Академический Документы

Профессиональный Документы

Культура Документы

Design Calculation Pipe Rhicknes Bop Piping

Загружено:

Wisnu Setiawan0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров19 страницPipe Thickness calculation for BOP Piping PLTU Rote 1x3 MW

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPipe Thickness calculation for BOP Piping PLTU Rote 1x3 MW

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров19 страницDesign Calculation Pipe Rhicknes Bop Piping

Загружено:

Wisnu SetiawanPipe Thickness calculation for BOP Piping PLTU Rote 1x3 MW

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 19

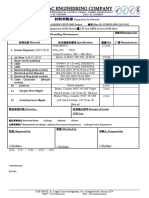

Engineering Manager

civil/structure Chief Manager

Mechanical Chief Manager

Electrical Chief Manager

Procurement Manager

Project Manager

Marketing Manager

PPC Manager

Production Manager

HH

a/c Man

Document Control

Project Manager

H

Engineering Manager

a

iz

a

Document Control

CONSORTIUM ZUG ~ WASKITA KARYA

JI. Rawa Melati Blok AI No. 5 Tegal Alur, Jakarta Barat 11820

Tel. +62-21 55952077; Fax. +62-2155951873

Email pltu_rote@yahoo.com

PT. PLN (PERSERO)

UIP. KITRING NUSRA

PT. ZUG Indu

Pipe Thickness Calculation Main Steam Pipe

PLTU Rote 2x3MW-

oo

oes

bee, | feted

fete ear OT |e] asf

ei na | aos

ee

ie

Lets ro [ose

Sse aie [sues

jin

aT

(n/s) a = selected | preferable 30~60(a/s)

Simctin tase] ae oe

lbw un) ee eee [s-594. 54 (QHV/W)

(as) 41.2 41.2 o=QeV/ (© /594, 7)?

psicier ie | ae | aw berae warn

tb was of

deviation Clam [estenlates|

———— O12 on calculated |steam water pipe, and 0.5 in|

Pest ticaeea Cola) Jcommon, and the others are

aad xiao

|thickness of pipe _S (am) at .

aia ae eet} =}

7 ew

" |Friction=A#¥°(1/V)/(2e®/1

ee Fie

rictional resistance check

lcoefficient A Lkliad 0.0196 rable

resistence of valve ond

pine fittings bar ey setts

eauivatent 1ength of valve

and pine fietinas

Triction ave

Tellge pas z 7 fetested

parca resistance eneck

Icoefficient ‘ 1 [table

subtotal partial resistance

Jcoefficient e ‘

— - T—ontected 4

partial resistance 7 ae eneek

octet atte

socal partial resistance

efficient 2 a

redvcor plese n facta

parcial resistance ‘check

lcoefficient es 03 beable

estore partial resistance

fficient e Ls

valve piece z 7 etecead

partial resTntance, check

Icoefficient os 05 rable

Jsubtotal partial resistance

poet icient

JG Industry Indonesia

Pipe Thickness Calculation Main Feed Water Pipe

PLTU Rote 2x3MW

litolier main boiler feedwater pipeline

feed water

> to boiter| pipeline to

iP

selected pipeline 60x 5 | _Ob0xE

| Flow @ Gat B Z seecied

design pressure Pibarg) 2 a selected

Design temperature TCC ) | 160 105 | “selected

edie secitic votive VT onions | o.coiou4 | _teckup

‘pipe materials 06 Geb_|Ai06 G

Desian temperature of ;

lsteel with stress - Mpa ed er cd

Weld correction factor io no Lookup

JAlowable stress that the

eae Baa) 04 0.4 Lookup

,_[eaeuate the diameter

pipetine

Jbesian velocity ¥ (w/s) 3 3 selected | [Prefersbl

leatcutated dianeter sare root oF

eal 53.1 32.0 | Caleuation |, 1st "2" of

i ceranmeel 60 60 53 o-ciz-2eca

fee eta flor rete 30 29 =D (17/598, 74E1/504.7)

[3 [wall thickness calculation I

erase 1.64 1.62 | Calculation pr-rovees a var

Joulation Stam

Pine wall thickness

jnegative deviation added | 0.29 0.29 | caleuation fo. 765 frst. ves

lvelue Cl om

ea-corrostn

evice tite, st

Pie wall thickness oe pane eam fr st

Jcorrosion margin C2 mm peer

Jand the others

lite thietr.

