Академический Документы

Профессиональный Документы

Культура Документы

2524 8 Chifley Sustainable Structural and Fire Engineering

Загружено:

Julio MzpАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2524 8 Chifley Sustainable Structural and Fire Engineering

Загружено:

Julio MzpАвторское право:

Доступные форматы

ctbuh.

org/papers

Title: 8 Chifley Sustainable Structural and Fire Engineering

Author: Andrew Johnson, Principal, Arup

Subjects: Building Case Study

Fire & Safety

Structural Engineering

Sustainability/Green/Energy

Keywords: Fire Safety

Structural Engineering

Sustainability

Publication Date: 2015

Original Publication: Global Interchanges: Resurgence of the Skyscraper City

Paper Type: 1. Book chapter/Part chapter

2. Journal paper

3. Conference proceeding

4. Unpublished conference paper

5. Magazine article

6. Unpublished

Council on Tall Buildings and Urban Habitat / Andrew Johnson

8 Chifley Sustainable Structural and Fire

Engineering

Abstract

Andrew Johnson

Principle

8 Chifleys unique aesthetic has attracted much of the attention, however the 34 storey 150m tall

Arup,

buildings overall quality, sustainable performance, and structural efficiency, both in construction

Sydney, Australia

and in final form, are similarly significant. Realizing a project of this vision required innovation

in design technology throughout construction. The first building to be completed in Australia by

renowned architect Rogers Stirk Harbour & Partners in conjunction with Lippmann Associates,

Andrew is a Principal of Arup and structural engineer with a

8 Chifley possesses a number of unique features. These elements of the building and the

passion for design integrating innovation in architecture and

structural efficiency to create better buildings. Andrews engineering solutions that facilitated them directly reduced capital cost, and increased lettable

structural expertise includes tall buildings across a broad area without which the project may not have been commercially viable for the owner or appeal

cross-section of regions and environments including Australia,

Asia, Middle East, and the UK. Many of these projects have

to the tenant market.

been delivered as integrated multi-disciplinary teams, allowing

highly integrated and effective building solutions. Andrew also Keywords: Dematerialization, Fire Safety, Structural Engineering, Sustainability

has significant experience on long-span structures for stadia

and exhibition buildings.

The north facing side core tower is uniquely located at the end of a city block of less than

1,300m2, with streets on three sides. Unusual for contemporary urban sites, the building was

governed by maximum allowable floor area as opposed to maximum height; therefore an

innovative solution to office floor plate efficiency and maximizing lettable area was paramount.

The proposal at competition stage for open-air fire stairs realized a concession in the planning

regulations at the time, meaning that the fire stair area was not deducted from the net lettable

area which would have been the case if the stairs had been fully enclosed.

Highly efficient open plan floor plates in two stacked commercial modules of 9 and 12 floors

respectively, are raised at both street and mid-level on expressed jump structures. Each primary

module is further subdivided into a number of three and four storey vertical villages within

these modules. Each village comprises total floor areas of up to 2,700m2 to maximise the ability

to attract tenants that might otherwise prefer large contiguous floor plates that are not available

in this part of the Sydney CBD.

The use of expressed external structural steel framing - freeing up the interior space planning

- with a desire for this steel structure to be legible within the architecture promoted a

performance based structural design solution outside of generic codified procedures to omit

fire protection, and in turn further dematerialise the building. The engineering solutions that

are so integral in achieving the success of the building are on display from the moment you

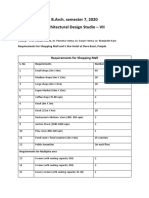

Figure 1. Typical village floor plan at architectural concept, and completed building. Only two columns are located

within the floorplate on the village floors (Source: RSHP & Brett Boardman)

CTBUH 2015 New York Conference | 671

between the mega-columns. These

orthogonal braced frames resist

over 60% of north-south building

overturning at the base, and up to

95% over the top half of the building

(see Figure 4);

Four interior columns are located in

each of the two stacked modules,

providing clear 12m wide floor

planning zones on each wing.

These columns are transferred to

the external megacolumns at the

Level 18 and Level 6 jump structures,

maximizing gravity loads on the east

and west braced frames;

Expressed composite steel transfer

columns, post-tensioned ties, and

composite steel and precast concrete

Figure 2. Stability and Gravity System (Source: Arup) jump-start decks from Ground to

of structural performance requirements, Level 6, and Level 18 to Level 21. The

first read the building in the city skyline with compatibility with overall design intent, inclined columns and primary beams

the distinctive red bracing and expressed cost-effectiveness, buildability, and speed of are filled with reinforced concrete

cantilevered fire stairs. This only increases construction (see Figure 2 & 3). for the fire load case. The secondary

as you approach the main lobby - a floating

beams and their connections are not

transparent frameless glass box utilizing The gravity and stability system

provided with passive fire protection,

performance based fire engineering to comprises:

and behave compositely with the

assist minimizing the visual obstruction of Four external insitu concrete precast and insitu slab;

supporting framing. megacolumns on an 18m by

A reinforced concrete southern core,

37.5m grid. The insitu concrete is

Figure 1 indicates a typical office village floor, comprising of the lift and service

poured inside permanent precast

and a view of the completed building. risers. This core was proportioned

shell formwork located outside the

primarily for gravity loads and east-

building faade. At foundation level

west stability;

these columns support all of the

Structural System office floor gravity load due to the Post-tensioned beam and reinforced

two primary transfer structures; concrete slab typical floor structures.

