual BB12Jessie BechaydaОценок пока нет

- Ac 65-15aДокумент623 страницыAc 65-15aAlejandrito SegundoОценок пока нет