Pine wall thickness

Jealeulation of at least. | 219 2.30 | Calculation

Is Com)

[Solection of pipeline wall 7

thickness (ax) es SS

a pipeline Length a) i

[channel resistance (bar Tis lear

jstraight pipeline »

|" resistance (bar ca °

straight pipeTine Length L] aq a aay

ca)

Than the friction —bar/a | 0.0205 | 6.0319,

Friction drag coefficient | ¢.oxg4 | 0,008 | Loomup

a

[valve pine

Jo) |rittings, eteresistance Lema | 0.760

bar

1 elbor Ga) [ 15 5 selected

local Friction drag a

eles 0.3976 | 0.9978 | Lookup

subtotal Local Friction

coofficient 5.968 188s

2 Diverges three (set) r o selected

local Friction drag

Ee eee 13 13 Lookup

‘subtotal Local Friction

coefficient ES °

3 Tapered pipe (et) 3 o selected

erleal Friction drag at an Lookup

subtotal Local Friction

larax coefficient °° :

[Globe feheck

4 valve Gate valve [fiebe _ fehecke

count 5 2 o 2 |setectea

Tocal Friction drag

ae 5 5 os fs Ir Lookup

‘subtotal Local Friction

Jicag coefficient 2 a oes i

[> Itevel Discrepancy Bar) [a0 0 selected

Regulating valve

to fRegelets wn 4.0 0.0 Lookup

heater Bar) 2.00

boiler feed water pipeline

ead water

1 10 totter [pipetine to

i

feed pane Sos | amas

Ti go Zz oat

besign asome Pang) [12 72 | seeded

Design temperature TC) [160 ios [ele

edn specific valve V

=e ‘.oor08ss | a.oo10m | Lookup

ide mate ome —[ nea

Pesien teparstare of

[steel with stress — Mpe ea may Lookup

Weld correction fate 1 Tt} oot

towable ress thatthe

Alowable ses a4 a4 | tock

7 fata Te dave

ne

estan velocity ¥ as) 3 2 | selected |proferatie

pe

sisi? eimier ai | s20 | cate | ae wert ee

elect the Tanter

a % 60 sa [evcrr-oncas

ectal sea Tow Tate =e

ecaly a0 28 Se

wal mines ca T

Pie wall thickness wor

ae Let Le __| cataaton a8 nary

Pipe wall thickness

eestive deviotion added | 0.29 0.29 | caetton | 0,169}.

alae Cla

ercarrsin marta # destin sree

pine watt thickness oe oe | coaaton fits tetra ter ie

era rats lata saan eu sare

bre tke

Pipe wall ictavas

tevlation of at least | 2.19 20 | caeuation

an)

Boection of pipeline wall

Ithickness (am) i ae

aol Looe [ a i

fel tanisance ts) —[ BL LE oa ea

trate pipeline , al

© |roststance (bar ) bad

sraleht pipeline Teostht] ap eo

io :

Thay te Rico tae | —Laa —|

Friction arr wetficiot Tp eanr | oom | tzoap

Natve pine

c|ettcingsetcresistace | 1.489 | 0.951

ss

aber ete 7 [aed

Local Friction raz [9 grg | 9078 | Lookup

fabtatal Lacal PTetion

cag_coef ficient eee ee)

2 Diverges three (et) i 0 selected

Local Friction drag

Sa Ls 15 Lookup

subtotal Local Friction

larag_coofticient Ee a

3 Tapered pipe (set) 3 0 wleded

local Friction drag

ee 03 0.3 Lookup

subtotal Local Friction

larag coefficient eo :

4 valve Gate valve [élobe valve | Sheek

valve

cS 5 3 ° 7 2 selected

Tocal Friction drag ;

ef icient 5 so} ° 7 tote

subtotal Local Friction

[enteat tered a 2 ° 35 u

@ |tevel Discrepancy (Bar) oo oo wleded

Regulating valve

co fegniatin = 4.0 0.0 Lookup

SL [uP hoster (Ban oo

2 Diverses three Get) i selected

Local Friction drag

efficient es Lookup

subtotal Local Friction i

larax_coofticien e

3 Tapered pipe (Get) @ selected

Local Friction drag

lcootficient = Lookup

subtotal Local Friction A

lavag_cootticient

check

4 valve Gate valve [Globe valve

valve |

cont 2 ° 1 [selected

Tocal Friction drag

coefficient as if ike

subtotal Local Friction

laren cosftieient S z eo a

@ ievel Discrepancy Gar) a0 sweced

u [Resuloting valve resistance ma Too

(Bar)