The structural system is a hybrid assembly Secondary beams are 725mm deep

Steel cross-bracing in the north-

comprising insitu concrete, precast concrete, at 6m spacing and span 18m onto

south direction between the

composite steel and concrete, and structural 800mm deep primary beams. The

external megacolumns. Below

steel frame. Each of the structural materials secondary beams cantilever a further

ground level the bracing transitions

were selected based on a combination 4.75m to the northern faade. A

to reinforced concrete shear walls

150mm thick slab on permanent

metal deck formwork spans 4.8m

clear between the secondary beams;

Steel framed external and open fire

stairs, cantilevered from the concrete

core;

Composite steel and concrete multi-

level plant room on top of the core;

Structural steel and cable supported

roof structure to house PV array;

Pad foundations on sandstone of up

to 8MPa allowable bearing pressure.

Due to the system efficiency

and proportioning, no tension is

developed at foundation level. The

stability system was proportioned

such that the south core with

minimal gravity load suffers some lift-

off at ultimate limit states conditions.

Figure 3. Typical floor structure. Full floor (left) and village floor (right). 3D views from below under (Source: Arup)

672 | CTBUH 2015 New York Conference

Figure 4. Distribution of moment and shear between the cores and braced frames under wind loading in the north- Figure 5. Fire zoning for consideration of lost bracing

south direction (Source: Arup) elements in the fire load case (Source: Arup)

Performance Fire Engineered Solutions egress stairs and omission of passive system for this building in accommodating

Relating to Structure fire protection to the stair structure; the eccentric core location. Running the

Omission of passive fire protection to full height of the building, the braces are

The following elements were subject geometrically set out to align with the three

steel columns supporting lightweight

to detailed performance structural fire storey village module creating a series of

construction roof to glass box on

engineering assessment utilizing the six storey high Xs, resisting over 60% of the

Level 18 skygarden and Level 30 roof

International Fire Engineering Guidelines, building overturning moment at foundation

top terrace pop-up box and roof array;

and additional international standards and level in the north-south direction with no

guidance. No fire rating to the stainless steel

net tension. The efficiency of the 18m wide

cable hangers from underside of level

Omission of passive fire protection braced frame width in combination with the

6 to support glass roof to the main

to steel primary wind and seismic modest building height and relatively low

lobby glass box.

bracing elements (megabracing); seismicity of Sydney, allowed bracing to be

Omission of passive fire protection to omitted from the north face to maximize

the expressed secondary steel beams Megabracing views of Chifley Square and Sydney harbour.

and the connections of the Level 6 Transverse stability was provided by the

The bold red mega braces on the eastern southern concrete core combined with the

reverse podium and Level 21 terrace

and western elevations are a powerful design eccentric braced frames of the jump start

jump structures (megaframe);

feature as well as a highly efficient stability transfer structures, with additional torsional

Use of exterior unenclosed steel fire

stability from the north-south frames.

Sitting proud of the cladding line, these external

elements provided an unusual construction

and design challenge. Due to the nature of

the bracing forces equally in tension and

compression with no gravity load, steel was the

natural material choice. However, protecting

these elements from fire whilst maintaining

the legibility of the material as fundamental

to the architecture was key to the success of

the scheme. Alternative bracing materials such

as precast concrete, insitu concrete, precast

concrete encased steel, and insitu filled steel

elements were also considered from an early

stage. Steel was finally selected based on ease

of erection outside the line of the floorplate, the

element function and structural size, and finally

the innovative approach to performance design

out the passive fire protection.

As the building contains a slender reinforced

concrete core at the southern faade selected

on the basis of ease and cost of construction

Figure 6. Structural analysis under fire load case with Zone 2 fire condition (Source: Arup)

CTBUH 2015 New York Conference | 673

and compatibility with the concrete floors,

this element can maintain a degree of lateral

stability under a fire load case where capacity

may be lost in the unprotected mega-braces.

Further, the geometry and use of the building

allowed an analysis and assessment of real fires

that naturally split the building up into a series

of zones considered to be limiting based on

formation and spread of fire (see Figure 5):

Zone 1: Fire at ground level lobby or

street level. Analysis of vehicular and

lobby fires six levels below the first

commercial floor with a clear outside

reverse-podium space demonstrated

that spread to the low-rise building

block would not occur;

Zone 2: Fire in the low-rise office block

Level 6 to Level 18. It was considered

that a typical office fire commencing

at Level 6 could spread to Level 18, but

was highly unlikely to jump to Level

Figure 7. Pinned link node (Source: Brett Boardman)

21 the bottom floor of the high-rise

due to the three storey external space

between Level 18 and Level 21;

Zone 3: Fire on the Level 18 lobby. On

the basis of the fire load at this level it

was demonstrated that the fire would

not jump to Level 21 the first office

floor plate of the upper block;

Zone 4: Fire in the high-rise block Level

21 to Level 30.

Further to this analysis, the building has

three street boundaries and only one shared

boundary. The megabracing elements are

therefore protected against fire from adjacent

buildings on the basis of the separation

afforded by the streets, and to the south

adequate separation due to the depth of the

Figure 8. Reverse podium structural arrangement and completed structure (Source: Arup)

8 Chifley core.

Due to the proximity of the bracing to

the floor plate, assessment of limiting

temperatures against associated member

capacities of the steel brace sections indicated

that their capacity was overcome relatively

quickly for typical office fires. A series of global

structural stability analyses were subsequently

performed with braces removed to model the

structural condition under each fire load case

relating to the zonal fire assessment. As there

is no specified lateral loading requirement

under the Australian Standards for the fire

load case, lateral loads based on two cases

where assessed:

i - An applied lateral load of 33% of

ultimate wind load in accordance

with BS5950-80, representing a wind

load of approximately 6 month

return period;

Figure 9. Fundamental dynamic mode shapes (Source: Arup)

674 | CTBUH 2015 New York Conference

also assists in releasing extension of the

braces in a fire, and became a defining feature

of the building.

Megaframe

Occurring twice, these large expressed

transfer structures create two generously

proportioned column free voids; the lower

public domain at plaza level and a private

three storey high terrace at L18. The two

prominent outdoor spaces are created by

transferring the four internal columns in

both the low and high rise blocks out to their

respective external mega columns, delivering

gravity loads to the exterior bracing frames,

ensuring no tension is developed under

lateral loading.

The transfer frames also provide a significant

component of the lateral resisting system in

the east-west direction, assisting to control

the induced torsion from the southern core,

demonstrated in the fundamental mode

shapes (see Figure 9).

Figure 10. Composite megaframe assembly (Source: Arup) Materiality and constructability of the inclined

and horizontal elements were fundamental to

the construction programme and buildability,

leading to the use of composite steel and

reinforced in-situ filled sections for all primary

elements. With the southern structural core

constructed slightly ahead, the megaframe

structures were designed and constructed as

jump decks, allowing the insitu concrete post-

tensioned floors above to be formed from this

level with no back-propping below.

The steel shell for the inclined columns

and primary beams acts compositely with

the concrete at general serviceability and

ultimate limit states. During a fire the steel

shell is sacrificial. This resulted in a rapidly

constructible series of hollow steel columns

and beam shells which once attached to

Figure 11. Exterior steel fire stairs (Source: Brett Boardman) the free-standing megacolumns and bolted

together on site were self-stable. The steel

ii - A notional load of 1% of gravity This steel allowed for rapid site installation secondary beams were then installed, and

load applied laterally at each floor. workshop to site to erection complete - with precast planks craned in so that no temporary

no additional finishing trades, and provided propping was required through the six and

These analyses demonstrated that stability the clear structural legibility the architects three storey voids at Level 6 and Level 18

and strength were satisfied without major were striving for. respectively (see Figure 10). A self-compacting

modifications to the detailing required under concrete fill to the columns was pumped from

An articulated pinned-link node at the

general serviceability and ultimate limit the bottom, whilst the primary beams were

intersection of the X bracing geometry

states (Figure 6). U-shaped sections and filled conventionally.

was developed to release elastic gravity

An insitu reinforced diaphragm slab was then

The outcome was conventional fillet welded loads, time-dependant gravity loads from

poured over the precast planks.

steel 4 plate semi-box beams conventionally shortening of the concrete megacolumns,

painted, saving over 1300m2 of conventional and thermal loads, enabling the braces to Honesty and legibility of the expressed

passive fire protection and cladding, or be sized for wind and seismic shear only a structure dictated the jump deck floor

expensive external epoxy intumescent and saving of approximately 40% in the brace system should mimic that of the typical

additional steel tonnage to achieve adequate tonnage and significantly reducing the end concrete scheme, with steel composite

surface to mass ratio. connection complexity at the interface with secondary beams at 6m centres.

the concrete frame. This articulated element

CTBUH 2015 New York Conference | 675

The fire engineering assessment undertaken separating distance and assessment Villages

at Zones 1 & 3 (see Figure 5) and detailed of fire vs steel limiting temperature

fire analysis using CFAST concluded that from the adjacent office space. The The structural geometry is driven by the

limiting temperatures of the secondary stair framing was originally proposed multiple stacked villages - the stacked villages

beams and their connections were not to be supported from the core on enabled 8 Chifley to market itself towards

reached (less than 550C, and the original the three-storey village planning larger firms, by providing offices larger than

specification for 660m2 of exterior epoxy grid, however this was adjusted to those typically associated with a small site.