Cp

Pipe Thickness Calculation Low Pressure Feed Water Pipe

PLTU Rote 2x3MW

low pressure feed water pipeline 1.

deseretor

to feed ps0

\selected pipeline OB9x4

1_| Flow Q {t/b) 22 selected

design pressure _PQbarg)— 12 selected

Design temperature TOC ) 15 selected

lsedia specific valve V

ee 4. c01048 Look

pipe makers sm |

Design teaporature of sol

lwith stress ~ Mpa wee Lookup

Wold correction factor To Took

PAlowable sess thatthe bade

en ot Lookup

2_|caloulate the diameter pipeline

Jesign veloci' (n/s) ppretaralils)

|Design velocity W (m/s) 1.5 selected [p59

siento aanoe 7.7 | elation | eure vn af 8 7

Select tho Gianotor ;

ae © e__[escrr-aecoe

eee 12 tn o604

wal tines atation

ie well thickness

lcalculation S1_Cum) 008 cane

Pie wal thickness

egetive devition add ot Catetaion | 0. 1765fsero728 asm

value Cl an

Pipe med thtekness 10 Calculation S190. 1765

corrosion margin C2 am

(eres en pemeeeey Nite te ts0 for summer lps,

Jealculation of at Least 1.05 Cateuton [if if, 8 for see mee oe

Scam ie titer

Selection of pipeline wall

thickness (mm) a

Dosim pipeline Teaghe) oi

TJetanne] resistance (bar) Ti La

straight pipeline

© Tresistance (bar ) eu

straight pipoline Tenath ‘i a

(mn)

Than-the-frctTonbar/a To

rieton drag oeiciont 0286 ‘okay

Naive pipe

© Wrictings, etoresistance bar =

elbow Ga) 5 sleded

Tocal Friction dra

coefficient es Lookup

subtotal Local Frletion ae

licag coefficient

Pipe Thickness Calculation First Stage Steam Extraction Pipe

PLTU Rote 2x3MW

[] iss sate stem entation pipe

1# steon | 2F steam

turbine | turbine

selected pipe ©16x3 | ©7633,

2.5" 2.5"

1_|steam flow Q___ (om) * oe

Jactual media Tow rate

o/s) 28.8 28.8

calealation of pipe

lll thickness

Jcalcalated thickness of calealate [ayaa aay

ine wall Si (om) _|_-8 O08 a ‘

additional value of

ulate

pipe wall thickness 0.01 aor |oaleutete er sion 67

negative deviation Clam

[corrosion sarin ©

lesign sevice life, #

corrosion margin of pive caleulate fis 0 for stean rotor

jrall thickness C2 am oa GS a foie, en 0.8 tn

mon, athe thers

caleulated ainimm calealate

0.45 0.45

thicknoss of pipe Sam) a

selected thickness of Med] celiac

pine

desta pipe Length Ge 3 Ea

irotal pipe resistance a a

[straight pipe resistance

o [& 0.13 0.13 Pp-tstriction

Lest oF staleht pipe e aun |e

7 ; Tawa 7771000

Friction _bar/a 0.0035] 0.0035 fe

frictional resistance check

lcoefticient A 0084 | 028 rable

resistance of valve and

® Iie fittings bar oat ot

Jequivalent length of

lvalve and pipe fittings

)

Friction bar/m

1 elbor Des 2 2 |relected

partial resistance 5 check

lcoefticient 0.3976 | 93976 rable

subtotal partial 5

esistance coefficient | * 574 | 3.5784

2 Tee p z 2 [selected

partial resistance leheck

coefficient ue 13 trabie

subtotal partial

sistance coofficiont As bad

Is reducer piece r 1 [selected

partial resistance Jeneck

oofficient o8 08 Irae

Jsubtotal partial

esistance coofficient 08 os

It valve piece i 1 |relected

partial resistance 7 Jcheck

coefficient ie 15 table

subtotal partial

resistance coefficient ue zee

Bar

© | squia tevet difference |__°? 0.0 [selected

vw fresistance of regulating | 9 4 eau eee

valve Bar

ESA

Pipe Thickness Calculation Third Stage Steam Extraction Pipe

PLTU Rote 2x3MW

‘Third steam extraction pipe

1# twbine | 28 cabin

selected pipe 1334 | 13394

i =

1 |stean flor @ G7) 238 0.98 | selected

léesign stean pressure

(berg) ae eu estimated.