intumescent coating was saved. Therefore, a floor by floor supporting system, Each village was created using three floors, one

a consistent paint finish could be achieved vertically continuous to maximize full floor and two U shaped floors, providing

on all exterior steelwork both concrete structural redundancy; a central atrium and focal point for each.

filled composite and plain steel elements. Not only do the village voids increase tenant

The stairs re-enter the building core

interconnectivity, they dramatically increase

at Level 5 and egress along the street

the amount of daylight penetration into the

to the south boundary, necessitating

floor plates, view of the faade from the deeper

Fire Stairs entering a fire and smoke isolated

workstations, and consequently make the floor

corridor from outside at level 5.

A key component in realizing the building slabs more appealing and lettable.

Stair pressurization was alleviated with the

feasibility was the use of open exterior fire

use of external open stars, reducing energy Large internal floor connections of four stories,

escape stairs, as open stairs were not counted

demand and contributing to sustainable significantly greater than the prescriptively

as developable floor area under the City of

credentials of the building. allowed two storeys under the Building

Sydney planning regulations at the time a

Code of Australia were achieved using a

concession that had not previously been

realized in Sydney. As the site development

controlling criteria was maximum area and

not height, over 600m2 was realized as

additional lettable floor area on the basis of

achieving an approved open stair solution

equivalent to over 50% of one of the nine

full floors in the building. Over the 10 year

development feasibility analysis of the project

this is a substantial quantity of income in the

mid to high 7 figure bracket.

Key project issues were identified that

required resolution (see Figure 11 & 12):

The stairs were carefully designed to

minimize the impact of acrophobia

and adverse weather impacts

particularly during fire drills. This

assessment involved comparing

the carefully designed balustrade Figure 12. Fire separation to external stairs (Arup)

to metric data for stature and eye

height. A virtual model of the stairs

was created to assist the team

in understanding the degree of

enclosure and the consequent sense

of comfort and security occupants

would feel while egressing;

Following the above, a prototype

geometric stair was constructed on

the roof of the existing 26 storey

building prior to demolition and

tested by the client;

The exterior stairways were protected

by a Tyco sprinkler wall wetting

system on the interior portion of the

adjacent glass faade;

The stair structure was steel,

cantilevered from the concrete core in

a veirendeel arrangement, separated

from the interior space by 2hr fire

rated walls to the core area, and

Figure 13. Comparison of 8 Chifley to DtS interconnection criteria (Source: Arup)

676 | CTBUH 2015 New York Conference

fire engineered risk based approach and evacuation analysis and robust smoke The conceptual design and realization of

egress assessments. These were focused detection and alarm interfaces allow for the exterior open fire stairs contributed

directly upon risk to occupants in terms of quick and efficient occupant movement heavily to the commercial feasibility

egress and smoke exposure. The assessment complimentary to the design intent of the project. During the design

quantitatively compared the number of development and detailed design of the

occupants possibly affected in a Deemed- building, performance based structural

to-Satisfy (DtS) scenario compared to the and fire engineering saved over 2,000m2

Conclusion

proposed design. This demonstrated that of conventional passive fire protection

with the number of occupants affected in The engineering of 8 Chifley was integrated and cladding or exterior epoxy based

the proposed solution, in consideration of from the conceptual stage of the building and intumescent to expressed steel elements,

available exit widths available, the risk of worked in collaboration with the architect and that were instead finished with a traditional

unsafe egress was no greater than in a DtS client. The client objectives, architectural brief, painted corrosion protection systems and

design. This enabled the safe interconnection and the challenges of the site, necessitated successfully detailed as an inherent and

of the floors (see Figure 13). an innovative set of solutions to deliver value legible component of the architecture.

and realize the feasibility of the project - not In turn, construction of the building was

The fire engineering analysis allowed for realized ahead of programme and has

only in excellence of individual discipline

costly and obtrusive mechanical exhaust been the recipient of a series of awards

responses, but more importantly through

systems to be omitted, with a degree of in Australia for commercial development,

the holistic integration of these services to

compartmentalisation provided by smoke architecture, engineering, and sustainability.

produce a world class building that exceeded

curtains that deploy upon fire alarm. The

client expectations.

References:

Nouvel, J., Beissel, B. (2014). One Central Park, Sydney. CTBUH Journal. 2014 Issue IV, pp. 12-18.

Guacomello, E. (2015). A New Urban Forest Rises in Milan. CTBUH Journal. 2015 Issue I, pp. 12-18.

Modi, S. (2014). Improving the Social Sustainability of High-Rises. CTBUH Journal. 2014 Issue I, pp. 24-30.

Generalova, E., Generalov, V. (2014). Designing High-Rise Housing: The Singapore Experience. CTBUH Journal. 2014 Issue IV, pp. 40-15.

Wood, A. (2014). Rethinking the Skyscraper in the Ecological Age: Design Principles for a New High-Rise Vernacular. Proceedings of the

CTBUH 2014 Shanghai Conference Future Cities: Towards Sustainable Vertical Urbanism. Shanghai, China. 16th-19th September 2014, pp. 26-38.

ISBN: 978-0-939493-38-8.

Fansworth, D. (2014). Modular Tall Building Design at Atlantic Yards B2. Proceedings of the CTBUH 2014 Shanghai Conference Future Cities:

Towards Sustainable Vertical Urbanism. Shanghai, China. 16th-19th September 2014, pp. 492-499. ISBN: 978-0-939493-38-8.

Willis, C. (2014). The Logic of Luxury: New Yorks New Super-Slender Towers. Proceedings of the CTBUH 2014 Shanghai Conference Future

Cities: Towards Sustainable Vertical Urbanism. Shanghai, China. 16th-19th September 2014, pp. 357-364. ISBN: 978-0-939493-38-8.

CTBUH 2015 New York Conference | 677

Вам также может понравиться

- The senses in interior design: Sensorial expressions and experiencesОт EverandThe senses in interior design: Sensorial expressions and experiencesОценок пока нет

- 2421 Shanghai Tower Building A Green Vertical City in The Heart of Shanghai PDFДокумент9 страниц2421 Shanghai Tower Building A Green Vertical City in The Heart of Shanghai PDFShavangОценок пока нет

- 1833 Designing High Rise Housing The Singapore Experience PDFДокумент7 страниц1833 Designing High Rise Housing The Singapore Experience PDFLuis Eugenio Perez FerrerasОценок пока нет

- Two International Finance Centre Technical PaperДокумент12 страницTwo International Finance Centre Technical PaperMuhammad Azuan TukiarОценок пока нет

- 229756Документ126 страниц229756Karpaga MoorthyОценок пока нет

- Askari Tower Bye-LawsДокумент34 страницыAskari Tower Bye-LawsSanan ChОценок пока нет

- Lcu Landscape and Site Parameter For Recreational CentreДокумент16 страницLcu Landscape and Site Parameter For Recreational CentreAlabi David oluwatobilobaОценок пока нет

- Project Management TWKA PDFДокумент48 страницProject Management TWKA PDFpremdylОценок пока нет

- 1670 Evaluation Techniques of Damping in BuildingsДокумент9 страниц1670 Evaluation Techniques of Damping in BuildingsApetsi AmpiahОценок пока нет

- Programme Interpretation 2Документ2 страницыProgramme Interpretation 2Reena Rajdeep100% (1)

- Tagum City Climate Policy Review and Urban Design Project Brief Draft ProposalДокумент33 страницыTagum City Climate Policy Review and Urban Design Project Brief Draft ProposalLuis S Alvarez JrОценок пока нет

- Daylighting in Classrooms - The Daylight Factor As A Performance CriterionДокумент2 страницыDaylighting in Classrooms - The Daylight Factor As A Performance CriterionJocelyn GraciaОценок пока нет

- Doca Steak Burger RestaurantДокумент6 страницDoca Steak Burger Restaurantprak sokimhakОценок пока нет

- UAH Proposed Mixed-Use DevelopmentДокумент52 страницыUAH Proposed Mixed-Use Developmentpgattis7719100% (1)

- Maharaja Ranjit Singh Punjab Technical University, BathindaДокумент7 страницMaharaja Ranjit Singh Punjab Technical University, BathindaBharat AhujaОценок пока нет

- Southpoint Park Shoreline Restoration ProjectДокумент33 страницыSouthpoint Park Shoreline Restoration ProjectrooseveltislanderОценок пока нет

- The Museum Hotel AntakyaДокумент9 страницThe Museum Hotel AntakyaIqbal PratamaОценок пока нет

- Convention Center Requirements Contiguous Space Study Report With SDCCC Clients Prospects BreakoutДокумент16 страницConvention Center Requirements Contiguous Space Study Report With SDCCC Clients Prospects BreakoutNandini SОценок пока нет

- 10 Case Study Greenlands Suzhou Center WujiangДокумент10 страниц10 Case Study Greenlands Suzhou Center WujiangPritha WidhyatОценок пока нет

- Architectural Design Student CenterДокумент9 страницArchitectural Design Student CenterLeen RimawiОценок пока нет

- Unit 5Документ42 страницыUnit 5ashok Pradhan0% (1)

- Bio-Urban Hub: Third Places. by This Design Aims To Explore A More Unified, Mixed and InterlinkedДокумент7 страницBio-Urban Hub: Third Places. by This Design Aims To Explore A More Unified, Mixed and InterlinkedMaria Paul100% (1)

- Park ThesisДокумент222 страницыPark ThesisAnonymous hprsT3WlPОценок пока нет

- Architectural Design Studio RequirementsДокумент3 страницыArchitectural Design Studio RequirementsSankrita SivamОценок пока нет