Jcesign steam temperature

Ir cc) 7 St | estinated

specific volume of steam eheck

canes 2.905 2.05 | check

material of selected

loipe 538 A538

allowable stress of n

steel under design 129.5 129.5 nee

temperature Moe table

correction factor of check

welding seam zo mu tab).

basic allonable stress oa a check [=e 4,

correction factor _ table [5100.5 , 538°C 240.7

caloulation of pine

2 laiamoter

ldesign flow rate W

(m/s) ci Q selected |reterable 30~60

calculated pipe dianeter sauare root of

pw (om) 184 126-4 [oaleulace Iason. oeaenm

selected pipe outer

jdiameter © om) ual uy eo

Jactual media flow rate

ows) sl. 5.1

caloulation of pipe

lvall_ thickness

en venta O08 0.05 | calculate |si-Po/(26 nzP0)

in a

additional value of

lpipe wall thickness 0.01 0,01 | catcutate fr-sten. 167

egative deviation Clan d

ie

Jssign sevice life, it

corrosion margin of pipe caloulate |i 0 fr steam water

wall thickness C2 om a oe u A te Voip, and 0.8 in

Jccamon, and the others

thi

calculated minim |

thickness of pine Sm) | %*% oN |e

selected thickness of

. aa J] 40 | selected

pie Con)

design pipe Length fi z

[total pipe resistance

+ oor [om

w fereleat Pipe resistance | 9, 997 0.0070 Jp-Letzaem Friction

Lene of trait vine | 7 [tees

; TTS

friction tava [oon

[tac | emo

ictioml relsiance a

lcoefficient A oom poe table

fesistaree of valve and

a

i pipe fittings bar oe oy

culate tenth of

faive and pipe ritiags

(m)

Friction bar/a

Lelie aes [a Talend

efficient ue 0.31108 rable

resistance coefficient a pas

eT a o—falecad

pert vctsteee chek

lcoefficient ed el table

sabtotel Ta

resistance coefficient e 2

a a steal

pertia resistance chek

\coef ficient ez GJ table

btotel pera

|resistance coefficient, ps oe

ale pies 7 Lael

partal resistance ‘heat

coefficient Ce as table

esistance coefficient

Pipe Thickness Calculation Condensed Water Pipe

PLTU Rote 23MW

condensed water pipeline

denser puup Uo deaeratar )

jected pele See

[he oa ie seladed

Lesizn pressure Para) Lz selected

Design temperature TCC J a0 selected

Jucdia specific valive V

ms 0.00101 Lookup

pipe materials rea

Jtesian teuperoture of steal

with stress — Mpa ae oo

ld correction factor ro Task

JAlowable stress thatthe basic

lrectorty) oA —

[7 lees the diameter piping

esisn velocity ¥ @/s) 15 selected preferable. 52

siete Sleer ee od ee

Retece the eraer a i sae

lctual wedia How vate © Rae geet arr

a 13 01/54. 01/504.7

[5 — wal icknesscaleuation I

ine wall thickness

calculation $i_(am) oot oan

Pipe wall thickness

negative deviation added oot Cateaton fo. 765

alue Cl se

+ desi soice tif,

pave ra ees 1.0 Calculation Jit is 0 for steam water pipe, and 0.5 in

corrosion margin C2 ma [mtn sd the thors are ther

[Fie wall thickness

calculation of at least Lot Caclaton

en

Selection of pipeline wall

{thickness Cm) =

asian pineline Tenge Ze.