- IT Application Final AssignmentДокумент15 страницIT Application Final AssignmentWanОценок пока нет

- Dewan Tunku Canselor AnalysisДокумент11 страницDewan Tunku Canselor Analysisainos_alaiОценок пока нет

- Ao Case Study Al-Bahr enДокумент2 страницыAo Case Study Al-Bahr enTarun KumarОценок пока нет

- One Thousand Museum Miami Condos BrochureДокумент49 страницOne Thousand Museum Miami Condos BrochureLucas LechugaОценок пока нет

- Architectural Study PPPA VДокумент15 страницArchitectural Study PPPA VPeter NobelОценок пока нет

- Final EOI For MOhali Five Star Hotel Revised 250708Документ1 страницаFinal EOI For MOhali Five Star Hotel Revised 250708Preeti TiggaОценок пока нет

- B3 Tendering Rules PN6Документ27 страницB3 Tendering Rules PN6Eduardo CappellinaОценок пока нет

- The Lunchbox Brief PDFДокумент13 страницThe Lunchbox Brief PDFTaurusОценок пока нет

- Residence: Casestudy, Desktopstudy, Anthropo MetryДокумент52 страницыResidence: Casestudy, Desktopstudy, Anthropo Metrymrunalini KolaОценок пока нет

- Policarpio, Chara Mae B. Workshop # 4 A Proposed Research and Training Center For Organic AgricultureДокумент3 страницыPolicarpio, Chara Mae B. Workshop # 4 A Proposed Research and Training Center For Organic AgricultureChaz PolicarpioОценок пока нет

- Graham Macphee The Architecture of The Visible Technology and Urban Visual CultureДокумент241 страницаGraham Macphee The Architecture of The Visible Technology and Urban Visual Cultureasf-asfОценок пока нет

- Literature Study: Books Referred: 1. Metric Handbook 2. Time Savers Standards Building Types 3. NeufertsДокумент32 страницыLiterature Study: Books Referred: 1. Metric Handbook 2. Time Savers Standards Building Types 3. NeufertsJayanthi BaskaranОценок пока нет

- Professional Practice: Induction Course For New C&S Engineers 5, 6 & 7 September 2016, Hotel Armada Petaling JayaДокумент46 страницProfessional Practice: Induction Course For New C&S Engineers 5, 6 & 7 September 2016, Hotel Armada Petaling JayaPerunding KPRОценок пока нет

- Legislature Parliament Architecture of DemocracyДокумент11 страницLegislature Parliament Architecture of DemocracySaurav ShresthaОценок пока нет

- Glasgow's Riverside Museum of Transport and TravelДокумент20 страницGlasgow's Riverside Museum of Transport and TravelAlvera SerapainОценок пока нет

- ADP Site Analysis at JB (Ms Teh's Group)Документ110 страницADP Site Analysis at JB (Ms Teh's Group)David J. ChaiОценок пока нет

- Heritage ConservationДокумент17 страницHeritage ConservationAkash KarwaОценок пока нет

- Keshar Mahal Presentation - 28-07-2019Документ112 страницKeshar Mahal Presentation - 28-07-2019Aswain Tamrakar100% (1)

- Flexible HousingДокумент184 страницыFlexible HousingvineethОценок пока нет

- MCEC Floor Plan2013Документ13 страницMCEC Floor Plan2013manrocks3425100% (1)

- 30 ST Mary Axe - Abbas Riazibeidokhti PDFДокумент18 страниц30 ST Mary Axe - Abbas Riazibeidokhti PDFpuppyarav2726Оценок пока нет

- Case StydyДокумент44 страницыCase StydyEphrem HailuОценок пока нет

- Analyse Invest Final 2Документ185 страницAnalyse Invest Final 2Sharda SharmaОценок пока нет

- Architectural Legislation LEC !Документ18 страницArchitectural Legislation LEC !Pranika Mahajan100% (2)

- Defining Climatic Zones For Architectural Design in NigeriaДокумент14 страницDefining Climatic Zones For Architectural Design in NigeriaIvan AvramovОценок пока нет

- Valuing Open Lot and Heritage BuildingsДокумент1 страницаValuing Open Lot and Heritage BuildingsGUIA MELISSE CAPILIОценок пока нет

- 31 Case Study Mode Gakuen Cocoon TowerДокумент5 страниц31 Case Study Mode Gakuen Cocoon TowerPrateekshaNathaniОценок пока нет

- 7 Building TypesДокумент160 страниц7 Building TypesSashwat GhaiОценок пока нет

- Brent Civic Centre BuildingДокумент7 страницBrent Civic Centre BuildingAgnes Cheverloo CastilloОценок пока нет

- Conference Center StandardsДокумент20 страницConference Center StandardsShubham nigamОценок пока нет

- Design Consideration For DisabilitiesДокумент19 страницDesign Consideration For DisabilitiesDhaval SheliyaОценок пока нет

- (Flexible Hotel Design) Rethinking Hotel Design To Address Short Term Demand FluctuationsДокумент113 страниц(Flexible Hotel Design) Rethinking Hotel Design To Address Short Term Demand FluctuationsdesignfrrОценок пока нет

- Biophilic ArchitectureДокумент16 страницBiophilic ArchitectureKashaf sayedОценок пока нет

- Architect's Role in Building's Seismic PerformanceДокумент6 страницArchitect's Role in Building's Seismic PerformanceBajocarОценок пока нет

- 2015 AwardsBook Preview - Desbloqueado PDFДокумент20 страниц2015 AwardsBook Preview - Desbloqueado PDFJulio MzpОценок пока нет

- Edificios Altos Una Propuesta ViableДокумент3 страницыEdificios Altos Una Propuesta ViableJulio MzpОценок пока нет

- 2335 Next Tokyo 2045 A Mile High Tower Rooted in Intersecting Ecologies PDFДокумент7 страниц2335 Next Tokyo 2045 A Mile High Tower Rooted in Intersecting Ecologies PDFJulio MzpОценок пока нет

- 1065 Pavements in The Sky Use of The Skybridge in Tall Buildings PDFДокумент9 страниц1065 Pavements in The Sky Use of The Skybridge in Tall Buildings PDFJulio MzpОценок пока нет

- 1618 Evacuation Design Strategy For High Rise Buildings PDFДокумент7 страниц1618 Evacuation Design Strategy For High Rise Buildings PDFJulio MzpОценок пока нет

- 1065 Pavements in The Sky Use of The Skybridge in Tall Buildings PDFДокумент9 страниц1065 Pavements in The Sky Use of The Skybridge in Tall Buildings PDFJulio MzpОценок пока нет

- 2015 AwardsBook Preview - Desbloqueado PDFДокумент20 страниц2015 AwardsBook Preview - Desbloqueado PDFJulio MzpОценок пока нет

- Basis of Structural Design (MLIT)Документ43 страницыBasis of Structural Design (MLIT)Vinod Kumar Chowdary AlluriОценок пока нет

- 2014 AwardsBook Preview PDFДокумент22 страницы2014 AwardsBook Preview PDFJulio MzpОценок пока нет

- 2013 AwardsBook Preview PDFДокумент24 страницы2013 AwardsBook Preview PDFJulio MzpОценок пока нет

- 2015 AwardsBook Preview - Desbloqueado PDFДокумент20 страниц2015 AwardsBook Preview - Desbloqueado PDFJulio MzpОценок пока нет

- 2012 AwardsBook Preview PDFДокумент24 страницы2012 AwardsBook Preview PDFJulio MzpОценок пока нет

- 1618 Evacuation Design Strategy For High Rise Buildings PDFДокумент7 страниц1618 Evacuation Design Strategy For High Rise Buildings PDFJulio MzpОценок пока нет

- 1065 Pavements in The Sky Use of The Skybridge in Tall Buildings PDFДокумент9 страниц1065 Pavements in The Sky Use of The Skybridge in Tall Buildings PDFJulio MzpОценок пока нет

- 1618 Evacuation Design Strategy For High Rise Buildings PDFДокумент7 страниц1618 Evacuation Design Strategy For High Rise Buildings PDFJulio MzpОценок пока нет

- 2625 Deep Foundations For High Rise Buildings in Hong Kong PDFДокумент11 страниц2625 Deep Foundations For High Rise Buildings in Hong Kong PDFsungshinnОценок пока нет

- 2335 Next Tokyo 2045 A Mile High Tower Rooted in Intersecting Ecologies PDFДокумент7 страниц2335 Next Tokyo 2045 A Mile High Tower Rooted in Intersecting Ecologies PDFJulio MzpОценок пока нет

- 1324 Shanghai World Financial Center Without CompromiseДокумент6 страниц1324 Shanghai World Financial Center Without CompromiseJulio MzpОценок пока нет

- 1065 Pavements in The Sky Use of The Skybridge in Tall BuildingsДокумент9 страниц1065 Pavements in The Sky Use of The Skybridge in Tall BuildingsJulio MzpОценок пока нет

- 1618 Evacuation Design Strategy For High Rise BuildingsДокумент7 страниц1618 Evacuation Design Strategy For High Rise BuildingsJulio MzpОценок пока нет

- Guidelines For Seismic Performance of Tall BuildingsДокумент104 страницыGuidelines For Seismic Performance of Tall BuildingsUggly Jo100% (1)

- Next Tokyo 2045 A Mile High Tower Rooted in Intersecting EcologiesДокумент7 страницNext Tokyo 2045 A Mile High Tower Rooted in Intersecting EcologiesLARED21Оценок пока нет

- 2625 Deep Foundations For High Rise Buildings in Hong KongДокумент11 страниц2625 Deep Foundations For High Rise Buildings in Hong KongJulio MzpОценок пока нет