f channel resistance (bar Lio 17, S1036145,

strata nipetine

resi stan (bar ed

straight pipeline Tength L 2 ==

Thon the friction tala ODE

Picton dan cotFitent ocue ca

Nove pipe

|? |rittings cteresistance bar oad

1 elton ei) iw sales

Local Friction drag

voefficient oer Lone

subtotal Local Ffetion ;

rag_coef ficient a

2 Diverges three Goi) Zz secs

Loca Friction rag

aan 1a Lookup

‘btotal Local Friction

A 2.6

irag_coefticient

3 Tapered pipe — (ot) r slected

Local Friction drag

leoofficient 2 eae

subtotal Local Friction

ax iticient ea

4 valve Gate valve [Globe valve =

Jeount so 0 [selected

Local Fiction dag as [5 be [Lookup

subtotal Local Friction

larag coofficiont Wi ae i

lino step steam ejector

[ Jextractor (Bax) bail sueiel

[a IL? heater (Bar) 0.20 Lookup

J) _[Reswlating valve resistance as Look

(ear)

Pipe Thickness Calculation Close Cooling Circulating Water Pipe

PLTU Rote 2x3MW

Tndustrial pump [Auxiliary equipment

to Auxiliary | to Plate heat

equipnent ‘exchanger

selected pipeline 21985 21935,

ii | Fos @ Gay 220 20 selected

ldesign pressure Pibarg) 0.38 0.38) selected

sign temperature TC ) 30 8 selected,

Jnedia specific value V

a 0.001004 0.001007 Lookup

pipe materials se 7538

Design tomperature of steel

leith stress ~ sp te ue Lookup

Weld correction factor Lo io Lookup

JAlowable stress that the basic

am) 0.4 0.4 Lookup

[2 [calculate the diameter pi

design velocity ¥ (a/s) selected fprererab

|—} ie 13

[calculated diaweter Ga) [197.6 17.9 Calculation

Select the diameter —® (an) 08 08 219-285

coun) olla flor rate wu uO

[5 [wal thickness calculation

Pine wall thickness

pete 0.08, 0.03 Calculation

Pine wall thickness

lncgative deviation added 0.01 0.01 Calculation fo. 1765

value C1 om.

Pine wall thickness lculato

wrrosion wargin C2 em e Cekcslation

JPive wall thickness:

lcaicutation of at least 1.24 1.24 Calculation

om

Jselection of pipeline wall ; =

ldnickness 50 50 ane

| |Besign pipeline Tength Cm

[i Johanne) resistance (ba) 1.08 oe. 173 [oar

[straight pipeline

jo fire = oat 0.41

[straight pipeline length 1 a = ea

Se

Friction drag coetfictont wan vee ine

Naive pipe

Io |rivrings,etoresistance bar | 0S on

1 elbow (set) is 18 ‘selected |

Local Friction drag

[neeuesel 0.378 0.378 Lookup

‘subtotal Local Friction

M 6.804

larag coefficient a=

2 Diverges three (et) z a weed

vet Frietion dese A pr Lookup

‘subtotal Local Friction

larag coefficient ae s8

3 Tapered pipe (Get) z z weed

Tocal Friction drag

octficient ee oy) Gen

subtotal Local Friction

. 6

Jsox coefticient os ° I

4 valve slain vale ive _letve

feoune 2 tt 1 selectea

eat Fiction das 16 os bp lLookup

subtotal Looal Friction

sob

lirag_ coefficient » s ft

Is FILTER. os

Вам также может понравиться

- Aux Boiler Remaining Erec & CommДокумент6 страницAux Boiler Remaining Erec & CommWisnu Setiawan100% (1)

- Welding Ducting Monitoring Sheet #1Документ3 страницыWelding Ducting Monitoring Sheet #1Wisnu SetiawanОценок пока нет

- Unit 2 Ducting Monitoring SheetДокумент5 страницUnit 2 Ducting Monitoring SheetWisnu SetiawanОценок пока нет

- Unit 1 Ducting Monitoring SheetДокумент2 страницыUnit 1 Ducting Monitoring SheetWisnu SetiawanОценок пока нет

- Aux Boiler CommissioningДокумент3 страницыAux Boiler CommissioningWisnu Setiawan100% (1)

- DOC-20190828 - PetunjukДокумент3 страницыDOC-20190828 - PetunjukWisnu SetiawanОценок пока нет

- 1 PBДокумент8 страниц1 PBJwsОценок пока нет

- Work Calender Bulan Juni PDFДокумент1 страницаWork Calender Bulan Juni PDFWisnu SetiawanОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)