- 1720 WTC Towers Innovative Design Features and Structural ModelingДокумент5 страниц1720 WTC Towers Innovative Design Features and Structural ModelingJulio MzpОценок пока нет

- Swanston Square Apartment Tower 2016 02-18-14!49!05Документ2 страницыSwanston Square Apartment Tower 2016 02-18-14!49!05Julio MzpОценок пока нет

- Ranbaxy Laboratories LimitedДокумент9 страницRanbaxy Laboratories LimitedNeerajОценок пока нет

- Continuous Rolling MillДокумент8 страницContinuous Rolling Millrazen_inОценок пока нет

- Chapter 1 - Introduction - Trade Theories (Part 3 of 3)Документ22 страницыChapter 1 - Introduction - Trade Theories (Part 3 of 3)kirthi nairОценок пока нет

- Phule Revati Impact FinalДокумент32 страницыPhule Revati Impact FinalManohar DhadwadОценок пока нет

- Report Fyp Final JackДокумент73 страницыReport Fyp Final JackAdly_arkimОценок пока нет

- 9A03503 Machine ToolsДокумент4 страницы9A03503 Machine ToolssivabharathamurthyОценок пока нет

- CC 302 Highway Engineering: Pn. Norizan Binti MasllehДокумент38 страницCC 302 Highway Engineering: Pn. Norizan Binti MasllehSimon TangОценок пока нет

- Maxwell Corporation - Distribution: QuestionsДокумент1 страницаMaxwell Corporation - Distribution: QuestionssakuraaОценок пока нет

- Wire Rope Brochure Black Bear Hoist MBIДокумент14 страницWire Rope Brochure Black Bear Hoist MBITh NattapongОценок пока нет

- SD Slip ManualДокумент9 страницSD Slip ManualGregory StewartОценок пока нет

- Parts ListДокумент18 страницParts ListRobin Dario Noriega CastañoОценок пока нет

- Air New Zealand's DC8 Era Part 2Документ36 страницAir New Zealand's DC8 Era Part 2Leonard G MillsОценок пока нет

- RetrofittingДокумент36 страницRetrofittingNagesh ChitariОценок пока нет

- Casting Foundry Manual PDFДокумент89 страницCasting Foundry Manual PDFThenarasumohanvelu100% (1)

- Logwasher-Rotomax Logwasher Specification QMJ Aug11Документ3 страницыLogwasher-Rotomax Logwasher Specification QMJ Aug11kaustav999Оценок пока нет

- TxDoT 6210 Vertical Mositure Barrier Specs PDFДокумент3 страницыTxDoT 6210 Vertical Mositure Barrier Specs PDFthadikkaranОценок пока нет

- FLSmidth TST JawCrusher BrochureДокумент8 страницFLSmidth TST JawCrusher BrochureFranz Anggi100% (2)

- DTS User Training SLidesДокумент107 страницDTS User Training SLidesChris BennettОценок пока нет

- David PortfolioДокумент39 страницDavid PortfolioKaziKwanguОценок пока нет

- Taller Planeación AgregadaДокумент3 страницыTaller Planeación AgregadaJulio RodelОценок пока нет

- Frankfinn AssignmentДокумент26 страницFrankfinn AssignmentGurpreet DhingraОценок пока нет

- Unconventional Machining Processes - Introduction and ClassificationДокумент3 страницыUnconventional Machining Processes - Introduction and ClassificationVishal KumarОценок пока нет

- Lucrare de Examen La Disciplina Limba Straina IiДокумент6 страницLucrare de Examen La Disciplina Limba Straina IiTóth CsabiОценок пока нет

- Metal-Casting Processes: Kalpakjian - Schmid Manufacturing Engineering and Technology © 2001 Prentice-Hall Page 11-1Документ52 страницыMetal-Casting Processes: Kalpakjian - Schmid Manufacturing Engineering and Technology © 2001 Prentice-Hall Page 11-1ShadmanSakiefHridoyОценок пока нет

- Retail Store Design (Unit IV)Документ126 страницRetail Store Design (Unit IV)Shikhar SrivastavaОценок пока нет

- Appendix 2A - Application Checklist - ICH - NDA - GDAДокумент39 страницAppendix 2A - Application Checklist - ICH - NDA - GDAnasimОценок пока нет

- Fatigue Strength of Thermo-Mechanically Controlled Process Steel and It's Weld JointДокумент1 страницаFatigue Strength of Thermo-Mechanically Controlled Process Steel and It's Weld JointDavid CrownОценок пока нет

- Potential Suppliers in Latvia For The Automotive Industry 2013 20130527 152118Документ32 страницыPotential Suppliers in Latvia For The Automotive Industry 2013 20130527 152118Fredie IsaguaОценок пока нет

- Manual de Soldadura Vol 3 Aws PDFДокумент304 страницыManual de Soldadura Vol 3 Aws PDFColeccionadorMarvel100% (1)